Characterization of Chitin, Chitosan by DSC

Diunggah oleh

Geronimouzt LoverzHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Characterization of Chitin, Chitosan by DSC

Diunggah oleh

Geronimouzt LoverzHak Cipta:

Format Tersedia

Carbohydrate Polymers 49 (2002) 185193

www.elsevier.com/locate/carbpol

Characterization of chitin, chitosan and their carboxymethyl derivatives

by differential scanning calorimetry

F.S. Kittur a, K.V. Harish Prashanth a, K. Udaya Sankar b, R.N. Tharanathan a,*

a

Department of Biochemistry and Nutrition, Central Food Technological Research Institute, Mysore 570013, India

b

Department of Food Engineering, Central Food Technological Research Institute, Mysore 570013, India

Received 22 February 2001; revised 25 June 2001; accepted 3 August 2001

Abstract

Chitin, chitosan and their O,N-carboxymethyl derivatives were characterized by differential scanning calorimetry (DSC) mainly focusing

on changes in physical and chemical structures at different levels of acetyl and carboxymethyl contents. The thermograms were characterized

by endo- and exotherms corresponding to water evaporation and decomposition of the polymer, respectively. However, each endo- or

exothermic peak temperature and area changed as a function of primary and higher order structures of the macromolecule. It was found that

the enthalpy value for endotherm increased with increase in amino and carboxymethyl contents. Further, in the case of carboxymethyl

derivatives, no glass transition was observed despite the presence of substantial amount of amorphous content. During decomposition, the

decomposition peak temperature and area changed as a function of molecular weight (MW), acetyl and carboxymethyl contents. A

theoretical basis was adopted to correlate the heat of the reaction, DH, to the degree of deacetylation (%DD) and carboxymethylation

(DS). A good correlation was obtained when the corresponding peak area and peak height were plotted against %DD and DS. q 2002

Elsevier Science Ltd. All rights reserved.

Keywords: Chitin; Chitosan; Carboxymethyl derivatives; Differential scanning calorimetry; Enthalpy; Glass transition; Degree of deacetylation; Degree of

substitution

1. Introduction

Chitin is a natural polysaccharide found particularly in

the shells of crustaceans such as crab and shrimp, the

cuticles of insects, and the cell walls of fungi. It is one of

the most abundant biopolymers next to cellulose. Chitin is

substantially composed of 2-acetamido-2-deoxy-d-glucopyranose (N-acetyl-d-glucosamine, GlcNAc) units linked

by b-(1,4-) linkage. Chitosan obtained from chitin, mainly

by N-deacetylation with an alkaline treatment is chiey

composed of 2-amino-2-deoxy-d-glucopyranose (d-glucosamine, GlcN) units. Chitin/chitosan and their carboxymethyl derivatives have received much attention in the

recent decades for their special properties (Nishimura,

Nishi & Tokura, 1986; Sandford, 1989) and inexpensive,

abundant resources. It is well known that some of the

structural characteristics such as degree of acetylation

(DA), degree of substitution (DS) and molecular weight

(MW) of chitin/chitosan and their derivatives greatly inuence various properties such as solubility, physiological

* Corresponding author.

E-mail address: tharanathan@yahoo.co.uk (R.N. Tharanathan).

activities (Hirano & Nagano, 1989; Kendra, Christian &

Hadwiger, 1989; Suzuki, Watanabe, Mikami & Suzuki,

1990), chemical reactivity and biodegradability.

Invariably chemical (Muzzarelli, Tanfani, Emanuelli &

Mariotti, 1982; Pangburn, Trescony & Heller, 1984),

chromatographic (Niola, Basora, Chornet & Vidal, 1993;

Sato, Mizutani, Tsuge, Ohtani, Aoi, Tak-asu et al., 1998)

and spectroscopic (Aiba, 1986; Moore & Roberts, 1980;

Varum, Anthonsen, Grasdalen & Smidsord, 1991) methods

are used to study structures of these polymers. Thermal

methods, such as thermogravimetry (TGA), differential

scanning calorimetry (DSC) and differential thermal

analysis (DTA) have emerged as powerful thermoanalytical

techniques to monitor characteristic physical and chemical

changes in both natural and synthetic polymers. These

methods yield curves that are unique for a particular composition of matter and even slight changes in chemical structure and composition or molecular architecture will bring

about discrete and reproducible variations in the thermograms. Further, some of these changes involve the loss of

material in volatilization which can be quantitatively

measured by TGA.

In fact DSC is ideally suited for rapid screening and nger

0144-8617/02/$ - see front matter q 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0144-861 7(01)00320-4

186

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

printing purpose of materials, in solid state, as a function of

temperature. Miyashita, Kobayashi, Kimura, Suzuki and

Nishio (1997), studied the transition behavior and phase

structure of chitin/poly (2-hydroxyethyl methacrylate)

composites by DSC. The effect of N,O-carboxymethyl

chitosan on phase behavior of chitosan/viscose rayon blends

was studied by Yunlin, Liu, Fu, Li and Ya (1998). A survey

of recent literature shows that thermal methods have been

rarely used for monitoring the chemical and physical

changes during various modications of chitin and chitosan.

In the present work the feasibility of using DSC for such

studies is further explored.

2. Materials and methods

2.1. Preparation of chitosan samples

Chitosan samples (chitosan AE) were prepared through

heterogeneous alkaline deacetylation of shrimp chitin to

different degrees. Chitosan D and E were further puried

by dissolving in 1% aqueous acetic acid followed by ltration to remove insoluble material. The soluble chitosan was

precipitated with 1 N sodium hydroxide, washed thoroughly

with double distilled water and lyophilized. Chitosans with

different MW but of same acetyl content were prepared by

enzymatic hydrolysis using A.niger pectinase. The viscosity

average MW of the chitosan was calculated by the MarkHouwink equation; h Km M a ; where Km 3:5 1024 ;

a 0:76 (Rinaudo, Milas & Ledung, 1993).

2.2. Preparation of carboxymethyl derivatives of chitin and

chitosan

Carboxymethyl chitin was prepared by the method of

Tokura, Nishi, Tsutsumi and Somarin (1983), O-carboxymethyl chitosan was prepared by N-deacetylating carboxymethyl chitin in aqueous 10% sodium hydroxide containing

sodium borohydride (0.1%) for 10 h at 808C (Hirano, Hayashi & Hirochi, 1992).

2.3. Preparation of N,O-carboxymethyl chitosan

To a chitosan (5 g) suspension in 50 ml isopropanol,

13 ml of 10 M sodium hydroxide was added in six equal

portions over a period of 20 min under agitation. The alkaline slurry was stirred for an additional 45 min. Different

amounts of monochloroacetic acid were added to achieve

different degrees of substitution. The reaction mixture was

heated at 608C for 2 h, cold distilled water (5 ml) was added

and its pH was adjusted to 7.0 with glacial acetic acid. The

reaction mixture was ltered and the solid N,O-carboxymethyl derivative was washed with 70% methanol, and

dried in an oven at 608C (Hayes, 1986). The derivatives

were puried by dissolving in water to remove insolubles

(scarcely substituted product), ltered, dialyzed against

double distilled water and lyophilized.

2.4. Infrared spectroscopy

IR spectra were recorded in KBr discs on a Impact 410

Nicolet FTIR spectrometer under dry air at room temperature. Degree of acetylation (%DA) of chitosans was determined following the method of Miya, Iwamoto, Yoshikawa

and Mima (1980) and degree of carboxymethylation (DS)

was determined from the ratio of the absorbencies at 1418

and 1312 cm 21 (Nahalka, Nahalkova, Gemeiner &

Blanarik, 1998). Degree of deacetylation (%DD) was

computed from %DA.

2.5. High performance size exclusion chromatography

(HPSEC)

This was performed on Shimadzu HIC-6A system

controller and CR-YA Chromatopack integrator units, tted

with columns E-linear and E-1000 m-Bondapack

(30 cm 3.9 mm, i.d.) and an RI detector connected in

series with a guard column. The columns were eluted with

distilled water at a ow rate of 1.0 ml min 21. The operating

temperature was 278C and the injection volume was 10.0 ml.

The MW of carboxymethyl derivatives of chitosan was

determined from a calibration curve (plot of log MW versus

retention time) prepared for standard dextrans (T-10 to

T-2000) of known MW.

2.6. X-ray Diffractometry

Powder X-ray diffraction patterns were obtained by using

a EG-7G solid state Germanium liquid nitrogen cooled

detector Scintag XDS-2000 instrument equipped with a

u u goniometer, with the following operating conditions:

30 kV and 25 mA with a CuKa radiation at 1.54184 nm.

The relative intensity was recorded in scattering range

(2u ) of 4608. The crystallinity index (CrI) was determined

as per the method of Struszezyk (1987).

2.7. Differential scanning calorimetry

This was carried out using a Rheometric Scientic (UK)

equipment using thermal software version 5.42 supported

on Compaq computer and calibrated as per the standard

procedures. The equipment was provided with an autocool

accessory for the programmed cooling. Accurately weighed

(5 mg) material was placed into aluminium cup and sealed.

An empty cup was used as reference and runs were

performed at least in triplicate and the average mean values

are given. The experiment consisted of two separate series,

one heating the samples from 505508C and the other in the

temperature range 32208C. In the latter case, the samples

were heated upto 2208C, cooled to 38C followed by immediate rescanning in the same temperature range. For each

series, two separate pans of the same sample were prepared

and analyzed under continous ow of dry nitrogen gas

(10 ml min 21) at a heating rate of 208C min 21.

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

187

Fig. 2. DSC thermograms of (a) O-carboxymethyl chitin, (b) O-carboxymethyl chitosan, (c) N,O-carboxymethyl chitosan.

Fig. 1. DSC thermograms of (a) chitin, (b) chitosan-A %DD 25; (c)

chitosan-B %DD 48; (d) chitosan-C %DD 79; (e) chitosan-D

%DD 84 and (f) chitosan-E %DD 89:

3. Results and discussion

Figs. 1 and 2 show the transitions detected in the thermograms of chitin, chitosan and their carboxymethyl derivatives. The rst thermal event (series 1) registered in all

samples was a wide endothermic peak centred between

1251508C with an onset at 901088C. The minimum

amount of the polysaccharide required to detect this

endothermic peak varied considerably. In the case of

carboxymethyl derivatives, a minimum of 2 mg of material

was needed to detect this transition, which was related to the

evaporation of water present in the sample. Values for the

transition temperatures and their associated enthalpies are

given in Table 1. Heating of the samples up to 2208C

followed by a immediate second run in the same temperature range (series 2) yielded a thermogram with a reduced

peak area (Fig. 3), supporting the view that water evaporation occurred during the rst DSC scan.

The loss in weight (,15%) was conrmed by weighing

the cups before and after the DSC runs. Moisture release

during heating of the polymer material equilibrated over

P2O5 suggests that the samples were not truely `anhydrous'

and that some bound water was not completely removed

during drying in the desiccator. It is suggested that desiccators be evacuated to accomplish faster and complete

removal of water. The onset of endothermic peak should

be related to pressure build up because of water evaporation

inside the cups. The pressure at which the seams of the cup

started to leak can be estimated ,2.0 bar, which corresponds to approximate vapour pressure of water.

Polysaccharides usually have a strong afnity for water,

and in the solid state these macromolecules may have disordered structures which can be easily hydrated. As is known,

the hydration properties of these polysaccharides depend on

the primary and supramolecular structures (Kacurakova,

Belton, Hirsch & Ebringerova, 1998; Phillips, Takigami &

Takigami, 1996). Therefore, the endotherm related to the

evaporation of water is expected to reect physical and

molecular changes during N-deacetylation and carboxymethylation. Close examination of thermograms in Figs. 1

and 2 (and Table 1) reveals that there are differences in the

peak area and position of peak temperature of endotherm,

indicating that these macromolecules differ in their water

holding capacity and strength of water-polymer interaction.

In the case of chitin and its N-deacetylated analogs (Fig. 1),

the endothermic peak area increased with increase in Ndeacetylation. A similar behavior was also observed in the

case of N,O-carboxymethyl chitosan when the DS was

increased from 01.27 (results not shown). O- and Ncarboxymethyl derivatives of chitin and chitosan showed

higher DH values than chitosans (Table 1). The fact that

the DH increased with increase in N-deacetylation and

carboxymethylation indicates that a denite correlation

exists between the water holding capacity and chemical

and supramolecular structures of these polymers. In chitin,

the initial water molecules are associated with hydrophilic

hydroxyl groups. As the deacetylation and carboxymethylation proceeds, the newly created hydrophilic centres, i.e.

188

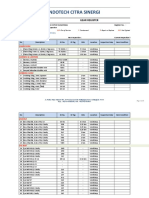

Polymer

Chitin

Chitosan-A

Chitosan-B

Chitosan-C

Chitosan-D

Chitosan-E

O-carboxymethyl chitin

O-carboxymethyl chitosan

N,O-carboxymethyl chitosan

a

Endotherm (8C)

Exotherm I (8C)

Exotherm II (8C)

To a

Tp a

Tc a

DH a (mJ mg 21) To a

Tp a

Tc a

DH a (mJ mg 21) To a

Tp a

Tc a

DH a (mJ mg 21)

96:1 ^ 0:1

98:8 ^ 0:1

95:7 ^ 0:1

108:6 ^ 0:0

94:5 ^ 0:1

100:2 ^ 0:0

102:8 ^ 0:1

81:6 ^ 0:0

94:0 ^ 0:1

139:0 ^ 0:1

125:1 ^ 0:1

140:8 ^ 0:1

144:6 ^ 0:1

143:7 ^ 0:0

146:2 ^ 0:0

164:7 ^ 0:1

134:8 ^ 0:1

126:3 ^ 0:1

204:8 ^ 0:1

164:1 ^ 0:1

199:0 ^ 0:0

200:4 ^ 0:1

204:5 ^ 0:1

193:1 ^ 0:1

207:5 ^ 0:1

201:4 ^ 0:0

200:1 ^ 0:1

158:3 ^ 0:1

160:8 ^ 0:1

187:7 ^ 0:0

200:0 ^ 0:0

218:9 ^ 0:1

232:6 ^ 0:0

335:1 ^ 0:1

405:3 ^ 0:1

280:1 ^ 0:1

397:0 ^ 1:1

425:5 ^ 0:0

313:7 ^ 0:0

314:1 ^ 0:1

311:1 ^ 0:1

302:5 ^ 0:0

251:7 ^ 0:1

302:7 ^ 0:1

283:3 ^ 0:1

414:2 ^ 0:2

453:5 ^ 0:1

337:5 ^ 0:0

338:4 ^ 0:1

338:1 ^ 0:1

333:1 ^ 0:1

281:6 ^ 0:0

333:0 ^ 0:0

372:0 ^ 0:1

225:7 ^ 0:2

251:9 ^ 0:1

275:9 ^ 0:1

2135:1 ^ 0:1

2150:0 ^ 0:3

2170:2 ^ :03

266:0 ^ 0:9

2157:5 ^ 0:1

2235:0 ^ 0:0

313:3 ^ 0:1

407:3 ^ 0:0

436:1 ^ 0:1

172:8 ^ 0:3

The values presented are average of three experiments with standard deviation.

350:7 ^ 0:6

406:3 ^ 0:1

291:8 ^ 0:0

294:5 ^ 0:1

284:4 ^ 0:1

256:1 ^ 0:0

217:5 ^ 0:1

266:7 ^ 0:0

259:3 ^ 0:1

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

Table 1

Thermal transitions of chitin, chitosan and their carboxymethyl derivatives (To, onset temperature, Tp peak temperature Tc completion temperature, DH enthalpy,-not detected)

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

189

Fig. 3. Second run DSC curves of (a) chitin, (b) chitosan, (c) O-carboxymethyl chitin, (d) O-carboxymethyl chitosan, (e) N,O-carboxymethyl chitosan.

Fig. 4. DSC thermograms of chitosans with same acetyl content but with

different molecular weights. Curve a (native chitosan, MW, 95,000), curve

b (depolymerized chitosan, MW, 30,000), curve c (deploymerized chitosan,

MW, 8000).

amine and carboxymethyl groups in the polysaccharide

chain bind more number of water molecules and hence

increase the content of bound water. Furthermore, the

decrease in ordered structure due to chemical modication

may contribute signicantly towards increase in the content

of sorbed water.

Penetration of alkali into the chitin crystallites with the

cleavage of acetyl groups conceivably modies the initial

order and chemical structure of chitin macromolecule.

Ottoy, Varum and Smidsrod (1996) observed this on chitosans prepared under heterogeneous conditions. They

related the broadening of CP MAS- 13C-NMR signal to the

presence of amorphous regions. Carboxymethylation is also

expected to reduce the crystallinity of chitin and chitosans

as it involves drastic reaction conditions. We conrmed the

above hypothesis by X-ray diffractometry and IR spectroscopy. Chitosan A (Fig. 1, curve b) showed a %DD of 25%

and CrI of 70. On the other hand chitosans B, C, D and E

(Fig. 1, curves c,d, e and f) indicated %DD of 48, 79, 84, and

89 and CrI of 65, 60,54 and 45, respectively. In the case of

carboxymethyl derivatives, X-ray diffractometry indicated a

drastic decrease in crystallinity upon carboxymethylation.

CrI values for O-carboxymethyl chitin, O-carboxymethyl

chitosan and N,O-carboxymethyl chitosan were 33, 19 and

22, whereas the DS values were 0.7, 0.7 and 1.27, respectively (Fig. 2). On the basis of these results it can be deduced

that, the increase in the content of polar groups together with

increase in amorphous region, causes an increase in the

water holding capacity upon N-deacetylation and carboxymethylation.

Fig. 3 shows the second heating scans after quenching the

initially heated samples with liquid N2. The temperature

range of 32208C was selected for two reasons; 1) to

avoid endothermic signal related to the melting of frozen

water around 08C and 2) to limit the possible sample degradation due to decomposition. As can be seen from the

thermograms, a broad endothermic peak with Tp occurring

around 1758C reappeared. This transition can be considered

as due to re-evaporation into free state of bound water associated with the hydrophilic groups in the macromolecular

chain. As is known, higher temperature forces both sorbed

and rmly bound water into the free state away from the

inuence of polymer network. On cooling, a part of it

reverts back to bound state. This state of water, i.e. nonfreezing bound water, has been shown to remain relatively a

constant event after successive cycles of heating and cooling

(Kacurakova et al., 1998).

Appelqvist, Cooke and Gidley (1993) and Gidley and

Bociek (1988) reported an endothermic peak in the range

50708C for a range of polysaccharides at a moisture level

between 5 and 25%, which they attributed to enthalpic association between water and carbohydrate. However, the

current consensus for the structural origin of this endotherm

has been shown to favor an enthalpy relaxation (Livings,

Breach, Donald & Smith, 1997), a common feature of physical ageing of many synthetic polymers and their blends

(Berens & Hodge, 1982; Hodge & Berens, 1982). In the

present study, the origin of an endotherm due to enthalpy

relaxation seems very unlikely since, P2O5 drying of the

samples impedes relaxation process and weight loss

190

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

Fig. 5. (a) Correlation of DSC peak height with %DD of chitosan. (b) Correlation of DSC peak area with %DD of chitosan.

observed during the rst scan reects a mechanism other

than enthalpy relaxation.

No glass transition (Tg) was observed in the second heating scans of chitin, chitosan and their carboxymethyl derivatives. Concerning the Tg of chitin and chitosan, it has been

predicted previously to be latent in the decomposition

temperature .2308C (Jiang, Su, Caracci, Bunning, Cooper

& Adams, 1999), as in the case of cellulose. However, in the

thermogram of chitin (curve a) shown in Fig. 3, there

appears a gradual change in the slope of the curve in the

neighbourhood of 1258C, just before the endotherm. This

transition, however, appeared below 1208C for carboxymethyl chitin (Fig. 3, curve c). The origin of this transition

was interpreted due to local relaxation of the backbone

chain of chitin (Pizzoli, Ceccorulli & Scandola, 1991) and

not due to Tg. The size of the step change in specic heat

(Cp) in the thermogram depends on the fraction of amorphous phase present. In the case of carboxymethyl derivatives as discussed previously, a substantial amount of

amorphous phase is already present. This, therefore, in

theory, should exhibit a clear Tg. However, the present

studies showed no evidence in favor of Tg; the DSC

measurements showed no stepwise increase in specic

heat, suggesting that the Tg value of carboxymethyl derivatives probably lies at rather higher temperature, where

degradation prevents its determination.

The second main thermal event registered for these polysaccharides (Figs. 1 and 2) was a wide exothermic peak

when heated between 50 and 5508C, whose area was used

to express the overall exothermic effect connected with

decomposition, DH. Due to differences in chemical and

structural characteristics, remarkable differences in the

exothermic transitions in chitin and chitosan were observed

(Fig. 1). The exothermic peak in chitin and chitosan A (Fig.

1, curve a and b) occurring in the range 3904308C was

shifted to lower temperature concomitantly with an increase

in peak area with increase in N-deacetylation. Such a shift to

lower temperature was attributed to a decrease in thermal

stability as a consequence of decreased acetyl content and

degree of polymerization (dp). De-N-acetylation of chitin

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

191

Fig. 7. DSC thermograms of N,O-carboxymethyl chitosans (a) DS,0.22 (b)

DS,0.55 (c) DS,1.10 (d) DS,1.27.

Fig. 6. Infrared spectra of N,O-carboxymethyl chitosan (a) DS,0.22 (b)

DS,0.55 (c) DS,1.10 (d) DS,1.27.

under alkaline conditions causes substantial depolymerization due to glycosidic bond cleavage as a result of `peeling'

reaction. Therefore, it is reasonable to assume that a

decrease in dp could also lead to decrease in thermal stability. This was further conrmed by analysis of chitosans

with the same acetyl content but with different MW values.

Chitinases, chitosanases and their related enzymes catalyze

the cleavage of only the glycosidic bond keeping the acetyl

groups intact. Therefore, the products of enzymatic hydrolysis essentially differ with respect to their MW. Fig. 4

shows the DSC thermograms for native and enzyme depolymerized chitosans. As can be seen, DSC curves are

progressively shifted to lower temperature with decrease

in MW. Curve a (native chitosan, Tp 3228C) was shifted

to 3208C with decrease in MW from 95,000 to 30,000 Da

(curve b). The shift was, however, more signicant in the

case of chitosan with a MW 8000 Da (curve c, Tp 3128C).

In brief it is concluded that the decomposition peak

temperature (Tp) decreases with decrease in acetyl content

and dp.

The observed lower DH value for decomposition of chitin

(highly crystalline) suggests that the decomposition efciency might be different from its N-deacetylated analogues,

because of differences in the mechanism of cleavage of Nacetyl groups. The increase in DH upon deacetylation, therefore, should reect a different mechanism for the chitosan

due to the presence of free unsubstituted amine groups. With

this in mind, it was decided to investigate if there is any

relationship between DH and DA. A theoretical basis

proposed by Chatterjee and Schwenker (1972), that relates

the heat of reaction, DH, of an endothermic or exothermic

peak generated by the thermal response of the substituent

group to DS was adopted. The values of peak height and

area when plotted against %DD, good correlation coefcients R 2 of 0.99 and 0.97, respectively (Fig. 5a and b)

were observed. From the Fig. 5a and b, the relationship

between DH and %DD given by Chatterjee and Schwenker

(1972) is proven to be true and helped to deduce %DD from

the DSC data.

Fig. 2 shows the thermal transitions for O- and N- carboxymethyl derivatives of chitin and chitosan. In each case a well

dened new peak appeared, consistent with backbone cleavage, which in some way may also involve simple cleavage

of substituent groups. Curve a (carboxymethyl chitin)

exhibited exotherms at 2508C and 4078C, in addition to a

small exotherm observed in chitin (curve a, Fig. 1). The

exotherm at lower temperature can be attributed to decomposition of highly substituted regions in the polysaccharide.

Conversion of carboxymethyl chitin to carboxymethyl chitosan (curve b) resulted in the disappearance of both high and

low temperature exotherms, and a new peak appeared in the

temperature range of 2703008C. Since the carboxymethyl

groups are stable under the conditions of alkaline deacetylation, the shift of decomposition peak to lower temperature

can be attributed to decrease in acetyl content and dp during

deacetylation, as discussed previously. This was further

conrmed by HPSEC, which indicated a relative MW of

12 105 and 7:9 105 Da for carboxymethyl derivatives

of chitin and chitosan, respectively. The thermograms of

192

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

Fig. 8. (a) Correlation of DSC peak height with DS of N,O-carboxymethyl chitosan. (b) Correlation of DSC peak area with DS of N,O-carboxymethyl chitosan.

O-carboxymethyl and N,O-carboxymethyl chitosans were

similar, except for the decomposition which appeared at

lower temperature. Nonetheless, each curve was distinctly

and measurably different from the base curve (Fig. 1, curves

a and b) so that their unequivocal identication was assured.

It was decided to study the effect of carboxymethylation

on chitosan and to determine the relationship between peak

area and peak height wiith DS. N,O-Carboxymethyl chitosan was selected because of ease of preparation with high

DS value. Fig. 6 shows the FTIR spectra for the variously

carboxymethylated chitosans. As can be seen, the intensity

of the band at 1735 cm 21 (COOH) increased with increase

in carboxymethylation. Fig. 7 shows the representative DSC

curves for N,O-carboxymethyl chitosans with DS 0:22;

0.55, 1.10 and 1.27. A new exothermic peak, Tp in the

range 2803008C was observed which was generated during

earlier stages of chitosan decomposition, overlapping with

the actual chitosan decomposition peak Tp 3168C: In

order to determine the peak area, it was necessary to extra-

polate the high temperature side back to the baseline and to

measure the area thus enclosed. At higher DS value, the area

became fully resolved. Also an increase in carboxymethylation led to an increase in DH. These differences indicate

different mechanisms of chitosan decomposition taking

place in the presence of carboxymethyl groups. Additionally, a plasticizing action is also envisaged for carboxymethyl group (Biliaderis, 1982).

Fig. 8a and b show the calibration curves obtained by

plotting the peak area and peak height versus DS of N,Ocarboxymethyl chitosan. A linear regression coefcient R 2

of 0.99, a slope of 139.5 and a Y-intercept of 63.2 was obtained

based on peak area. On the other hand, when the peak height

was used, the corresponding linear regression coefcient,

slope and Y-intercept were 0.99, 3.48 and 0.49, respectively.

Thus, both the height and area appear to be parameters to

measure and correlate the DS. These results indicate that the

DS of any sample can be determined from the DSC data using

the calibration curves shown in Fig. 8a and b.

F.S. Kittur et al. / Carbohydrate Polymers 49 (2002) 185193

4. Conclusions

DSC was demonstrated to be an effective technique to

evaluate the process of N-deacetylation and carboxymethylation. The thermal transitions for chitin, chitosan and their

carboxymethyl derivatives took place in two stages reecting changes in both chemical and physical structures.

During decomposition stage, a decomposition peak

characteristic of a modied chitin and chitosan appeared

as a function of MW, acetyl and carboxymethyl contents.

Furthermore, in the case of chitin and N,O-carboxymethyl

chitosan, DH value increased with increase in amine and

carboxymethyl contents. The relationship between DH and

DS was proved to be true. Fig. 5a and b and Fig. 8a and b

showed how well the peak parameters correlate with DS. It

is possible that the %DD/DS of chitosan and N,O-carboxymethyl chitosan of any acetyl/carboxymethyl content can

be obtained by this relationship, showing DH to be a good

measure to determine the former.

Acknowledgements

We acknowledge and thank Prof. S. Subramanian (Indian

Institute of Science, Bangalore, India) for obtaining the Xray diffraction patterns. FSK thanks the Council of Scientic and Industrial Research, New Delhi, India, for a Senior

Research Fellowship.

References

Aiba, S. (1986). International Journal of Biological Macromolecules, 8,

173176.

Appelqvist, I. A. M., Cooke, D., & Gidley, M. J. (1993). Carbohydrate

Polymers, 20, 291299.

Berens, A. R., & Hodge, I. M. (1982). Macromolecules, 15, 756761.

Biliaderis, C. G. (1982). Journal of Agricultural and Food Chemistry, 30,

925930.

Chatterjee, P. K., & Schwenker, R. F. (1972). TAPPI, 55, 111115.

Gidley, M. J., & Bociek, S. M. (1988). Journal of American Chemical

Society, 110, 38203829.

Hayes E. R. (1986). USPatent No. 4,619,995.

Hirano, S., & Nagano, N. (1989). Agricultural and Biological Chemistry,

53, 30653069.

193

Hirano, S., Hayashi, K., & Hirochi, K. (1992). Carbohydrate Research,

225, 175178.

Hodge, I. M., & Berens, A. R. (1982). Macromolecules, 15, 762770.

Jiang, H., Su, W., Caracci, S., Bunning, J., Cooper, T., & Adams, W.

(1999). Journal of Applied Polymer Science, 61, 11631171.

Kacurakova, M., Belton, P. S., Hirsch, J., & Ebringerova, A. (1998). Journal of the Science of Food and Agriculture, 77, 3844.

Kendra, D. F., Christian, D., & Hadwiger, L. A. (1989). Physiology and

Molecular Plant Pathology, 35, 215230.

Livings, S. J., Breach, C., Donald, A. M., & Smith, A. C. (1997). Carbohydrate Polymers, 34, 347355.

Miya, M., Iwamoto, R., Yoshikawa, S., & Mima, S. (1980). International

Journal of Biological Macromolecules, 2, 323325.

Miyashita, Y., Kobayashi, R., Kimura, N., Suzuki, H., & Nishio, Y. (1997).

Carbohydrate Polymers, 34, 221228.

Moore, G. K., & Roberts, G. A. F. (1980). International Journal of Biological Macromolecules, 2, 115116.

Muzzarelli, R. A. A., Tanfani, F., Emanuelli, M., & Mariotti, S. (1982).

Carbohydrate Research, 107, 199215.

Nahalka, J., Nahalkova, J., Gemeiner, P., & Blanarik, P. (1998). Biotechnology Letters, 20, 841845.

Niola, F., Basora, N., Chornet, E., & Vidal, P. F. (1993). Carbohydrate

Research, 238, 19.

Nishimura, S., Nishi, N., & Tokura, S. (1986). Carbohydrate Research,

146, 251258.

Ottoy, M. H., Varum, K. M., & Smidsrod, O. (1996). Carbohydrate Polymers, 29, 1724.

Pangburn, S. H., Trescony, P. V., & Heller, J. (1984). In J. P. Zikakis,

Chitin, chitosan and related enzymes (pp. 39). New York: Academic

Press.

Phillips, G. O., Takigami, S., & Takigami, M. (1996). Food Hydrocolloids,

10, 1119.

Pizzoli, M., Ceccorulli, G., & Scandola, M. (1991). Carbohydrate

Research, 222, 205213.

Rinaudo, M., Milas, M., & Ledung, P. (1993). International Journal of

Biological Macromolecules, 15, 281284.

Sandford, P. A. (1989). In G. Sjak-Braek, T. Anthonsen & P. Sandford,

Chitin and chitosan, London: Elsevier Applied Science pp. 5169.

Sato, H., Mizutani, S., Tsuge, S., Ohtani, H., Aoi, K., Tak-asu, A., Okada,

M., Kobayashi, S., Kiyosada, T, & Shoda, S. (1998). Analytical Chemistry, 70, 712.

Struszezyk, H. (1987). Journal of Applied Polymer Science, 33, 177179.

Suzuki S., Watanabe T., Mikami T. & Suzuki M. (1990). Proceedings of the

5th International Conference on Chitin and Chitosan, USA, pp. 96105.

Tokura, S., Nishi, N., Tsutsumi, A., & Somarin, O. (1983). Polymer Journal

(Tokyo), 15, 485489.

Varum, K. M., Anthonsen, M. W., Grasdalen, H., & Smidsord, O. (1991).

Carbohydrate Research, 217, 1927.

Yunlin, G., Liu, X., Fu, Q., Li, Z., & Ya, K. (1998). Carbohydrate

Polymers, 36, 6166.

All in-text references underlined in blue are linked to publications on ResearchGate, letting you access and read them immediately.

Anda mungkin juga menyukai

- Cutting Aws C5.3 2000 R2011Dokumen33 halamanCutting Aws C5.3 2000 R2011Serkan AkşanlıBelum ada peringkat

- Perkins - General Ti BulletinDokumen65 halamanPerkins - General Ti BulletinUTEL CARTERBelum ada peringkat

- Gaara Hiden Series Light NovelDokumen127 halamanGaara Hiden Series Light NovelartfardadBelum ada peringkat

- A705F Schematic Circuit Diagram HALABTECHDokumen11 halamanA705F Schematic Circuit Diagram HALABTECHbcscneg0% (1)

- Transient Thermal Conduction ExampleDokumen14 halamanTransient Thermal Conduction ExampleDevendra BangarBelum ada peringkat

- Gravitational Fields 1Dokumen18 halamanGravitational Fields 1Smart linkBelum ada peringkat

- ButadineDokumen68 halamanButadineraihonaBelum ada peringkat

- Storage Tank Design Calculation - Api 650: Close Floating RoofDokumen32 halamanStorage Tank Design Calculation - Api 650: Close Floating RoofhgagBelum ada peringkat

- DPL MDDokumen3 halamanDPL MDCoy IngramBelum ada peringkat

- Sample CBAP Elicitation Scenario Based Questions Set 01Dokumen31 halamanSample CBAP Elicitation Scenario Based Questions Set 01Rubab Javaid100% (1)

- The Use of Chitosan As A Solid Base Catalyst For TDokumen8 halamanThe Use of Chitosan As A Solid Base Catalyst For TRicardo Fajardo DíazBelum ada peringkat

- Stabilization of Gold Nanoparticles by Hydrophobically-Modified PolycationsDokumen12 halamanStabilization of Gold Nanoparticles by Hydrophobically-Modified PolycationsBarbara_Sorce_9524Belum ada peringkat

- Yen 2009Dokumen7 halamanYen 2009Dwi suparwatiBelum ada peringkat

- Studies On Graft Copolymerization of Chitosan With Synthetic MonomersDokumen9 halamanStudies On Graft Copolymerization of Chitosan With Synthetic MonomersRicardo Fajardo DíazBelum ada peringkat

- Synthesis and Thermal Behavior of Metallic CobaltDokumen8 halamanSynthesis and Thermal Behavior of Metallic CobaltAndrei DianaBelum ada peringkat

- A Kinetic Study of The Thermal Degradation of Chitosan-Metal ComplexesDokumen10 halamanA Kinetic Study of The Thermal Degradation of Chitosan-Metal ComplexesFernanda Stuani PereiraBelum ada peringkat

- 124-Article Text-380-1-10-20170924 PDFDokumen9 halaman124-Article Text-380-1-10-20170924 PDFsiti asiaBelum ada peringkat

- The Role Played by The Interactions of Small Molecules With Chitosan and Their Transitiona TempraturesDokumen14 halamanThe Role Played by The Interactions of Small Molecules With Chitosan and Their Transitiona TempratureslimnypjBelum ada peringkat

- Liquid-Liquid Equilibrium Data and Thermophysical Properties Forternary Systems Composed of Water, Acetic Acid and Different SolventsDokumen16 halamanLiquid-Liquid Equilibrium Data and Thermophysical Properties Forternary Systems Composed of Water, Acetic Acid and Different SolventsMaria Paula BuitragoBelum ada peringkat

- Polymer Degradation and Stability Volume 76 Issue 2 2002 (Doi 10.1016/s0141-3910 (02) 00016-2) C.Q. Qin Y.M. Du L. Xiao - Effect of Hydrogen Peroxide Treatment On The Molecular Weight and StrucDokumen8 halamanPolymer Degradation and Stability Volume 76 Issue 2 2002 (Doi 10.1016/s0141-3910 (02) 00016-2) C.Q. Qin Y.M. Du L. Xiao - Effect of Hydrogen Peroxide Treatment On The Molecular Weight and StrucHenpon AingBelum ada peringkat

- 20 Synthesis of NC From BagasseDokumen4 halaman20 Synthesis of NC From BagasseVịt Siêu Ngu DốtBelum ada peringkat

- Character Is at Ion of Chitin and ADokumen85 halamanCharacter Is at Ion of Chitin and AnhasinhhocBelum ada peringkat

- Galed 2005Dokumen5 halamanGaled 2005carlos scrivanoBelum ada peringkat

- Extraction and Characterization of Chitin PDFDokumen8 halamanExtraction and Characterization of Chitin PDFdiegojrendonbBelum ada peringkat

- William 2019 J. Phys. Conf. Ser. 1358 012002Dokumen8 halamanWilliam 2019 J. Phys. Conf. Ser. 1358 012002ReemaBelum ada peringkat

- 1999 Prochazkova Determinación Cuantitiva de Quitosano Por NinhidrinaDokumen8 halaman1999 Prochazkova Determinación Cuantitiva de Quitosano Por NinhidrinaRodrigo MiguelBelum ada peringkat

- Synthesis, Characterization and Thermal Studies of Keto-RDX or K-6Dokumen11 halamanSynthesis, Characterization and Thermal Studies of Keto-RDX or K-6Puturrú De FuáBelum ada peringkat

- Bi Ti O: It Is Not What You Have Read: J. Roberto Esquivel-Elizondo, Beverly Brooks Hinojosa, and Juan C. NinoDokumen10 halamanBi Ti O: It Is Not What You Have Read: J. Roberto Esquivel-Elizondo, Beverly Brooks Hinojosa, and Juan C. NinoLulueleBelum ada peringkat

- 120C Waktu 12 JamDokumen13 halaman120C Waktu 12 JamcherinesakinahBelum ada peringkat

- Ccto Anamitra3Dokumen13 halamanCcto Anamitra3Jhasaketan NayakBelum ada peringkat

- E-Mail: Ribeiroc@iq - Unesp.br: QUÍMICA NOVA, 22 (1) (1999) 41Dokumen6 halamanE-Mail: Ribeiroc@iq - Unesp.br: QUÍMICA NOVA, 22 (1) (1999) 41Siva RamBelum ada peringkat

- Geothermics: Halldor G. Svavarsson, Sigurbjorn Einarsson, Asa BrynjolfsdottirDokumen5 halamanGeothermics: Halldor G. Svavarsson, Sigurbjorn Einarsson, Asa BrynjolfsdottirBryan PajaritoBelum ada peringkat

- Preparation and Characterization of Water-Soluble Chitin and Chitosan DerivativesDokumen11 halamanPreparation and Characterization of Water-Soluble Chitin and Chitosan Derivativesalchemik1515Belum ada peringkat

- DS RMN ChitosanDokumen6 halamanDS RMN ChitosanAlban Sánchez SánchezBelum ada peringkat

- Caracterisation Chitosan 1Dokumen4 halamanCaracterisation Chitosan 1Ali SulaimanBelum ada peringkat

- Articles: Optimization of Chitin Extraction From Shrimp ShellsDokumen7 halamanArticles: Optimization of Chitin Extraction From Shrimp ShellsJuan Pablo EspinosaBelum ada peringkat

- 2.-Galicia - J. Chem. Eng. Data 2013, 58, 1255 1264 - 5Dokumen10 halaman2.-Galicia - J. Chem. Eng. Data 2013, 58, 1255 1264 - 5Moltimer Folchart CrawBelum ada peringkat

- Pyrolisis 8 OkDokumen7 halamanPyrolisis 8 OkegofientsBelum ada peringkat

- Studies On Glass Transition Temperature of Chitosan With Four TechniquesDokumen6 halamanStudies On Glass Transition Temperature of Chitosan With Four TechniquesJuanJimenezBelum ada peringkat

- Pour Javad I 2003Dokumen7 halamanPour Javad I 2003wakanda foreverBelum ada peringkat

- Infrared ArticleDokumen23 halamanInfrared ArticleTadeu MaTASBelum ada peringkat

- Preparation of Fungal Chitin and Chitosan From Shiitake StipesDokumen13 halamanPreparation of Fungal Chitin and Chitosan From Shiitake Stipesيحيى بورغدةBelum ada peringkat

- Demin 1Dokumen9 halamanDemin 1Endarto YudoBelum ada peringkat

- 1 s2.0 S0021979704004333 MainDokumen5 halaman1 s2.0 S0021979704004333 MainAulia Sukma HutamaBelum ada peringkat

- Nanomaterials 10 01049Dokumen13 halamanNanomaterials 10 01049Zakiah UslinawatyBelum ada peringkat

- PVA Containing Chito-Oligosaccharide Side Chain: Yong-Woo Cho, Sung-Soo Han, Sohk-Won KoDokumen7 halamanPVA Containing Chito-Oligosaccharide Side Chain: Yong-Woo Cho, Sung-Soo Han, Sohk-Won Koseranim22Belum ada peringkat

- J. Chem. ThermodynamicsDokumen9 halamanJ. Chem. ThermodynamicsBautista PVBelum ada peringkat

- Synthesis of Diethylacetal: Thermodynamic and Kinetic StudiesDokumen9 halamanSynthesis of Diethylacetal: Thermodynamic and Kinetic StudiesrukwavuBelum ada peringkat

- Hydro EfbDokumen7 halamanHydro EfbFA MonsterBelum ada peringkat

- Removal of Cadmium and Hexavalent Chromium From Electroplating Waste Water Using Thiocarbamoyl ChitosanDokumen6 halamanRemoval of Cadmium and Hexavalent Chromium From Electroplating Waste Water Using Thiocarbamoyl ChitosanSabiho GinoBelum ada peringkat

- Mohadi 2018 J. Phys.: Conf. Ser. 1095 012032 PDFDokumen6 halamanMohadi 2018 J. Phys.: Conf. Ser. 1095 012032 PDFrisfiBelum ada peringkat

- Mohadi 2018 J. Phys.: Conf. Ser. 1095 012032Dokumen6 halamanMohadi 2018 J. Phys.: Conf. Ser. 1095 012032risfiBelum ada peringkat

- Thongchai2020 Article IntegrationOfCollagenIntoChitoDokumen7 halamanThongchai2020 Article IntegrationOfCollagenIntoChitoNelson SouzaBelum ada peringkat

- Chitosan Tres ImportantDokumen6 halamanChitosan Tres Importantsacha--16Belum ada peringkat

- Article - Water Insolublepolymer FreeuniDokumen11 halamanArticle - Water Insolublepolymer FreeunifuatBelum ada peringkat

- Brazilian Journal of Chemical EngineeringDokumen7 halamanBrazilian Journal of Chemical Engineeringngoc33Belum ada peringkat

- DesalinizationDokumen14 halamanDesalinizationmarcofriuli2Belum ada peringkat

- Dehydration TribasicDokumen6 halamanDehydration TribasicDaniela JosepettiBelum ada peringkat

- Applied Acoustics: Willian Garcia Birolli, Jorge Augusto de Moura Delezuk, Sérgio Paulo Campana-FilhoDokumen4 halamanApplied Acoustics: Willian Garcia Birolli, Jorge Augusto de Moura Delezuk, Sérgio Paulo Campana-FilhoIvan CisnerosBelum ada peringkat

- 2006 Fishman PDFDokumen8 halaman2006 Fishman PDFPAYAMBelum ada peringkat

- The Effect of Chitin and Chitosan of Crab Shell On Water Sorption of Isotherm and Denaturation of Myofibrils During Dehydration ProcessDokumen9 halamanThe Effect of Chitin and Chitosan of Crab Shell On Water Sorption of Isotherm and Denaturation of Myofibrils During Dehydration Processsop sopBelum ada peringkat

- 186421-Article Text-474027-1-10-20190514 Obtencion de La Chalcona SustituidaDokumen7 halaman186421-Article Text-474027-1-10-20190514 Obtencion de La Chalcona SustituidaAndres ChitivaBelum ada peringkat

- 1 s2.0 S1381514807003021 MainDokumen10 halaman1 s2.0 S1381514807003021 MainIbnu SalehBelum ada peringkat

- Binary Phase Diagrams of Pyridinecarboxamide IsomersDokumen7 halamanBinary Phase Diagrams of Pyridinecarboxamide Isomersvestuario17.1Belum ada peringkat

- Chitin Chitosan ProductionDokumen19 halamanChitin Chitosan ProductionOmer MukhtarBelum ada peringkat

- Thermal and Solid State Assembly Behavior of Amphiphilic Aliphatic Polyether Dendrons With Octadecyl PeripheriesDokumen7 halamanThermal and Solid State Assembly Behavior of Amphiphilic Aliphatic Polyether Dendrons With Octadecyl PeripheriesDremHpBelum ada peringkat

- Extraction and Characterization of Chitin and Chitosan From Blue Crab and Synthesis of Chitosan Cryogel ScaffoldsDokumen14 halamanExtraction and Characterization of Chitin and Chitosan From Blue Crab and Synthesis of Chitosan Cryogel ScaffoldsApt Fitri RosdianaBelum ada peringkat

- Transition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesDari EverandTransition Metal-Catalyzed Pyridine Synthesis: Transition Metal-Catalyzed Heterocycle Synthesis SeriesBelum ada peringkat

- Fuels, Chemicals and Materials from the Oceans and Aquatic SourcesDari EverandFuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrancesca M. KertonBelum ada peringkat

- Timing Chain InstallationDokumen5 halamanTiming Chain InstallationToriTo LevyBelum ada peringkat

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDokumen3 halamanIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriBelum ada peringkat

- Mbeya University of Science and TecnologyDokumen8 halamanMbeya University of Science and TecnologyVuluwa GeorgeBelum ada peringkat

- ZEOS-AS ManualDokumen2 halamanZEOS-AS Manualrss1311Belum ada peringkat

- M 02 0001Dokumen3 halamanM 02 0001Miguel ruizBelum ada peringkat

- (LS 1 English, From The Division of Zamboanga Del SurDokumen17 halaman(LS 1 English, From The Division of Zamboanga Del SurKeara MhieBelum ada peringkat

- Student Material CN Version - 2017.11.10Dokumen25 halamanStudent Material CN Version - 2017.11.10Jagaddeesha BRBelum ada peringkat

- Switch RotatoriosDokumen12 halamanSwitch RotatoriosRoberto AndrésBelum ada peringkat

- CAT 438 3kk Esquema ElectricoDokumen2 halamanCAT 438 3kk Esquema ElectricocasigreBelum ada peringkat

- Symptoms and DiseasesDokumen8 halamanSymptoms and Diseaseschristy maeBelum ada peringkat

- PQA824 ManualDokumen100 halamanPQA824 ManualElkin AguasBelum ada peringkat

- Self Awareness and Self Management: NSTP 1Dokumen7 halamanSelf Awareness and Self Management: NSTP 1Fritzgerald LanguidoBelum ada peringkat

- Mini Riset Bahasa Inggris BisnisDokumen10 halamanMini Riset Bahasa Inggris BisnissyahsabilahBelum ada peringkat

- What Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?Dokumen3 halamanWhat Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?miretade titoBelum ada peringkat

- Inspection List For Electrical PortableDokumen25 halamanInspection List For Electrical PortableArif FuadiantoBelum ada peringkat

- Lesson 2 Principles of Cooperative ConversationDokumen9 halamanLesson 2 Principles of Cooperative Conversationdelilah o balladBelum ada peringkat

- Executive Summary: 0.1 Name of The WorkDokumen12 halamanExecutive Summary: 0.1 Name of The WorkDevdoot SahuBelum ada peringkat

- Piramal Revanta - Tower 3Dokumen13 halamanPiramal Revanta - Tower 3bennymahaloBelum ada peringkat

- NRP Grade 11 READING ENHANCEMENT March 1Dokumen3 halamanNRP Grade 11 READING ENHANCEMENT March 1LORELYN DELA CRUZBelum ada peringkat

- PDF - Gate Valve OS and YDokumen10 halamanPDF - Gate Valve OS and YLENINROMEROH4168Belum ada peringkat

- Vocabulary: Activity 1Dokumen18 halamanVocabulary: Activity 1Aurora GonzalezBelum ada peringkat