Sa 240

Diunggah oleh

gst ajahJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sa 240

Diunggah oleh

gst ajahHak Cipta:

Format Tersedia

SPECIFICATION FOR HEAT-RESISTING

CHROMIUM AND CHROMIUM-NICKEL STAINLESS

STEEL PLATE, SHEET, AND STRIP FOR

PRESSURE VESSELS

SA-240

(Identical with ASTM Specification A 240-97a, except for editorial differences in Table 1.)

1.

Scope

2.

1.1 This specification covers chromium, chromiumnickel, and chromium-manganese-nickel stainless and

heat-resisting steel plate, sheet, and strip for pressure

vessels.

Referenced Documents

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 480/A 480M Specification for General Requirements

for Flat-Rolled Stainless and Heat-Resisting Steel

Plate, Sheet, and Strip

E 112 Test Methods for Determining Average Grain Size

E 527 Practice for Numbering Metals and Alloys (UNS)

1.2 Some steels covered by this specification, especially the chromium steels, because of their particular

alloy content and specialized properties, may require

special care in their fabrication and welding. Specific

procedures are of fundamental importance, and it is

presupposed that all parameters will be in accordance

with approved methods capable of producing the desired

properties in the finished fabrication.

2.2 SAE Standard:

J 1086 Practice for Numbering Metals and Alloys (UNS)

3.

General Requirements

3.1 The following requirements for orders for material

furnished under this specification shall conform to

the applicable requirements of the current edition of

Specification A 480/A 480M.

1.3 The values stated in either inch-pound units or

SI units are to be regarded separately as standard. The

values stated in each system are not exact equivalents;

therefore, each system must be used independently of

the other. Combining values from the two systems may

result in nonconformance with the specification.

3.1.1 Definitions,

3.1.2 General requirements for delivery,

3.1.3 Ordering information,

3.1.4 Process,

3.1.5 Special tests,

1.4 This specification and the applicable material

specifications are expressed in both inch-pound and SI

units. However, unless the order specifies the applicable

M specification designation (SI units), the material

shall be furnished in inch-pound units.

3.1.6 Heat treatment,

3.1.7 Dimensions and permissible variations,

3.1.8 Workmanship, finish and appearance,

363

ASME B&PVC

sec2a$u160 06-04-99 09:08:07

pd: sec2a Rev 14.04

A99

SA-240

1998 SECTION II

3.1.9 Number of tests/test methods,

3.1.10 Specimen preparation,

3.1.11 Retreatment,

3.1.12 Inspection,

3.1.13 Rejection and rehearing,

3.1.14 Material test report,

3.1.15 Certification, and

3.1.16 Packaging, marking, and loading.

4.

Chemical Composition

4.1 The steel shall conform to the requirements as

to chemical composition specified in Table 1, and

shall conform to applicable requirements specified in

Specification A 480/A 480M.

5.

Mechanical Properties

5.1 The material shall conform to the mechanical

properties specified in Table 2.

A99

6.

Grain Size for Austenitic H Types

6.1 The austenitic H Types shall conform to an

average grain size of ASTM No. 7 or coarser as

measured by Test Methods E 112.

364

ASME B&PVC

sec2a$u160 06-04-99 09:08:07

pd: sec2a Rev 14.04

A99

ASME B&PVC

0.050.10

0.020

0.020

0.15

0.03

0.03

0.15

0.15

0.030

0.06

0.12

0.08

0.03

0.10

0.08

0.15

0.15

0.08

0.030

0.040.10

0.040.06

0.08

0.08

0.030

0.12

0.018

0.015

0.160.24

0.050.10

0.08

0.040.10

0.08

0.040.10

0.08

0.040.10

0.08

0.040.10

...

904LG

...

201

...

...

...

202

...

XM-19H

XM-31H

XM-17H

XM-18H

...

XM-29H

301

302

304

304L

304H

...

304N

XM-21

304LN

305

...

...

...

...

309S

309HG

309CbG

309HCbG

310S

310HG

310CbG

310HCbG

N08810

N08904

N08926

S20100

S20103

S20153

S20161

S20200

S20400

S20910

S21400

S21600

S21603

S21800

S24000

S30100

S30200

S30400

S30403

S30409

S30415

S30451

S30452

S30453

S30500

S30600

S30601

S30615

S30815

S30908

S30909

S30940

S30941

S31008

S31009

S31040

S31041

0.030

0.10

CarbonD

...

...

TypeC

N08367

N08800

UNS

DesignationB

sec2a$u160 06-04-99 09:08:07

2.00

2.00

2.00

2.00

2.00

14.0016.00

7.509.00

7.509.00

7.009.00

11.5014.50

2.00

2.00

2.00

2.00

2.00

0.80

2.00

2.00

2.00

2.00

2.00

0.500.80

2.00

0.80

2.00

2.00

2.00

2.00

2.00

5.507.50

5.507.50

6.407.50

4.006.00

7.5010.0

7.009.00

4.006.00

1.50

2.00

1.50

Manganese

Sulfur

Silicon

Chromium

Nickel

Molybdenum

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.060

0.060

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.020

0.030

0.030

0.040

0.045

0.045

0.045

0.045

0.030

0.060

0.045

0.045

0.040

0.060

0.040

0.040

0.045

0.040

0.045

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.020

0.013

0.030

0.030

0.030

0.030

0.030

0.035

0.010

0.030

0.030

0.015

0.040

0.030

0.030

0.030

0.015

0.030

0.015

0.75

1.50

0.75

1.50

0.75

0.301.00

0.75

0.75

3.504.50

0.75

1.00

0.75

0.75

0.75

0.75

1.002.00

0.75

0.75

0.75

0.75

3.74.3

5.005.60

3.24.0

1.402.00

0.75

0.75

0.75

1.00

0.50

1.00

0.75

0.75

3.004.00

1.00

1.00

0.75

1.00

1.00

1.00

24.0026.00

24.0026.00

24.0026.00

24.0026.00

22.0024.00

17.0018.50

17.5022.00

17.5022.00

16.0018.00

17.0019.00

16.0018.00

17.0019.00

18.0020.00

18.0020.00

18.0020.00

18.0019.00

18.0020.00

18.0020.00

18.0020.00

17.0019.00

17.018.5

17.0018.00

17.019.5

20.0022.00

22.0024.00

22.0024.00

22.0024.00

19.0023.00

19.0021.00

16.0018.00

16.0018.00

16.0017.50

15.0018.00

17.0019.00

15.0017.00

20.5023.50

19.023.0

20.0022.00

19.023.0

19.0022.00

19.0022.00

19.0022.00

19.0022.00

12.0016.00

1.00

5.007.00

5.007.00

8.009.00

2.253.75

6.008.00

8.0010.00

8.0010.50

8.0012.00

8.0010.50

9.0010.00

8.0010.50

8.0010.50

8.0012.00

10.5013.00

14.015.5

17.0018.00

13.516.0

10.0012.00

12.0015.00

12.0015.00

12.0016.00

23.0028.00

24.0026.00

3.505.50

3.505.50

4.005.00

4.006.00

4.006.00

1.503.00

11.5013.50

30.035.0

23.5025.50

30.035.0

...

...

...

...

...

...

2.003.00

2.003.00

...

...

...

...

...

...

...

...

...

...

...

...

0.20

0.20

...

...

...

...

...

4.05.0

6.07.0

...

...

...

...

...

...

1.503.00

...

6.007.00

...

Austenitic (Chromium-Nickel) (Chromium-Manganese-Nickel)

Phosphorus

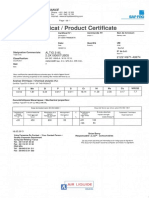

TABLE 1

CHEMICAL COMPOSITION REQUIREMENTS, %A

...

...

...

...

...

0.140.20

...

...

...

0.35 min

0.250.50

0.250.50

0.080.18

0.200.40

0.10

0.10

0.10

0.10

...

0.120.18

0.100.16

0.160.30

0.100.16

...

...

0.050

0.10

0.150.25

0.25

0.25

0.100.25

0.080.20

0.25

0.150.30

0.200.40

...

0.180.25

...

Nitrogen

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

0.50

0.35

...

...

...

...

...

1.02.0

0.51.5

...

...

1.00

...

...

...

...

0.75

0.75

0.75

Copper

...

Al 0.150.60

Ti 0.150.60

Al 0.150.60

Ti 0.150.60

...

...

...

...

...

...

...

...

Cb 0.100.30

V 0.100.30

...

...

...

...

...

...

...

...

...

...

Ce 0.030.08

...

...

...

...

...

...

Al 0.81.5

Ce 0.030.08

...

...

Cb 10 C min,

1.10 max

Cb 10 C min,

1.10 max

...

...

Cb 10 C min,

1.10 max

Cb 10 C min,

1.10 max

Other ElementsE, F

PART A FERROUS MATERIAL SPECIFICATIONS

SA-240

365

pd: sec2a Rev 14.04

A99

ASME B&PVC

sec2a$u160 06-04-99 09:08:07

...

347

347H

348

S34565

S34700

S34709

S34800

...

XM-15H

...

...

...

S32615

S32654

S33228

S35315

S38100

321H

S32109

348H

316N

316LN

317

317L

...

...

317LNG

...

321

S31651

S31653

S31700

S31703

S31725

S31726

S31753

S32050

S32100

S34809

0.08

316CbG

S31640

0.040.08

0.08

0.040.10

0.08

0.040.10

0.030

0.08

0.07

0.020

0.040.08

0.040.10

0.08

0.030

0.08

0.030

0.030

0.030

0.030

0.030

0.08

0.030

0.020

0.030

0.08

0.030

0.040.10

0.08

...

...

316

316L

316H

316TiG

S31050

S31254

S31266

S31600

S31603

S31609

S31635

CarbonD

TypeC

310MoLNG

UNS

DesignationB

2.00

2.00

2.00

2.00

2.00

5.007.00

2.00

2.00

2.004.00

1.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

1.50

2.00

2.00

2.00

1.00

2.004.00

2.00

2.00

2.00

2.00

Manganese

Sulfur

Silicon

Chromium

Nickel

Molybdenum

0.040

0.030

0.045

0.045

0.045

0.030

0.045

0.045

0.030

0.020

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.045

0.035

0.045

0.045

0.030

0.030

0.035

0.045

0.045

0.045

0.045

0.030

0.030

0.030

0.030

0.030

0.010

0.030

0.030

0.005

0.015

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.020

0.030

0.030

0.010

0.010

0.020

0.030

0.030

0.030

0.030

1.202.00

1.502.50

0.75

0.75

0.75

1.00

0.75

4.86.0

0.50

0.030

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

1.00

0.75

0.75

0.50

0.80

1.00

0.75

0.75

0.75

0.75

24.0026.00

17.0019.00

17.0019.00

17.0019.00

17.0019.00

23.0025.00

17.0019.00

16.519.5

24.0025.00

26.028.0

17.0019.00

16.0018.00

16.0018.00

18.0020.00

18.0020.00

18.0020.00

17.0020.00

18.0020.00

22.0024.00

17.0019.00

16.0018.00

24.0026.00

19.5020.50

23.0025.00

16.0018.00

16.0018.00

16.0018.00

16.0018.00

34.0036.00

17.5018.50

9.0013.00

9.0013.00

9.0013.00

16.0018.00

9.0013.00

19.022.0

21.0023.00

31.033.0

9.0012.00

10.0014.00

10.0014.00

11.0015.00

11.0015.00

13.5017.50

13.5017.50

11.0015.00

20.0022.00

9.0012.00

10.0014.00

21.0023.00

17.5018.50

21.0024.00

10.0014.00

10.0014.00

10.0014.00

10.0014.00

...

...

...

...

...

4.005.00

...

0.301.5

7.008.00

...

...

2.003.00

2.003.00

3.004.00

3.004.00

4.05.0

4.05.0

3.004.00

6.006.80

...

2.03.0

2.003.00

6.006.50

5.007.00

2.003.00

2.003.00

2.003.00

2.03.0

Austenitic (Chromium-Nickel) (Chromium-Manganese-Nickel)

Phosphorus

TABLE 1 (CONTD)

CHEMICAL COMPOSITION REQUIREMENTS, %A

0.120.18

...

...

...

...

0.400.60

...

...

0.450.55

...

...

0.100.16

0.100.16

0.10

0.10

0.20

0.100.20

0.100.22

0.240.34

0.10

0.10

0.100.16

0.180.22

0.350.60

0.10

0.10

...

0.10

Nitrogen

...

...

...

...

...

...

...

1.52.5

0.300.60

...

...

...

...

...

...

...

...

...

0.40

...

...

...

0.501.00

0.503.00

...

...

...

...

Copper

...

...

W 1.003.00

...

...

...

Ti 5 (C + N)

min, 0.70 max

Cb 10 C min,

1.10 max

...

...

...

...

...

...

...

...

Ti 5 (C + N)

min, 0.70 max

Ti 4 (C + N)

min, 0.70 max

...

...

Ce 0.050.10

Cb 0.61.0

Al 0.025

Cb 0.10

Cb 10 C min,

1.00 max

Cb 8 C min,

1.00 max

Cb + Ta 10 C

min, 1.00 max

Ta 0.10 max

Co 0.20

Cb + Ta 8 C min,

1.00 max

Ta 0.10 max

Co 0.20

Ce 0.030.08

...

Other ElementsE, F

SA-240

1998 SECTION II

366

pd: sec2a Rev 14.04

A99

ASME B&PVC

...

...

...

...

410

...

410S

...

...

...

429G

430

439

S40920

S40930

S40945

S40975

S41000

S41003

S41008

S41045

S41050

S41500E

S42900

S43000

S43035

...

S32803

405

409I

...

329

...

S32900

S32950

S40500

S40900I

S40910

...

...

...

...

...

...

...

...

...

...

TypeC

S31200

S31260

S31803

S32001

S32205

S32304

S32520

S32550

S32750

S32760

UNS

DesignationB

sec2a$u160 06-04-99 09:08:07

0.040

0.05

0.12

0.12

0.07

0.15

0.03

0.08

0.030

0.030

0.030

0.030

1.00

0.51.0

1.00

1.00

1.00

1.00

1.50

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.030

0.030

1.00

0.50

1.00

2.00

2.00

1.00

2.00

4.06.0

2.00

2.50

1.50

1.5

1.20

1.00

Manganese

0.08

0.015

0.08

0.03

0.030

0.03

0.030

0.030

0.030

0.030

0.030

0.04

0.030

0.030

CarbonD

0.045

0.030

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.040

0.020

0.040

0.035

0.045

0.030

0.030

0.040

0.030

0.040

0.035

0.040

0.035

0.030

Phosphorus

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.030

0.010

0.010

0.010

0.030

Chromium

23.0028.00

26.0029.00

24.026.0

24.026.0

21.023.0

19.521.5

22.023.0

21.524.5

24.0026.00

24.027.0

24.026.0

24.0026.00

2.505.00

3.505.20

5.56.5

5.507.50

4.506.50

1.003.00

4.506.50

3.005.50

5.508.00

4.56.5

6.008.00

6.008.00

Nickel

1.00

0.60

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

10.5012.50

11.514.0

14.0016.00

16.0018.00

17.0019.00

11.5013.50

10.5012.50

11.5013.50

12.0013.00

10.5011.75

10.5011.75

10.511.7

10.511.7

10.511.7

11.5014.50

28.0029.00

0.601.10

3.55.5

...

0.75

0.050

0.75

1.50

0.60

0.50

0.501.00

0.50

0.50

0.50

0.50

0.60

3.04.0

Ferritic or Martensitic (Chromium)

0.75

0.60

1.00

0.75

1.00

1.00

1.00

1.00

0.80

1.0

0.80

1.00

Duplex (Austenitic-Ferritic)

Silicon

0.0035 0.55

0.030

0.010

0.030

0.030

0.020

0.030

0.020

0.030

0.020

0.030

0.020

0.010

Sulfur

TABLE 1 (CONTD)

CHEMICAL COMPOSITION REQUIREMENTS, %A

...

0.51.0

...

...

...

...

...

...

...

...

...

...

...

...

...

1.82.5

1.02.0

1.002.50

1.22.0

2.503.50

2.503.50

0.60

3.003.50

0.050.60

3.005.00

2.93.9

3.005.00

3.004.00

Molybdenum

0.10

...

...

...

0.04

...

...

...

0.030

0.030

0.030

0.030

0.030

0.030

0.020

(C + N)

0.030

max

...

...

0.150.35

0.140.20

0.100.30

0.080.20

0.050.17

0.140.20

0.050.20

0.200.35

0.100.25

0.240.32

0.200.30

Nitrogen

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

0.200.80

...

1.00

...

0.050.60

0.503.00

1.52.5

0.50

0.501.00

Copper

Ti 6 (C + N)

min; 0.50 max

Ti 8 (C + N)

min; 0.150.50

(Cb + Ti) 0.08 + 8

(C + N) min;

0.75 max; Ti

0.05 min

Cb 0.180.40

Ti 0.050.20

Ti 6 (C + N) min

and 0.75 max

...

N 0.030 max

...

Cb 9 (C + N)

min, 0.60 max

...

...

...

...

Ti 0.20 + 4 (C +

N) min; 1.10

max Al 0.15

max

Al 0.100.30

Cb 0.150.50

12 (C + N) min

...

W 0.100.50

...

...

...

...

...

...

...

W 0501.00

Cr + 3.3 Mo + 16

N p 40 min

...

...

Other ElementsE, F

PART A FERROUS MATERIAL SPECIFICATIONS

SA-240

367

pd: sec2a Rev 14.04

A99

ASME B&PVC

sec2a$u160 06-04-99 09:08:07

0.010

0.030

0.010

0.030

0.030

0.025

0.025

0.30

1.00

0.30

1.00

1.00

1.00

0.40

0.75

1.00

1.00

1.00

1.00

1.00

Manganese

0.025

0.040

0.025

0.040

0.040

0.040

0.020

0.040

0.040

0.040

0.040

0.040

0.040

Phosphorus

0.020

0.030

0.020

0.030

0.030

0.030

0.020

0.020

0.012

0.030

0.030

0.030

0.030

Sulfur

Chromium

Nickel

0.20

1.00

0.20

1.00

1.00

0.75

0.40

0.75

1.00

1.00

1.00

1.00

1.00

28.030.0

18.0020.00

28.030.0

28.0030.00

25.028.0

24.526.0

25.0027.50

25.0027.00

19.0021.00

17.519.5

17.019.0

16.0018.00

16.0018.00

2.02.5

0.50

0.15

1.00

1.03.50

3.54.5

0.50

0.50

0.60

1.00

0.50

...

...

Ferritic or Martensitic (Chromium)

Silicon

3.54.2

...

3.54.2

3.604.20

3.004.00

3.54.5

0.751.50

0.751.50

...

1.752.50

...

0.751.25

0.751.25

Molybdenum

0.020

...

0.020

0.045

0.040

0.035

0.015E

0.04

0.03

0.035

0.030

...

...

Nitrogen

0.15

...

0.15

...

...

...

0.20

0.20

0.300.60

...

...

...

...

Copper

...

Cb 5 C min; 0.80

max

Ti + Cb 0.20 + 4

(C + N) min;

0.75 max

Al 0.15 max

Ti + Cb 0.20 + 4

(C + N) min;

0.80 max

Cb 10 (C + N)

0.80

Ti 0.201.00

7 (C + N) min

Cb 0.050.20 Ni +

Cu 0.50 max

Ti + Cb 0.20 + 4

(C + N) min;

0.80 max

Ti + Cb p 0.20

1.00 and 6

(C + N) min

(C + N) 0.025 max

Ti + Cb p 0.20

1.00 and 6

(C + N) min

(C + N) 0.025 max

Ti 0.070.30

Cb 0.100.60

N 0.030 max

Ti + Cb p 0.20

+ 4 (C + N) min;

0.80 max

Other ElementsE, F

Maximum, unless range or minimum is indicated.

Designation established in accordance with Practice E 527 and SAE J 1086.

C Unless otherwise indicated, a grade designation originally assigned by the American Iron and Steel Institute (AISI).

D Carbon analysis shall be reported to nearest 0.01% except for the low-carbon types, which shall be reported to nearest 0.001%.

E The terms Columbium (Cb) and Niobium (Nb) both relate to the same element.

F When two minimums or two maximums are listed for a single type, as in the case of both a value from a formula and an absolute value, the higher minimum or lower maximum shall apply.

G Common name, not a trademark, widely used, not associated with any one producer.

H Naming system developed and applied by ASTM.

I S40900 (Type 409) has been replaced by S40910, S40920, and S40930. Unless otherwise specified in the ordering information, an order specifying S40900 or Type 409 shall be satisfied

by any one of S40910, S40920, or S40930 at the option of the seller. Material meeting the requirements of S40910, S40920, or S40930, may at the option of the manufacturer be certified

as S40900.

...

...

S44635

S44800

S46800

...

S44627

...

...

XM-27H

S44700

S44735

0.010G

XM-33H

S44626

...

0.06

...

S44500

S44660

0.020

444

S44400

0.030

...

S43932

0.12

0.12

CarbonD

...

...

TypeC

S43400

S43600

UNS

DesignationB

TABLE 1 (CONTD)

CHEMICAL COMPOSITION REQUIREMENTS, %A

SA-240

1998 SECTION II

368

pd: sec2a Rev 14.04

PART A FERROUS MATERIAL SPECIFICATIONS

SA-240

TABLE 2

MECHANICAL TEST REQUIREMENTS

UNS Designation

TypeA

Tensile

Strength, min

ksi

MPa

Yield

StrengthB

min

ksi

MPa

Elongation in 2

in. or 50 mm,

min, %

A99

Hardness, maxC

Brinell

Rockwell B

Cold Bend

Austenitic (Chromium-Nickel) (Chromium-Manganese-Nickel)

N08367

Sheet and Strip

Plate

N08800

N08810

N08904

N08926

S20100

S20100

S20103

S20153

S20161

S20200

S20400

S30100

S30200

S30400

S30403

S30409

S30415

S30451

S30453

S30500

S30600

S30601

S30615

S30815

S30908

S30909

S30940

S30941

S31008

S31009

S31040

S31041

S31254

S31266

S31600

S31603

S31653

S31609

S31635

S31640

S31651

S31700

S31725

S31726

S31703

S31753

S32050

S32100

S32109

S32615I

S32654

S33228

S34565

S34700

S34709

S34800

S34809

S35315

...

...

904LF

...

201-1G

201-2G

201LF

201LNF

...

202

...

301

302

304

304L

304H

...

304N

304LN

305

...

...

...

...

309S

309HF

309CbF

309HCbF

310S

310HF

310CbF

310HCbF

...

...

316

316L

316LN

316H

316TiF

316CbF

316N

317

...

...

317L

317LN

...

321

321H

...

...

...

...

347

347H

348

348H

...

100

95

75

65

71

94

75

95

95

95

125

90

95

75

75

75

70

75

87

80

75

75

78

78

90

87

75

75

75

75

75

75

75

75

94

109

75

70

75

75

75

75

80

75

75

80

75

80

98

75

75

80

109

73

115

75

75

75

75

94

690

655

520

450

490

650

515

655

655

655

860

620

655

515

515

515

485

515

600

550

515

515

540

540

620

600

515

515

515

515

515

515

515

515

650

750

515

485

515

515

515

515

550

515

515

550

515

550

675

515

515

550

750

500

795

515

515

515

515

650

45

45

30D

25D

31

43

38

45

38

45

50

38

48

30

30

30

25

30

42

35

30

30

35

37

40

45

30

30

30

30

30

30

30

30

44

61

30

25

30

30

30

30

35

30

30

35

30

35

48

30

30

32

62

27

60

30

30

30

30

39

310

310

205D

170D

220

295

260

310

260

310

345

260

330

205

205

205

170

205

290

240

205

205

240

255

275

310

205

205

205

205

205

205

205

205

300

420

205

170

205

205

205

205

240

205

205

240

205

240

330

205

205

220

430

185

415

205

205

205

205

270

30.0

30.0

30.0E

30.0

35.0

35.0

40.0

40.0

40.0

45.0

40.0

40.0

35.0

40.0

40.0

40.0

40.0

40.0

40.0

30.0

40.0

40.0

40.0

30.0

35.0

40.0

40.0

40.0

40.0

40.0

40.0

40.0

40.0

40.0

35.0

35.0

40.0

40.0

40.0

40.0

40.0

30.0

35.0

35.0

40.0

40.0

40.0

40.0

40.0

40.0

40.0

25

40.0

30.0

35.0

40.0

40.0

40.0

40.0

40.0

...

241

...

...

...

...

...

217

217

241

255

241

241

217

201

201

201

201

217

201

201

183

...

...

217

217

217

217

217

217

217

217

217

217

223

...

217

217

217

217

217

217

217

217

217

223

217

217

250

217

217

...

250

217

241

201

201

201

201

217

100

...

...

...

90

...

95

100

95

100

25H

...

100

95

92

92

92

92

95

92

92

88

...

...

95

95

95

95

95

95

95

95

95

95

96

...

95

95

95

95

95

95

95

95

95

96

95

95

...

95

95

...

...

95

100

92

92

92

92

95

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

not

required

required

required

required

required

required

...

...

required

required

required

...

required

required

required

required

required

required

required

required

required

required

...

required

required

...

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

required

369

ASME B&PVC

sec2a$u160 06-04-99 09:08:07

pd: sec2a Rev 14.04

SA-240

1998 SECTION II

TABLE 2 (CONTD)

MECHANICAL TEST REQUIREMENTS

A99

UNS Designation

TypeA

Tensile

Strength, min

ksi

MPa

Yield

StrengthB

min

ksi

MPa

Elongation in 2

in. or 50 mm,

min, %

Hardness, maxC

Brinell

Rockwell B

Cold Bend

Austenitic (Chromium-Nickel) (Chromium-Manganese-Nickel)

S38100

S30452

Sheet and

Plate

S31050

S21600

Sheet and

Plate

S21603

Sheet and

Plate

S20910

Sheet and

Plate

S24000

Sheet and

Plate

S21400

Sheet

Strip

S21800

XM-15J

XM-21J

75

515

30

205

40.0

217

95

not required

90

85

80

620

585

550

50

40

35

345

275

240

30.0

30.0

30

241

241

217

100

100

95

not required

not required

not required

100

90

690

620

60

50

415

345

40.0

40.0

241

241

100

100

not required

not required

100

90

690

620

60

50

415

345

40.0

40.0

241

241

100

100

not required

not required

105

100

725

690

60

55

415

380

30.0

35.0

241

241

100

100

not required

not required

100

100

690

690

60

55

415

380

40.0

40.0

241

241

100

100

not required

not required

...

125

105

95

860

725

655

70

55

50

485

380

345

40.0

40.0

35.0

...

...

241

...

...

100

not required

not required

not required

...

...

...

...

...

...

...

...

...

...

329

...

100

100

90

90

90

87

112

110

116

108

90

100

690

690

620

620

620

600

770

760

795

750

620

690

293

290

293

...

293

290

310

302

310

270

269

293

31H

...

31H

25D

31H

32H

...

32H

32H

...

28H

32H

not required

...

not required

not required

not required

not required

not required

not required

not required

not required

not required

not required

Strip

310MoLNF

XM-17H

Strip

XM-18J

Strip

XM-19J

Strip

XM-29J

Strip

XM-31J

Duplex (Austenitic-Ferritic)

S31200

S31260

S31803

S32001

S32205

S32304

S32520

S32550

S32750

S32760

S32900

S32950K

65

70

65

65

65

58

80

80

80

80

70

70

450

485

450

450

450

400

550

550

550

550

485

485

25.0

20.0

25.0

25.0

25.0

25.0

25.0

15.0

15.0

25.0

15.0

15.0

Ferritic or Martensitic (Chromium)

S32803

S40500

S40900L

S40910

S40920

S40930

S40945

S40975

S41000

S41003

S41008

S41045

S41050

S41500

S42900

S43000

S43035

S43400

S43600

S43932

S44400

S44500

S44626

S44627

S44635

...

405

409L

...

...

...

...

...

410

...

410S

...

...

...

429F

430

439

...

...

...

...

...

XM-33J

XM-27J

...

87

60

600

415

72

25

500

170

16.0

20.0

241

179

100

88

not required

180

55

55

55

55

60

65

66

60

55

60

115

65

65

60

65

65

60

60

62

68

65

90

380

380

380

380

415

450

455

415

380

415

795

450

450

415

450

450

415

415

427

470

450

620

25

25

25

30

40

30

40

30

30

30

90

30

30

30

35

35

30

40

30

45

40

75

170

170

170

205

275

205

275

205

205

205

620

205

205

205

240

240

205

275

205

310

275

515

20.0

20.0

20.0

22.0

20.0

20.0

18.0

22.0M

22.0

22.0

15.0

22.0M

22.0M

22.0

22.0

22.0

22.0

20.0

22

20.0

22.0

20.0

179

179

179

...

197

217

223

183

...

183

302

183

183

183

...

...

183

217

...

217

187

269

88

88

88

80

92

96

20H

89

80

89

32H

89

89

89

89

89

89

96

83

96

90

28F

180

180

180

180

180

180

not required

180

180

180

not required

180

180

180

180

180

180

180

180

180

180

180

370

ASME B&PVC

sec2a$u160 06-04-99 09:08:07

pd: sec2a Rev 14.04

PART A FERROUS MATERIAL SPECIFICATIONS

SA-240

TABLE 2 (CONTD)

MECHANICAL TEST REQUIREMENTS

Tensile

Strength, min

UNS Designation

TypeA

ksi

MPa

Yield

StrengthB

min

ksi

MPa

Elongation in 2

in. or 50 mm,

min, %

A99

Hardness, maxC

Brinell

Rockwell B

Cold Bend

241

223

255

223

...

100

20F

25F

20F

90

180

180

180

180

180

Ferritic or Martensitic (Chromium)

S44660

S44700

S44735

S44800

S46800

...

...

...

...

...

85

80

80

80

60

585

550

550

550

415

65

60

60

60

30

450

415

415

415

205

18.0

20.0

18.0

20.0

22

A

B

Unless otherwise indicated, a grade designation originally assigned by the American Iron and Steel Institute (AISI).

Yield strength shall be determined by the offset method at 0.2% in accordance with Test Methods and Definitions A 370. Unless otherwise

specified (see Specification A 480/A 480M, paragraph 4.1.11 in Ordering Information), an alternative method of determining yield strength

may be based on total extension under load of 0.5%.

C Either Brinell or Rockwell B Hardness is permissible.

D Yield strength requirements shall not apply to material under 0.020 in. (0.50 mm) in thickness.

E Not applicable for thickness under 0.010 in. (0.25 mm).

F Common name, not a trademark, widely used, not associated with any one producer.

G Type 201 is generally produced with a chemical composition balanced for rich side (Type 201-1) or lean side (Type 201-2) austenite stability

depending on the properties required for specific applications.

H Rockwell C scale.

I For S32615, the grain size as determined in accordance with the Test Methods E 112, Comparison Method, Plate II, shall be No. 3 or finer.

J Naming system developed and applied by ASTM.

K Prior to Specification A 24089b, the tensile value for S32950 was 90 ksi.

L S40900 (Type 409) has been replaced by S40910, S40920, and S40930. Unless otherwise specified in the ordering information, an order

specifying S40900 or Type 409 shall be satisfied by any one of S40910, S40920, or S40930 at the option of the seller. Material meeting

the requirements of S40910, S40920, or S40930, may at the option of the manufacturer be certified as S40900.

M Material 0.050 in (1.27 mm) and under in thickness shall have a minimum elongation of 20.0%.

370.1

ASME B&PVC

sec2a$u160 06-04-99 09:08:07

pd: sec2a Rev 14.04

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Intro - New Covenant TheologyDokumen15 halamanIntro - New Covenant TheologyDavid SalazarBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Biosimilars: Pros and Cons in Current Practice: MBBS, MRCP (Uk), FRCP (Edin), FamsDokumen51 halamanBiosimilars: Pros and Cons in Current Practice: MBBS, MRCP (Uk), FRCP (Edin), FamshoneyworksBelum ada peringkat

- Individual Assignment I Google Search Network CampaignDokumen15 halamanIndividual Assignment I Google Search Network CampaignMokshita VajawatBelum ada peringkat

- Joint Coating Application & Pipe Coating Procedure-009-RappDokumen8 halamanJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahBelum ada peringkat

- JK Creek and River Crossing ProcedureDokumen10 halamanJK Creek and River Crossing Proceduregst ajah100% (1)

- Dia 2,4 MM Certificate - 2110091740062678 ALTIG 316 LDokumen1 halamanDia 2,4 MM Certificate - 2110091740062678 ALTIG 316 Lgst ajah100% (1)

- Commisioning Check ListDokumen21 halamanCommisioning Check Listgst ajahBelum ada peringkat

- Joint Coating Application & Pipe Coating ProcedureDokumen7 halamanJoint Coating Application & Pipe Coating Proceduregst ajahBelum ada peringkat

- PIPELINE WELD NUMBERING SYSTEMDokumen9 halamanPIPELINE WELD NUMBERING SYSTEMgst ajah100% (2)

- Sigmadur GlossDokumen5 halamanSigmadur Glossgst ajahBelum ada peringkat

- Buffing ProcDokumen2 halamanBuffing Procgst ajahBelum ada peringkat

- 13 - Piping Sample ReportDokumen5 halaman13 - Piping Sample ReportS Surya Dharma100% (3)

- Atmakaraka PDFDokumen46 halamanAtmakaraka PDFrohitsingh_8150% (4)

- Hardness Pro Form1Dokumen2 halamanHardness Pro Form1gst ajah100% (1)

- Hardness Pro Form1Dokumen2 halamanHardness Pro Form1gst ajah100% (1)

- Cambridge Lower Secondary Checkpoint: English 1111/01Dokumen11 halamanCambridge Lower Secondary Checkpoint: English 1111/01Erling Kizito100% (1)

- What Is Six Sigma: Everything You Need To Know About It: by Pankaj KumarDokumen16 halamanWhat Is Six Sigma: Everything You Need To Know About It: by Pankaj KumarSuman DewanBelum ada peringkat

- Quality inspection report for gas flow componentsDokumen1 halamanQuality inspection report for gas flow componentsgst ajahBelum ada peringkat

- PT Gerbang Sarana Baja: Buffing Procedure OF Pressure VesselDokumen2 halamanPT Gerbang Sarana Baja: Buffing Procedure OF Pressure Vesselgst ajahBelum ada peringkat

- Certificate Kawat PDFDokumen1 halamanCertificate Kawat PDFgst ajahBelum ada peringkat

- Altig 316L PDFDokumen1 halamanAltig 316L PDFgst ajahBelum ada peringkat

- GP J025!07!010 Ymn BTS Telkomsel SASDokumen3 halamanGP J025!07!010 Ymn BTS Telkomsel SASgst ajahBelum ada peringkat

- Penguard Midcoat MIO: Technical Data SheetDokumen4 halamanPenguard Midcoat MIO: Technical Data Sheetgst ajahBelum ada peringkat

- JK Pipeline Welding & Installation Traceability Procedure CoDokumen1 halamanJK Pipeline Welding & Installation Traceability Procedure Cogst ajahBelum ada peringkat

- Pipeline Weld Joint & Ragiograph Film Numbering System CoverDokumen1 halamanPipeline Weld Joint & Ragiograph Film Numbering System Covergst ajahBelum ada peringkat

- PLQ45011 PDFDokumen1 halamanPLQ45011 PDFgst ajahBelum ada peringkat

- Penguard Midcoat MIO: Technical Data SheetDokumen4 halamanPenguard Midcoat MIO: Technical Data Sheetgst ajahBelum ada peringkat

- Chemical and Mechanical Analysis of Welding RodDokumen1 halamanChemical and Mechanical Analysis of Welding Rodgst ajahBelum ada peringkat

- TDS Jotamastic 70 GB English ProtectiveDokumen4 halamanTDS Jotamastic 70 GB English ProtectiveSatish VishnubhotlaBelum ada peringkat

- ACP-2017!01!04.Lampiran Tds Hardtop XPDokumen5 halamanACP-2017!01!04.Lampiran Tds Hardtop XPBayumi Tirta JayaBelum ada peringkat

- ACP-2017!01!04.Lampiran Tds Hardtop XPDokumen5 halamanACP-2017!01!04.Lampiran Tds Hardtop XPBayumi Tirta JayaBelum ada peringkat

- GP J025!07!010 Ymn BTS Telkomsel SASDokumen3 halamanGP J025!07!010 Ymn BTS Telkomsel SASgst ajahBelum ada peringkat

- JK Creek and River Crossing Procedure CoverDokumen1 halamanJK Creek and River Crossing Procedure Covergst ajahBelum ada peringkat

- JK Creek and River Crossing Procedure CoverDokumen1 halamanJK Creek and River Crossing Procedure Covergst ajahBelum ada peringkat

- Attachment A - CRCPDokumen3 halamanAttachment A - CRCPgst ajahBelum ada peringkat

- 022 Hydrotest-ProcedureDokumen5 halaman022 Hydrotest-Proceduregst ajahBelum ada peringkat

- Capers ComplaintDokumen9 halamanCapers ComplaintWIS Digital News StaffBelum ada peringkat

- Webquest Biotechnology RubricDokumen2 halamanWebquest Biotechnology Rubricapi-556285637Belum ada peringkat

- Tugas BHS InggrisDokumen2 halamanTugas BHS InggrisJust NestBelum ada peringkat

- Unit 8Dokumen2 halamanUnit 8The Four QueensBelum ada peringkat

- About Meat Eating in Sikh DharmDokumen4 halamanAbout Meat Eating in Sikh Dharmvijay123inBelum ada peringkat

- Who May Apply Under Article 32: Article 32 and Article 226 Comparative StudyDokumen2 halamanWho May Apply Under Article 32: Article 32 and Article 226 Comparative StudySai Malavika TuluguBelum ada peringkat

- TGT EnglishDokumen3 halamanTGT EnglishKatta SrinivasBelum ada peringkat

- In Sunni IslamDokumen5 halamanIn Sunni IslamMk AkangbeBelum ada peringkat

- Ethics Lecture Notes For Academic Year - Situation 1 Your Family Is An Exclusive Vacation On A - StuDocuDokumen1 halamanEthics Lecture Notes For Academic Year - Situation 1 Your Family Is An Exclusive Vacation On A - StuDocuRaveine JabatBelum ada peringkat

- Swatch Case AnalysisDokumen3 halamanSwatch Case Analysisgunjanbihani100% (1)

- What Is Link AdaptationDokumen4 halamanWhat Is Link AdaptationAshutosh SinghBelum ada peringkat

- Coordinates: Primary Practice QuestionsDokumen10 halamanCoordinates: Primary Practice QuestionsJames KeruBelum ada peringkat

- Advertisement On Sunflowers Perfume by Elizabeth ArdenDokumen18 halamanAdvertisement On Sunflowers Perfume by Elizabeth ArdenNur Fajarwati ZuchrifahBelum ada peringkat

- O'laco Vs Cocho ChitDokumen16 halamanO'laco Vs Cocho ChitAngel Pagaran AmarBelum ada peringkat

- Case - 1 Marketing and Distribution of MushroomDokumen2 halamanCase - 1 Marketing and Distribution of MushroomKetan BohraBelum ada peringkat

- Vegetation of PakistanDokumen10 halamanVegetation of PakistanAhmad sadiqBelum ada peringkat

- scn625 Summativeeval SarahltDokumen6 halamanscn625 Summativeeval Sarahltapi-644817377Belum ada peringkat

- Chap 01Dokumen47 halamanChap 01HappyDayBelum ada peringkat

- Vaishali Ancient City Archaeological SiteDokumen31 halamanVaishali Ancient City Archaeological SiteVipul RajputBelum ada peringkat

- General Physics Mass, Weight, DensityDokumen37 halamanGeneral Physics Mass, Weight, DensityMat MinBelum ada peringkat

- AthletesDokumen494 halamanAthletesLuis CarlosBelum ada peringkat

- How To Improve Planogram ManagementDokumen5 halamanHow To Improve Planogram ManagementАнтон ДроздовBelum ada peringkat

- Disirders of Synaptic Plasticity and Schizophrenia - J.smythiesDokumen559 halamanDisirders of Synaptic Plasticity and Schizophrenia - J.smythiesBrett CromptonBelum ada peringkat