Us 20140309468

Diunggah oleh

Lily DianaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Us 20140309468

Diunggah oleh

Lily DianaHak Cipta:

Format Tersedia

US 20140309468A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2014/0309468 A1

(43) Pub. Date:

(54)

MANUFACTURE OF ETHYLENE

(52) U.S.Cl.

CPC .. C07C1/30 (2013.01); C07C2/861 (2013.01)

(71) Applicant: John E. STAUFFER, Greenwich, CT

(1J3)

(72)

Inventor:

Oct. 16, 2014

USPC

........................................................ ..

585/324

John E. STAUFFER, Greenwich, CT

(57)

(1J3)

ABSTRACT

(21) App1.No.: 13/859,886

Ethylene is produced from ethane in two steps: ?rst, ethane is

(22) Filed:

Apr. 10, 2013

Publication Classi?cation

oxychlorinated to ethyl chloride; and second, ethyl chloride

from the ?rst step is cracked to produce ethylene and hydro

gen chloride. The process de?ned in claim 1 further including

(51)

Int. Cl.

C07C 1/30

C07C 2/86

(2006.01)

(2006.01)

the step of recycling hydrogen chloride from the second step

to the ?rst (chlorination) step.

Patent Application Publication

Oct. 16, 2014

US 2014/0309468 A1

H01

Fig.

Oct. 16, 2014

US 2014/0309468 A1

MANUFACTURE OF ETHYLENE

FIELD OF THE INVENTION

[0001]

The present invention relates to a process for manu

facturing ethylene from ethane. The process comprises two

chemical reactions. In the ?rst reaction, ethane, oxygen and

hydrogen chloride are passed over a catalyst to produce ethyl

chloride and water. The second reaction converts ethyl chlo

ride in the presence of a second catalyst to ethylene and

hydrogen chloride.

oxychlorination and cracking reactions are carried out at

pressures in the range of l to 10 atmospheres.

[0011] Ethyl chloride produced as an intermediate in the

present invention can be supplemented or replaced by ethyl

chloride derived by the hydrochlorination of ethyl alcohol.

[0012] Other advantages, features and characteristics of the

present invention, as well as methods of operation and func

tions of the related elements of the structure, and the combi

nation of parts and economies of manufacture, will become

more apparent upon consideration of the following detailed

description and the appended claims with reference to the

BACKGROUND OF THE INVENTION

[0002]

One of the principal routs to the production of eth

accompanying photographs, the latter being brie?y described

hereinafter.

ylene involves cracking ethane at high temperatures. Puri?ed

ethane obtained from re?nery gas streams or from natural gas

is heated to temperatures of about 816 C. The thermal crack

BRIEF SUMMARY OF THE DRAWINGS

The results of the thermal cracking depend on such

[0013] The description herein makes reference to the

accompanying drawing wherein like reference numerals refer

to like parts throughout the several views and wherein:

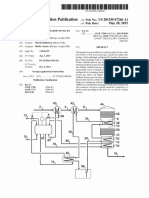

[0014] FIG. 1 is a block diagram showing the principal

variables as temperature, pressure and residence time, collec

tively referred to as cracking severity. Even under the best of

features of the process. Intermediate and product streams are

indicated on the ?ow sheet.

conditions, numerous byproducts limit the production of eth

ylene. Thus, a representative yield of ethylene is about 80

percent.

[0004] Because of the formation of byproducts ranging

DETAILED DESCRIPTION OF THE

ILLUSTRATIVE EMBODIMENT

ing, which takes place without a catalyst involves free radi

cals and a chain reaction.

[0003]

from hydrogen and methane to butane and higher molecular

weight hydrocarbons, extensive processing is needed to sepa

rate the ethylene product. This requirement is made more

stringent because many of the uses of ethylene, for example,

polyethylene production, demand high purity material.

[0005] For the above reasons, present know-how for pro

ducing ethylene from ethane has severe drawbacks. Capital

investment is substantial and operating ef?ciencies are aver

age.

SUMMARY OF THE INVENTION

[0015] The advantages of the present invention are best

understood through an appreciation of the relevant chemistry.

The two chemical reactions that take place are illustrated by

the following equations:

C2H6+HC1+0.502>C2H5C1+HZO

1.

C2H5Cl>C2H4+HC1

2.

[0016]

In these expressions, C2H6 represents ethane, HCl is

hydrogen chloride, 02 is oxygen, C2H5Cl is ethyl chloride,

H20 is water and C2H4 is ethylene.

[0017] When the above equations are combined, the overall

[0006] It is an object of the present invention to offer alter

native technology with favorable economics and robust fea

tures. This, as well as other objects and advantages of the

present invention will become apparent from the following

description and the ?gure that is included with this disclosure.

process is represented as follows:

[0007] A process is provided for the synthesis of ethylene

[0019] Both reactions represented by equations 1 and 2

require catalysts to be effective. The reaction of equation 1,

from ethane according to two chemical reactions operated in

sequence. First, a stream comprising ethane, oxygen and

hydrogen chloride is passed over an oxychlorination catalyst

to produce ethyl chloride and water. The ethyl chloride

obtained in the ?rst reaction is next cracked over a second

catalyst to form ethylene and hydrogen chloride. By option

ally recycling the hydrogen chloride from the second reaction

to the ?rst reaction, there is no net consumption of this inter

mediate.

[0008] A key feature of the present invention is the oxy

chlorination catalyst. This catalyst contains the chlorides of

copper, lead, and an alkali metal. Under operating conditions,

this catalyst mix is molten.

[0009] A number of catalyst compositions are effective in

cracking ethyl chloride. Among these catalysts are Zinc chlo

ride, activated carbon and silica alumina.

[0010] Operating conditions for the process are as follows.

The oxychlorination of ethane is conducted at a temperature

in the range of 350 to 400 C. An excess of ethane is advan

tageous in this reaction. The cracking of ethyl chloride takes

place at a temperature in the range of 325 to 375 C. Both

[0018] From equation 3, it is to be noted that there is no net

consumption of chlorine or chlorine compounds.

often known as oxychlorination, depends on the presence of a

copper salt although other compounds such as those of iron

are reported in the literature. Thus, copper chloride cycles

back and forth from cupric chloride to cuprous chloride

through the intermediate cupric oxychloride.

[0020] The second most important constituent of the chlo

rination catalyst is lead chloride. In essence this compound is

a negative catalyst. Its presence inhibits the burning of ethane

to carbon monoxide and carbon dioxide. In this regard, lead

chloride is critical to the success of the present invention.

[0021] Finally, an alkali metal chloride is incorporated into

the catalyst. Whether lithium, sodium, potassium or cesium

chloride are used singly or together, an alkali metal chloride

serves to depress the melting point of the catalyst mix. This

phenomenon is important in increasing the catalyst activity.

[0022] The reaction shown by equation 2 also depends on a

catalyst to take place. When ethyl chloride is heated to a high

temperature in the range of 500 to 650 C. without a catalyst,

hardly any ethylene product is obtained. At the upper end of

this range, the principal reaction is the formation of carbon.

Oct. 16, 2014

US 2014/0309468 A1

[0023]

The effective catalysts for the reaction of equation 2

chloride are formed. The exit gases are separated in an

are numerous. However, three catalysts in particular are note

absorption apparatus (not shown) to produce the ethylene

worthy. Activated charcoal shows some activity, but it is less

effective than other catalysts. Zinc chloride provides out

standing conversions. The only drawback to Zinc chloride is

its volatility, so steps need to be taken to maintain its activity.

product and hydrogen chloride for recycling to the oxychlo

rination reactor. If an excess of ethane is used in the process,

this reactant is also recycled.

EXAMPLE

Finally, silica alumina appears to meet all of the criteria of an

effective catalyst: high activity, long life and good speci?city.

[0024] Operating conditions for the process of the present

invention are critical. The oxychlorination reaction shown by

equation 1 requires a temperature in the range of 350 to 400

C. This reaction is exothermic so means must be provided to

remove the heat of reaction. One approach is to use an excess

[0029] The catalyst composition for the oxychlorination of

ethane to ethyl chloride was 40 mol percent copper chloride,

30 mol percent potassium chloride, 10 mol percent sodium

chloride, and 20 mol percent lead chloride. The reaction was

run at 370 C. At steady state conditions, 81.4 percent of the

ethane was unreacted, 14.0 percent converted to ethyl chlo

of ethane in the feed. Not only will the surplus improve heat

transfer, but it will also improve the yield of ethyl chloride by

reducing the formation of higher chlorinated ethanes. When

ride, 0.6 percent converted to 1, 1 dichloroethane, 2.2 percent

to ethylene dichloride, 1.4 percent to trichloroethane and 0.4

an excess of ethane is used, oxygen gas is the preferred

oxidant instead of air.

dioxide was detected. The ethyl chloride was cracked over a

[0025] In special situations where there is a surplus of ethyl

alcohol such as that produced by the fermentation of biomass,

ethyl chloride can be produced by reacting ethyl alcohol with

hydrogen chloride. The classical preparation of ethyl chloride

by this means uses a Zinc chloride catalyst at a temperature in

the range of 110 to 140 C.

[0026] The cracking operation illustrated by equation 2

functions best at a temperature in the range of 325 to 375 C.

This reaction is endothermic so that heat must be supplied to

the reactor. This requirement is facilitated by the use of a shell

and tube reactor design, which also is recommended for the

oxychlorination reaction.

[0027] The present invention is complicated by the forma

tion of coproducts, but these compounds can be of some use.

Ethane can be further chlorinated to produce ethylene dichlo

ride and trichloroethane. Both of these compounds are valu

able products. Ethylene dichloride can be cracked to produce

vinyl chloride, and trichloroethane can also be cracked to give

vinylidene chloride.

[0028] For a better appreciation of the present invention,

FIG. 1 is helpful. This ?gure is a block diagram showing the

principal pieces of equipment. Feed gases are introduced to

oxychlorination reactor 1 and the e?luent from the reactor is

cooled in a heat exchanger before water is removed in phase

separator 2. The chlorinated products pass to distillation col

umn 3 where ethyl chloride is removed overhead from the

higher chlorinated ethane coproducts. Next, the ethyl chlo

ride is fed to cracking fumace 4 where ethylene and hydrogen

percent to tetrachloroethane. No carbon monoxide or carbon

silica alumina catalyst at 350 C. to give a near quantitative

yield of ethylene. The catalyst was 12.4 weight percent AlZO3

and 87.3 percent SiO2 and had a surface area of 300 m2/g.

[0030] While the invention has been described in connec

tion with what is presently considered to be the most practical

and preferred embodiment, it is to be understood that the

invention is not to be limited to the disclosed embodiments

but, on the contrary, is intended to cover various modi?ca

tions and equivalent arrangements included within the spirit

and scope of the appended claims, which scope is to be

accorded the broadest interpretation so as to encompass all

such modi?cations and equivalent structures as is permitted

under the law.

What is claimed is:

1. A process for the manufacture of ethylene from ethane

comprising the steps of chlorinating ethane with hydrogen

chloride and oxygen to give ethyl chloride and water at a

temperature in the range of 350 to 400 C. in the presence of

a catalyst comprising copper chloride, lead chloride and an

alkali metal chloride, and thereafter, cracking ethyl chloride

from the chlorination reaction to give ethylene and hydrogen

chloride at a temperature in the range of 325 to 375 C. over

a catalyst selected from the group Zinc chloride, activated

charcoal, and silica alumina.

2. The process as de?ned in claim 1 further including the

step of recycling hydrogen chloride from the second step to

the ?rst (chlorination) step.

*

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- LAMPIRAN 5 Flowsheet Unit SynloopDokumen1 halamanLAMPIRAN 5 Flowsheet Unit SynloopLily DianaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Lampiran 1perhitungan Tugas KhususDokumen3 halamanLampiran 1perhitungan Tugas KhususLily DianaBelum ada peringkat

- Soal TOEFL - Reading ComprehensionDokumen3 halamanSoal TOEFL - Reading ComprehensionElizabeth PoedjionoBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- 1Dokumen12 halaman1Lily DianaBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Lampiran 4 Quenching Design 105 DDokumen1 halamanLampiran 4 Quenching Design 105 DLily DianaBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Fulbright Master Application Form 1Dokumen10 halamanFulbright Master Application Form 1Print WarnetBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Msds Molten SulphurDokumen9 halamanMsds Molten SulphurLily DianaBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Membrane Filtration HandbookDokumen129 halamanMembrane Filtration Handbookmario_nqn89% (9)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Danone at A GlanceDokumen21 halamanDanone at A GlanceGudang ErsopBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Pertemuan 02 Rancangan Pabrik (14 Oktober 2015)Dokumen15 halamanPertemuan 02 Rancangan Pabrik (14 Oktober 2015)Lily DianaBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Pertemuan 05 Rancangan Pabrik (04 November 2015)Dokumen15 halamanPertemuan 05 Rancangan Pabrik (04 November 2015)Lily DianaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- PDF Abstrak Id Abstrak-20376774Dokumen1 halamanPDF Abstrak Id Abstrak-20376774Lily DianaBelum ada peringkat

- LAMPIRAN 5 Flowsheet Unit SynloopDokumen1 halamanLAMPIRAN 5 Flowsheet Unit SynloopLily DianaBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Moist Air PropertiesDokumen12 halamanMoist Air PropertiesLily DianaBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Paten Sulfur Mixer PDFDokumen7 halamanPaten Sulfur Mixer PDFLily DianaBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Paten Kak DeviDokumen33 halamanPaten Kak DeviLily DianaBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Furfural PatentDokumen5 halamanFurfural PatentLily DianaBelum ada peringkat

- Us 20140309468Dokumen4 halamanUs 20140309468Lily DianaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Pertemuan 05 Rancangan Pabrik (04 November 2015)Dokumen15 halamanPertemuan 05 Rancangan Pabrik (04 November 2015)Lily DianaBelum ada peringkat

- PaperDokumen10 halamanPaperLily DianaBelum ada peringkat

- Konversi Sulfur Di Proses Pembakaran 1 PDFDokumen6 halamanKonversi Sulfur Di Proses Pembakaran 1 PDFLily DianaBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Proses Wsa 2 PDFDokumen2 halamanProses Wsa 2 PDFLily DianaBelum ada peringkat

- Us 20150147266 A 1Dokumen18 halamanUs 20150147266 A 1Lily DianaBelum ada peringkat

- Us5108731 PDFDokumen12 halamanUs5108731 PDFLily DianaBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- 10195en Rev6 PDFDokumen8 halaman10195en Rev6 PDFLily DianaBelum ada peringkat

- Topsoe Wet Gas Sulphuric Acid (WSA) TechnologyDokumen8 halamanTopsoe Wet Gas Sulphuric Acid (WSA) Technologytsaleh100% (1)

- Us 8138371Dokumen10 halamanUs 8138371Lily DianaBelum ada peringkat

- Topsoe Wet Gas Sulphuric Acid (WSA) TechnologyDokumen8 halamanTopsoe Wet Gas Sulphuric Acid (WSA) Technologytsaleh100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Wsa Condenser PDFDokumen21 halamanWsa Condenser PDFLily DianaBelum ada peringkat

- c01Dokumen21 halamanc01Mustafa BakırBelum ada peringkat

- Module 1 Kinetics of Materials Reading MaterialsDokumen8 halamanModule 1 Kinetics of Materials Reading MaterialsmayBelum ada peringkat

- Table of Test SpecificationDokumen2 halamanTable of Test Specificationjgd2080Belum ada peringkat

- Cambridge Igcse Chemistry Book TopicsDokumen2 halamanCambridge Igcse Chemistry Book TopicsMohammad IslamBelum ada peringkat

- Sydney Boys 2020 Chemistry Trials & SolutionsDokumen38 halamanSydney Boys 2020 Chemistry Trials & SolutionsNhân Lê Nguyễn ThiệnBelum ada peringkat

- 1 Factors That Affect Reaction Rates PDFDokumen6 halaman1 Factors That Affect Reaction Rates PDFThaarvena RetinaBelum ada peringkat

- Chloride Metallurgy 2011Dokumen34 halamanChloride Metallurgy 2011Manojlovic Vaso100% (1)

- McMurry Chapter 8Dokumen72 halamanMcMurry Chapter 8Christine TapawanBelum ada peringkat

- Chemical Reactor Inherent Safety Index A PDFDokumen9 halamanChemical Reactor Inherent Safety Index A PDFAnilBelum ada peringkat

- Ring Opening Reaction of EpoxidesDokumen5 halamanRing Opening Reaction of Epoxides4t43t34yBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Transition Metals ColoursDokumen24 halamanTransition Metals ColoursTomNaccaratoBelum ada peringkat

- Pharmaceutical Catalysis HandbookDokumen108 halamanPharmaceutical Catalysis HandbookLeda PrandiBelum ada peringkat

- Main Group Organometallic ChemistryDokumen7 halamanMain Group Organometallic ChemistryMuhammad ZubairBelum ada peringkat

- Preparation of AzomethineDokumen4 halamanPreparation of Azomethinepranjal JaiswalBelum ada peringkat

- SS2 Chemistry 1st Term Lesson Note PDFDokumen73 halamanSS2 Chemistry 1st Term Lesson Note PDFAugustine AmaechiBelum ada peringkat

- JSCS Vol79 No9Dokumen185 halamanJSCS Vol79 No9Walid Ebid ElgammalBelum ada peringkat

- HKDSE CHEMISTRY - Book 4B AnsDokumen47 halamanHKDSE CHEMISTRY - Book 4B AnsSteven Chu100% (2)

- Cambridge MatchGrid - IGCSE - CompleteChemDokumen3 halamanCambridge MatchGrid - IGCSE - CompleteChemHakan OlgunBelum ada peringkat

- REVIEWERDokumen11 halamanREVIEWERLianne MaristellaBelum ada peringkat

- Expt 2 New Chem 1036Dokumen6 halamanExpt 2 New Chem 1036leon fenrirBelum ada peringkat

- MetalsDokumen24 halamanMetals4D-31 WONG YUEN TSZBelum ada peringkat

- Reaction Types 2Dokumen2 halamanReaction Types 2jefferson33% (3)

- Reduction Behavior of Carbon Composite Iron Ore Hot Briquette in Shaft Furnace and Scope On Blast Furnace Performance Reinforcement PDFDokumen9 halamanReduction Behavior of Carbon Composite Iron Ore Hot Briquette in Shaft Furnace and Scope On Blast Furnace Performance Reinforcement PDFAgustine SetiawanBelum ada peringkat

- Grade 5 PPT - Science - Q1 - W3 - Day 1Dokumen99 halamanGrade 5 PPT - Science - Q1 - W3 - Day 1Precilla Halago100% (2)

- Recent Advancement in Synthesis of Isatin As Anticonvulsant Agents A Review 2161 0444.1000417Dokumen12 halamanRecent Advancement in Synthesis of Isatin As Anticonvulsant Agents A Review 2161 0444.1000417Tayyab Hussain DaarBelum ada peringkat

- Module XXX Tablet TechnologyDokumen3 halamanModule XXX Tablet Technologyapi-479998232Belum ada peringkat

- Hydrocarbons MarathonDokumen353 halamanHydrocarbons MarathonGully GamingBelum ada peringkat

- Chemical Rate AnalysisDokumen10 halamanChemical Rate AnalysisAshwinBafnaBelum ada peringkat

- EnzymeDokumen31 halamanEnzymemiriam harriottBelum ada peringkat

- Tetrahedron 59 (2003) 1301-1307 PDFDokumen7 halamanTetrahedron 59 (2003) 1301-1307 PDFLibros FacultadBelum ada peringkat

- Result N Discussion Exp3 Sku - PDFDokumen2 halamanResult N Discussion Exp3 Sku - PDFFadila AbdulnurBelum ada peringkat

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDari EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaBelum ada peringkat

- Sully: The Untold Story Behind the Miracle on the HudsonDari EverandSully: The Untold Story Behind the Miracle on the HudsonPenilaian: 4 dari 5 bintang4/5 (103)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDari EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindBelum ada peringkat

- The Fabric of Civilization: How Textiles Made the WorldDari EverandThe Fabric of Civilization: How Textiles Made the WorldPenilaian: 4.5 dari 5 bintang4.5/5 (57)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDari EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincPenilaian: 3.5 dari 5 bintang3.5/5 (137)

- System Error: Where Big Tech Went Wrong and How We Can RebootDari EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootBelum ada peringkat

- Hero Found: The Greatest POW Escape of the Vietnam WarDari EverandHero Found: The Greatest POW Escape of the Vietnam WarPenilaian: 4 dari 5 bintang4/5 (19)