2 Comparing Electric Machine Sys-Tems

Diunggah oleh

Anonymous E4Rbo2sJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2 Comparing Electric Machine Sys-Tems

Diunggah oleh

Anonymous E4Rbo2sHak Cipta:

Format Tersedia

Electric machine

The academic study of electric machines is the universal study of electric motors and electric generators.

By the classic denition, electric machine is synonymous

with electric motor or electric generator, all of which are

electromechanical energy converters: converting electricity to mechanical power (i.e., electric motor) or mechanical power to electricity (i.e., electric generator).

The movement involved in the mechanical power can be

rotating or linear.

ways the case. Motors and generators can be designed

with or without iron to improve the path of the magnetic eld (teeth to reduce the air gap is a common example) and with and without permanent magnets (PM),

with dierent pole number etc., but still belong to dierent classes of machines. Electric machines can be synchronous meaning that the magnetic eld set up by the

stator coils rotates with the same speed as the rotor; or

asynchronous, meaning that there is a speed dierence.

PM machines and reluctance machines are always synchronous. Brushed machines with rotor windings can be

synchronous when the rotor is supplied with DC or AC

with same frequency as stator or asynchronous when stator and rotor are supplied with AC with dierent frequencies. Induction machines are usually asynchronous, but

can be synchronous, if there are superconductors in the

rotor windings.

The apparatus that converts energy in three categories:

generators which convert mechanical energy to electrical

energy, motors which convert electrical energy to mechanical energy, and transformers which change the

voltage level of an alternating current.

Although transformers do not contain any moving parts

they are also included in the family of electric machines

because they utilise electromagnetic phenomena.[1]

Electric machines, in the form of electric motors, consume approximately 60% of all electricity produced.

Electric machines (i.e., electric generators) produce virtually all electricity consumed. Electric machines have

become so ubiquitous that they are virtually overlooked

as an integral component of the entire electricity infrastructure. Developing ever more ecient electric machine

technology and inuencing their use are crucial to any

global conservation, green energy, or alternative energy

strategy.

2 Comparing electric machine systems

Comparing the cost-performance between electric machine systems of dierent classication or from dierent manufacturers is dicult without a critical baseline

of metrics. For equitable comparison of eciency, cost,

torque, and power between electric machine systems, the

comparison should be matched with the same voltage and

speed at a given frequency of excitation; or instead, the

additional cost, eciency, and real-estate of the transmis1 Classications

sion for instance for coupling to the speed of the application, the transformer for matching voltage, the frequency

When classifying electric machines (motors and genera- converter to match excitation frequency, etc., should be

tors) it is reasonable to start with physical principle for included.

converting electric energy to mechanical energy. If the Other parameters that should always be considered in any

controller is included as a part of the machine all ma- revealing comparison:

chines can be powered by either alternating or direct current, although some machines will need a more advanced

Duty Cycle although directly related to cost, econtroller than others. Classication is complicated by

ciency, and power density, duty cycle gives meaning

the possibilities of combining physical principles when

to application applicability;

constructing an electrical machine. It can, for example,

Peak Torque Potential the closeness of peak torque

be possible to run a brushed machine as a reluctance mapotential to continuous torque indicates the safe

chine (without using the rotor coils) if the rotor iron has

margin of the design;

the correct shape.

Cost, Eciency, and Real-estate of the Electronic

Controller unless integrated and included in the

specications of the electric machine system, the

electronic controller, which is required for practical

system operation, should always be included.

Generally all electric machines can be turned inside out,

so rotor and stator exchange places. All rotating electric machines have an equivalent linear electric machine

where stator moves along a straight line instead of rotating. The oppositelinear to rotary dualis not al1

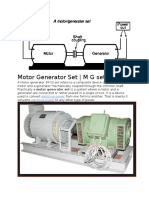

MOTOR

Utilization of the Magnetic Core and frame assem- have the eld winding on the rotor and the armature windbly As an example: with the wound-rotor doubly ing on the stator.

fed electric machine as the only exception, rotor as- AC generators are classied into several types.

semblies, which consume nearly half the volume of

the electric machine, passively participate in the en In an induction generator, the stator magnetic ux

ergy conversion process and are under-utilized.

induces currents in the rotor. The prime mover then

drives the rotor above the synchronous speed, causing the opposing rotor ux to cut the stator coils pro3 Generator

ducing active current in the stator coils, thus sending power back to the electrical grid. An induction

generator draws reactive power from the connected

system and so cannot be an isolated source of power.

In a Synchronous generator (alternator), the current

for the magnetic eld is provided by a separate DC

current source.

3.2 DC generator

Electric generator.

Main article: Electric generator

An electric generator is a machine that converts mechanical energy into electrical energy.An electric generator

works based on the principle that whenever conductor

cuts the magnetic eld,an emf is induced which will cause

the current to ow if conductor circuit is closed.Take the

working of Simple loop Generator as an example.

4 Motor

An electric generator is a device that converts mechanical

energy to electrical energy. A generator forces electrons

to ow through an external electrical circuit. It is somewhat analogous to a water pump, which creates a ow of

water but does not create the water inside. The source

of mechanical energy, the prime mover, may be a reciprocating or turbine steam engine, water falling through a

turbine or waterwheel, an internal combustion engine, a

wind turbine, a hand crank, compressed air or any other

source of mechanical energy.

The two main parts of an electrical machine can be described in either mechanical or electrical terms. In mechanical terms, the rotor is the rotating part, and the stator

is the stationary part of an electrical machine. In electrical terms, the armature is the power-producing component and the eld is the magnetic eld component of an

electrical machine. The armature can be on either the

rotor or the stator. The magnetic eld can be provided

by either electromagnets or permanent magnets mounted

on either the rotor or the stator. Generators are classied

into two types, AC generators and DC generators.

3.1

AC generator

An AC generator converts mechanical energy into

alternating current electricity. Because power transferred

into the eld circuit is much less than power transferred

into the armature circuit, AC generators nearly always

Electric motor.

Main article: Electric motor

An electric motor converts electrical energy into

mechanical energy. The reverse process of electrical generators, most electric motors operate through interacting

magnetic elds and current-carrying conductors to generate rotational force. Motors and generators have many

similarities and many types of electric motors can be

run as generators, and vice versa. Electric motors are

found in applications as diverse as industrial fans, blowers

and pumps, machine tools, household appliances, power

tools, and disk drives. They may be powered by direct

current or by alternating current which leads to the two

main classications: AC motors and DC motors.

4.1

AC motor

Main article: AC motor

An AC motor converts alternating current into mechanical energy. It commonly consists of two basic parts, an

outside stationary stator having coils supplied with alternating current to produce a rotating magnetic eld, and

an inside rotor attached to the output shaft that is given a

torque by the rotating eld. The two main types of AC

motors are distinguished by the type of rotor used.

Induction (asynchronous) motor, the rotor magnetic

eld is created by an induced current. The rotor

must turn slightly slower (or faster) than the stator

magnetic eld to provide the induced current. There

are three types of induction motor rotors, which are

squirrel-cage rotor, wound rotor and solid core rotor.

Transformer.

current in the rst or primary winding creates a varying

magnetic ux in the transformers core and thus a varying

magnetic eld through the secondary winding. This varying magnetic eld induces a varying electromotive force

(EMF) or "voltage" in the secondary winding. This eect

is

called mutual induction.

Synchronous motor, it does not rely on induction and

so can rotate exactly at the supply frequency or sub- There are three types of transformers

multiple. The magnetic eld of the rotor is either

generated by direct current delivered through slip

1. Step-up transformer

rings (exciter) or by a permanent magnet.

2. Step-down transformer

4.2

DC motor

Main article: DC motor

The brushed DC electric motor generates torque directly

from DC power supplied to the motor by using internal commutation, stationary permanent magnets, and rotating electrical magnets. Brushes and springs carry the

electric current from the commutator to the spinning wire

windings of the rotor inside the motor. Brushless DC motors use a rotating permanent magnet in the rotor, and stationary electrical magnets on the motor housing. A motor

controller converts DC to AC. This design is simpler than

that of brushed motors because it eliminates the complication of transferring power from outside the motor to the

spinning rotor. An example of a brushless, synchronous

DC motor is a stepper motor which can divide a full rotation into a large number of steps.

Transformer

3. Isolation transformer

There are four types of transformers based on structure

1. core type

2. shell type

3. power type

4. instrument type

6 Electromagnetic-rotor machines

Electromagnetic-rotor machines are machines having

some kind of electric current in the rotor which creates

a magnetic eld which interacts with the stator windings.

The rotor current can be the internal current in a permanent magnet (PM machine), a current supplied to the rotor through brushes (Brushed machine) or a current set

up in closed rotor windings by a varying magnetic eld

(Induction machine).

Main article: Transformer

6.1 Permanent magnet machines

A transformer is a static device that converts alternating

current from one voltage level to another level (higher

or lower), or to the same level, without changing the

frequency. A transformer transfers electrical energy

from one circuit to another through inductively coupled

conductorsthe transformers coils. A varying electric

PM machines have permanent magnets in the rotor which

set up a magnetic eld. The magnetomotive force in a

PM (caused by orbiting electrons with aligned spin) is

generally much higher than what is possible in a copper coil. The copper coil can, however, be lled with a

RELUCTANCE MACHINES

ferromagnetic material, which gives the coil much lower the machine which is set up by induction.

magnetic reluctance. Still the magnetic eld created by

modern PMs (Neodymium magnets) is stronger, which

means that PM machines have a better torque/volume and

torque/weight ratio than machines with rotor coils under

continuous operation. This may change with introduction 6.3 Induction machines

of superconductors in rotor.

Since the permanent magnets in a PM machine already

introduce considerable magnetic reluctance, then the reluctance in the air gap and coils are less important.

This gives considerable freedom when designing PM machines.

It is usually possible to overload electric machines for a

short time until the current in the coils heats parts of the

machine to a temperature which cause damage. PM machines can in less degree be subjected to such overload

because too high current in the coils can create a magnetic eld strong enough to demagnetise the magnets.

Induction machines have short circuited rotor coils where

a current is set up and maintained by induction. This

requires that the rotor rotates at other than synchronous

speed, so that the rotor coils are subjected to a varying

magnetic eld created by the stator coils. An induction

machine is an asynchronous machine.

Induction eliminates the need for brushes which is usually a weak part in an electric machine. It also allows

designs which make it very easy to manufacture the rotor. A metal cylinder will work as rotor, but to improve

eciency a squirrel cage rotor or a rotor with closed

windings is usually used. The speed of asynchronous induction machines will decrease with increased load because a larger speed dierence between stator and rotor

6.2 Brushed machines

is necessary to set up sucient rotor current and rotor

magnetic eld. Asynchronous induction machines can be

Brushed machines are machines where the rotor coil is made so they start and run without any means of control

supplied with current through brushes in much the same if connected to an AC grid, but the starting torque is low.

way as current is supplied to the car in an electric slot car

track. More durable brushes can be made of graphite or A special case would be an induction machine with suliquid metal. It is even possible to eliminate the brushes perconductors in the rotor. The current in the superconin a brushed machine by using a part of rotor and stator ductors will be set up by induction, but the rotor will run

as a transformer which transfer current without creating at synchronous speed because there will be no need for a

torque. Brushes must not be confused with a commuta- speed dierence between the magnetic eld in stator and

tor. The dierence is that the brushes only transfer elec- speed of rotor to maintain the rotor current.

tric current to a moving rotor while a commutator also Another special case would be the brushless double fed

provide switching of the current direction.

induction machine, which has a double set of coils in the

There is iron (usually laminated steel cores made of sheet stator. Since it has two moving magnetic elds in the stametal) between the rotor coils and teeth of iron between tor, it gives no meaning to talk about synchronous or asynthe stator coils in addition to black iron behind the sta- chronous speed.

tor coils. The gap between rotor and stator is also made

as small as possible. All this is done to minimize magnetic reluctance of the magnetic circuit which the magnetic eld created by the rotor coils travels through, something which is important for optimizing these machines. 7 Reluctance machines

Large brushed machines which are run with DC to the

stator windings at synchronous speed are the most common generator in power plants, because they also supply

reactive power to the grid, because they can be started

by the turbine and because the machine in this system

can generate power at constant speed without a controller.

This type of machine is often referred to in the literature

as a synchronous machine.

This machine can also be run by connecting the stator

coils to the grid, and supplying the rotor coils with AC

from an inverter. The advantage is that it is possible to

control rotating speed of the machine with a fractionally

rated inverter. When run this way the machine is known

as a brushed double feed induction machine. Induction is misleading because there is no useful current in

Reluctance machines have no windings in rotor, only a

ferromagnetic material shaped so that electromagnets

in stator can grab the teeth in rotor and move it a little. The electromagnets are then turned o, while another set of electromagnets is turned on to move stator

further. Another name is step motor, and it is suited for

low speed and accurate position control. Reluctance machines can be supplied with PMs in stator to improve performance. The electromagnet is then turned o by

sending a negative current in the coil. When the current

is positive the magnet and the current cooperate to create

a stronger magnetic eld which will improve the reluctance machines maximum torque without increasing the

currents maximum absolute value.

Electrostatic machines

In electrostatic machines, torque is created by attraction

or repulsion of electric charge in rotor and stator.

Electrostatic generators generate electricity by building up electric charge. Early types were friction machines, later ones were inuence machines that worked

by electrostatic induction. The Van de Graa generator

is an electrostatic generator still used in research today.

Homopolar machines

Homopolar machines are true DC machines where current is supplied to a spinning wheel through brushes. The

wheel is inserted in a magnetic eld, and torque is created

as the current travels from the edge to the centre of the

wheel through the magnetic eld.

10

Electric machine systems

For optimized or practical operation of electric machines,

todays electric machine systems are complemented with

electronic control.

11

References

Chapman, Stephen J. 2005. Electrical Machinery

Fundamentals. 4th Ed. New York: McGraw Hill.

[1] Flanagan. Handbook of Transformer Design and Applications, Chap. 1 p1.

12

12

12.1

TEXT AND IMAGE SOURCES, CONTRIBUTORS, AND LICENSES

Text and image sources, contributors, and licenses

Text

Electric machine Source: https://en.wikipedia.org/wiki/Electric_machine?oldid=737269036 Contributors: Wtshymanski, Uncle G, Mandarax, Wavelength, Chris the speller, Joefaust, Kvng, Wizard191, Zureks, Emilio Juanatey, Alaibot, Ccrrccrr, Cander0000, Fklatt, Spinningspark, Jdaloner, Fratrep, Versanil, El bot de la dieta, Dthomsen8, Addbot, Materialscientist, Joneb, Prari, FrescoBot, Oashi, Elmf,

Moldus, Teapeat, ClueBot NG, Nomi12892, Mir Quayam Abbas, Oleg-ch, Tentinator, YiFeiBot, EoRdE6, Markshale, Otoniel S. and

Anonymous: 19

12.2

Images

File:ManitobaHydroPointeduBois_Generator.jpg

Source:

https://upload.wikimedia.org/wikipedia/commons/f/f5/

ManitobaHydroPointeduBois_Generator.jpg License: Public domain Contributors: Transferred from en.wikipedia to Commons by

Drilnoth using CommonsHelper. Original artist: Wtshymanski at English Wikipedia

File:Silniki_by_Zureks.jpg Source: https://upload.wikimedia.org/wikipedia/commons/3/3a/Silniki_by_Zureks.jpg License: CC BY-SA

3.0 Contributors: Own work Original artist: Zureks

File:Trafostation_Alter_Hellweg_IMGP4722.jpg Source:

https://upload.wikimedia.org/wikipedia/commons/a/a3/Trafostation_

Alter_Hellweg_IMGP4722.jpg License: CC BY-SA 2.0 de Contributors: Own work Original artist: The original uploader was Smial at

German Wikipedia

12.3

Content license

Creative Commons Attribution-Share Alike 3.0

Anda mungkin juga menyukai

- Coursework of Utilisation and GenerationDokumen14 halamanCoursework of Utilisation and GenerationKusiimaBelum ada peringkat

- Building Science Electrical / HVACDokumen16 halamanBuilding Science Electrical / HVACManjeet CinghBelum ada peringkat

- 19P205 Electrical MachinesDokumen34 halaman19P205 Electrical Machinessumanthlogn007Belum ada peringkat

- KronDokumen4 halamanKronDeepak Singh100% (1)

- Electrical Machine II: EEEEC11 (3 - 0 - 2) Semester 4Dokumen250 halamanElectrical Machine II: EEEEC11 (3 - 0 - 2) Semester 4sanjoni.jainBelum ada peringkat

- Peres 10PPS103 2 Electrical Machines PDFDokumen71 halamanPeres 10PPS103 2 Electrical Machines PDFThanigaivel RajaBelum ada peringkat

- Eee 2303 Electrical MachinesDokumen7 halamanEee 2303 Electrical MachinesKOSGEI CORNELLIUS KIPTANUI EE102/G/5632/18Belum ada peringkat

- Overview of Uninterruptible Power Supply SystemDokumen18 halamanOverview of Uninterruptible Power Supply SystemMoe Thant OoBelum ada peringkat

- Group 2 Ac Motors Technical ReportDokumen12 halamanGroup 2 Ac Motors Technical Reporttristan jeff bautistaBelum ada peringkat

- Electric MotorsDokumen16 halamanElectric MotorsReszler ArnoldBelum ada peringkat

- Electrical MachinesDokumen14 halamanElectrical Machinesdeepakreddy1226Belum ada peringkat

- Chapter 5 Electrical MachineDokumen27 halamanChapter 5 Electrical MachineBirhex FeyeBelum ada peringkat

- DC Machinery IntroductionDokumen12 halamanDC Machinery IntroductionGyd Lester H. CañalisoBelum ada peringkat

- Introduction To Basic MachinesDokumen6 halamanIntroduction To Basic MachinesFaizan SaeedBelum ada peringkat

- DC Motor - Wikipedia, The Free EncyclopediaDokumen2 halamanDC Motor - Wikipedia, The Free Encyclopediadonodoni0008Belum ada peringkat

- Altena TorDokumen8 halamanAltena TorJb EnarioBelum ada peringkat

- Investigatory Project DC Motor and Ac GeDokumen29 halamanInvestigatory Project DC Motor and Ac Gemuskansaini1306Belum ada peringkat

- ProjectDokumen25 halamanProjectAsif MuhammadBelum ada peringkat

- Induction MotorDokumen20 halamanInduction MotorVenkata SubramanianBelum ada peringkat

- AC generators:AC Generators Are Known As Single-Phase Generators and Are Limited To 25kWDokumen9 halamanAC generators:AC Generators Are Known As Single-Phase Generators and Are Limited To 25kWJera ObsinaBelum ada peringkat

- Type of NC SystemDokumen20 halamanType of NC Systemamit kumarBelum ada peringkat

- Automotive Charging System: Chapter FourDokumen23 halamanAutomotive Charging System: Chapter FourIsaac TesfayeBelum ada peringkat

- Electrical MachinesDokumen7 halamanElectrical Machinesusama jabbarBelum ada peringkat

- MotorDokumen32 halamanMotorDeke Elektronik IndustriBelum ada peringkat

- Chapter 2 Prime MoversDokumen90 halamanChapter 2 Prime Moversaimi wahabBelum ada peringkat

- Electric Motor IT ReportDokumen9 halamanElectric Motor IT ReportVincentBelum ada peringkat

- Assignment - Answered - Electrical MachinesDokumen3 halamanAssignment - Answered - Electrical Machinesappiagyei nicholasBelum ada peringkat

- Module 3Dokumen19 halamanModule 3Pragati ShindeBelum ada peringkat

- Types of Electrical Motors1Dokumen12 halamanTypes of Electrical Motors1AnilBelum ada peringkat

- Electrical Generators PDFDokumen71 halamanElectrical Generators PDFchaithra hsBelum ada peringkat

- Construction of Simple Electric MotorDokumen5 halamanConstruction of Simple Electric MotormohkristBelum ada peringkat

- Generating Electricity by Using Exhaust GasDokumen4 halamanGenerating Electricity by Using Exhaust GasAnonymous j0aO95fgBelum ada peringkat

- Physics ProDokumen21 halamanPhysics ProjayanthiBelum ada peringkat

- Study of Electricity Generated by Ceiling Fan & Car WheelDokumen6 halamanStudy of Electricity Generated by Ceiling Fan & Car WheelSaru TVBelum ada peringkat

- DC Machines and DrivesDokumen10 halamanDC Machines and DrivesMahadev KovalliBelum ada peringkat

- Electric MachinesDokumen4 halamanElectric Machinesمحمد حسین فیض اللهیBelum ada peringkat

- IntroductionDokumen5 halamanIntroductionjayantabhbasuBelum ada peringkat

- Reaction PaperDokumen6 halamanReaction PaperAngelo Escoro Dante100% (1)

- Electrical Machine 7-26-2016Dokumen94 halamanElectrical Machine 7-26-2016Engr. Raheel khanBelum ada peringkat

- AlternatorDokumen23 halamanAlternatorpremameBelum ada peringkat

- Electrical MachinesDokumen38 halamanElectrical Machineshephzi28Belum ada peringkat

- Armature (Electrical Engineering) - Wikipedia, The Free EncyclopediaDokumen3 halamanArmature (Electrical Engineering) - Wikipedia, The Free EncyclopediaChytra DivakarBelum ada peringkat

- Assignment Ac DCDokumen10 halamanAssignment Ac DCKamil KhairiBelum ada peringkat

- SM Report HandoutDokumen4 halamanSM Report HandoutShang Divina EbradaBelum ada peringkat

- Chapter 1: Introduction To Electrical Machines Acm 03 - DC and Ac MachineryDokumen14 halamanChapter 1: Introduction To Electrical Machines Acm 03 - DC and Ac MachineryGlaze GregorioBelum ada peringkat

- Classification of Synchronous GeneratorDokumen5 halamanClassification of Synchronous Generatormuhammad afaq IEEEBelum ada peringkat

- Basic Electrical MachinesDokumen4 halamanBasic Electrical MachinesGedion AvatarBelum ada peringkat

- DC Machine 1Dokumen5 halamanDC Machine 1amiteetumtech2013Belum ada peringkat

- Doubly Fed Electric MachineDokumen19 halamanDoubly Fed Electric MachineChristopher PerkinsBelum ada peringkat

- Electric Motors (English Project) PDFDokumen10 halamanElectric Motors (English Project) PDFAvramov Iulian Cristian50% (2)

- Motor Study Material: UniversalDokumen1 halamanMotor Study Material: UniversalDinesh VelBelum ada peringkat

- Ee 21Dokumen4 halamanEe 21Vanvan BitonBelum ada peringkat

- DC MotorDokumen3 halamanDC MotorAhmad AzizudinBelum ada peringkat

- Enercon-Experiment 1Dokumen10 halamanEnercon-Experiment 1Aldrin QuiambaoBelum ada peringkat

- DC Machine Me Chapter 1Dokumen55 halamanDC Machine Me Chapter 1Ganyu AyakaBelum ada peringkat

- DC MotorDokumen8 halamanDC Motorven_avv3382Belum ada peringkat

- Generators grp7Dokumen25 halamanGenerators grp7CnoJenesis VODSBelum ada peringkat

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDari EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlPenilaian: 5 dari 5 bintang5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesDari EverandPower Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesBelum ada peringkat

- Mountain RangeDokumen5 halamanMountain RangeAnonymous E4Rbo2sBelum ada peringkat

- Jerky: Jerky Is Lean Trimmed Meat That Has Been Cut Into StripsDokumen6 halamanJerky: Jerky Is Lean Trimmed Meat That Has Been Cut Into StripsAnonymous E4Rbo2sBelum ada peringkat

- Sierra Morena: Central Plateau and Providing The Watershed Between The Valleys of TheDokumen7 halamanSierra Morena: Central Plateau and Providing The Watershed Between The Valleys of TheAnonymous E4Rbo2sBelum ada peringkat

- Adel Sedra: Adel S. Sedra Is An Egyptian Canadian Electrical Engineer andDokumen4 halamanAdel Sedra: Adel S. Sedra Is An Egyptian Canadian Electrical Engineer andAnonymous E4Rbo2sBelum ada peringkat

- Jebel Musa (Morocco)Dokumen3 halamanJebel Musa (Morocco)Anonymous E4Rbo2sBelum ada peringkat

- Tariq Ibn ZiyadDokumen5 halamanTariq Ibn ZiyadAnonymous E4Rbo2sBelum ada peringkat

- Konakovsky District (Russian: КонакDokumen7 halamanKonakovsky District (Russian: КонакAnonymous E4Rbo2sBelum ada peringkat

- Demonstrative PDFDokumen8 halamanDemonstrative PDFAnonymous E4Rbo2sBelum ada peringkat

- Bantoid Languages PDFDokumen2 halamanBantoid Languages PDFAnonymous E4Rbo2sBelum ada peringkat

- Nandi-Markweta Languages PDFDokumen6 halamanNandi-Markweta Languages PDFAnonymous E4Rbo2sBelum ada peringkat

- Crumple ZoneDokumen7 halamanCrumple ZoneAnonymous E4Rbo2sBelum ada peringkat

- Kipsigis LanguageDokumen3 halamanKipsigis LanguageAnonymous E4Rbo2s100% (1)

- Class (Computer Programming)Dokumen12 halamanClass (Computer Programming)Anonymous E4Rbo2sBelum ada peringkat

- Function OverloadingDokumen4 halamanFunction OverloadingAnonymous E4Rbo2sBelum ada peringkat

- Cleve MolerDokumen2 halamanCleve MolerAnonymous E4Rbo2sBelum ada peringkat

- Eispack: DocumentationDokumen1 halamanEispack: DocumentationAnonymous E4Rbo2sBelum ada peringkat

- Cephalopod LimbDokumen9 halamanCephalopod LimbAnonymous E4Rbo2sBelum ada peringkat

- OHEDokumen8 halamanOHEMohammad Zakir50% (2)

- S18 Series Sensors (AC Voltage) DatasheetDokumen1 halamanS18 Series Sensors (AC Voltage) DatasheetPaulomario RemuzgoBelum ada peringkat

- Power Electronics 1Dokumen4 halamanPower Electronics 1Sai Shanker100% (1)

- Electron Diffraction TubeDokumen4 halamanElectron Diffraction TubeIch Habe KopfschmerzenBelum ada peringkat

- Datasheet Irlr2905Dokumen10 halamanDatasheet Irlr2905Alberto BritosBelum ada peringkat

- Ml12334a502 PDFDokumen5 halamanMl12334a502 PDFHitarthGohelBelum ada peringkat

- Definition of V-I Characteristics of SCRDokumen3 halamanDefinition of V-I Characteristics of SCRSukhpal SinghBelum ada peringkat

- Distribution System Protection EXAMDokumen14 halamanDistribution System Protection EXAMMark Ynothna Sincero TabunanBelum ada peringkat

- Electrical Drawings - R2 Detail Electrical Drawings - R2 Termination Details - R2Dokumen96 halamanElectrical Drawings - R2 Detail Electrical Drawings - R2 Termination Details - R2kumar gauravBelum ada peringkat

- RE7ML11BU TelemecaniqueDokumen22 halamanRE7ML11BU TelemecaniqueHugo FermartiBelum ada peringkat

- HR003-05 High Resistance Ground GdeDokumen28 halamanHR003-05 High Resistance Ground GderrrajaashokBelum ada peringkat

- 3RP1505-1BP30 DatasheetDokumen7 halaman3RP1505-1BP30 DatasheetAngel Dc HinostrozaBelum ada peringkat

- Datasheet S8050M D HY3D - C305482Dokumen6 halamanDatasheet S8050M D HY3D - C305482Mauricio ChirichignoBelum ada peringkat

- Item Description Quantity Spare Parts List For Outdoor UnitsDokumen3 halamanItem Description Quantity Spare Parts List For Outdoor UnitsJosephBelum ada peringkat

- EE 109 System ProtectionDokumen4 halamanEE 109 System ProtectionIan Acuzar PunzalanBelum ada peringkat

- Lab 3.1 Do It Yourself CapacitorDokumen2 halamanLab 3.1 Do It Yourself CapacitorJohn Mancia100% (1)

- Resin Insulators PPS PPQ BT PIAS PDFDokumen12 halamanResin Insulators PPS PPQ BT PIAS PDFJOSE DANIEL PEREZBelum ada peringkat

- Pro Of: Wye-Delta Winding Configuration For Brushless Operation of A Wound Field Synchronous MachineDokumen8 halamanPro Of: Wye-Delta Winding Configuration For Brushless Operation of A Wound Field Synchronous MachineAsif HussainBelum ada peringkat

- AEG AC Motor AMME 80Z BA2Dokumen14 halamanAEG AC Motor AMME 80Z BA2TonyBelum ada peringkat

- ZvsDokumen22 halamanZvsgopalchandramahatoBelum ada peringkat

- TNSCST-Student Project Scheme 1Dokumen6 halamanTNSCST-Student Project Scheme 1Maha Lakshmi100% (1)

- DP3L1-565 (IO) Open Loop Stepping Driver ManualDokumen18 halamanDP3L1-565 (IO) Open Loop Stepping Driver ManualNguyen QuanBelum ada peringkat

- 2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyDokumen12 halaman2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyAnonymous oKr1c2WBelum ada peringkat

- Raymond Service InformationDokumen3 halamanRaymond Service InformationPedro LopezBelum ada peringkat

- Eng. Umar CV12Dokumen6 halamanEng. Umar CV12Zeeshan YasinBelum ada peringkat

- KCGG 122 & 142 KCEG 112, 142, 152 & 242: Overcurrent ProtectionDokumen8 halamanKCGG 122 & 142 KCEG 112, 142, 152 & 242: Overcurrent ProtectionTSBelum ada peringkat

- Stolces J. 70 Years of Radio Tubes and Valves 2ed 1997 - Part1Dokumen20 halamanStolces J. 70 Years of Radio Tubes and Valves 2ed 1997 - Part1Anonymous 60esBJZIjBelum ada peringkat

- 78DXXL: Unisonic Technologies Co., LTDDokumen8 halaman78DXXL: Unisonic Technologies Co., LTDSlava VanatBelum ada peringkat

- Single Phase Semi ConverterDokumen18 halamanSingle Phase Semi Convertermohamed enanyBelum ada peringkat

- HVDC 60years PDFDokumen10 halamanHVDC 60years PDFAdrian FernandezBelum ada peringkat