Material Comparison

Diunggah oleh

GauthamSarangDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Material Comparison

Diunggah oleh

GauthamSarangHak Cipta:

Format Tersedia

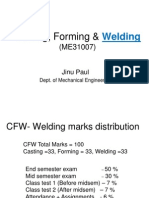

Metals & Materials, MMAT 280

Appendix: A Comparison of

Materials

1/15/2005

28

Metals & Materials, MMAT 280

Metals

1/15/2005

29

Metals & Materials, MMAT 280

Metals:

Metallic Bonding: Delocalized gas of electrons

Advantages

relatively high moduli (stiff)

can be made strong by

alloying or working

nominally ductile

relatively high toughness

paramagnetic or

ferromagnetic

good conductors

1/15/2005

Disadvantages

failure by fatigue

most susceptible to

environmental attack

(corrosion and oxidation)

30

Metals & Materials, MMAT 280

Metals cont.

Ferrous Metals

Metal

Carbon Steels

Stainless Steels

Cast Irons

Light Alloys

Aluminum Alloys

Magnesium Alloys

Copper Alloys

Titanium Alloys

Copper

Bronze

Brass

Nickel Alloys

1/15/2005

Examples of Application

Utensils, construction, automotive,

transmission towers

Off shore drilling rigs, naval construction,

chemical transport, food preparation,

medical instruments

Cylinders, piston, motor blocks,

construction, wear resistant materials

Aerospace, construction, transport,

packaging, electrical conductors

Aerospace, automotive, sporting

equipment

Aerospace, chemical industry

Electrical conductors

heat exchangers, chemical industry,

maritime industry

Pressure vessels, fittings

Aerospace (turbines), money

31

Metals & Materials, MMAT 280

Ceramics and Glasses

1/15/2005

32

Metals & Materials, MMAT 280

Ceramics and Glasses:

Ionic & Covalent Bonding: Directional & Strong

Advantages

Disadvantages

High moduli (stiff)

High strength

Abrasion resistant

High melting point

Resist corrosion and

oxidation

Transparent

Good electrical insulators

Brittle

Statistical spread in

strength

Strength in compression ~

15x strength in tension

Notch sensitive

1/15/2005

More Difficult to Design With

33

Metals & Materials, MMAT 280

Ceramics & Glasses cont.

Ceramics

Bulk Ceramics

Hydrated Ceramics

(cement, plaster)

Ceramic Powders

Industrial Ceramics

Glasses

1/15/2005

Examples of Application

Construction

Rocks

Construction

Fired Ceramics

(bricks, pottey)

Fibres (glass,

carbon)

Construction, electrical insulators, hygienic

applications, houshold

Reinforcements in polymer composites

Particles

(alumina, silicon

carbide, magnesia)

Reinforcements in polymer and metal

composites

Abrasive Particles

Alumina, Silicon

Nitride, Silicon

Carbide

Cutting wheels, polishing cloths

High temperature furnaces, heat sheilds

Windows, food preparation

34

Metals & Materials, MMAT 280

Polymers & Elastomers

1/15/2005

35

Metals & Materials, MMAT 280

Polymers and Elastomers

Secondary & Covalent Bonding: Anisotropic

Advantages

Can have high strength

High elastic deformation

(flexible)

low coefficient of friction

corrosion resistant

Easy to form

can be coloured

1/15/2005

Disadvantages

Creep at rm. temp.

Properties change a

great deal with

temperature

Low melting points

Low moduli

difficult to recycle

36

Metals & Materials, MMAT 280

Polymers and Elastomers cont.

Thermoplastics

Thermosets

Elastomers

Foams

1/15/2005

Polymers

Acrylobutadiene

styrene (ABS)

Acrylics

Cellulose Acetate

Polyamide (Nylons)

Polycarbonates

Polyether ether

ketone (PEEK)

Polyvinylechloride

(PVC)

Epoxy

Phenols

Polyesters

Polyamides

Silicone

Examples of Application

Clothing, household appliances

Clothing

Overhead transparencies

Clothing, strong fabrics

Windows, food storage

Microwave oven dishes,

Credit cards, plumbing, window sashes

Glue, connectors, molding

Electrical components

Fabrics

Integrated circuit supports

Electrical applications, structural

applications (below 200oC)

Tires, joints

Tires

Butyl

Polyethylene

Chloride

Ethyl vinyl acetate

Polyurethane

Flexible Foams

Medical equipment

shock absorbers

Automotive interiors

Rigid Foams

Shock absorbers, thermal insulators

Elastomeric Foams

Thermal or acoustic insulators

37

Metals & Materials, MMAT 280

Composites

1/15/2005

38

Metals & Materials, MMAT 280

Composites:

Various Bonding

Advantages

Combine attractive

qualities of other

materials

Engineer properties to

demand

Light

Stiff

Strong

1/15/2005

Disadvantages

Expensive

Difficult to join

Often difficult to

fabricate

39

Metals & Materials, MMAT 280

Composites cont.

Composites

Polymer Matrix

Thermoplastic

Matrix

Metal Matrix

Ceramic Matrix

1/15/2005

Examples of Application

Mechanical components, protection

screens

Thermoset Matrix

Aerospace, spoting equipment

Elastomer Matrix

Tires

Aluminum Matrix

Aerospace, sporting equipment, electronic

packaging

Titanium Matrix

Aerospace turbines

Copper Matrix

Alumina Matrix

High strength electrical conductors

High temperature mechanical applications

Cermets

Cutting tools, polishing materials

40

Metals & Materials, MMAT 280

Natural Materials

1/15/2005

41

Metals & Materials, MMAT 280

Natural Materials:

Bonding at different levels

Advantages

Highly Recyclable

Often high strength

Variety of physical and

mechanical properties

1/15/2005

Disadvantages

Large variability in

properties

difficult to control

Renewable?

42

Metals & Materials, MMAT 280

Summary & Review

Take a broad initial view of the material

kingdom examining 6 basic families

As designers we need to familiarize

ourselves with the range of properties

available from each class

Each class of material has advantages

and disadvantages

See material properties reflected in their

applications

1/15/2005

43

Metals & Materials, MMAT 280

Characterizing Materials: available

resources

Optical Metallography

Cut samples into

sections ~ 1 cm x 1 cm

x 1 cm

Mount in thermoset

(e.g. bakelite)

Mechanically grind and

polish to give mirror

surface

Use an acid/base to

etch the sample

surface to reveal

internal structure

(microstructure),

coatings, porosity

Reference:

Metals

1/15/2005

Handbook vol. 8

44

Metals & Materials, MMAT 280

Hardness Testing:

Push diamond pyramid /

hardened steel ball into

surface of the sample

H ~ 3f

Simple method for deducing

strength of a component

Can indicate type of material,

type of heat treatment,

surface treatment, etc.

Gives information on yield

strength, wear resistance,

fracture strength

1/15/2005

45

Metals & Materials, MMAT 280

Scanning Electron Microscopy/

Energy Dispersive X-Ray

(SEM-EDX) Analysis

SEM operates in a similar

manner to optical microscopy

light vs. electrons

Better depth of field, higher

resolution, sensitive to composition

EDX: incident electrons interact

with atoms near surface of sample

collisions result in ejection of a)

electrons and b) x-rays from

sample

X-rays characteristic of atoms

within the sample

1/15/2005

46

Metals & Materials, MMAT 280

Polymer Identification

ResinKit available

Based on simple

qualitative

questionnaire

Requires engineering

judgement

1/15/2005

47

Metals & Materials, MMAT 280

Miscellaneous Equipment

Thermocouples

Tachometer

Oscilloscope

Multimeter

Lightmeter

General

Tools/Laboratory

Equipment

1/15/2005

48

Anda mungkin juga menyukai

- Microstructure and Materials Properties: Julien BoisseDokumen33 halamanMicrostructure and Materials Properties: Julien BoisseJinoyVargheseTharuBelum ada peringkat

- 0 Introduction To MetalDokumen139 halaman0 Introduction To MetalMichael TanjayaBelum ada peringkat

- Dr. Ahmad Nawaz: Lecture 02: Introduction To Engineering Materials and Their StructuresDokumen34 halamanDr. Ahmad Nawaz: Lecture 02: Introduction To Engineering Materials and Their StructuresAhmad NawazBelum ada peringkat

- Chapter 1Dokumen27 halamanChapter 1nishanthinnythesingBelum ada peringkat

- Lect 1 2Dokumen35 halamanLect 1 2umangmodi32Belum ada peringkat

- Introduction To Materials and Processes PDFDokumen0 halamanIntroduction To Materials and Processes PDFjayeshjpillaiBelum ada peringkat

- Material Science IntroductionDokumen43 halamanMaterial Science IntroductionAsadAliBelum ada peringkat

- Course Content: No. Title Slide NoDokumen54 halamanCourse Content: No. Title Slide NoDilip YadavBelum ada peringkat

- Why study materials engineering in 40 charactersDokumen15 halamanWhy study materials engineering in 40 charactersDuaa GadoraaBelum ada peringkat

- Introduction to Materials Science for NDTDokumen96 halamanIntroduction to Materials Science for NDTMircea Dubenco100% (1)

- Lecture - 2Dokumen23 halamanLecture - 2Harshini SBelum ada peringkat

- Introduction To Materials and ProcessesDokumen42 halamanIntroduction To Materials and ProcessesMark Ian HernandezBelum ada peringkat

- 4 - Lec 3 - 1 MaterialDokumen55 halaman4 - Lec 3 - 1 MaterialMohd Shukri IsmailBelum ada peringkat

- The Concept of Construction Materiales: Ingles TecnicoDokumen12 halamanThe Concept of Construction Materiales: Ingles TecnicoMir DJairoBelum ada peringkat

- Introduction to the Classification of Materials in EngineeringDokumen18 halamanIntroduction to the Classification of Materials in Engineering22-Rodriguez Perez ErickBelum ada peringkat

- Engineering MaterialsDokumen34 halamanEngineering Materialssourav mahajanBelum ada peringkat

- EMS 223 Chapter 1Dokumen38 halamanEMS 223 Chapter 1charles makasabiBelum ada peringkat

- Handout On Civil EngineeringDokumen10 halamanHandout On Civil EngineeringKevinEdwuardBerriosFloresBelum ada peringkat

- Handout On Civil EngineeringDokumen10 halamanHandout On Civil EngineeringKevinEdwuardBerriosFloresBelum ada peringkat

- Introduction To Engineering Materials ScienceDokumen41 halamanIntroduction To Engineering Materials Sciencetntran91Belum ada peringkat

- Material Science IntroductionDokumen47 halamanMaterial Science IntroductionMuhammadIskandar100% (1)

- CML 231 Material Science and Engineering: Assistant Professor, Che Department VnitDokumen19 halamanCML 231 Material Science and Engineering: Assistant Professor, Che Department VnitGajanan SawantBelum ada peringkat

- Introduction To Engineering Materials: 1 Sanjib Jaypuria, SME, KIIT UniversityDokumen21 halamanIntroduction To Engineering Materials: 1 Sanjib Jaypuria, SME, KIIT Universitytanishka narayanBelum ada peringkat

- CHP 1 - Intro To Material PropertiesDokumen33 halamanCHP 1 - Intro To Material PropertiesDũng TrầnBelum ada peringkat

- Semester V Paper Code ETME 305 L4 T0 C4Dokumen26 halamanSemester V Paper Code ETME 305 L4 T0 C4Amit JangraBelum ada peringkat

- Materials Classification GuideDokumen38 halamanMaterials Classification GuideMohanrajRajangamBelum ada peringkat

- Lecture 1Dokumen12 halamanLecture 1siphosakhemdunge114Belum ada peringkat

- IE 351 Lecture 3 Materials Types Properties ApplicationsDokumen55 halamanIE 351 Lecture 3 Materials Types Properties Applicationsumi_hayyatBelum ada peringkat

- سمنر السيراميكDokumen15 halamanسمنر السيراميكشمس الضحىBelum ada peringkat

- Selection of Corrosion Resistant MaterialsDokumen17 halamanSelection of Corrosion Resistant Materialsحاتم غيدان خلفBelum ada peringkat

- Unit-II EME AerospaceDokumen51 halamanUnit-II EME AerospacePranil Vijay SawalakheBelum ada peringkat

- Classification of Engineering MaterialsDokumen8 halamanClassification of Engineering MaterialshamzaalisheriffBelum ada peringkat

- Material Science NotesDokumen11 halamanMaterial Science NotesRyan Ryan RyanBelum ada peringkat

- Pengenalan Karakterisasi MaterialDokumen23 halamanPengenalan Karakterisasi Materialfikri wahyu pratamaBelum ada peringkat

- 2013 CCD Material ChartsDokumen18 halaman2013 CCD Material ChartsRegi Octa PerdanaBelum ada peringkat

- 01 Introduction MatEDokumen54 halaman01 Introduction MatEBede Ramulfo Juntilla SedanoBelum ada peringkat

- MSM-Material Science & Metallurgy FundamentalsDokumen26 halamanMSM-Material Science & Metallurgy FundamentalsDyako D TaherBelum ada peringkat

- Introduction To Structural Materials: Prof Prashant P Date F13, 1 Floor Mech Engg. Phone 7511 Email: Ppdate@iitb - Ac.inDokumen53 halamanIntroduction To Structural Materials: Prof Prashant P Date F13, 1 Floor Mech Engg. Phone 7511 Email: Ppdate@iitb - Ac.inOm DesaiBelum ada peringkat

- Classification of Engg - MaterialsDokumen21 halamanClassification of Engg - MaterialsRajat GoelBelum ada peringkat

- Manufacturing ProcessesDokumen17 halamanManufacturing ProcessesasowdiBelum ada peringkat

- Materials for Rockets and Missiles: Properties and Applications in AerospaceDokumen18 halamanMaterials for Rockets and Missiles: Properties and Applications in AerospaceDiamoundDomeProgram R&D100% (1)

- Electrical Engineering Materials (Em) 1Dokumen26 halamanElectrical Engineering Materials (Em) 1Hezron gibronBelum ada peringkat

- Material Science and EngineeringDokumen28 halamanMaterial Science and EngineeringIyes FreefallBelum ada peringkat

- CHAPTER 2 Materials TechnologyDokumen29 halamanCHAPTER 2 Materials TechnologyAkhi IslamBelum ada peringkat

- Composite IntroductionDokumen34 halamanComposite IntroductionDurga RajBelum ada peringkat

- Jeppiaar SRR Engineering College: SyllabusDokumen9 halamanJeppiaar SRR Engineering College: SyllabusKeerthika VenkatesanBelum ada peringkat

- 1-Outokumpu-Welding Stainless-Steel-Handbook PDFDokumen36 halaman1-Outokumpu-Welding Stainless-Steel-Handbook PDFTuTuy AnBelum ada peringkat

- Material SelectionDokumen60 halamanMaterial SelectionKhoa Nguyễn AnhBelum ada peringkat

- Introduction To Materials Science and EngineeringDokumen41 halamanIntroduction To Materials Science and EngineeringIntan Shafinaz CollinsBelum ada peringkat

- Casting, Forming & WeldingDokumen90 halamanCasting, Forming & WeldingmahdiBelum ada peringkat

- UNIT 1-LN The Materials and Process UniverseDokumen27 halamanUNIT 1-LN The Materials and Process UniverseSEPBelum ada peringkat

- Karakterisasi Material PDFDokumen40 halamanKarakterisasi Material PDFmiftakhurBelum ada peringkat

- GENG211 - 01_introductionDokumen41 halamanGENG211 - 01_introductionTaleb AbboudBelum ada peringkat

- Unit 1. Materials Selection:: The Ces EdupackDokumen23 halamanUnit 1. Materials Selection:: The Ces EdupackAndy CallingtonBelum ada peringkat

- Properties of Materials - Part 1 (1)Dokumen23 halamanProperties of Materials - Part 1 (1)ShankarBelum ada peringkat

- Unit III - Introduction To Manufacturing EngineeringDokumen281 halamanUnit III - Introduction To Manufacturing EngineeringJohnBelum ada peringkat

- Sanjay Mazumdar: Book Used To Cover The Manufacturing AspectsDokumen33 halamanSanjay Mazumdar: Book Used To Cover The Manufacturing AspectsMichael LeinerBelum ada peringkat

- Tech Eng 06 Engineering Materials - 2023Dokumen30 halamanTech Eng 06 Engineering Materials - 2023ilyasorhanli.9427Belum ada peringkat

- The Essentials of Material Science and Technology for EngineersDari EverandThe Essentials of Material Science and Technology for EngineersPenilaian: 5 dari 5 bintang5/5 (1)

- Case Study On Lean Manufacturing For Minimization of Defeccts in The Fabrication Process of ShipbuildingDokumen7 halamanCase Study On Lean Manufacturing For Minimization of Defeccts in The Fabrication Process of ShipbuildingGauthamSarangBelum ada peringkat

- MBA ZG623T Project Work EC-1 - Project Work Outline Evaluation Sheet-SignedDokumen1 halamanMBA ZG623T Project Work EC-1 - Project Work Outline Evaluation Sheet-SignedGauthamSarangBelum ada peringkat

- MBA ZG623T Project Work EC-1 - Project Work Outline Evaluation SheetDokumen1 halamanMBA ZG623T Project Work EC-1 - Project Work Outline Evaluation SheetGauthamSarangBelum ada peringkat

- University Details 12333Dokumen20 halamanUniversity Details 12333GauthamSarangBelum ada peringkat

- Welder Qualification Test ResultsDokumen1 halamanWelder Qualification Test ResultsGauthamSarangBelum ada peringkat

- Lecture1a PDFDokumen38 halamanLecture1a PDFAnand1832Belum ada peringkat

- Course Details: Southern African Institute of WeldingDokumen2 halamanCourse Details: Southern African Institute of WeldingGauthamSarangBelum ada peringkat

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDokumen1 halamanAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkBelum ada peringkat

- Prices and Dates International Welding InspectionDokumen6 halamanPrices and Dates International Welding InspectionGauthamSarangBelum ada peringkat

- Arka Inspection ReportsDokumen3 halamanArka Inspection ReportsGauthamSarangBelum ada peringkat

- Failure Why 1 Why 2 Why 3 Magnitude Significance Cause Indent Failure TypeDokumen1 halamanFailure Why 1 Why 2 Why 3 Magnitude Significance Cause Indent Failure TypeGauthamSarangBelum ada peringkat

- Pest Comtrol 123Dokumen1 halamanPest Comtrol 123GauthamSarangBelum ada peringkat

- Installation Step For Windows XP1 and XP2 For Idea ZTE MF667Dokumen6 halamanInstallation Step For Windows XP1 and XP2 For Idea ZTE MF667GauthamSarangBelum ada peringkat

- Open Die Forging: Forgings RelationshipsDokumen2 halamanOpen Die Forging: Forgings RelationshipsGauthamSarangBelum ada peringkat

- Tax Invoice: Total Booking Amount INR 2462.88Dokumen1 halamanTax Invoice: Total Booking Amount INR 2462.88GauthamSarangBelum ada peringkat

- ChatLog Meet Now 2018 - 08 - 28 12 - 09Dokumen1 halamanChatLog Meet Now 2018 - 08 - 28 12 - 09GauthamSarangBelum ada peringkat

- Welder Qualification Test ResultsDokumen1 halamanWelder Qualification Test ResultsGauthamSarangBelum ada peringkat

- CHW BrochureDokumen20 halamanCHW BrochureGauthamSarangBelum ada peringkat

- Schweißnahtfehler + Bilder (X)Dokumen12 halamanSchweißnahtfehler + Bilder (X)razerhazerBelum ada peringkat

- Procedure For Change of Employing Organization Important InstructionsDokumen1 halamanProcedure For Change of Employing Organization Important InstructionsRahul KushwahaBelum ada peringkat

- Latest Software Installation Steps For Idea Netsetter MF667Dokumen3 halamanLatest Software Installation Steps For Idea Netsetter MF667GauthamSarangBelum ada peringkat

- Lecture1a PDFDokumen38 halamanLecture1a PDFAnand1832Belum ada peringkat

- Demo Weld Cost Calc XLDokumen10 halamanDemo Weld Cost Calc XLKhalid Ahmod ShibleeBelum ada peringkat

- Aws Welding ShowDokumen21 halamanAws Welding Showhemant1886Belum ada peringkat

- Ride Details Bill DetailsDokumen3 halamanRide Details Bill DetailsGauthamSarang0% (1)

- ChatLog Meet Now 2018 - 03 - 21 12 - 13Dokumen1 halamanChatLog Meet Now 2018 - 03 - 21 12 - 13GauthamSarangBelum ada peringkat

- Contai 1Dokumen115 halamanContai 1Nezharia Nurza HarcaBelum ada peringkat

- ChatLog Meet Now 2018 - 06 - 25 16 - 24Dokumen1 halamanChatLog Meet Now 2018 - 06 - 25 16 - 24GauthamSarangBelum ada peringkat

- Chatlog For Portal Access 2018-08-30 10 - 21Dokumen1 halamanChatlog For Portal Access 2018-08-30 10 - 21GauthamSarangBelum ada peringkat

- Chatlog For Portal Access 2018-08-30 10 - 21Dokumen1 halamanChatlog For Portal Access 2018-08-30 10 - 21GauthamSarangBelum ada peringkat

- Boron Sources As Sintering Additives For Alumina-Based Refractory CastablesDokumen10 halamanBoron Sources As Sintering Additives For Alumina-Based Refractory CastablesIris GiovannelliBelum ada peringkat

- New Materials For Micro Scale Sensors and ActuatorsDokumen129 halamanNew Materials For Micro Scale Sensors and ActuatorsAnOnYmOuS_1995Belum ada peringkat

- Development and Characterization of Glass Ceramic From Coc1 PDFDokumen99 halamanDevelopment and Characterization of Glass Ceramic From Coc1 PDFminahilBelum ada peringkat

- Proven Sensor Technology For Safe Results: Origin of PrecisionDokumen36 halamanProven Sensor Technology For Safe Results: Origin of PrecisionTruong Anh TuanBelum ada peringkat

- SILRES® PROVIDES PERFECT WATER REPELLENCY FOR HEAVY CLAY PRODUCTSDokumen22 halamanSILRES® PROVIDES PERFECT WATER REPELLENCY FOR HEAVY CLAY PRODUCTSiysernaBelum ada peringkat

- Invertis Journal of Renewable Energy Vol 2 No 1Dokumen21 halamanInvertis Journal of Renewable Energy Vol 2 No 1ycgoswami100% (1)

- CompositeDokumen8 halamanCompositeAniket JainBelum ada peringkat

- Sem 6Dokumen12 halamanSem 6Pronoy Kumar SinhaBelum ada peringkat

- Materials SinteringDokumen7 halamanMaterials Sinteringjose mirandaBelum ada peringkat

- Investigation On The Dielectric Properties of Mg-Doped (Ba Ca) (Ti ZR) O CeramicsDokumen5 halamanInvestigation On The Dielectric Properties of Mg-Doped (Ba Ca) (Ti ZR) O CeramicsSamah SamahBelum ada peringkat

- Impact Damage in Layered GlassDokumen8 halamanImpact Damage in Layered GlassCristian PerezBelum ada peringkat

- ASM Specialty Handbook Tool Materials - All $307Dokumen7 halamanASM Specialty Handbook Tool Materials - All $307Wilfredo Salas MarcosBelum ada peringkat

- XrFuse 2 & 6: Zero Contamination Electric Fusion MachinesDokumen6 halamanXrFuse 2 & 6: Zero Contamination Electric Fusion MachinesJumarni M SaiyeBelum ada peringkat

- Demag Ve CımbızDokumen45 halamanDemag Ve CımbızRemzi GömekBelum ada peringkat

- Technical Data of Vacuum Formed Ceramic Fiber PDFDokumen2 halamanTechnical Data of Vacuum Formed Ceramic Fiber PDFba ajinBelum ada peringkat

- An Overview of Ceramic Molds For Investment Casting of Nickel SuperalloyesDokumen19 halamanAn Overview of Ceramic Molds For Investment Casting of Nickel SuperalloyesJuan SarmientoBelum ada peringkat

- Cotronics Resbond 919 SDSDokumen1 halamanCotronics Resbond 919 SDSThalia ShuhanBelum ada peringkat

- TUNDISH COVER RefractoryDokumen3 halamanTUNDISH COVER RefractoryMashiur RahmanBelum ada peringkat

- Rosa Brochure Output - 14.10.2020Dokumen48 halamanRosa Brochure Output - 14.10.2020PHHPBelum ada peringkat

- 1 s2.0 S2238785419304600 MainDokumen10 halaman1 s2.0 S2238785419304600 Mainsketchup1990Belum ada peringkat

- CPRI ReportDokumen104 halamanCPRI ReportPavan KhetrapalBelum ada peringkat

- Devcon Catalog PDFDokumen24 halamanDevcon Catalog PDFSergio MarchettiBelum ada peringkat

- Article in Press: Journal of The European Ceramic SocietyDokumen8 halamanArticle in Press: Journal of The European Ceramic SocietyAnca NegrilaBelum ada peringkat

- Translucency of Dental Ceramics With Different ThicknessesDokumen7 halamanTranslucency of Dental Ceramics With Different ThicknessesjuanBelum ada peringkat

- Probe Selection Nondestructive TestingDokumen50 halamanProbe Selection Nondestructive TestingOlaveGuzmánBelum ada peringkat

- MCEN90014-Lab Manual CeramicsDokumen4 halamanMCEN90014-Lab Manual CeramicshamalBelum ada peringkat

- Is 15622-2006 PDFDokumen17 halamanIs 15622-2006 PDFravi03121100% (2)

- CF Paper 1260Dokumen1 halamanCF Paper 1260didapopescuBelum ada peringkat

- Some Environmental Aspects of BF EAF and ++++++Dokumen85 halamanSome Environmental Aspects of BF EAF and ++++++LeonardoBelum ada peringkat

- PBI Porcelain Bushing Insulator PDFDokumen76 halamanPBI Porcelain Bushing Insulator PDFJOSE DANIEL PEREZBelum ada peringkat