Copper Clad Steel

Diunggah oleh

John Noya VergaraHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Copper Clad Steel

Diunggah oleh

John Noya VergaraHak Cipta:

Format Tersedia

Copperweld

Wire and strand HARD DRAWN

Wire

3-Wire Strand

7-Wire Strand

19-Wire Strand

Consisting of a copper cladding metallurgically bonded to a steel core, Copperweld CCS wire effectively combines

the strength of steel with the conductivity and corrosion resistance of copper. Standard copper cladding thicknesses result in a composite

conductivity of 30% or 40% IACS. Copperweld wire is available with two types of steel: a strong, high carbon, steel for the high-strength (HS)

and extra-high-strength (EHS) grades and a low carbon (LC) steel for special applications.

Copperweld strand is concentrically stranded cable of one or more layers with left-hand lay in the outer layer unless otherwise specified. In

any strand, the individual wires are of the same size.

Copperweld hard-drawn wire and strand offers tensile strengths from 80000 - 270000 psi [5625 - 18983 kgf/cm 2]. For applications requiring

greater flexibility, Copperweld wire and strand are also available in an annealed state.

NOTE: Properties noted in these data sheets are typical values for standard applications. If your application

requires performance values beyond those noted, please contact

Copperwelds Engineering Support Center at

engineering@copperweld.com or +1.615.377.4200. Material selection, varying composition and processing conditions all provide

flexibility in how Copperweld can deliver exactly the product you need. Bimetallic conductors from Copperweld offer many distinct advantages,

and our engineering team works in concert with our clients to determine the proper components for the stringent requirements of their products.

Specifications:

ASTM B-227 Hard Drawn Copper-Clad Steel Wire

ASTM B-228 Concentric-Lay-Stranded Copper-Clad Steel Conductors

Bare solid Copperweld wires, high strength and

extra high strength physical and electrical characteristics

(METRIC UNITS)

Min Breaking Loads (kgf)

Conductor

Size

AWG

Diameter

High Strength

(inch)

(mm)

40%

COND

0.3249

8.25

3065

Extra High

Strength

30%

COND

30%

COND

3174

4561

Weight (kg/km)

40%

COND

30%

COND

440.5

435.9

Nominal DC

Resistance

at 20oC (/km)

Cross Section

Area

40%

COND

30%

COND

(cmil)

(mm2)

0.8058

1.0744

105560

53.49

0.2893

7.35

2633

2835

4021

349.2

345.6

1.0164

1.3551

83694

42.41

0.2576

6.54

2225

2408

3326

276.9

274.0

1.2819

1.7092

66358

33.62

0.2294

5.83

1855

2001

2747

219.6

217.3

1.6164

2.1552

52624

26.67

0.2043

5.19

1558

1731

2056

174.2

172.3

2.0380

2.7174

41738

21.15

0.1819

4.62

1292

1430

1721

138.1

136.6

2.5709

3.4278

33088

16.77

0.1620

4.11

1070

1179

1429

109.5

108.4

3.2413

4.3217

26244

13.30

0.1443

3.67

885

972

1180

86.89

85.98

4.0852

5.4469

20822

10.55

0.1285

3.26

731

799

970

68.90

68.18

5.1516

6.8687

16512

8.37

0.1144

2.91

601

656

787

54.61

54.04

6.4997

8.6663

13087

6.63

10

0.1019

2.59

498

542

642

43.33

42.88

8.1921

10.923

10384

5.26

12

0.0808

2.05

273

274

408

27.24

26.96

13.029

17.373

6529

3.31

NOTE:

Coefficient of Linear Expansion: 1.3 x 10-5/oC

Temperature Coefficient of Resistance: 4.05 x 10-3/oC

Modulus of Elasticity: Wire, 165.5 GPa

C OPPERWELD WIRE AND STRAND H ARD DRAWN

www.copperweld.com

Bare solid Copperweld wires, high strength and

extra high strength physical and electrical characteristics

(METRIC UNITS)

Min Breaking Loads (kgf)

Conductor

Size

AWG

Diameter

High Strength

Weight (kg/km)

Extra High

Strength

30%

COND

30%

COND

40%

COND

30%

COND

(inch)

(mm)

40%

COND

13

0.0720

1.83

225

230

324

21.63

14

0.0641

1.63

186

182

257

15

0.0571

1.45

136

145

204

16

0.0508

1.29

112

114

17

0.0453

1.15

93

91

18

0.0403

1.02

77

19

0.0359

0.91

20

0.0320

0.81

21

0.0285

22

23

Nominal DC

Resistance

at 20oC (/km)

Cross

Section Area

40%

COND

30%

COND

(cmil)

(mm2)

21.41

16.41

21.88

5184

2.63

17.15

16.97

20.70

27.60

4109

2.08

13.60

13.46

26.09

34.79

3260

1.65

161

10.77

10.66

32.96

43.95

2581

1.31

128

8.563

8.473

41.45

55.27

2052

1.04

74

102

6.777

6.706

52.38

69.84

1624

0.82

60

59

81

5.378

5.322

66.00

88.00

1289

0.65

50

48

64

4.273

4.228

83.09

110.8

1024

0.52

0.72

40

36

70

3.389

3.354

104.7

139.6

812

0.41

0.0253

0.64

31

29

55

2.671

2.643

132.9

177.2

640

0.32

0.0226

0.57

25

23

45

2.131

2.109

166.5

222.1

511

0.26

Bare Copperweld stranded cable, high strength and extra high strength

physical and electrical characteristics

(METRIC UNITS)

Min Breaking Loads (kgf)

Conductor

Size

AWG

Diameter

High Strength

30%

COND

Extra High

Strength

30%

COND

Weight (kg/km)

40%

COND

30%

COND

(inch)

(mm)

40%

COND

19 No. 5

0.910

23.10

22098

24448

29436

2660

19 No. 6

0.810

20.57

18305

20167

24433

19 No. 7

0.722

18.33

15141

16614

20182

19 No. 8

0.643

16.32

12496

13667

16591

NOMINAL

DC Resistance

at 20oC (/km)

Cross

Section Area

40%

COND

30%

COND

(cmil)

(mm2)

2632

0.1372

0.1829

628665

318.55

2110

2088

0.1730

0.2306

498636

252.66

1674

1656

0.2180

0.2907

395627

200.47

1327

1314

0.2749

0.3666

313733

158.97

19-Wire Strand

19 No. 9

0.572

14.53

10285

11216

13465

1052

1041

0.3469

0.4625

248660

126.00

19 No. 10

0.510

12.94

8509

9269

10983

834.8

826.0

0.4372

0.5829

197289

99.97

7 No. 4

0.613

15.57

9816

10908

12951

1231

1218

0.2941

0.3921

292169

148.04

7 No. 5

0.546

13.86

8141

9007

10845

976.1

965.9

0.3709

0.4946

231613

117.36

7 No. 6

0.486

12.34

6744

7430

9002

774.2

766.1

0.4677

0.6236

183708

93.09

7 No. 7

0.433

11.00

5578

6121

7436

614.3

607.9

0.5894

0.7859

145757

73.86

7 No. 8

0.386

9.79

4604

5035

6112

487.1

482.0

0.7433

0.9911

115586

58.57

7-Wire Strand

7 No. 9

0.343

8.72

3789

4132

4961

386.1

382.1

0.9378

1.2504

91612

46.42

7 No. 10

0.306

7.76

3135

3415

4046

306.3

303.1

1.1820

1.5760

72685

36.83

7 No. 12

0.242

6.16

1717

1723

2572

192.6

190.6

1.8799

2.5066

45700

23.16

3-Wire Strand

3 No. 4

0.440

11.18

4441

4934

5859

526.7

521.2

0.6848

0.9130

125215

63.45

3 No. 5

0.392

9.96

3683

4075

4906

417.5

413.2

0.8638

1.1517

99263

50.30

3 No. 6

0.349

8.87

3051

3361

4072

331.2

327.7

1.0891

1.4521

78732

39.89

3 No. 7

0.311

7.90

2523

2769

3364

262.7

260.0

1.3726

1.8302

62467

31.65

3 No. 8

0.277

7.03

2083

2278

2765

208.4

206.2

1.7309

2.3079

49537

25.10

3 No. 9

0.247

6.26

1714

1869

2244

165.1

163.4

2.1839

2.9119

39262

19.89

3 No. 10

0.220

5.58

1418

1545

1831

131.0

129.7

2.7526

3.6701

31151

15.78

3 No. 12

0.174

4.42

777

780

1163

82.38

81.52

4.3779

5.8371

19586

9.92

Breaking load of 7-wire and 19-wire Copperweld strands are taken as 90% of the sum of the breaking

loads of the individual wires; breaking load of 3-wire Copperweld strand is taken as 95% of the sum of

the breaking loads of the individual wires used in the manufacturing of the strand.

NOTE:

Modulus of Elasticity: Strand, 158.6 GPa

Coefficient of Linear Expansion: 1.3 x 10-5/oC

Temperature Coefficient of Resistance: 4.05 x 10-3/oC

Bare solid Copperweld wires, high strength and

extra high strength physical and electrical characteristics

(US/IMPERIAL UNITS)

Min Breaking Loads (lbf)

Conductor

Size

AWG

Diameter

(inch)

High Strength

40%

COND

Extra High

Strength

30%

COND

30%

COND

Weight (lbs/kft)

40%

COND

30%

COND

Nominal DC

Resistance

at 68oF (/kft)

40%

COND

Cross

Section Area

30%

COND

(cmil)

(in2)

0.3249

6757

6998

10055

296.0

292.9

0.2456

0.3275

105560

0.08291

0.2893

5804

6250

8865

234.7

232.2

0.3098

0.4130

83694

0.06573

0.2576

4905

5309

7332

186.1

184.1

0.3907

0.5210

66358

0.05212

0.2294

4090

4411

6055

147.6

146.0

0.4927

0.6569

52624

0.04133

0.2043

3435

3817

4532

117.0

115.8

0.6212

0.8283

41738

0.03278

0.1819

2849

3152

3795

92.77

91.81

0.7836

1.0448

33088

0.02599

0.1620

2360

2600

3150

73.58

72.82

0.9879

1.3173

26244

0.02061

0.1443

1952

2142

2602

58.38

57.78

1.2452

1.6602

20822

0.01635

0.1285

1611

1762

2139

46.30

45.82

1.5702

2.0936

16512

0.01297

0.1144

1326

1446

1736

36.70

36.31

1.9811

2.6415

13087

0.01028

10

0.1019

1097

1195

1416

29.11

28.81

2.4970

3.3293

10384

0.00816

12

0.0808

601

603

900

18.31

18.11

3.9713

5.2951

6529

0.00513

13

0.0720

497

507

714

14.54

14.38

5.0014

6.6686

5184

0.00407

14

0.0641

410

402

566

11.52

11.40

6.3102

8.4136

4109

0.00323

15

0.0571

300

319

449

9.142

9.047

7.9522

10.603

3260

0.00256

16

0.0508

247

252

356

7.236

7.160

10.047

13.396

2581

0.00203

17

0.0453

205

201

283

5.754

5.694

12.635

16.846

2052

0.00161

18

0.0403

169

163

224

4.554

4.506

15.964

21.286

1624

0.00128

19

0.0359

133

129

178

3.614

3.576

20.117

26.823

1289

0.00101

20

0.0320

110

106

141

2.871

2.841

25.320

33.760

1024

0.00080

21

0.0285

88

79

154

2.277

2.254

31.921

42.561

812

0.00064

22

0.0253

69

63

121

1.795

1.776

40.506

54.008

640

0.00050

23

0.0226

55

50

99

1.432

1.417

50.763

67.684

511

0.00040

24

0.0201

46

40

79

1.133

1.121

64.175

85.567

404

0.00032

NOTE:

Coefficient of Linear Expansion: 7.2 x 10-6/oF

Temperature Coefficient of Resistance: 2.1 x 10-3/oF

Modulus of Elasticity: Wire, 24 x 106 psi

C OPPERWELD WIRE AND STRAND H ARD DRAWN

Bare Copperweld stranded cable, high strength and extra high strength

physical and electrical characteristics

(US/IMPERIAL UNITS)

Min Breaking Loads (lbf)

Conductor

Size

AWG

Diameter

(inch)

High Strength

40%

COND

30%

COND

Weight (lbs/kft)

Extra High

Strength

40%

COND

30%

COND

30%

COND

NOMINAL

DC Resistance

at 68oF (/kft)

Cross

Section Area

40%

COND

30%

COND

(cmil)

(in2)

19-Wire Strand

19 No. 5

0.910

48718

53899

64895

1787

1769

0.0418

0.0558

628665

0.4938

19 No. 6

0.810

40356

44460

53865

1418

1403

0.0527

0.0703

498636

0.3916

19 No. 7

0.722

33379

36628

44494

1125

1113

0.0665

0.0886

395627

0.3107

19 No. 8

0.643

27548

30130

36577

892.0

882.7

0.0838

0.1117

313733

0.2464

19 No. 9

0.572

22675

24727

29686

707.0

699.6

0.1057

0.1410

248660

0.1953

19 No. 10

0.510

18759

20435

24214

560.9

555.1

0.1333

0.1777

197289

0.1550

7-Wire Strand

7 No. 4

0.613

21641

24047

28552

827.4

818.8

0.0896

0.1195

292169

0.2295

7 No. 5

0.546

17949

19858

23909

655.9

649.1

0.1131

0.1507

231613

0.1819

7 No. 6

0.486

14868

16380

19845

520.2

514.8

0.1425

0.1901

183708

0.1443

7 No. 7

0.433

12298

13495

16393

412.8

408.5

0.1797

0.2395

145757

0.1145

7 No. 8

0.386

10149

11101

13476

327.3

323.9

0.2266

0.3021

115586

0.0908

7 No. 9

0.343

8354

9110

10937

259.4

256.7

0.2858

0.3811

91612

0.0720

7 No. 10

0.306

6911

7529

8921

205.8

203.7

0.3603

0.4804

72685

0.0571

7 No. 12

0.242

3786

3799

5670

129.4

128.1

0.5730

0.7640

45700

0.0359

3-Wire Strand

3 No. 4

0.440

9790

10878

12916

353.9

350.2

0.2087

0.2783

125215

0.0983

3 No. 5

0.392

8120

8983

10816

280.5

277.6

0.2633

0.3511

99263

0.0780

3 No. 6

0.349

6726

7410

8978

222.5

220.2

0.3319

0.4426

78732

0.0618

3 No. 7

0.311

5563

6105

7416

176.6

174.7

0.4184

0.5578

62467

0.0491

3 No. 8

0.277

4591

5022

6096

140.0

138.5

0.5276

0.7034

49537

0.0389

3 No. 9

0.247

3779

4121

4948

111.0

109.8

0.6657

0.8875

39262

0.0308

3 No. 10

0.220

3126

3406

4036

88.04

87.12

0.8390

1.1186

31151

0.0245

3 No. 12

0.174

1713

1719

2565

55.36

54.78

1.3344

1.7792

19586

0.0154

Breaking load of 7-wire and 19-wire Copperweld strands are taken as 90% of the sum of

the breaking loads of the individual wires; breaking load of 3-wire Copperweld strand is

taken as 95% of the sum of the breaking loads of the individual wires used in the manufacturing of the strand.

NOTE:

Modulus of Elasticity: Strand, 23 x 106 psi

Coefficient of Linear Expansion: 7.2 X 10-6/oF.

Temperature Coefficient of Resistance: 2.1 x 10-3/oF.

AMERICAS

Copperweld Bimetallics LLC Nashville, Tennessee +1.615.377.4200

EUROPE/NORTH AFRICA

Dynext SRL Milan, Italy +39.333.749.6906

SOUTHERN AFRICA

ARB Electrical Wholesalers Durban, South Africa +27.82.827.0110

NORTHEAST ASIA/PACIFIC

Fushi Copperweld Inc. Beijing, China +86.411.8778.7555

SOUTHEAST ASIA

Copperweld Bimetallics LLC Bangkok, Thailand +1.931.652.2440

MIDDLE EAST

Mishnan Holdings Dammam, Saudi Arabia +966.13.826.6626

ED5200

REV 01/10

Anda mungkin juga menyukai

- Solution Manual for 100 Genesys Design Examples: Second EditionDari EverandSolution Manual for 100 Genesys Design Examples: Second EditionBelum ada peringkat

- Copper Weld BrochureDokumen4 halamanCopper Weld Brochurefarfugliare100% (1)

- Swa Cables - Bs5467Dokumen4 halamanSwa Cables - Bs5467Dao Ming ElijordeBelum ada peringkat

- Power Cables & Wires Technical ManualDokumen163 halamanPower Cables & Wires Technical Manualbharatsehgal00@gmail.comBelum ada peringkat

- HUATONG ESP CableDokumen18 halamanHUATONG ESP CableSIMON S. FLORES G.100% (1)

- N2 XFGB YDokumen4 halamanN2 XFGB YRinda_RaynaBelum ada peringkat

- Weld Like a Pro: Beginning to Advanced TechniquesDari EverandWeld Like a Pro: Beginning to Advanced TechniquesPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Swa Cables - Bs5467Dokumen5 halamanSwa Cables - Bs5467IppiBelum ada peringkat

- N2XSYDokumen5 halamanN2XSYRinda_RaynaBelum ada peringkat

- N2XYDokumen5 halamanN2XYRinda_RaynaBelum ada peringkat

- Pipeline and Energy Plant Piping: Design and TechnologyDari EverandPipeline and Energy Plant Piping: Design and TechnologyPenilaian: 5 dari 5 bintang5/5 (2)

- Swa Cable - Bs6724Dokumen6 halamanSwa Cable - Bs6724adventure11111Belum ada peringkat

- Wiring AccessoriesDokumen56 halamanWiring AccessoriesKrizia De PeraltaBelum ada peringkat

- Bare Solid Soft Drawn Copper WireDokumen1 halamanBare Solid Soft Drawn Copper WirevkmsBelum ada peringkat

- BS7870-4.10 33kv Single Core Un ArmouredDokumen3 halamanBS7870-4.10 33kv Single Core Un Armouredrudypl100% (1)

- Acsr Astm B Aluminium Conductor Steel Reinforced PDFDokumen10 halamanAcsr Astm B Aluminium Conductor Steel Reinforced PDFyetignrBelum ada peringkat

- Walkway GratingDokumen2 halamanWalkway Gratingbijukoottala100% (1)

- Conductor Iec StandardDokumen34 halamanConductor Iec StandardWalter Cataldo100% (2)

- Conductores Copperweld PDFDokumen4 halamanConductores Copperweld PDFMiguel Ángel Díaz SepúlvedaBelum ada peringkat

- s011 Usa OPGW SST StandardDokumen2 halamans011 Usa OPGW SST StandardJoel PalomaresBelum ada peringkat

- Electrics CablesDokumen10 halamanElectrics CablesGerson FernandesBelum ada peringkat

- Cable OpgwDokumen6 halamanCable OpgwJose Cisneros ManchegoBelum ada peringkat

- 11kV 3 Core PILC SWA BS6480 Cable SpecificationDokumen3 halaman11kV 3 Core PILC SWA BS6480 Cable SpecificationMuhammad TaufiqBelum ada peringkat

- B835-14 Standard Specification For Compact Round Stranded Copper Conductors Using Single Input Wire ConstructionDokumen3 halamanB835-14 Standard Specification For Compact Round Stranded Copper Conductors Using Single Input Wire ConstructionislamakthamBelum ada peringkat

- Weight Conductor CableDokumen94 halamanWeight Conductor CablemehulrabariBelum ada peringkat

- LG Bus Duct System: Leader in Electrics & AutomationDokumen51 halamanLG Bus Duct System: Leader in Electrics & AutomationRajneesh KatochBelum ada peringkat

- Accr Conductor PropertiesDokumen8 halamanAccr Conductor Propertiesdeepu_erBelum ada peringkat

- 10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2Dokumen11 halaman10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2m3eenBelum ada peringkat

- CablesDokumen20 halamanCablesalejotoroBelum ada peringkat

- Cleat WiringDokumen8 halamanCleat WiringHaseeb NawazBelum ada peringkat

- According To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesDokumen10 halamanAccording To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesRaj KiranBelum ada peringkat

- Acsr SpecsDokumen1 halamanAcsr SpecsPanda NoirBelum ada peringkat

- JNC Cables PDFDokumen30 halamanJNC Cables PDFVasudev AgrawalBelum ada peringkat

- LSIS Bus Duct System CatalogDokumen52 halamanLSIS Bus Duct System CatalogedcooBelum ada peringkat

- 33kV 3 Core XLPE SWA Stranded Copper Conductor HV CableDokumen3 halaman33kV 3 Core XLPE SWA Stranded Copper Conductor HV Cableerkamlakar2234Belum ada peringkat

- RZ1-K Power CableDokumen5 halamanRZ1-K Power CablegarysBelum ada peringkat

- 9282Dokumen13 halaman9282Frank StephensBelum ada peringkat

- CopperClad Wire and StrandDokumen20 halamanCopperClad Wire and Strandpriyanka236Belum ada peringkat

- Compact Round Stranded Copper Conductors Using Single Input Wire ConstructionDokumen3 halamanCompact Round Stranded Copper Conductors Using Single Input Wire ConstructionSix RameshBelum ada peringkat

- ALCOA Bus Cond (6 AL Tube)Dokumen28 halamanALCOA Bus Cond (6 AL Tube)Sanj PandeyBelum ada peringkat

- 交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆Dokumen3 halaman交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆jiahuanhe2023Belum ada peringkat

- AccuRibbon LXE 126 WebDokumen4 halamanAccuRibbon LXE 126 Webbharatsehgal00Belum ada peringkat

- N2 XSEKFGb YDokumen5 halamanN2 XSEKFGb YRinda_RaynaBelum ada peringkat

- Bare Copper Ground Wire ConductorDokumen1 halamanBare Copper Ground Wire ConductorAvoor KhanBelum ada peringkat

- APSEA 2009 EngDokumen7 halamanAPSEA 2009 EngJesus VaraBelum ada peringkat

- Userfiles Catalogos Acsr ConductorsDokumen8 halamanUserfiles Catalogos Acsr ConductorsAlif Maulana FirdausBelum ada peringkat

- RPG Cable GlandsDokumen6 halamanRPG Cable GlandsAhamed AshithBelum ada peringkat

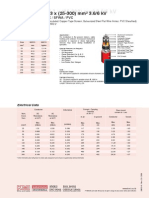

- Na2Xsefgby 3 X (25-300) MM 3.6/6 KVDokumen5 halamanNa2Xsefgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaBelum ada peringkat

- N2XSEBYDokumen5 halamanN2XSEBYRinda_RaynaBelum ada peringkat

- PC WireDokumen7 halamanPC Wirejupe01Belum ada peringkat

- 1 Core 33kv CC NewDokumen3 halaman1 Core 33kv CC NewAnandvikash SinghBelum ada peringkat

- Armor-X 600v (4) SouthwireDokumen3 halamanArmor-X 600v (4) SouthwireLuis RamirezBelum ada peringkat

- Furse Conductors SectionDokumen13 halamanFurse Conductors SectionAnil MarturiBelum ada peringkat

- Aluminum Alloy Introduction of Nari HuaishengDokumen16 halamanAluminum Alloy Introduction of Nari Huaishengmadhukarreddy2811Belum ada peringkat

- A-Fds-3g Datasheet Eng Glo Handbook FDS en 2022-07-11Dokumen94 halamanA-Fds-3g Datasheet Eng Glo Handbook FDS en 2022-07-11HamiltonmmBelum ada peringkat

- Keyseat Cutters Speeds and FeedsDokumen1 halamanKeyseat Cutters Speeds and FeedsdbaBelum ada peringkat

- E305 Metallurgy and Material Science Set1 1Dokumen2 halamanE305 Metallurgy and Material Science Set1 1NAGA16100% (1)

- Finite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsDokumen14 halamanFinite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsAhmet EcevitBelum ada peringkat

- NCR Log Sheet (CBPL)Dokumen6 halamanNCR Log Sheet (CBPL)lavekushBelum ada peringkat

- Astm C 864 - 05 (2015)Dokumen3 halamanAstm C 864 - 05 (2015)alexanderhdez100% (1)

- OPSS1213 Mar98Dokumen3 halamanOPSS1213 Mar98Tony ParkBelum ada peringkat

- Furse Conductor Network SectionDokumen21 halamanFurse Conductor Network SectionDoug WeirBelum ada peringkat

- F.2.6 Installation, Operating & Maintenance Manual MINITEK Impressed Current Hull Protection System 20 Amps SystemDokumen70 halamanF.2.6 Installation, Operating & Maintenance Manual MINITEK Impressed Current Hull Protection System 20 Amps Systembanda agungBelum ada peringkat

- CE312 Course Outline PDFDokumen22 halamanCE312 Course Outline PDFReynald Jhon SeratoBelum ada peringkat

- Electrodeposited Coatings of Copper Plus Nickel Plus Chromium and Nickel Plus ChromiumDokumen11 halamanElectrodeposited Coatings of Copper Plus Nickel Plus Chromium and Nickel Plus ChromiumPhúc ChâuBelum ada peringkat

- Techno Subh (S00480) - Vist 30 - LHDokumen5 halamanTechno Subh (S00480) - Vist 30 - LHSHAILESH PATELBelum ada peringkat

- T.Y. Lin International Pteltd. 1: Section: DefinitionDokumen6 halamanT.Y. Lin International Pteltd. 1: Section: DefinitionShishir Kumar NayakBelum ada peringkat

- Life Cycle Assessment of A Vaccine PatchDokumen1 halamanLife Cycle Assessment of A Vaccine Patchapi-375178431Belum ada peringkat

- Esr 2642Dokumen3 halamanEsr 2642Khin Sandi KoBelum ada peringkat

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDokumen2 halamanSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulBelum ada peringkat

- Cast Steel Grades ChartDokumen2 halamanCast Steel Grades ChartMajdi JerbiBelum ada peringkat

- Internship Report On RMCDokumen20 halamanInternship Report On RMCsampatharao.grnBelum ada peringkat

- Improvement in Properties of Porous Concrete Using FiberDokumen5 halamanImprovement in Properties of Porous Concrete Using FiberPawan Patidar0% (1)

- Sis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024Dokumen1 halamanSis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024GOWRIJEYASHANKAR S KBelum ada peringkat

- Fiche Tech - Freyssibar HSA en - v02Dokumen2 halamanFiche Tech - Freyssibar HSA en - v02Triệu Duy AnhBelum ada peringkat

- Experimental and Numerical Studies On The BehaviouDokumen13 halamanExperimental and Numerical Studies On The Behavioupradeep kankeriBelum ada peringkat

- Tubular Non Tubular AWS D1 1 PDFDokumen56 halamanTubular Non Tubular AWS D1 1 PDFRudy JakfBelum ada peringkat

- Ferrous and Non Ferrous MetalsDokumen4 halamanFerrous and Non Ferrous MetalsLyka Balacdao100% (1)

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseDokumen1 halamanCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseElwathig BakhietBelum ada peringkat

- Quality Control of Rebar Couplers in Splicing of Reinforcement BarsDokumen12 halamanQuality Control of Rebar Couplers in Splicing of Reinforcement BarsDong-Yong KimBelum ada peringkat

- PERMA E-622 ElectrodeDokumen1 halamanPERMA E-622 Electrodepedromiguel20Belum ada peringkat

- Experimental Study of Polypropylene Fiber-Reinforced ConcreteDokumen14 halamanExperimental Study of Polypropylene Fiber-Reinforced Concreteprajwal ursBelum ada peringkat

- Concrete TechnologyDokumen39 halamanConcrete Technologyazimkhtr@gmail.com100% (4)

- LEXAN HomogeniDokumen5 halamanLEXAN HomogeniKatarina CekovićBelum ada peringkat