Turbine Meter Tech Guide

Diunggah oleh

Oscar MarinHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Turbine Meter Tech Guide

Diunggah oleh

Oscar MarinHak Cipta:

Format Tersedia

Technical Guide

April 2015

Daniel Liquid Turbine Flow Meters

Technical Guide

Turbine Meter Theory

The basic theory behind Daniel liquid turbine meters is relatively

simple. Fluid flow through the meter impinges upon the turbine

blades which are free to rotate about an axis along the center

line of the turbine housing. The angular (rotational) velocity of

the turbine rotor is directly proportional to the fluid velocity

through the turbine. These features make the turbine meter an

ideal device for measuring flow rate.

assembly holds the turbine rotor in alignment with the fluid

flow. The angle of the turbine blades to the stream governs

the angular velocity and the output frequency of the meter.

A sharper blade angle provides a higher frequency output. In

general, the blade angle is held between 20 and 40 to the

flow. Lower angles cause too low of an angular velocity and loss

of repeatability, while larger angles cause excessive end thrust.

The output of the meter is taken by an electrical pickoff(s)

mounted on the meter body. The pickoffs output frequency

is proportional to the flow rate. In addition to its excellent

rangeability, a major advantage of the turbine meter is that

each electrical pulse is also proportional to a small incremental

volume of flow. This incremental output is digital in form, and

as such, can be totalized with a maximum error of one pulse

regardless of the volume measured.

Flow Rate Is Proportional to Angular

Velocity

The turbine meter and associated digital electronics form the

basis of any liquid metering system. An expanding blade hanger

Figure 1 below is a cross section of the internals of a Daniel

Series 1500 turbine meter. Flow through the turbine meter is

from left to right. The forward and rear suspension act as flow

guides, ensuring fluid motion through the meter is parallel to

the meters centerline. Flow impinging upon the angular blade

causes the rotor to spin at an angular velocity proportional to

flow rate.

Figure 1: Liquid Turbine Flow Meter Cross Section

www.EmersonProcess.com

Liquid Turbine Flow Meter

April 2015

Turbine Meter Parameters

The following terms are the most widely discussed parameters

of turbine meter applications.

Linearity

Linearity is the measure of variation in signal output across the

nominal flow range of the meter. Turbine meters have a nominal

K-factor which is the number of pulses output for a given volume

measured. This value varies across the meters flow range with

linearity being a measure of the variance of actual output from

the average K-factor. Advanced technology allows linearization

of the meter registration within a flow computer, enabling

further improvements in measurement accuracy.

Accuracy

Accuracy is a measure of how closely the instrument indicates

actual flow and is generally expressed as a percent of true

volume for a specific flow range. Accuracy at a particular flow

rate may be an order of magnitude better than rated flow

range accuracy.

Resolution

Resolution is a measure of the smallest increment of total flow

that can be individually recognized, normally defined by a single

pulse. Turbine meters have inherently high resolution.

Range

Repeatability

Repeatability is the ability of a meter to indicate the same

reading each time the same flow conditions exist. Turbine

meters exhibit excellent repeatability which is the most

important parameter to be considered for many applications.

Range is the ratio of maximum flow to minimum flow over

which the specified linearity will be maintained. Normal range

or turndown is given as 10:1 which is often exceeded depending

on meter size and required linearity.

0.15%

0.02%

Figure 2: Flow Ranges

www.EmersonProcess.com

Technical Guide

Daniel Liquid Turbine Flow Meter Systems

Daniel Series 1200 and 1500 Liquid Turbine Flow Meter Systems

combine turbine meters and electronic instrumentation to

measure volumetric total flow and/or flow rate. Each Daniel

turbine meter is comprised of a cylindrical housing that

contains a precise turbine rotor assembly. One or two magnetic

pickoffs are mounted in a boss on the meter body. As fluid

passes smoothly through the flow meter, it causes the rotor to

revolve with an angular velocity proportional to flow. The rotor

blades or rim buttons passing through the magnetic field of

the pickoff generate a pulsing voltage in the coil of the pickoff

assembly. Each voltage pulse represents a discrete volume.

The total number of pulses collected over a period of time

represents the total volume metered.

The sinusoidal signal from each pickoff has low amplitude and

may not normally be relied upon for transmission distances

over 6 meters (20 feet). The signal must, therefore, be amplified

which is achieved with a preamplification board mounted on

the turbine meter. These pulse signals are typically transmitted

to control room instrumentation such as flow computers,

and may also be required as input to prover computers which

calculate, display, transmit, control or record the flow sensed

by the rotor. The results may be displayed as pulse counts or

standard engineering units, such as gallons, barrels, cubic

meters, etc.

All Series 1200 and 1500 Liquid Turbine Flow Meters have, as

standard, the Local Mounted Enclosure (LME) which may be

fitted with one or two pickoffs and a dual channel preamplifier.

The pickoff mountings are oriented with the pickups 90

electrically out of phase. The Daniel Series 1500 Liquid Turbine

Flow Meter may be supplied with two LMEs, offering up to four

pulse outputs. Alternate pairs across the two LMEs are also 90

electrically out of phase.

Daniel manufactures the Series 1200 and 1500 Liquid

Turbine Flow Meters and the adjacent tube sections. Each

meter is precisely calibrated before shipment.

The meter systems are used to provide measurement

information in fluid transport, petroleum and chemical

processing, custody transfer of liquids, blending systems,

and in-product batching in field or plant operations. The

repeatability of the system ensures quality measurement

of fluids over a wide range of flow rates, temperatures,

compositions and viscosities.

Figure 3: Liquid Turbine Flow Meter System

www.EmersonProcess.com

Liquid Turbine Flow Meter

April 2015

Innovative Floating Rotor Design

Flowing fluid enters the turbine through the forward

suspension. When it encounters the sharp angle of the

upstream cone, the stream is deflected outward, increasing in

velocity and causing a slight static pressure drop. As the fluid

leaves the blade area, flow has redistributed. Velocity is reduced

slightly and static pressure has increased proportionally.

The difference between the two velocity pressures causes

the rotor to move upstream into the fluid flow. A slight offset

ensures this upstream force will not cause the rotor to strike the

forward thrust bearing.

The cross sectional area of the cone is slightly smaller than that

of the rotor hub with some flow impinging directly upon the

rotor hub, generating a downstream thrust. As a result, the

rotor floats in balance between upstream and downstream

cones, pushed forward by the pressure difference across the

blades and pushed backward by the flow impingement. The

only bearing surface other than the measured fluid is the

cemented carbide sleeve bearing insert (see figure 4).

In bi-directional meters, a second upstream cone replaces the

downstream cone and rangeability is reduced in reverse flow.

Figure 4: Rotor Assembly Cross Section

www.EmersonProcess.com

Technical Guide

Magnetic Pickoff of Rotor Velocity

The angular velocity of the turbine rotor is taken through the

turbine meter wall by means of a magnetic pickoff. Turbine

blades made of a paramagnetic material (i.e. properties cause

it to be attracted by a magnet) rotate past the pickoff coil,

generating irregular shaped voltage pulses. The frequency of

these pulses is linearly proportional to the angular velocity of

the rotor and thus to the flow rate. Additionally, each pulse

is incrementally proportional to a small unit of volume. The

amplitude of the pulses will vary in proportion to blade velocity

but is not considered in the measurement process. Flow rate

and total flow information is transmitted by frequency and by

counting (totalizing) the pulses.

The permanent magnet produces a magnetic field which

passes through the coil and is concentrated to a small point at

the pickoffs. In Figures 5 and 6 below, as a turbine blade (A)

moves into close proximity to the pickoff point, its magnetic

ONE

properties cause the magnetic field to deflect to accommodate

PULSE

A

its presence. This deflection causes a voltage to be generated

in the coil. As the blade passes under the pickoff point (B), this

voltage decays, only to build back in the opposite polarity as the

leaving blade which is now in position (C). This result is caused

by the magnetic field deflecting in the opposite direction. So

as each blade passes the pickoff, it produces a separate and

distinct voltage pulse. Since the fluid surrounding each blade

represents a discrete unit of volume, each electrical pulse also

represents a discrete unit of volume. Turbine meter output is

rated in pulses per gallon, pulses per liter, or other standard

engineering units.

ONE

UNIT

VOLUME

B

THIS 1/2 PULSE

IS NOT USED

BY READOUTS

MAGNETIC

SENSORS

(PICKOFFS)

LOCAL

MOUNTED

ENCLOSURE

(LME)

CLAMP

O-RING

INSULATOR

PICKOFF #1

LME

MOUNTING

BOX PAD

PICKOFF #2

C

ONE

PULSE

A

B

BLADES

MAGNETIC

SENSORS

(PICKOFFS)

Figure 5: Assembly of Local Mounted Enclosure

LOCAL

MOUNTED with Dual Pickoff Configuration

ENCLOSURE

(LME)

PICKOFF #1

LME

MOUNTING

BOX PAD

www.EmersonProcess.com

BLADES

ONE

UNIT

VOLUME

THIS 1/2 PULSE

IS NOT USED

BY READOUTS

Figure 6: Voltage Output, Peak to Peak

CLAMP

O-RING

INSULATOR

PICKOFF #2

Liquid Turbine Flow Meter

April 2015

Turbine Meter Rotor and Bearing Design

The primary differences in turbine meter technology are in the

design of the rotor and bearings. The rotor is an assembly of up

to 12 blades locked into a hub that rotates on a bearing(s). For

light liquid applications that require viscosities of 5 cst or less and

specific gravities of less than 0.70, the rotor does not normally

need a rim or shroud. For measuring more viscous liquids and

in larger size turbine meters (i.e. 200DN and above), a rim is

fitted to ensure sufficient rigidity in the rotor. A rim also offers

the advantage of higher pulse resolution. With a bladed rotor,

the number of pulses per revolution is limited to the number of

blades; in a rimmed rotor, the number of pulses per revolution

corresponds to the number of buttons or slots in the rim.

For intermittent duties on light, clean hydrocarbons that

may be found at tank truck terminals, ball bearings may

be used for a rotor bearing. Proper design of rotors with

ball bearings will use two ball races and a short axle upon

which the rotor is fitted. Where space is constrained, ball

races may be fitted directly into the rotor hub. This design is

particularly suited to low and varying flow rate applications,

and is utilized on the Series 1200 Liquid Turbine Flow Meter,

designed primarily for distribution applications such as load

racks. In these installations, liquids are typically light, refined

products.

Pipeline applications often require continuous operation

at fixed flow rates, requiring the turbine meter to offer

sufficient longevity to minimize maintenance intervals. In

these applications, tungsten carbide journal bearings are

used. As tungsten carbide is extremely hard wearing, these

bearings are often applied in more demanding measurement

applications such as crude oil.

An important point is limitations on viscosity are related to the

rangeability of the turbine flow meter. As the viscosity of the

measured liquid increases, the K-factor variations at different

flow rates increase. To maintain the linearity of the meter at the

required level as the viscosity of the measured liquid increases,

the turndown or rangeability of the meter must be reduced. For

typical pipeline applications where the flow meter will operate

at just one flow rate (or a very limited range of flow rates), a

turbine meter may be used to measure flows of high viscosity

liquids. The Series 1500 Liquid Turbine Flow Meter is designed

for pipeline applications and is equipped with robust internals

suited to continuous measurement of a wide range of liquids.

There may be a single hanger or hangers upstream and

downstream of the rotor. In the Series 1200 Meter, there is a

single upstream support for the rotor. In the Series 1500 Meter,

there are both upstream and downstream hangers.

Bearings may be either ball or tungsten carbide journal

bearings. Ball bearings are used to provide improved

performance at low flow rates and on clean product. These

bearings are a reliable, cost-effective solution.

The Series 1200 Meter deploys a cantilevered twin ball bearing

design. The meter is designed with a rotating shaft on two ball

bearing units and is available in DN25 to DN100 (1 inch to 4

inch) line sizes. For more demanding applications, a tungsten

carbide journal bearing assembly is available as an option for

DN80 and DN100 (3 inch and 4 inch) line sizes only.

Lightweight bladed rotors of this type mounted on ball bearings

are particularly well suited to the intermittent duty cycles

typical in loading rack applications. The design application is

limited to clean refined products. In the event the turbine is

used on slightly dirty products, use of tungsten carbide journal

bearings is recommended. Tungsten carbide bearings are

extremely hard wearing and used in turbine meters on a range

of applications from LPGs to crude oils.

Rimmed Rotors for Higher Resolution

In the larger diameter Series 1500 Meter (normally above

DN150 or 6 inch in line size), the resolution provided by a

blade-type rotor may be improved by the use of a rimmed or

shrouded rotor. This construction is standard for Daniel DN200

or 8 inch and larger meters. A lightweight stainless steel rim

or shroud carries small paramagnetic buttons which provide

greater resolution of flow by generating more pulses per unit

volume.

Series 1200 and 1500 Meters are supplied with local

mounted electronics (LME) as standard. The electronic

enclosure is attached to a boss which, in turn, is attached to

the meter body. This assembly may house two pickoffs in an

orientation with their outputs 90 electrically out of phase.

www.EmersonProcess.com

Technical Guide

The Daniel Series 1500 Liquid Turbine Flow Meter is offered

with its standard paramagnetic H. Mu button Rim type rotor

(Figure 7). Daniel offers a lite shrouded rotor that is designed

with slots in the rim in place of paramagnetic buttons and

provides a higher number of pulses per unit volume (Figure 8)

than the standard rotor which enables proving with a smaller

prover (Figure 9).

Figure 7: Rim Rotor DN80 to DN600 (3 inch to 24 inch)

Figure 8: Optional Lite Product Rim Rotor

DN80 to DN300 (3 inch to 12 inch)

www.EmersonProcess.com

Figure 9: Blade Rotor DN25 to DN150 (1 inch to 6 inch)

Liquid Turbine Flow Meter

April 2015

Daniel Series 1500 Liquid Turbine Flow Meter

The Series 1500 Meter is designed for applications requiring

rugged dependability with high accuracy and throughput.

Engineered for use on pipelines, marine loading and other

demanding systems, the internals are well proven in the Daniel

PT meter. The Series 1500 Meter utilizes these internals in a

body designed to accept Locally Mounted Electronics (LME) and

the latest pickoff and preamplifier technology.

Upstream and downstream self-centering hangers, a highly

durable rotor assembly utilizing a tungsten carbide sleeve and

journal bearings, and a floating rotor design make the Series

1500 Meter ideal for applications where downtime is not an

option.

In such applications, dual-pulse transmission is normally used to

allow the meter instrumentation (normally a flow computer) to

check the fidelity of pulse transmission. The single LME housing

contains one or two pickoffs and a dual channel preamplifier.

When configured with two pickoffs, the square wave outputs

are 90 electrically out of phase.

number of paramagnetic buttons than of blades may be used

on the stainless steel rim. A bladed rotor is limited to one pulse

per blade per revolution with the practical limit for the blades

being 12. With a rim or shroud, there may be up to 64 pulses

(buttons) per rotor revolution.

The rimmed design is optional on DN80 to DN150 (3 inch to 6

inch) turbines and is standard on DN200 (8 inch) and larger.

Regardless of the meter design and rotor configuration, the

blades are locked and welded into the desired angular position,

forming a solid, one piece rotor.

In the Series 1500 Meter, both upstream and downstream shaft

supports are deployed. The expanding hanger principle is used

to ensure positive self-centering of the internals. The shape of

the internal cones results in a reverse differential pressure that

counterbalances the downstream thrust on the rotor, allowing

the rotor to float on a fluid cushion. This floating action ensures

long life and minimal maintenance.

A second LME is an option on DN80 (3 inch) and larger meters.

For meters DN80 (3 inch) and larger with a dual LME, four

matched pulse outputs are possible. Corresponding pairs are

then 90 electrically out of phase.

Series 1500 Meter utilizes only tungsten carbide journal

bearings. In applications with fluids of adequate lubricity, a

film of the measured fluid lubricates the journal, contributing

to instrument longevity. These bearings are extremely

hard (Rockwell A-94) and polished with diamond paste to a

smoothness of 0.05 micron (a mirror finish).

The rotor may be blade-type or rimmed-type. Rimmed or

shrouded rotors have the advantages of greater structural

strength and the possibility of higher resolution, as a greater

10

www.EmersonProcess.com

Technical Guide

Local Mounted Enclosure (LME)

Configuration shown for temperature up to +60C (+140F)

Rim Type Rotor

Available in DN80 to DN600 (3 to 24 in)

Blade Type Rotor

Available in DN25 to DN150 (1 to 6 in)

Figure 10 - Daniel Series 1500 Liquid Turbine Flow Meter

Figure 10: Daniel Series 1500 Liquid Turbine Meter Assemblies

www.EmersonProcess.com

11

Liquid Turbine Flow Meter

April 2015

Daniel Series 1500 Meter Design Features

The linearity specification is dependent on the characteristics of the calibration fluid. For DN25 to 200 (1 inch to 8 inch) meters, SG

is 0.78 and KinVisc (cSt) is 2.1. For DN250 to 600 (10 inch to 24 inch) meters, SG is 1.0 and KinVisc (cSt) is 1.0.

Table 1: Linear Flow Range(1)

Nominal Size

Standard Flow Range

DN

M3/HR

BBL/HR

Min

Max

Extended

Max Flow

Rate(2)

10

100

115

Inches

Standard Flow Range

USGPM

Min

Max

Extended

Max Flow

Rate(2)

1.6

16

18

Extended

Min Flow Rate

Linearity

0.75% (1"-2.5")

0.50% (3"-24")

5.6

Standard Flow Range

Min

Max

Extended

Max Flow

Rate(2)

70

81

25

40

1.5

21

214

246

3.4

34

39

12

15

150

173

50

43

429

493

6.8

68

78

24

30

300

345

65

2.5

57

571

657

9.1

91

105

32

40

400

460

80

100

1,000

1,150

15.9

159

183

56

70

700

805

100

185

1,850

2,128

29.4

294

338

104

130

1,295

1,489

150

420

4,200

4,830

66.8

668

768

235

294

2,940

3,381

200

850

8,500

9,775

135

1,351

1,554

476

595

5,950

6,843

250

10

1,200

12,000

13,800

191

1,908

2,194

672

840

8,400

9,660

300

12

1,800

18,000

20,700

286

2,862

3,291

1,008

1,260

12,600

14,490

400

16

2,800

28,000

32,200

445

4,452

5,120

1,568

1,960

19,600

22,540

450

18

4,000

40,000

46,000

636

6,359

7,313

2,240

2,800

28,000

32,200

500

20

4,800

48,000

55,200

763

7,631

8,776

2,688

3,360

33,600

38,640

600

24

6,000

60,000

69,000

954

9,539

10,970

3,360

4,200

42,000

48,300

Table 2: Nominal K-Factor(3)

Nominal Size

DN

Pulses/M3

Pulses/BBL

Inches

Blade

Rim

Blade

Pulses/US Gal

Rim

Blade

Rim

25

21,000

132,086

40

1.5

9,660

60,760

50

5,460

65

2.5

2,730

80

2,100

4,620

13,209

29,059

100

1,000

2,940

6,287

18,492

24

70

150

245

1,050

1,532

6,604

5.8

25

N/A

34,342

500

N/A

17,171

230

130

N/A

65

50

110

200

550

3,461

13

250

10

250

1,585

6.0

300

12

400

16

200

N/A

100

1,268

N/A

634

4.8

N/A

2.4

450

18

100

634

2.4

500

20

100

634

2.4

600

24

100

634

2.4

(1) Bi-directional meters have a standard linear flow range as stated above. The minimum flow rate in the reverse direction is 20% of its maximum extended flow rate.

(2) Extended flow rate with 20% duty cycle not to exceed 2 hours per day.

(3) K-Factors for individual rotors vary. An acceptable rotor can be nominal 15%.

12

www.EmersonProcess.com

Technical Guide

Rangeability

Performance Based on

Specific Gravities

The flow ranges indicated in the previous tables show a nominal

flow range with a turndown of 10:1. The turbine meter will

report measurement repeatable to the indicated specification

based on the measurement of clean liquids such as water

(specific gravity 1, viscosity 1 cSt) and mineral spirits (specific

gravity 0.78, viscosity 2.1 cSt).

Liquid turbine meters are affected by changes in liquid density.

When measuring liquids with specific gravities of 0.7 or less, the

meters minimum flow rate must be increased to maintain the

meters linearity within the required limits. In this application,

the maximum flow rate may be increased to allow for greater

rangeability.

When liquids with properties outside of the range described by

these liquids are to be measured, the meter flow range will be

affected.

It is vital that proper back pressure be maintained (refer to page

19 for the formula for determining required back pressure).

Failure to do so may result in flashing and cavitation, which will

cause over ranging of, and damage to, the meter.

Extended flow rates on intermittent duty cycles are permitted

and shown in the flow meter design features table on page 10. It

should also be noted that the use of the meter in the extended

flow range should be limited to a 20% duty cycle.

Liquids with low specific gravities generally have high vapor

pressures and high coefficients of thermal expansion. When

measuring these liquids, it is extremely important that proper

installation, measurement and proving practice be followed

to provide stable temperatures and to negate the potential for

poor measurement and possible system damage.

The data on the following page is for the Series 1500 Meter.

Similar effects will be observed in all turbine meter designs.

Figure11: Daniel Series 1500 Liquid Turbine Flow Meter

www.EmersonProcess.com

13

Liquid Turbine Flow Meter

April 2015

Series 1500 Meter Flow Range Adjustments

The tables below represent the effect of specific gravity on the linear flow range.

Table 3A: Specific Gravity = 0.7 to 1 (Blade and Rim Type Internals)

Nominal Size

DN

Inches

25

1

40

1.5

50

2

65

2.5

80

3

100

4

150

6

BBL/HR

10

21

43

57

100

186

420

Minimum Linear Flow Rate

M3/HR

USGPM

1.6

7

3.4

15

6.8

30

9.1

40

15.9

70

29.5

130

66.8

294

BBL/HR

100

214

429

571

1,000

1,850

4,200

Maximum Linear Flow Rate

M3/HR

USGPM

15.9

70

34.1

150

68.1

300

90.9

400

159

700

294

1,295

668

2,940

Table 3B: Specific Gravity = 0.6 (Blade Type Internals Only)

Nominal Size

DN

Inches

25

1

40

1.5

50

2

65

2.5

80

3

100

4

150

6

BBL/HR

17

36

71

96

167

309

701

Minimum Linear Flow Rate

M3/HR

USGPM

2.7

12

5.7

25

11.4

50

15.2

67

26.6

117

49.1

216

112

491

BBL/HR

116

247

493

657

1,150

2,129

4,830

Maximum Linear Flow Rate

M3/HR

USGPM

18.4

81

39.3

173

78.4

345

105

460

183

805

338

1,490

768

3,381

Table 3C: Specific Gravity = 0.5 (Blade Type Internals Only)

Nominal Size

DN

Inches

25

1

40

1.5

50

2

65

2.5

80

3

100

4

150

6

BBL/HR

23

50

101

134

236

436

989

Minimum Linear Flow Rate

M3/HR

USGPM

3.6

16

7.9

35

16.1

71

21.3

94

37.5

165

69.3

305

157

692

BBL/HR

116

247

493

657

1,150

2,129

4,830

Maximum Linear Flow Rate

M3/HR

USGPM

18.4

81

39.1

172

78.4

345

105

460

183

805

338

1,490

768

3,381

Table 3D: Specific Gravity = 0.4 (Blade Type Internals Only)

Nominal Size

DN

Inches

25

1

40

1.5

50

2

65

2.5

80

3

100

4

150

6

BBL/HR

29

60

120

160

280

517

1,173

Minimum Linear Flow Rate

M3/HR

USGPM

4.5

20

9.5

42

19.1

84

25.4

112

44.5

196

82.2

362

187

821

BBL/HR

116

246

493

657

1,150

2,129

4,830

Maximum Linear Flow Rate

M3/HR

USGPM

18.4

81

39.1

172

78.4

345

105

460

183

805

338

1,489

768

3,381

Table 3E: Specific Gravity = 0.3 (Blade Type Internals Only)

Nominal Size

DN

Inches

25

1

40

1.5

50

2

65

2.5

80

3

100

4

150

6

14

BBL/HR

33

71

141

190

331

613

1,393

Minimum Linear Flow Rate

M3/HR

USGPM

5.2

23

11.4

50

22.5

99

30.2

133

52.7

232

97.4

429

221

975

BBL/HR

116

246

493

657

1,150

2,129

4,830

Maximum Linear Flow Rate

M3/HR

USGPM

18.4

81

39.1

172

78.4

345

105

460

183

805

338

1,489

768

3,381

www.EmersonProcess.com

Technical Guide

Series 1500 Meter Performance on High Viscosity Liquids

An increase in viscosity of the measured liquid will

reduce the rangeability of the flow meter. Generally, the

meters minimum flow rate will have to be increased to

maintain the meters linearity rating.

Note:

Use of the turbine meter on high viscosity liquids at the

maximum extended flow range is allowable but may

increase the turbines wear rate.

The increased flow rate may be determined according

to the following ratio:

The pressure drop through the meter may be

estimated (for low to medium viscosities) according to

the following formula:

Sizing Ratio = Liquid Viscosity (cSt)

Nominal Line Sizes

DP = (PD) x ()1/4 x (SG)3/4

or

DP = (PD) x (v)1/4 x (SG)

Sizing Ratio

Minimum Flow (% of Normal Maximum Flow Rate)

Use Normal Minimum Flow Rate

1.5

20%

25%

2.5

30%

35%

40%

45%

50%

55%

60%

Where:

DP = Estimated pressure drop

PD = Pressure drop for water at expected flow rate

= Absolute viscosity in centipoises

v = Kinematic viscosity in centistokes

SG = Specific gravity

Note: = (v) x (SG)

Example:

The sizing ratio of a 4 inch turbine meter measuring

a liquid of 8 cSt is 8/4, or 2. The normal maximum

flow rate for this meter size is 1450 GPM. The new

minimum flow rate is 25% of 1450, or 362.5 GPM. The

flow rate for this application is now 362 to 1450 GPM,

with standard linearity (0.15%) and repeatability of

(0.02%) maintained.

www.EmersonProcess.com

15

Liquid Turbine Flow Meter

April 2015

Daniel Series 1200 Liquid Turbine Flow Meter

Series 1200 Meter is designed specifically for load rack service

where repeatability is vital. The meter deploys a lightweight

rotor that is supported on self-cleaning, flow

through ball bearings. As a result, the meter is

versatile and is particularly suited to batch loading

of light hydrocarbons. The meter has been used

successfully on fluids with viscosities up to 6

centistokes. The meter can also be supplied with

optional tungsten carbide bearings for more

demanding applications.

The meter features an upstream expanding hanger

which centers the internals in the body with

cantilevered support of the rotor. It will operate

in any plane and is frequently used in the vertical

orientation with flow upward to save space on a load rack.

An integral flow conditioning plate (FCP) in Delrin (standard) or

aluminum (an option for DN80 and DN100, or 3 inch and 4 inch

meters) allows operation without upstream flow straightening.

This configuration is particularly valuable for vertical installation

of the meter on load racks. The FCP is available on DN40 (1.5

inch) meters and larger.

Stainless Steel Bearing Internals

Figure 12: Part Identification for a NPS 3 through 4 Meter

Tungsten Carbide Bearing Internals

* See Daniel Series 1200 Liquid Turbine Flow Meter datasheet for model selection

matrix

Local Mounted Enclosure

Figure 13: Part Identification for a NPS 3 through 4 Meter

Figure 14: Part Identification for

Local Mounted Enclosure (LME)

16

www.EmersonProcess.com

Technical Guide

Series 1200 Meter Design Features

The following data is applicable for Daniel Series 1200 Liquid Turbine Flow Meter calibrated on mineral spirits.

Table 4: Flow Rate

Nominal Size

DN

Inches

25

40

50

80

100

1

1.5

2

3

4

BBL/HR

Standard Flow Range

Minimum Maximum

8.6

19

31

93

143

86

186

314

929

1,429

* Extended

Maximum

Flow Range

99

214

361

1,068

1,785

M3/HR

Standard Flow Range

Minimum

Maximum

1.4

3.0

5.0

15

23

14

30

50

148

227

* Extended

Maximum

Flow Range

16

34

58

170

284

USGPM

Standard Flow Range

Minimum

Maximum

6

13

22

65

100

60

130

220

650

1,000

* Extended

Maximum

Flow Range

69

150

253

748

1,250

* Note: Extended maximum flow range with 20% duty cycle not to exceed 2 hours per day

Table 5: Nominal K-Factor

Nominal Size

K-Factor*

DN

Inches

Pulses/BBL

Pulses/M3

Pulses/USG

25

33,600

211,338

800

40

1.5

16,800

105,669

400

50

7,560

47,551

180

80

2,184

13,737

52

100

966

6,076

23

* Note: K-Factors for individual rotors vary. An acceptable rotor can be nominal 15%.

Figure 15: Daniel Series 1200 Liquid Turbine Flow Meter

www.EmersonProcess.com

17

Liquid Turbine Flow Meter

April 2015

Flow Conditioning

For a turbine meter to perform without increased uncertainty

and in a repeatable and accurate manner, the flowing stream

must be free of rotational components. The internal assembly

supports of a turbine meter offer a slight straightening effect

but additional flow straightening is normally required.

Generally, upstream flow straightening is achieved by installing

adequate upstream straightening sections that often comprise

a set of straightening vanes or a tube bundle. Guidance on this

subject is offered in the API Manual of Petroleum Measurement

Standards, Chapter 5, Section 3. A properly sized strainer

(40 mesh) is always recommended in close proximity of the

upstream meter tube.

For DN50 (2 inch) or smaller meters, straightening vanes are

not normally used. For most installations, 20D of upstream pipe

should be provided for adequate flow straightening (see figure

16).

For line sizes DN50 (2 inch) and larger, upstream flow

straightening sections are normally supplied with straightening

vanes. With this construction, the upstream straightening

section need only be 10D in length.

Daniel supplies upstream and downstream flow straightening

sections in either carbon steel or stainless steel, as required

by the application. The standard design offered is the twosection tube, with a single upstream and single downstream

straightening section. The upstream section contains the tube

bundle which is securely located within the pipe section (see

Figure 17).

Flow straightening sections may in fact be supplied in any

configuration with any line connection and to any specified

length. In some installations, a three-section flow straightening

configuration is required. By using this configuration, ready

access to the straightening vanes is afforded (see figure 18).

In some circumstances, the use of a Flow Conditioning Plate

(FCP) is possible. The FCP is available from DN80 to DN200

(3 inch to 8 inch) for the Series 1500 Meter and is standard on

the Series 1200 Meter (with the exception of the DN25 or 1

inch meter). When supplied, the FCP is an integral part of the

turbine meter and serves to reduce swirl in the same way as

flow straightening sections. It is of particular significance where

piping installations do not permit long upstream sections, such

as in load racks where space is at a premium.

Strainer

20D

Figure 16:

Small Diameter Meter Tube

5D

FLOW

Turbine Meter

Strainer

5D

10D

Figure 17:

Two-Section Meter Tube

FLOW

Turbine Meter

Line Model Straightening Vane

Meter Tube

Strainer

FLOW

Flange Model Straightening Vane

18

5D

10D

Figure 18:

Three-Section Meter Tube

Meter Tube

Turbine Meter

Meter Tube

www.EmersonProcess.com

Technical Guide

Back Pressure

It is essential to maintain sufficient back pressure on the turbine

meter to prevent flashing and cavitation. This back pressure is

particularly important when measuring liquids with high vapor

pressures, such as LPGs.

The pulses per unit volume / flow range curves below illustrate

the effects of back pressure. Not only does insufficient back

pressure lead to measurement inaccuracy, the resultant flashing

and cavitation is extremely damaging to the flow meter and

pipework.

The necessary back pressure required is given by the equation:

BP = (meter P X 2) + (VP X 1.25)

BP = Back pressure required

P = Meter pressure drop at maximum flow

VP = Equilibrium vapor pressure of the liquid at the operating

temperature, pounds per square inch absolute.

Figure 19: Effects of Back Pressure

www.EmersonProcess.com

19

Liquid Turbine Flow Meter

April 2015

Preamplifier

The turbine pickoff coil has high impedance and only offers

low voltage output. Transmission of flow signals requires low

impedance and high voltage, requiring amplification of the

pickoff signal.

Table 7: Standard

Preamplifier Available

Series 1200 and 1500 Meters are supplied with the LME and a

dual channel preamplifier as standard. The preamplifier shapes

and conditions the pickoff output signal, rendering it suitable

for transmission over distances of up to 914 meters (3,000 feet)

with the appropriate cabling.

The LME allows for either one or two pickoffs. The outputs

from the two pickoffs are 90o electrically out of phase which

facilitates proper dual-pulse fidelity checking.

Standard

DESCRIPTION

Dual Channel

MODEL

2818

Daniel Part #

1-504-05-550

INPUTS

The Model 2818 Dual Channel Preamplifier is the standard

Daniel offering for the Series 1200 and 1500 meters. The signals

from two inductive pickoff coils, positioned 90 electrically

out of phase, are strengthened and conditioned by a single

preamplifier. Fully potted in Delrin resin, the Model 2818 has

three possible outputs: powered pulse, variable voltage and

open collector.

# of Inputs (Pickoffs):

1 or 2

Supply Voltage:

10 to 30 VDC

Sensor Type:

Reluctance

Signal:

Sine Wave

Current:

10 to 30 VDC @ 40 mAp-p

Preamplifier Sensitivity:

40 mVpp

Frequency Response:

0 to 5 kHz

Pickoff Specifications

OUTPUTS (POWERED PULSE)

Type: 2-wire reluctance

Type:

Square Wave

Resistance: 600-900 Ohms

Frequency Range:

0 to 5 kHz

Amplitude:

0 to 5 V

Impedance:

1000 Ohm, 20 mA max

CONSTRUCTION

Delrin Housing

Solid Epoxy Encapsulation

TEMPERATURE RANGE

-40C to +85C

(-40F to +185F)

Inductance: 250 mH max.

Output: Sinusoidal 40mV p-p minimum @ minimum

flow with preamplifier load

Optional: 2pickoff coils (singe or dual LME) or 4 pickoff

coils (dual LME required)

CUSTOMER CONNECTION

Table 6: 2818 Dual Channel Preamplifier

Jumper Configurations

Jumper

Terminal Block 1 (TB1):

(1) +10 to 30 VDC

(2) Common

Jumper Positions

A

Out

J1-Chan. A Input

NA

40mV. PP Min

NA

J2-Chan. B Input

NA

40mV. PP Min

NA

J3-Chan. A Output

5v.Pulse

Sup. Volt. Pulse (10-30 VDC) O.C.

J4-Chan. B Output

5v.Pulse

Sup. Volt. Pulse (10-30 VDC) O.C.

(3) Common

(4) Channel A Output

(5) Channel B Output

(6) TTL Out A

(7) TTL Out B

PICKOFFS

Channel A (TB2):

(1) White

(2) Red

Channel B (TB3):

(1) White

(2) Red

20

www.EmersonProcess.com

Emerson Process Management

Daniel Measurement and Control, Inc.

North America / Latin America:

Headquarters

USA - Houston, Texas

T +1.713.467.6000

USA Toll Free 1.888.FLOW.001

www.Daniel.com

Europe: Stirling, Scotland, UK

T +44.1786.433400

Middle East, Africa: Dubai, UAE

T +971.4.811.8100

2015 Daniel Measurement and Control, Inc., All Rights Reserved. Printed in the USA.

DAN-LIQ-Turbine-Meter-TG-0415

Daniel Measurement and Control, Inc. (Daniel) is an Emerson Process Management business

unit. The Daniel name and logo are trademarks of Daniel Industries, Inc. The Emerson logo is a

trademark and service mark of Emerson Electric Co. All other trademarks are the property of their

respective companies.

Asia Pacific: Singapore

T +65.6777.8211

Anda mungkin juga menyukai

- DL8000 Preset Controller - For Measuring The Loading of Liquid Hydrocarbons Into Transporting TankersDokumen8 halamanDL8000 Preset Controller - For Measuring The Loading of Liquid Hydrocarbons Into Transporting Tankerssalem100% (1)

- Computador de CaudalDokumen11 halamanComputador de CaudalAlejandro100% (1)

- Presentación DL8000 PDFDokumen27 halamanPresentación DL8000 PDFJavier Castillo100% (1)

- VITO LT 4416448 - Rev2Dokumen6 halamanVITO LT 4416448 - Rev2RollyDuqueCampoverdeBelum ada peringkat

- Instruction Manual 847 Portable Enraf Terminal PDFDokumen24 halamanInstruction Manual 847 Portable Enraf Terminal PDFJavierfox98100% (1)

- CT Gen Twinseal 03Dokumen28 halamanCT Gen Twinseal 03Hakan ŞahinoğluBelum ada peringkat

- Endress-Hauser Proline Promass F 300 8F3B enDokumen20 halamanEndress-Hauser Proline Promass F 300 8F3B enNafis TaqiyuddinBelum ada peringkat

- d301244x012 PDFDokumen330 halamand301244x012 PDFMarcio Vieira Santana100% (1)

- Rotork Cma Asennus Ja Huolto Opas PDFDokumen64 halamanRotork Cma Asennus Ja Huolto Opas PDFLeonelvis PeraltaBelum ada peringkat

- CV Valvulas Twin SealDokumen20 halamanCV Valvulas Twin Sealprocesossictec100% (1)

- 3000 6000 E DataSheet 2-15-2017Dokumen13 halaman3000 6000 E DataSheet 2-15-2017adulqwulBelum ada peringkat

- Instruction Manual 973 Smartradar LT: 1 February 2002 Part No.: 4416.632 - Rev 0Dokumen56 halamanInstruction Manual 973 Smartradar LT: 1 February 2002 Part No.: 4416.632 - Rev 0Jagadesh CS NadarBelum ada peringkat

- Patent Abstract for Dual Chamber Orifice FittingDokumen25 halamanPatent Abstract for Dual Chamber Orifice FittingMarco Gonzalez100% (1)

- Iso 4266-4 2002 (E)Dokumen3 halamanIso 4266-4 2002 (E)DULCE GARCIABelum ada peringkat

- 854ATG-4416220 Rev6 PDFDokumen68 halaman854ATG-4416220 Rev6 PDFFabro Coronel50% (2)

- Danload 6000 Simulator Manual: Daniel Flow Products, Inc. Electronics Houston, TexasDokumen48 halamanDanload 6000 Simulator Manual: Daniel Flow Products, Inc. Electronics Houston, TexasNurdeny Pribadi100% (1)

- Ba01485den 0522-00Dokumen238 halamanBa01485den 0522-00Radient Mushfik100% (1)

- 3-9000-294 Rev GDokumen88 halaman3-9000-294 Rev GPalomino Vergara100% (1)

- 08003-A Senior Orifice Fittings 28-30 Inch 1.3MBDokumen60 halaman08003-A Senior Orifice Fittings 28-30 Inch 1.3MBjosecordova2014100% (1)

- Instruction Manual 862 Interface-Thermo-ElementDokumen16 halamanInstruction Manual 862 Interface-Thermo-ElementAlvaro Chang100% (1)

- Floboss 107 Flow Manager Instruction Manual Portuguese PT 133146Dokumen147 halamanFloboss 107 Flow Manager Instruction Manual Portuguese PT 133146Marcos Vasconcelos100% (1)

- Yta310 & Yta320 YokogawaDokumen8 halamanYta310 & Yta320 Yokogawahenryhariyadi100% (1)

- OMNI EPROM CPU Announcement PDFDokumen2 halamanOMNI EPROM CPU Announcement PDFNurdeny PribadiBelum ada peringkat

- Differential Dual Chamber Orifice Fitting - Lit.eta.0812 PDFDokumen21 halamanDifferential Dual Chamber Orifice Fitting - Lit.eta.0812 PDFmarceloBelum ada peringkat

- Vito MTT: Temperature and Water Bottom MeasurementDokumen6 halamanVito MTT: Temperature and Water Bottom Measurementjust_hammaBelum ada peringkat

- Manual Pro Mass 300Dokumen28 halamanManual Pro Mass 300Arkhano Jhoss Gio100% (1)

- The DL8000 Preset ControllerDokumen8 halamanThe DL8000 Preset ControllerMarcio Vieira Santana100% (1)

- 3-9008-004 Simplex Orifice FittingDokumen50 halaman3-9008-004 Simplex Orifice FittingMuhammad Afrizal KautsarBelum ada peringkat

- Proline Promass 84F Mass Flow MeterDokumen114 halamanProline Promass 84F Mass Flow MeterSardar PerdawoodBelum ada peringkat

- ATG Level Gauge Honeywell EnrafDokumen68 halamanATG Level Gauge Honeywell EnrafAymanBelum ada peringkat

- Medidores Tipo FittingDokumen32 halamanMedidores Tipo FittingEduardo ZuritaBelum ada peringkat

- Vito LTDokumen6 halamanVito LTSantiago OrtizBelum ada peringkat

- DanLoad 6000 spare parts and field wiring drawingsDokumen4 halamanDanLoad 6000 spare parts and field wiring drawingsleotostes2011Belum ada peringkat

- Instruction Manual S600+floboss Flow Computer PDFDokumen124 halamanInstruction Manual S600+floboss Flow Computer PDFMayavan A100% (1)

- d301244x012 PDFDokumen330 halamand301244x012 PDFFIRMANSYAH100% (1)

- 1500 Turbine Meter 3 18in Sizes Installation and Operation Manual 3 9008 504Dokumen60 halaman1500 Turbine Meter 3 18in Sizes Installation and Operation Manual 3 9008 504suhailfarhaan100% (1)

- 854 Instruction ManualDokumen66 halaman854 Instruction ManualAlberto BarradasBelum ada peringkat

- 862 MIR - Instruction Manual Vs30Dokumen20 halaman862 MIR - Instruction Manual Vs30ahmedsalehawadBelum ada peringkat

- Daniel Series 3800Dokumen384 halamanDaniel Series 3800Wilmar salgado cañate100% (1)

- OW200 Product Manual With AgarDAS (Released 2013)Dokumen141 halamanOW200 Product Manual With AgarDAS (Released 2013)AndersonBelum ada peringkat

- DANGC Manual 3-9000-537 M500Dokumen347 halamanDANGC Manual 3-9000-537 M500Eko Tri WasistoBelum ada peringkat

- Pub002 038 00 - 0812Dokumen44 halamanPub002 038 00 - 0812berdinsonBelum ada peringkat

- Enraf 854 Atg Interface Application NotesDokumen43 halamanEnraf 854 Atg Interface Application NotesArmando Angeles MartinezBelum ada peringkat

- Rotork AWT PDFDokumen12 halamanRotork AWT PDFTj Bro BroBelum ada peringkat

- Proline Promass 83 Profibus Dp/Pa: Description of Device FunctionsDokumen182 halamanProline Promass 83 Profibus Dp/Pa: Description of Device FunctionsHectorBelum ada peringkat

- HCU option board installation guideDokumen16 halamanHCU option board installation guideThái NgọcBelum ada peringkat

- Dan Sof TG 0122Dokumen30 halamanDan Sof TG 0122Erick Trujillo100% (1)

- 3, Promass F300 - TI01221DEN - 1022-00Dokumen134 halaman3, Promass F300 - TI01221DEN - 1022-00tlakiri100% (2)

- Instruction Manual 862 MIR Multiple Temperature Selector With MPU, HPU or OPU BoardDokumen20 halamanInstruction Manual 862 MIR Multiple Temperature Selector With MPU, HPU or OPU BoardNhatBelum ada peringkat

- Daniel 3812 Liquid Ultrasonic Flow Meter: For Direct or Remote Mount Meter ElectronicsDokumen138 halamanDaniel 3812 Liquid Ultrasonic Flow Meter: For Direct or Remote Mount Meter ElectronicsCSBelum ada peringkat

- DanLoad 6000 Communications Specification ManualDokumen244 halamanDanLoad 6000 Communications Specification Manualivan bragaBelum ada peringkat

- 14 Phase-Dynamics TechnicalDokumen18 halaman14 Phase-Dynamics Technicalfrancisco_iv_6Belum ada peringkat

- The Rotork IQ Range: A New Generation of Intelligent, Non-Intrusive 3-Phase Electric Valve ActuatorsDokumen28 halamanThe Rotork IQ Range: A New Generation of Intelligent, Non-Intrusive 3-Phase Electric Valve ActuatorsCapacitacion TodocatBelum ada peringkat

- 873 I - O ManualDokumen52 halaman873 I - O Manualaraya20100% (1)

- Petroleum Testing Laboratory ManualDokumen16 halamanPetroleum Testing Laboratory ManualKarthikeshwaran Ramasamy100% (2)

- Flow-X Manual IIb - Gas Metric Application - CM - FlowX - GM-EN - EDokumen102 halamanFlow-X Manual IIb - Gas Metric Application - CM - FlowX - GM-EN - EROberto cavacoBelum ada peringkat

- Daniel Ultrasonic Mark Iii Electronic Upgrade Kit InstructionsDokumen76 halamanDaniel Ultrasonic Mark Iii Electronic Upgrade Kit InstructionsPalomino VergaraBelum ada peringkat

- Daniel Series 500-700 Control Valves HandbookDokumen40 halamanDaniel Series 500-700 Control Valves Handbookjafo_211Belum ada peringkat

- Turbine Meter Tech GuideDokumen24 halamanTurbine Meter Tech GuideDenilson Souto Dos Santos100% (1)

- Dan Liq TM TG 0122Dokumen22 halamanDan Liq TM TG 0122Abdeldjalil AchourBelum ada peringkat

- Bala 08 Plates - Rev - 01 FORMAT - 001 000Dokumen1 halamanBala 08 Plates - Rev - 01 FORMAT - 001 000Oscar MarinBelum ada peringkat

- Draw CalderaDokumen1 halamanDraw CalderaOscar MarinBelum ada peringkat

- AWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)Dokumen17 halamanAWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)vuong17% (12)

- Weldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Dokumen1 halamanWeldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Oscar MarinBelum ada peringkat

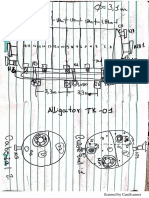

- Al Tk01 1Dokumen1 halamanAl Tk01 1Oscar MarinBelum ada peringkat

- WrightRE Web12 5 PDFDokumen12 halamanWrightRE Web12 5 PDFOscar MarinBelum ada peringkat

- IFC FabStrainers - CatDokumen40 halamanIFC FabStrainers - CatSpoonful BurnsideBelum ada peringkat

- Cand TKDokumen4 halamanCand TKOscar MarinBelum ada peringkat

- Horizontal Bladder Tank Pre Piped ArrangementDokumen8 halamanHorizontal Bladder Tank Pre Piped ArrangementJusthyTaquiriBelum ada peringkat

- 4 1 1 17 Oom Do Valle, Menezes, Reis, RebeloDokumen17 halaman4 1 1 17 Oom Do Valle, Menezes, Reis, RebeloFaizal RidhoBelum ada peringkat

- Insp CalculationDokumen20 halamanInsp CalculationAbu Huraira100% (2)

- Inspector's Calc's QuizDokumen3 halamanInspector's Calc's QuizSakthi PanneerSelvam TanjaiBelum ada peringkat

- bafd0550-a58c-4674-8a97-1d57c5a7be0fDokumen24 halamanbafd0550-a58c-4674-8a97-1d57c5a7be0fOscar MarinBelum ada peringkat

- Blasthole Drilling PDFDokumen304 halamanBlasthole Drilling PDFSanjay Kapoor100% (2)

- ISA SymbolsDokumen1 halamanISA SymbolsmustafasandikciBelum ada peringkat

- Weldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Dokumen1 halamanWeldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Oscar MarinBelum ada peringkat

- Weldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Dokumen1 halamanWeldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Oscar MarinBelum ada peringkat

- As-TB-A14 Band Sensor ApplicationsDokumen24 halamanAs-TB-A14 Band Sensor ApplicationsOscar MarinBelum ada peringkat

- DFX-7 Ultrasonic Flaw Detector ManualDokumen155 halamanDFX-7 Ultrasonic Flaw Detector ManualOscar MarinBelum ada peringkat

- PH: (780) 459 6720 Fax: (780) 459 7837: WarrantyDokumen2 halamanPH: (780) 459 6720 Fax: (780) 459 7837: WarrantyOscar MarinBelum ada peringkat

- Fire Protection BrochureDokumen4 halamanFire Protection BrochureOscar MarinBelum ada peringkat

- TicketDokumen2 halamanTicketbikram kumarBelum ada peringkat

- Air Cycle Refrigeration:-Bell - Coleman CycleDokumen21 halamanAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- High Frequency Voltage Probe Non-Availability on GeMDokumen2 halamanHigh Frequency Voltage Probe Non-Availability on GeMjudeBelum ada peringkat

- TransformerDokumen50 halamanTransformerبنیاد پرست100% (8)

- Alexander Lee ResumeDokumen2 halamanAlexander Lee Resumeapi-352375940Belum ada peringkat

- Chi Square LessonDokumen11 halamanChi Square LessonKaia HamadaBelum ada peringkat

- Pike River Case StudyDokumen7 halamanPike River Case StudyGale HawthorneBelum ada peringkat

- Brightline Guiding PrinciplesDokumen16 halamanBrightline Guiding PrinciplesdjozinBelum ada peringkat

- Sample Feedback IELTS Academic Task 1 Band 6 Double GraphDokumen3 halamanSample Feedback IELTS Academic Task 1 Band 6 Double GraphalinaemmeaBelum ada peringkat

- Safety interlock switches principlesDokumen11 halamanSafety interlock switches principlesChristopher L. AlldrittBelum ada peringkat

- Shri Siddheshwar Co-Operative BankDokumen11 halamanShri Siddheshwar Co-Operative BankPrabhu Mandewali50% (2)

- Blum2020 Book RationalCybersecurityForBusineDokumen349 halamanBlum2020 Book RationalCybersecurityForBusineJulio Garcia GarciaBelum ada peringkat

- Method Statement of Static Equipment ErectionDokumen20 halamanMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- Nammo Bulletin 2014Dokumen13 halamanNammo Bulletin 2014Dmitry Karpov0% (1)

- Lecture7 PDFDokumen5 halamanLecture7 PDFrashidBelum ada peringkat

- Scenemaster3 ManualDokumen79 halamanScenemaster3 ManualSeba Gomez LBelum ada peringkat

- The Basic New Keynesian Model ExplainedDokumen29 halamanThe Basic New Keynesian Model ExplainedTiago MatosBelum ada peringkat

- AB InBev Code of Business Conduct PDFDokumen10 halamanAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiBelum ada peringkat

- IT support tips for non-tech colleaguesDokumen7 halamanIT support tips for non-tech colleaguesLeo KrekBelum ada peringkat

- BC Specialty Foods DirectoryDokumen249 halamanBC Specialty Foods Directoryjcl_da_costa6894Belum ada peringkat

- Micro Controller AbstractDokumen6 halamanMicro Controller AbstractryacetBelum ada peringkat

- 04 Activity 2Dokumen2 halaman04 Activity 2Jhon arvie MalipolBelum ada peringkat

- Central BankDokumen65 halamanCentral BankFarazNaseer100% (1)

- For-tea Tea Parlour Marketing Strategy Targets 40+ DemographicDokumen7 halamanFor-tea Tea Parlour Marketing Strategy Targets 40+ Demographicprynk_cool2702Belum ada peringkat

- Triblender Wet Savoury F3218Dokumen32 halamanTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- Borneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Dokumen6 halamanBorneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Cheng LeongBelum ada peringkat

- Activate Adobe Photoshop CS5 Free Using Serial KeyDokumen3 halamanActivate Adobe Photoshop CS5 Free Using Serial KeyLukmanto68% (28)

- Vallance - Sistema Do VolvoDokumen15 halamanVallance - Sistema Do VolvoNuno PachecoBelum ada peringkat

- Library Management System (Final)Dokumen88 halamanLibrary Management System (Final)Ariunbat Togtohjargal90% (30)

- Personal InsuranceDokumen11 halamanPersonal InsuranceSumit Kumar SharmaBelum ada peringkat