Bitustick XL

Diunggah oleh

ganmosesDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bitustick XL

Diunggah oleh

ganmosesHak Cipta:

Format Tersedia

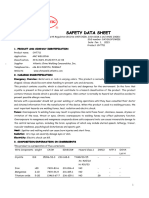

BITUSTICK XL

TDS_Bitustick-XL_GCC_0514

Cross laminated self adhesive waterproofing membrane

BituStiCK xl isaselfadhesivewaterproofingmembranebasedonatropicalgradeofpolymermodified

bitumen.thebitumencompoundislaminatedontoanimpervious,non-perforated,crosslaminated

HDpEfilm.BituStiCK xl conformstotherequirementsofBS8102.

characteristics

4 Speciallyformulatedfortropicalclimategrade

4 providesprotectionagainstwaterandvapor

4 Self adhesive. Requires just peeling off the

siliconefilmandstickingtothesurface

4 Excellentadhesiontoverticalandhorizontal

surfaces

4 Excellent resistance to chlorides, sulphates,

alkalisandacids

4 Goodtearandpunctureresistance

4 Excellenttensilestrength

Fields oF application

BituStiCK xl isusedaswaterproofinganddamp

proofing membrane intended for concrete

protection. it may be used for horizontal and

vertical application for tanking below ground

structures,subwaysandretainingwalls.

application instructions

betweenthemembraneandtheconcretesurface.

inadditiontothattheprimeralsoactsasabinder

for the dust which gets accumulated on the

concretesurfaceevenaftercleaning.

Alignment

Starttheinstallationofallmembranepliesfrom

thelowpointordrains,sothattheflowofwateris

overorparalleltotheplies,butneveragainstthe

laps.Alloverlapsatthemembraneseamsshallbe

installedsoastohave"up"slopelapsover"down"

slope laps. Begin membrane application by

unrollingtherollofBituStiCK xl membraneand

aligningthesidelaps.

Application

peeloffthereleasefilmfromtheselfadhesiveside

andstartunrollingthemembraneandpressitto

the surface. Smoothen the membrane from the

centertotheedgeswithawoodenpressinorder

to remove entrapped air. Furthermore, an iron

rollershallbeusedforrollingontopoftheapplied

theapplicationtemperatureshouldbebetween

5C to 55C. Application procedures may vary

slightly depending upon site conditions. the

general recommended guidelines for the

application of the self adhesive waterproofing

systemisasfollows:

Surfacepreparation

the surface shall be cleaned thoroughly of all

contaminants like dust, traces of curing

compound, oil and grease. All surface

imperfections, protrusions, structurally unsound

and friable concrete must be removed and

repairedwithasuitablepolyCREtE*concreterepair

mortar.

priming

ApplypolypRiME SB*(Solventbasedprimer)@46m/ltoacleansmoothanddrysurfacebybrush,

rollerorspray.Allowtheprimertodrypriortothe

applicationofthemembrane.Astheviscosityof

the primer is low, it easily penetrates into the

concrete pores which promotes the adhesion

Cement sand protective screed

Blinding

Forillustrationpurposeonly

www.henkelpolybit.com

Polyprime SB

membrane to ensure a proper and strong

adhesionofthebitumencompoundwiththebase

surface. Side overlaps shall be a minimum of

50mmontheselvedgeandendoverlaps100mm.

protection

the membrane shall be protected immediately

afterapplicationfromdamage,duetoongoing

site activities or from sharp aggregates during

backfillingbyatough,weather,warpandrotproof

asphaltic protection board (BituBoARD)*.

Alternatively,onhorizontalareasthemembrane

canalsobeprotectedbylayingacementsand

screed (50mm). BituBoARD can be fixed with a

doublesidedadhesivebitumentape(BitutApE tS)*.

TDS_Bitustick-XL_GCC_0514

handling

BituStiCK xl membranes are packed in loose

corrugated boxes to avoid any damage during

transitorduringstorageatsites.Careshouldbe

takenwhenstoringthemembranesatsitesand

shouldnotbekeptwithincloseproximityofany

sharporprotrudingedgestoavoidpuncturingor

damagingthemembrane.

BituStiCK xl membranesmustbestoredinashaded

areaonwoodenpalletsneatlycoveredbyathick

fabric and tied securely in a manner that will

minimize exposure to sunlight & uV. the

membraneshallbeprotectedfromallsourcesof

heat.theshelflifeis12monthsifstoredasper

recommendations.Excessiveexposuretosunlight,

uV and other sources of heat will result in

considerable deterioration of the product and

reduceitsshelflife.

storage & shelF liFe

health & saFety

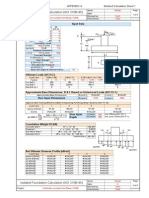

technical speciFication

pRopERtiES

thickness,[mm]

Massperunit

area,[kg/m2]

topsurfacing

Softeningpoint

(R&B), [C ]

tensilestrength,

[Film][N/mm2]

Elongation[Film],

[%]

tearstrength[Film],

[N/mm]

Adhesionstrength,

primedsubstrate[N/mm]

Self[N/mm]

punctureresistance,[N]

Hydrostaticpressure

@7bar(70m)

Waterabsorption,

[Film][%]@24hrs

Watervaportransmission,[g/m2/24hrs]

Chemical

Resistance[pH]

Cross laminated

Tear resistant

Cross

laminated

HDpEFilm

>105

long42

trans48

long230

trans180

long340

trans310

2.0

2.2

>220

No

leakage

0.14

<0.1

2.5-11.5

tESt

StANDARDS

DiNEN1849-1

DiNEN1849-1

AStMD36

AStMD882

AStMD882

AStMD1004

AStMD1000

AStME154

BSEN12390

(part8)

AStMD570

AStME96

AStMD543

AStMD1970

AStMC836

Allvaluesgivenaresubjectto5-10%variation

supply

polypRiME SB

BituBoARD

BitutApE tS

Puncture resistant

1.62.1

1.62.1

lowtempflexibility,

-15C

Crackbridgingability, >1.5mm

BituStiCK xl

BituStiCK xl containsatackybitumencompound

andduringapplicationcanadheretohumanskin.

Bitumenstainscanberemovedbyusingacloth

dippedinasuitablecleaner.

VAluES

1.6mm 1mx10m,

wt16kg#

1mx20m,

wt32kg#

2.1mm 1mx10m,

wt21kg#

20lpail&200ldrum

3.2mm 2mx1m,

wt7.7kg#

6.0mm 2mx1m,

wt14.0kg#

50mmx10m,wt0.6kg#

Woodenpress

140mmx210mm

ironRoller

(recommended

specification)

HeadDia38mm, wt1.5kg#

Width100mm

length350mm

*RefertowebsitefortDS

#

Approximateweight

Apartfromtheinformationgivenhereitisalsoimportanttoobservetherelevantguidelinesandregulationsofvariousorganisationsandtradeassociationsaswell

astherespectivestandards.theaforementionedcharacteristicsarebasedonpracticalexperienceandappliedtesting.Warrantedpropertiesandpossibleuseswhich

gobeyondthosewarrantedinthisinformationsheetrequireourwrittenconfirmation.Alldatagivenwasobtainedatanambientandmaterialtemperatureof

+23Cand50%relativeairhumidityunlessspecifiedotherwise.pleasenotethatunderotherclimaticconditionshardeningcanbeacceleratedordelayed.

theinformationcontainedherein,particularlyrecommendationsforthehandlinganduseofourproducts,isbasedonourprofessionalexperience.Asmaterials

andconditionsmayvarywitheachintendedapplication,andthusarebeyondoursphereofinfluence,westronglyrecommendthatineachcasesufficienttestsare

conductedtocheckthesuitabilityofourproductsfortheirintendeduse.legalliabilitycannotbeacceptedonthebasisofthecontentsofthisdatasheetoranyverbaladvicegiven,unlessthereisacaseofwilfulmisconductorgrossnegligenceonourpart.thistechnicaldatasheetsupersedesallpreviouseditionsrelevantto

thisproduct.

ManufacturedinG.C.C.

Henkelpolybitindustriesltd.

p.o.Box293,ummAlQuwain,uAE

tel:+97167670777,Fax:+97167670197

henkelpolybit@henkelpolybit.com

Henkelpolybitindustriesltd.

p.o.Box2230,AlKhobar31952,KSA

tel:+966138084061/62,Fax:+966138121164

dammam@henkelpolybit.com

www.henkelpolybit.com

Anda mungkin juga menyukai

- U.S. Army Explosives and Demolitions HandbookDari EverandU.S. Army Explosives and Demolitions HandbookBelum ada peringkat

- Underpass DWGDokumen1 halamanUnderpass DWGganmosesBelum ada peringkat

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ionic Bond of LoveDokumen1 halamanIonic Bond of LoveMohd FarisBelum ada peringkat

- ICC-ES-AC 86-0619-AltDokumen10 halamanICC-ES-AC 86-0619-AltrcBelum ada peringkat

- BITUBOARDDokumen2 halamanBITUBOARDVladimir SimeunovicBelum ada peringkat

- Bitustick XL TDSDokumen2 halamanBitustick XL TDSsanthoshBelum ada peringkat

- Bitustick XL 1.6mmDokumen123 halamanBitustick XL 1.6mmThiva karBelum ada peringkat

- 6 2 1 2 3 Bitustick XLDokumen2 halaman6 2 1 2 3 Bitustick XLglen cristian riveraBelum ada peringkat

- Mea Polybit Tds Polybit Bitustick XL en MeaDokumen2 halamanMea Polybit Tds Polybit Bitustick XL en MeaSabeer HafizBelum ada peringkat

- Waterproofing6.0 WebDokumen16 halamanWaterproofing6.0 Webakash nairBelum ada peringkat

- Itustick Itustick: HDPE Surfaced Bituminous Waterproofing MembraneDokumen2 halamanItustick Itustick: HDPE Surfaced Bituminous Waterproofing Membraneglen cristian riveraBelum ada peringkat

- Bitustick XLSDokumen2 halamanBitustick XLSAbed DaherBelum ada peringkat

- 7Thioflex 600填缝胶胶水Dokumen4 halaman7Thioflex 600填缝胶胶水cfmszailBelum ada peringkat

- Bitustick XLS HynkleDokumen2 halamanBitustick XLS HynkleMohamed ShehataBelum ada peringkat

- Mea Polybit Tds Polybit Bitustick en MeaDokumen2 halamanMea Polybit Tds Polybit Bitustick en MeaVengatesh HariBelum ada peringkat

- BITUTEX FBR fibre reinforced solvented bitumen paintDokumen2 halamanBITUTEX FBR fibre reinforced solvented bitumen paintRupesh GenesisBelum ada peringkat

- BitucellDokumen2 halamanBitucellzultrsb689Belum ada peringkat

- BitucellDokumen2 halamanBitucellDillesh ReddyBelum ada peringkat

- Bitustick P: Polyester Reinforced Waterproofing MembraneDokumen2 halamanBitustick P: Polyester Reinforced Waterproofing MembraneHafnazSabeerBelum ada peringkat

- Samshield XL1500 - 2100Dokumen3 halamanSamshield XL1500 - 2100pandey71087Belum ada peringkat

- Nitomortar ELDokumen4 halamanNitomortar ELmilanbrasinaBelum ada peringkat

- Construction Waterproofing MaterialsDokumen11 halamanConstruction Waterproofing MaterialsAyush TiwariBelum ada peringkat

- WaterproofingDokumen34 halamanWaterproofingThomas CrawfordBelum ada peringkat

- Hydrocell XL PDFDokumen2 halamanHydrocell XL PDFmilanbrasinaBelum ada peringkat

- 6 2 1 2 7 Bitustick PDokumen2 halaman6 2 1 2 7 Bitustick PRobin Denkins PaulBelum ada peringkat

- BITUSTICK - XL-Tecnical Data SheetDokumen2 halamanBITUSTICK - XL-Tecnical Data Sheetaldred_chezka100% (1)

- Mea Polybit Tds Polybit Bitustick R 3000 en MeaDokumen2 halamanMea Polybit Tds Polybit Bitustick R 3000 en MeaMuhamed RiskhanBelum ada peringkat

- Polycoat RbeDokumen2 halamanPolycoat RbeganmosesBelum ada peringkat

- BitucellDokumen2 halamanBitucellMuhammad ShoaibBelum ada peringkat

- Fosroc BitucellDokumen2 halamanFosroc Bitucellahmed abdulBelum ada peringkat

- Bitumen Impregnated FibreboardDokumen2 halamanBitumen Impregnated Fibreboardaidilza100% (1)

- Nitoproof 230 PDFDokumen2 halamanNitoproof 230 PDFmilanbrasinaBelum ada peringkat

- Proofex SM PDFDokumen4 halamanProofex SM PDFmilanbrasinaBelum ada peringkat

- Thioflex 600Dokumen4 halamanThioflex 600Conifer YuBelum ada peringkat

- Watertite SA 35 Anti-Root Waterproofing MembraneDokumen2 halamanWatertite SA 35 Anti-Root Waterproofing MembraneAlexi ALfred H. TagoBelum ada peringkat

- Thioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards ComplianceDokumen5 halamanThioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards CompliancemustafaBelum ada peringkat

- Water ProofingDokumen6 halamanWater ProofingManishaDhimanBelum ada peringkat

- Thioflex 600 PDFDokumen4 halamanThioflex 600 PDFmilanbrasinaBelum ada peringkat

- Thioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards ComplianceDokumen5 halamanThioflex 600: Multi-Component, Gun and Pouring Grade, Poly-Sulphide Sealant Uses Standards ComplianceBahaa MohamedBelum ada peringkat

- Fosroc Bitucell Sealed Expansion JointDokumen2 halamanFosroc Bitucell Sealed Expansion JointAli Civil007Belum ada peringkat

- DR Fixit Waterproofing ReckonerDokumen40 halamanDR Fixit Waterproofing ReckonerSusheel TalrejaBelum ada peringkat

- Fosroc Thioflex 600 SealantDokumen4 halamanFosroc Thioflex 600 SealantmangjitBelum ada peringkat

- Thioflex 600Dokumen5 halamanThioflex 600talatzahoorBelum ada peringkat

- Water ProofingDokumen8 halamanWater ProofingDev SharmaBelum ada peringkat

- Major Features: High Performance Fire Retardant SBS Modified Bitumen Waterproofing MembraneDokumen2 halamanMajor Features: High Performance Fire Retardant SBS Modified Bitumen Waterproofing Membranesr2011glassBelum ada peringkat

- Brushbond FLX III Waterproofing MembraneDokumen3 halamanBrushbond FLX III Waterproofing MembranebijubijayBelum ada peringkat

- Thioflex 600Dokumen4 halamanThioflex 600wikaBelum ada peringkat

- Note On LeakshieldDokumen1 halamanNote On Leakshieldrama6to9Belum ada peringkat

- WaterproofingReckoner PDFDokumen40 halamanWaterproofingReckoner PDFhelloitskalaiBelum ada peringkat

- Fosroc Thioflex 600: Multi-Component, Gun and Pouring Grade, Polysulphide Sealant UsesDokumen4 halamanFosroc Thioflex 600: Multi-Component, Gun and Pouring Grade, Polysulphide Sealant UsesAnonymous 0wHSC3FXOrBelum ada peringkat

- PlastijointDokumen4 halamanPlastijointm.elsanee.cubicBelum ada peringkat

- Boscoseal Torch OnDokumen3 halamanBoscoseal Torch OnjbonvierBelum ada peringkat

- Protectosil CIT PDFDokumen3 halamanProtectosil CIT PDFFrancois-Belum ada peringkat

- Submittal Thioflex 600 (1)Dokumen71 halamanSubmittal Thioflex 600 (1)jawad izallalenBelum ada peringkat

- Fosroc Bitucell Expansion Joint FillerDokumen2 halamanFosroc Bitucell Expansion Joint FillerIna RoseBelum ada peringkat

- Watertite SA 16Dokumen2 halamanWatertite SA 16Alexi ALfred H. TagoBelum ada peringkat

- Expanse Al 600Dokumen4 halamanExpanse Al 600raza102Belum ada peringkat

- WP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Dokumen2 halamanWP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Ade KurniawanBelum ada peringkat

- Materials For Sealing Joints in Water Retaining Concrete StructuresDokumen4 halamanMaterials For Sealing Joints in Water Retaining Concrete StructuresKumar AtrayBelum ada peringkat

- Flexible Expansion Joint MembraneDokumen4 halamanFlexible Expansion Joint MembranemilanbrasinaBelum ada peringkat

- Thioflex 600 - Joint SealantDokumen104 halamanThioflex 600 - Joint SealantamirskbkbkBelum ada peringkat

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Dari EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Belum ada peringkat

- Water-Based Paint Formulations, Vol. 3Dari EverandWater-Based Paint Formulations, Vol. 3Penilaian: 4.5 dari 5 bintang4.5/5 (6)

- IC - B1 - SW - SP03 - v1.0 - Week 3Dokumen4 halamanIC - B1 - SW - SP03 - v1.0 - Week 3ganmoses100% (2)

- Arihant - Mat Solvedpaper 2012Dokumen26 halamanArihant - Mat Solvedpaper 2012Extra MarksBelum ada peringkat

- A4 80Dokumen2 halamanA4 80alwezalokBelum ada peringkat

- Angle of Repose & Angle of FrictionDokumen4 halamanAngle of Repose & Angle of Frictionganmoses50% (2)

- Soil Compaction Earthworks - Notes PDFDokumen47 halamanSoil Compaction Earthworks - Notes PDFGnabBangBelum ada peringkat

- A4 80Dokumen2 halamanA4 80alwezalokBelum ada peringkat

- Road Geometric Design Manual PDFDokumen690 halamanRoad Geometric Design Manual PDFganmosesBelum ada peringkat

- Specifications Part1Dokumen3 halamanSpecifications Part1ganmosesBelum ada peringkat

- Geogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFDokumen115 halamanGeogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFChan Hoi KitBelum ada peringkat

- 002 Waterstop FactsDokumen0 halaman002 Waterstop FactsganmosesBelum ada peringkat

- Heavy PlatesDokumen41 halamanHeavy PlatesganmosesBelum ada peringkat

- Admixtures in ConcreteDokumen15 halamanAdmixtures in ConcreteSundara LingamBelum ada peringkat

- Admixtures For ConcreteDokumen4 halamanAdmixtures For ConcreteMuhammad Shahbaz KhokharBelum ada peringkat

- SSINA - Designer's Handbook - Stainless Steel FastenersDokumen23 halamanSSINA - Designer's Handbook - Stainless Steel FastenersSerguei DobrinBelum ada peringkat

- 316 316L Data SheetDokumen2 halaman316 316L Data SheetHanna ChanBelum ada peringkat

- Epoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidDokumen4 halamanEpoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidganmosesBelum ada peringkat

- 316 316L Data Bulletin PDFDokumen0 halaman316 316L Data Bulletin PDFRKLNBelum ada peringkat

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDokumen3 halamanAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesBelum ada peringkat

- DCL Test ChargesDokumen1 halamanDCL Test ChargesganmosesBelum ada peringkat

- SpeedyDokumen4 halamanSpeedyBudhi KurniawanBelum ada peringkat

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDokumen1 halamanGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesBelum ada peringkat

- Bearing Capacity of SoilsDokumen138 halamanBearing Capacity of SoilsMuqeem Khan100% (1)

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDokumen1 halamanGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesBelum ada peringkat

- Nitomortar FC PDFDokumen2 halamanNitomortar FC PDFganmosesBelum ada peringkat

- FPI FiberglassbookDokumen164 halamanFPI FiberglassbookA_ValsamisBelum ada peringkat

- Grain Size AnalysisDokumen5 halamanGrain Size AnalysisganmosesBelum ada peringkat

- Conventional AC DesignDokumen42 halamanConventional AC Designabdikarim_omarBelum ada peringkat

- DG3 Sheeting PDFDokumen8 halamanDG3 Sheeting PDFganmosesBelum ada peringkat

- A Report On Civil Engineering Student's Internship Programme (CESIP) of Building ConstructionDokumen29 halamanA Report On Civil Engineering Student's Internship Programme (CESIP) of Building Constructionhammad dhillonBelum ada peringkat

- Indian Railways MIG Wire Technical RequirementsDokumen17 halamanIndian Railways MIG Wire Technical RequirementsJoherBelum ada peringkat

- Datasheet Potassium Formate KFORMSOLpdfDokumen1 halamanDatasheet Potassium Formate KFORMSOLpdfJuan MancipeBelum ada peringkat

- Design of Biogas DigestersDokumen22 halamanDesign of Biogas DigestersSharath Chandra100% (5)

- Safety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228Dokumen5 halamanSafety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228sergio.lopezBelum ada peringkat

- Analyisis of en of AM350Dokumen15 halamanAnalyisis of en of AM350Jesús JáquezBelum ada peringkat

- A Study of The Effect of Magnetite Additions To Shell Molds On THDokumen106 halamanA Study of The Effect of Magnetite Additions To Shell Molds On THneel gajBelum ada peringkat

- Tabele Saturacije PDFDokumen20 halamanTabele Saturacije PDFTrkulja GoranBelum ada peringkat

- Mix Proportioning of M80 Grade Self-Compacting ConDokumen3 halamanMix Proportioning of M80 Grade Self-Compacting ConfaseehBelum ada peringkat

- Nanotechnology: A Platform For Education ChangeDokumen7 halamanNanotechnology: A Platform For Education Changeapi-251873743Belum ada peringkat

- BaugsDokumen10 halamanBaugsmarcoliveriniqzBelum ada peringkat

- Polarography PDFDokumen37 halamanPolarography PDFTejwant Singh KangBelum ada peringkat

- MasterCast 141MDokumen5 halamanMasterCast 141Mrobin rezkBelum ada peringkat

- GTU BE Semester V Mass Transfer Operations I Exam Summer 2016Dokumen2 halamanGTU BE Semester V Mass Transfer Operations I Exam Summer 2016Shivam PanchalBelum ada peringkat

- 00-H-0008 Air-Cooled Water ChillersDokumen14 halaman00-H-0008 Air-Cooled Water Chillershabibansari2010Belum ada peringkat

- Haematoxylin (Ehrlich) : Intended UseDokumen3 halamanHaematoxylin (Ehrlich) : Intended Useyohanes e. gunawanBelum ada peringkat

- Arches: Theory of StructuresDokumen20 halamanArches: Theory of StructuresAravind BhashyamBelum ada peringkat

- Defects / Imperfections in Crystalline MaterialsDokumen41 halamanDefects / Imperfections in Crystalline Materialsjayant thakareBelum ada peringkat

- Zimbabwe School Examinations Council Chemistry 6031/3Dokumen12 halamanZimbabwe School Examinations Council Chemistry 6031/3takundavs100% (2)

- MIDC UNITSDokumen16 halamanMIDC UNITSSatej SatyanBelum ada peringkat

- Api600 Valve Trim ChartDokumen2 halamanApi600 Valve Trim ChartBoankBelum ada peringkat

- NONWOVEN - Vinay Kumar MidhaDokumen11 halamanNONWOVEN - Vinay Kumar Midhaglobal-marketin8184Belum ada peringkat

- Presentación SHOTPEEN 2016Dokumen48 halamanPresentación SHOTPEEN 2016aeroericBelum ada peringkat

- Murashige and Skoog Basal Medium (M5519)Dokumen1 halamanMurashige and Skoog Basal Medium (M5519)Dyo MandeBelum ada peringkat

- Arandelas Hill Side A325Dokumen1 halamanArandelas Hill Side A325Oscar SanabriaBelum ada peringkat

- Isolated Foundation Calculation (ACI 318M-95) : Input DataDokumen5 halamanIsolated Foundation Calculation (ACI 318M-95) : Input DataJuan CarlosBelum ada peringkat

- Sand ManufacturingDokumen5 halamanSand ManufacturingJournalNX - a Multidisciplinary Peer Reviewed JournalBelum ada peringkat

- Daphne Eponex No2Dokumen5 halamanDaphne Eponex No2Fu NamBelum ada peringkat