Prelab 3

Diunggah oleh

Jihan PacerJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Prelab 3

Diunggah oleh

Jihan PacerHak Cipta:

Format Tersedia

Determination of Bulk Density and Void Content of Aggregates

Objectives:

To be able to determine the bulk density

and voids ofthe aggregate sample.

Significance and Use:

Bulk Density is the mass of the unit

volume of bulk aggregate material where

the volume includes the volume of the

individual particles and volume of voids

between the particles. It depends on how

densely the aggregate is packed. For

example, in a coarse aggregate, a higher

bulk density means that there are few

voids which are to be filled by the fine

aggregate and cement.Therefore, bulk

density can be used to measure the volume

that the graded aggregate will occupy in

concrete, including the solid aggregate

particles and the voids between them.

Additionally, the bulk density is required

for the volume method of mixture

proportioning. Void content of the

aggregates are usually used to determine

the amount of water needed to add to the

aggregates in making concrete. Thus in

concrete making, aggregates with a high

void content needs more water than low

void content aggregates since the water

will first fill the pores between the

individual particles before it will be used

in the hydration process of concrete.

and bottom true and even, and sufficiently

rigid to retain its form under rough usage.

The measure shall have a height

approximately equal to the diameter, but in

no case shall the height be less than 80 %

nor more than 150 % of the diameter. The

capacity of the measure shall conform to

the limits in Table 1 in ASTM C29 for the

aggregate size to be tested. The thickness

of metal in the measure shall be as

described in Table 2. The top rim shall be

smooth and plane within 0.25 mm and

shall be parallel to the bottom within 0.5.

The interior wall of the measure shall be a

smooth and continuous surface.

4. Shovel or Scoop

For Calibration of Measure, the following

materials are needed:

1. Plate Glass- A piece of plate glass,

at least 6 mm [14in.] thick and at

least 25 mm [1 in.] larger than the

diameter of

the measure to be calibrated.

2. Grease

3. Thermometer- range of at least

10C - 32C and is readable to at

least 0.5C

4. Balance

Methodology:

Materials:

Preparation:

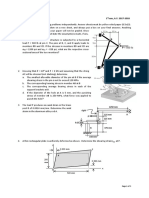

1. Balance- accurate within 0.1 % of the

test load at any point within the range of

use, graduated to at least 0.05 kg. The

range of use shall be considered to extend

from the mass of the measure empty to the

mass of the measure plus its contents at

1920 kg/m3.

The sample was obtained and reduced in

accordance to Practice D75 and Practice

C702. The test sample size was

approximately 125-200% of the full

capacity of the measure. Care was taken as

to prevent segregation of aggregates. The

sample was then dried to 110 +/- 5 C

2. Tamping Rod-A round, straight steel

rod, 16 mm in diameter and approximately

600 mm in length, having the tamping end,

or both ends, rounded to a hemispherical

tip, the diameter of which is 16 mm.

Test Method:

3. Measure- preferably provided with

handles. It shall be watertight, with the top

Calibration of Measure:

This procedure should be done when

recalibrating the measure.Measure should

be recalibrated at least once a year or

whenever there is reason to question the

accuracy of the measure.

The mass of the plate glass was

determined. Then, the measure was filled

with water and covered with plate glass in

a manner as to eliminate bubbles and

excess water. Leakage of water from the

measure was prevented by placing a thin

layer of grease on the rim of measure and

any water that overflowed was also

removed. The mass of water, plate glass

and measure was determined. The density

of water was also determined by

measuring the temperature of water and

following Table 3 from ASTM C29. The

volume, V, of the measure and factor, F,

for the measure was calculated.

Selection of Procedure:

Shoveling procedure should be used only

for loose bulk density when specified.

Otherwise, for aggregates with nominal

maximum size of 37.5 mm or less, the

compact bulk density will be determined

by rodding procedure and by jigging

procedure for aggregates with 37.5 mm to

125 mm nominal maximum size.

Rodding Procedure:

The measure was filled with aggregates to

1/3 of its capacity and leveled at the

surface. The layer of aggregates was

rodded with 25 strokes of tamping rod

spread evenly over the surface. Then, the

measure was filled to 2/3 of its capacity

and again rodded in the same manner as

the first layer.Then, the measure was filled

to overflowing and rodded again. The

surface of aggregate was leveled in such a

way that larger pieces of coarse aggregates

approximately balance the larger voids in

the surface below the top of the measure.

Lastly,the mass of the measure plus its

content and mass of measure only

weredetermined.

Note: In rodding of the first layer of

aggregates, the rod was not allowed to

strike the bottom of the measure. For

second and third layers, more force is

needed than the first one but not to the

degree that the tamping rod will penetrate

the previous layer of aggregate.

Jigging Procedure

The measure was filled in three

approximate equal layers and

compacted by placing the measure

on a firm base such as cementconcrete floor so that the opposite

sides was raised and the measure

was allowed to drop in such a

manner as to hit with a sharp,

slapping blow. Through this method,

aggregates will arrange in a densely

compacted condition. Each layer was

compacted through this manner 50

times, 25 times on each side. The

surface of aggregates was leveled

using fingers or straightedge in the

same manner stated in the rodding

procedure. Lastly, the mass of the

measure plus its content and mass of

measure only were determined.

Shoveling Procedure

The measure was filled to overflowing

capacity discharging the aggregate from a

height not to exceed 50 mm above the top

of measure. Care was taken to avoid

segregation of aggregates. The surface

was leveled in the same manner as the

rodding and jigging procedure. Lastly, the

mass of the measure plus its content and

mass of measure only were determined.

Calculation:

M=

GT

=( GT ) X F

V

M- Bulk density of aggregate

G- Mass of aggregate plus measure

T- Mass of measure

V- Volume of measure

F- Factor for measure

Void Content

Voids=

( SW )M

X 100

S XW

M- Bulk density of aggregate

S- Bulk specific gravity determined by

C127 or C128

W- Density of water

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- PDokumen30 halamanPJihan PacerBelum ada peringkat

- Lecture 2.0 - Introduction To LRFD Bridge DesignDokumen51 halamanLecture 2.0 - Introduction To LRFD Bridge DesignJihan PacerBelum ada peringkat

- References For Thesis ProposalDokumen6 halamanReferences For Thesis ProposalJihan PacerBelum ada peringkat

- 0 DegreesDokumen97 halaman0 DegreesJihan PacerBelum ada peringkat

- DesignDokumen3 halamanDesignJihan PacerBelum ada peringkat

- Lecture 9 Intro To Finite Element Method Part 2Dokumen32 halamanLecture 9 Intro To Finite Element Method Part 2Jihan PacerBelum ada peringkat

- CP 9. EXAMPLES Particle Kinetics-Force Inertia MethodDokumen2 halamanCP 9. EXAMPLES Particle Kinetics-Force Inertia MethodJihan PacerBelum ada peringkat

- Complex Fourier Series PDFDokumen15 halamanComplex Fourier Series PDFJihan PacerBelum ada peringkat

- Intro To PdesDokumen16 halamanIntro To PdesJihan PacerBelum ada peringkat

- CP 5Dokumen2 halamanCP 5Jihan PacerBelum ada peringkat

- Che 413 - Environmental Engineering: Submitted By: Pacer, Judea SDokumen11 halamanChe 413 - Environmental Engineering: Submitted By: Pacer, Judea SJihan PacerBelum ada peringkat

- Exercises PHYSICSDokumen2 halamanExercises PHYSICSJihan PacerBelum ada peringkat

- Name: Date: SN: Quiz 4: D-K Transformation Prove That The Flexibility Matrix For The Given Beam Below IsDokumen2 halamanName: Date: SN: Quiz 4: D-K Transformation Prove That The Flexibility Matrix For The Given Beam Below IsJihan PacerBelum ada peringkat

- B, (B) The Number of Revolutions Executed byDokumen2 halamanB, (B) The Number of Revolutions Executed byJihan PacerBelum ada peringkat

- Review ProblemsDokumen3 halamanReview ProblemsJihan PacerBelum ada peringkat

- 2010 Besavilla Transportation Engineering PDFDokumen8 halaman2010 Besavilla Transportation Engineering PDFJihan PacerBelum ada peringkat

- Art Man and Society (Symbolism)Dokumen6 halamanArt Man and Society (Symbolism)Jihan PacerBelum ada peringkat

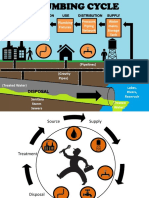

- Water Source: Sewage Plants Gravity Piping Networks Plumbing Fixtures Pressure, Piping Network Water Mains, Storage TankDokumen2 halamanWater Source: Sewage Plants Gravity Piping Networks Plumbing Fixtures Pressure, Piping Network Water Mains, Storage TankJihan PacerBelum ada peringkat

- Voiding Taxation: Judea Pacer BSCE 2-1Dokumen10 halamanVoiding Taxation: Judea Pacer BSCE 2-1Jihan PacerBelum ada peringkat

- B, (B) The Number of Revolutions Executed byDokumen2 halamanB, (B) The Number of Revolutions Executed byJihan PacerBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Fiesta Mk6 EnglishDokumen193 halamanFiesta Mk6 EnglishStoicaAlexandru100% (2)

- XLPE-AL 33 KV Single Core Cable - Hoja de Datos - NKT CablesDokumen2 halamanXLPE-AL 33 KV Single Core Cable - Hoja de Datos - NKT CableskjkljkljlkjljlkBelum ada peringkat

- PS User Security SetupDokumen30 halamanPS User Security Setupabhi10augBelum ada peringkat

- Despiece Completo ThwaittesDokumen60 halamanDespiece Completo ThwaittesJuan Antonio Cano Diaz100% (1)

- The Voice: and The Musical InstrumentsDokumen12 halamanThe Voice: and The Musical InstrumentsnireadaetaBelum ada peringkat

- A Tracer Study On Btte GraduatesDokumen15 halamanA Tracer Study On Btte GraduatesOzalleAngryBertBelum ada peringkat

- S7-1200 DataSheetDokumen14 halamanS7-1200 DataSheetperuhayaBelum ada peringkat

- NASM3Dokumen4 halamanNASM3GFS ConsultoriaBelum ada peringkat

- Multiquadrant Dynamics in The Speed-Torque PlaneDokumen41 halamanMultiquadrant Dynamics in The Speed-Torque PlanethanvandhBelum ada peringkat

- Bubble Point Temperature - Ideal Gas - Ideal Liquid: TrialDokumen4 halamanBubble Point Temperature - Ideal Gas - Ideal Liquid: TrialNur Dewi PusporiniBelum ada peringkat

- Dutch Cone Penetrometer Test: Sondir NoDokumen3 halamanDutch Cone Penetrometer Test: Sondir NoAngga ArifiantoBelum ada peringkat

- Ibps Po Interview Capsule-1Dokumen8 halamanIbps Po Interview Capsule-1atingoyal1Belum ada peringkat

- Nyuszi SzabásmintaDokumen3 halamanNyuszi SzabásmintaKata Mihályfi100% (1)

- Lab 01 IntroductionDokumen4 halamanLab 01 IntroductiontsikboyBelum ada peringkat

- Is Iec 60534 2 1 1998Dokumen48 halamanIs Iec 60534 2 1 1998Sreeram PanigrahiBelum ada peringkat

- J416V06 enDokumen4 halamanJ416V06 enMartin KratkyBelum ada peringkat

- CL21C650MLMXZD PDFDokumen45 halamanCL21C650MLMXZD PDFJone Ferreira Dos SantosBelum ada peringkat

- Colleg Fee StructureDokumen1 halamanColleg Fee StructureSriram SaiBelum ada peringkat

- Reckitt Benkiser (Case Study) For SCMDokumen13 halamanReckitt Benkiser (Case Study) For SCMDiptiman GuhaBelum ada peringkat

- Tears of My Enemies Funny Juice Box Enamel Pin BaDokumen1 halamanTears of My Enemies Funny Juice Box Enamel Pin BaBoban StojanovićBelum ada peringkat

- Contact List For All NWGDokumen22 halamanContact List For All NWGKarthickBelum ada peringkat

- Professional Project ManagementDokumen2 halamanProfessional Project ManagementVirginia Virgie100% (3)

- Wyche Bridge 2000Dokumen12 halamanWyche Bridge 2000BhushanRajBelum ada peringkat

- 119 SQL Code Smells PDFDokumen69 halaman119 SQL Code Smells PDFdivemustgoBelum ada peringkat

- Bat 12v 18ah - Amp9039 - UkDokumen2 halamanBat 12v 18ah - Amp9039 - UkAbdoullai camaraBelum ada peringkat

- Timetable Victoria Chichester PDFDokumen2 halamanTimetable Victoria Chichester PDFLizzie CosterBelum ada peringkat

- Waste To Wealth Green Potential From Palm Biomass in MalaysiaDokumen9 halamanWaste To Wealth Green Potential From Palm Biomass in MalaysiaLai Mei EeBelum ada peringkat

- Lutec Katalog PDFDokumen166 halamanLutec Katalog PDFSpeedyBelum ada peringkat

- Facility Layout Case StudyDokumen8 halamanFacility Layout Case StudyHitesh SinglaBelum ada peringkat

- Naging: Case SelectingDokumen5 halamanNaging: Case SelectingPrabhakar RaiBelum ada peringkat