Stewarts Pressure Guages

Diunggah oleh

Dakota BassHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Stewarts Pressure Guages

Diunggah oleh

Dakota BassHak Cipta:

Format Tersedia

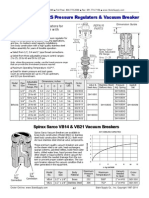

Heavy Duty, All Stainless Steel Gauges

2 Model - 20S (20SV) NPT (SV = VIBRAGAUGE option)

4 Models - 40S (40SV) NPT

& 41S (41SV) NPT

6 Models - 60S (60SV) NPT

& 61S (61SV) NPT

Dry, Liquid Fillable or Pre-Filled. VIBRAGAUGE Option also available.

VIBRAGAUGE for Dampening of vibration & pulsation without liquid filling.

-

Case pressure-relief grommet (Topside on liguid-fillable models, Backside on dry models).

White-painted aluminium dial, Black-printed figures.

Black-anodised aluminium pointer (Micrometer adjustable is standard on 4 & 6 dial sizes).

AISI 316 Stainless Socket & Element.

AISI 316 Stainless Steel Case & Bayonet Ring (standard).

IP CLASS = IP66. Operating temperature range = -4F to 140F (-20 to 60C) without loss of accuracy.

Orifice Restrictor Screw (standard 0.9mm, 0.4mm on request).

ACCURACY

0 - 10,000 psi

15 & 20K psi

30K psi & up

= 0.5% of span on 4 & 6 (1.0% on 2).

= 1% of span on 4 & 6 (1.5% on 2).

= 1.5% of span (Also inches on H2O ranges).

LENS

Laminated Safety Glass, removable / replaceable - 4mm (0.16 thick)

MOUNTING TYPES & CASE TYPES

No Code: Bottom Connection

LB:

Lower Back Connection.

CB:

Center Back available by special order (Not available on 20S).

FP:

Front Flange for Panel Mounting.

C:

C-Clamp Fixing for Panel Mounting (Not Available with Safety Case).

R:

Rear Flange for Wall Mounting.

S:

Solid Front /Blow-out Back (Safety Case).

PRESSURE RANGE CODES

(up to 60,000 psi available on 6 Solid Front / Blow-out Back Case)

Range Code

Range (psi)

Range Code

V30

30" HG-0 vacuum

300

Range (psi)

0-300

R315

Receiver 3-15

400

0-400

C15

30" HG-0-15

600

0-600

C30

30" HG-0-30

800

0-800

C60

30" HG-0-60

1K

0-1,000

C100

30" HG-0-100

1500

0-1,500

C160

30" HG-0-160

2K

0-2,000

C200

30" HG-0-200

3K

0-3,000

C300

30" HG-0-300

4K

0-4,000

15

0-15

5K

0-5,000

30

0-30

6K

0-6,000

60

0-60

10K

0-10,000

Model shown is 41S-2K

To order other models by part no, See below.

100

0-100

15K

0-15,000

160

0-160

20K

0-20,000

20K

1/4 MPF (Female)

1/4 MPM (Male)

9/16 MPM (Male)

200

0-200

30K

0-30,000

30K

1/4 HPF (Female)

1/4 HPM (Male)

9/16 HPM (Male)

35K

0-35,000

35K

1/4 HPF (Female)

1/4 HPM (Male)

9/16 HPM (Male)

Text i n Red denotes HIGH PRESSURE CONNECTIONS REQUIRED

HIGH PRESSURE CONNECTIONS AVAILABLE

Note:- On Model 20S Max Pressure = 20K, High Pressure Connection = 1/4 MPM(Male)

HOW TO ORDER BY PART NO

1/ Model number selected. (VIBRAGAUGE option: add "V" to model).

2/ Choose Pressure Range (code).

3/ Choose Mounting Type (code).

4/ If Special Adder Codes are needed add code or (description).

psi / bar scale = B, psi /kPa scale = K, Monel wetted parts = M, Safety Zone Reective Glow = G, Cleaned for Oxygen Service = O

5/ Liquid Filling. If desired GF= Glycerin, SF=Silicone, FF=Fluorolube.

FOR EXAMPLE AS SHOWN

4 inch Dial All 316 Stainless Steel, NPT, Bottom Connection, 0 - 2000 psi

1-MODEL

2-RANGE CODE

3-MOUNTING TYPE

4-SPECIAL ADDER CODES

5-FILLING

41S

2K

NONE

NONE

NONE

We manufacture a wide range of instruments to customers special requirements

We shall be pleased to discuss and advise on your specifications.

20S20161111

Specifications and dimensions given in this leaflet represent the state of engineering at the time of printing.

Engineering modifications may take place without prior notice.

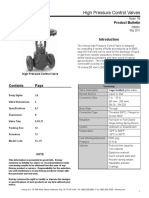

Heavy Duty, All Stainless Steel Gauges

2 Model - 20S (20SV) NPT (SV = VIBRAGAUGE option)

4 Models - 40S (40SV) NPT

& 41S (41SV) NPT (or Non-Fillable Case = 44S & 44SV or 45S & 45SV)

6 Models - 60S (60SV) NPT

& 61S (61SV) NPT (or Non-Fillable Case = 62S & 62SV or 63S & 63SV)

Rear Flange Wall Mounting (R)

Direct Mounting (Standard. no code)

Front Flange Panel Mounting (FP) & (LB)

Clamp Fixing Panel Mounting (C)

Dimension Chart (Same for VIBRAGAUGE Option Models)

Model

20S

Dia.

63mm/2.5 IN

40S/41S 100mm/4 IN

60S/61S 160mm/6 IN

A Dims

85

39

3.35

132

5.2

196

7.72

1.54 3.09 0.45

51

121 17.5

1.99 4.76 0.69

51

78.5 11.5 68.50

184 17.5

1.99 7.84 0.69

58

31

9.5

21.5

18

29

37

67

62

13

3.8

75

3.5

2.70 2.28

112

83

88

1.22 0.37 0.85 0.71 1.14

48.5

15

24.5

32

34

39

1.46 2.64 2.44 0.51

48.5

110

99

18

18

0.15 2.95 0.14

6

118

109

114 48.5

15

24.5

32

34

39

48.5

172

148

18

18

5.8

178

66

2.60

4.41 3.27 3.46 1.91 0.59 0.96 1.26 1.34 1.54 1.91 4.33 3.90 0.71 0.71 0.24 4.65 0.24

162

Cut Out

106

4.17

5.8

153

6.38 4.29 4.49 1.91 0.59 0.96 1.26 1.34 1.54 1.91 6.77 5.83 0.71 0.71 0.23 7.01 0.23

6.02

Solid front safety case (S)

20S

63mm/2.5 IN

40S/41S 100mm/4 IN

60S/61S 160mm/6 IN

85

3.35

132

5.20

196

7.72

42

78.5

20

1.65 3.09 0.79

65

121

30

2.56 4.76 1.18

66

184

30

2.60 7.24 1.18

68.5

58

2.70 2.28

112

83

42.5

1.67 0.79 0.96 0.71 1.18

88

65

20

29

24.5

41

18

34

30

37

42

1.65

42

67

4.41 3.27 3.46 2.56 1.14 1.61 1.34 1.46 1.65 2.64

162

109

114

65

29

41

34

37

42

92

6.38 4.29 4.49 2.56 1.14 1.61 1.34 1.46 1.65 3.62

62

12

2.44 0.47

99

21

21

3.8

75

3.8

0.15 2.95 0.15

6

118

3.90 0.83 0.83 0.24 4.65 0.24

21

21

5.8

178

66

2.75

106

4.17

148

5.8

155

5.83 0.83 0.83 0.23 7.01 0.23

6.10

Gas & Steam in excess of 400 psi (25 bar) pressure can represent danger if there is a rupture in the Bourdon Tube measuring this gas.

To minimize the danger, gauges in this application should be Solid Front type, having solid front between Bourdon tube & dial, safety window & blow-out back

to allow any discharge to release to the rear of the gauge.

Athough there is not necessarily any great risk in the use of gauges for gases at pressure less than 400psi (25 bar), a blow-out valve should be incorporated

& the purchaser should have regard to the nature of the gas & the installation conditions &, if necessary, order a gauge of the Solid Front type.

The essence of this type of gauge is safety.

(Surface mounted rear flange gauges of the Solid Front Type Case should be fitted with distance pieces of not less that 3/4 (20mm) long to allow them to be mounted away from wall or panel)

VIBRAGAUGE dampened movement option provides twice the life of dry gauges, without liquid filling. Eliminates pointer flutter & liquid fill lines.

Before use please consult our recommendations regarding selection & installation or consult ASME B40.100.

STEWARTS - USA

6786 Tipperary

HOUSTON, TX 77061 USA

Phone: 713-643-1022

Fax:

713-643-2855

Toll Free: 1-800-901-1316

Web:

stewartsusa.com

Anda mungkin juga menyukai

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationDari EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- STEWART-BUCHANAN - Model 63 Series Pressure GaugeDokumen2 halamanSTEWART-BUCHANAN - Model 63 Series Pressure GaugeNazrul IslamBelum ada peringkat

- IMChap 014 SDokumen14 halamanIMChap 014 STroy WingerBelum ada peringkat

- Pneumatic Tyres: CMR Engineering CollegeDokumen17 halamanPneumatic Tyres: CMR Engineering CollegeHemanth Rama Krishna YernagulaBelum ada peringkat

- Pressure GaugeDokumen24 halamanPressure GaugerizalBelum ada peringkat

- CV For Pressure Up To 50bDokumen4 halamanCV For Pressure Up To 50bmattuiffBelum ada peringkat

- Bermad - Filtro en y 70fDokumen2 halamanBermad - Filtro en y 70fYadir BojacaBelum ada peringkat

- Hydac Testpoint PDFDokumen4 halamanHydac Testpoint PDFEsteve CastilloBelum ada peringkat

- Soft Seal Piston Valves Drain ValvesDokumen24 halamanSoft Seal Piston Valves Drain ValveswenigmaBelum ada peringkat

- Dimargrow ManometrosDokumen75 halamanDimargrow ManometrosStalinBelum ada peringkat

- Mc. Daniel - Pressure GaugeDokumen6 halamanMc. Daniel - Pressure GaugeMuhammad FuadyBelum ada peringkat

- Strainer Spec SheetDokumen3 halamanStrainer Spec Sheetswaraj4uBelum ada peringkat

- Propiedades MecánicasDokumen14 halamanPropiedades MecánicasGregor SamsaBelum ada peringkat

- Valve Test & Repair Equipment: Catalogue 2018Dokumen68 halamanValve Test & Repair Equipment: Catalogue 2018Kauffman LOKOBelum ada peringkat

- Series 805YD Specification SheetDokumen2 halamanSeries 805YD Specification SheetFEBCOBelum ada peringkat

- FT MedPress AutoclaveDokumen12 halamanFT MedPress AutoclaveAymeeenBelum ada peringkat

- 6 D204 D 01Dokumen4 halaman6 D204 D 01AshrafELWardagyBelum ada peringkat

- Top Guide Control ValveDokumen32 halamanTop Guide Control Valveachari_swapnilBelum ada peringkat

- Series 760 P/E Valve PositionersDokumen4 halamanSeries 760 P/E Valve PositionerssalasineBelum ada peringkat

- SSV, SSV-D, SSV-M VerdelersDokumen7 halamanSSV, SSV-D, SSV-M VerdelersBehi BshBelum ada peringkat

- Regulador American Meter PDFDokumen6 halamanRegulador American Meter PDFjmcg1974Belum ada peringkat

- Gs-Flange SystemDokumen188 halamanGs-Flange SystemMarcin MarcinkiewiczBelum ada peringkat

- Needle ValvesDokumen18 halamanNeedle ValvesPablo RodriguezBelum ada peringkat

- HOTSTART Weathertight Industrial Immersion Heater Part NumbersDokumen2 halamanHOTSTART Weathertight Industrial Immersion Heater Part NumbersShankar PediredlaBelum ada peringkat

- A23-28 656seriesDokumen6 halamanA23-28 656serieskevinmathew27Belum ada peringkat

- Valvula Check 6000 Lbsv3xDokumen6 halamanValvula Check 6000 Lbsv3xMaik AmayaBelum ada peringkat

- Us Tray Catalog 2011Dokumen8 halamanUs Tray Catalog 2011Ramesh AnanthanarayananBelum ada peringkat

- FNW CommoditiesPVFSpecSalesSheetDokumen28 halamanFNW CommoditiesPVFSpecSalesSheetVishalBelum ada peringkat

- Series 406NRSRW Specification SheetDokumen2 halamanSeries 406NRSRW Specification SheetWattsBelum ada peringkat

- GWC Valve International - Dual Plate Check ValvesDokumen20 halamanGWC Valve International - Dual Plate Check ValvesGWC Valve InternationalBelum ada peringkat

- SFS Products BrochureDokumen14 halamanSFS Products BrochureJoshuaBelum ada peringkat

- Model 1535: 2-Inch Stainless Steel Pressure Gauges For SemiconductorDokumen4 halamanModel 1535: 2-Inch Stainless Steel Pressure Gauges For SemiconductorcarbonatiteBelum ada peringkat

- Viking Serie 4195 Sec - 144Dokumen10 halamanViking Serie 4195 Sec - 144woosasdBelum ada peringkat

- AUTOCLAVE - AdapterCouplingDokumen52 halamanAUTOCLAVE - AdapterCouplingAjimKe'enBelum ada peringkat

- Pressure and Vacuum Relief Valves for Storage TanksDokumen5 halamanPressure and Vacuum Relief Valves for Storage TanksFreddy Gómez GuillénBelum ada peringkat

- Comportas Series 20Dokumen13 halamanComportas Series 20Leandro BuosiBelum ada peringkat

- Venteo de Emergencia 94200-3FDokumen3 halamanVenteo de Emergencia 94200-3FSantiago PeñuelaBelum ada peringkat

- Ss01014 SmithDokumen6 halamanSs01014 SmithAchmad TabaBelum ada peringkat

- Esv Ie2 TD en PDFDokumen68 halamanEsv Ie2 TD en PDFCristian Muñoz AlarcónBelum ada peringkat

- Series 826YD Specification SheetDokumen2 halamanSeries 826YD Specification SheetFEBCOBelum ada peringkat

- SSC Cat Spirax Sarco Vacuum BreakersDokumen1 halamanSSC Cat Spirax Sarco Vacuum BreakersEb RahimBelum ada peringkat

- TescomDokumen16 halamanTescomrafaareBelum ada peringkat

- KIMRAY ValveDokumen16 halamanKIMRAY ValveDenny Iskandar 'S-chuck'Belum ada peringkat

- Valvulas PDFDokumen32 halamanValvulas PDFMilena Lemus FonsecaBelum ada peringkat

- Series 806YD Specification SheetDokumen2 halamanSeries 806YD Specification SheetFEBCOBelum ada peringkat

- 8450 1 11 10Dokumen20 halaman8450 1 11 10Slobodan AnticBelum ada peringkat

- PBX Indust Pressure GaugeDokumen6 halamanPBX Indust Pressure GaugeTerri-Anne HallinanBelum ada peringkat

- Test Pressure GaugeDokumen2 halamanTest Pressure GaugerodcavicchioniBelum ada peringkat

- 836e Br001 - en P (Flow Switch)Dokumen8 halaman836e Br001 - en P (Flow Switch)Imran Shahzad KhanBelum ada peringkat

- Svedala RV Eng GerardDokumen6 halamanSvedala RV Eng GerardPaseandoPorlaVidaBelum ada peringkat

- EFCO Valve Repair ProductsDokumen20 halamanEFCO Valve Repair Productsjay_rajeshirkeBelum ada peringkat

- Catalogo de VarecDokumen4 halamanCatalogo de VarecisidriskyBelum ada peringkat

- 4620 & 4630 BrochureDokumen1 halaman4620 & 4630 BrochureSaleem MohammedBelum ada peringkat

- Hy14-3300 MV PDFDokumen6 halamanHy14-3300 MV PDFPartsGopher.comBelum ada peringkat

- 8" Submersible Motors Standard: ApplicationsDokumen7 halaman8" Submersible Motors Standard: Applicationswpt_meBelum ada peringkat

- Fixed Displacement Pump Technical SpecsDokumen20 halamanFixed Displacement Pump Technical SpecsTaz Juan GBelum ada peringkat

- Interruptor de Presion - AscoDokumen9 halamanInterruptor de Presion - AscoJosephGutierrezBelum ada peringkat

- Danflo Liquid Surge Relief Valve MJDokumen8 halamanDanflo Liquid Surge Relief Valve MJSelvan McsBelum ada peringkat

- Newnes Workshop Engineer's Pocket BookDari EverandNewnes Workshop Engineer's Pocket BookPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Introduction - Week 2Dokumen37 halamanIntroduction - Week 2Tayyab AhmedBelum ada peringkat

- Notifier Battery Calculations-ReadmeDokumen11 halamanNotifier Battery Calculations-ReadmeJeanCarlosRiveroBelum ada peringkat

- RMA 3000 Remote Meter Assemblies Specifications: 34-ST-03-81, July 2017Dokumen8 halamanRMA 3000 Remote Meter Assemblies Specifications: 34-ST-03-81, July 2017Amir LopezBelum ada peringkat

- Time TableDokumen7 halamanTime TableChethan .H.GBelum ada peringkat

- Physical parameters shaping of Farwa Lagoon - LibyaDokumen7 halamanPhysical parameters shaping of Farwa Lagoon - LibyaAsadeg ZaidBelum ada peringkat

- Tutorial CorelDRAW-X8Dokumen10 halamanTutorial CorelDRAW-X8Ajay BhargavaBelum ada peringkat

- ANSYS ACT Developers GuideDokumen506 halamanANSYS ACT Developers GuideEDIZONBelum ada peringkat

- Front Panel & Display Technical Data: User ManualDokumen2 halamanFront Panel & Display Technical Data: User ManualJulio PorleyBelum ada peringkat

- Fans Reference GuideDokumen160 halamanFans Reference Guidekarthikraja21100% (13)

- Sem 2Dokumen128 halamanSem 2Agustin A.Belum ada peringkat

- Pumps - IntroductionDokumen31 halamanPumps - IntroductionSuresh Thangarajan100% (1)

- Excel 2007 Lesson 7 QuizDokumen5 halamanExcel 2007 Lesson 7 Quizdeep72Belum ada peringkat

- Tradesman Electronics PDFDokumen13 halamanTradesman Electronics PDFsandeepxrBelum ada peringkat

- Lecture 2 Principle of EMRDokumen33 halamanLecture 2 Principle of EMRizhar engkuBelum ada peringkat

- Product Presentation Nova Blood Gas AnalyzerDokumen38 halamanProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- 3RP15 05-1aDokumen3 halaman3RP15 05-1atycristinaBelum ada peringkat

- MTech Information Security FINAL 10052018Dokumen20 halamanMTech Information Security FINAL 10052018sirisha vBelum ada peringkat

- Affixation (Landscape)Dokumen4 halamanAffixation (Landscape)difafalahudinBelum ada peringkat

- Manual 1Dokumen37 halamanManual 1Şahin GüngörBelum ada peringkat

- Windows Mbox Viewer User Manual 1.0.3.4Dokumen33 halamanWindows Mbox Viewer User Manual 1.0.3.4Billy NoelBelum ada peringkat

- Bottazzini RiemannDokumen36 halamanBottazzini RiemanncedillaBelum ada peringkat

- 11+ Entrance Examination: Specimen PaperDokumen8 halaman11+ Entrance Examination: Specimen PaperNayem Hossain HemuBelum ada peringkat

- Lecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanDokumen18 halamanLecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanLaura AmwayiBelum ada peringkat

- Vtol Design PDFDokumen25 halamanVtol Design PDFElner CrystianBelum ada peringkat

- Methods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1Dokumen3 halamanMethods For Assessing The Stability of Slopes During Earthquakes-A Retrospective 1ilijarskBelum ada peringkat

- FOT - CG Limitation A320neo - Web ConferenceDokumen7 halamanFOT - CG Limitation A320neo - Web Conferencerohan sinha100% (2)

- MleplustutorialDokumen13 halamanMleplustutorialvorge daoBelum ada peringkat

- Unit-I-2-Marks-With-Ans3 Hydrology1 - BY Civildatas - Blogspot.in PDFDokumen4 halamanUnit-I-2-Marks-With-Ans3 Hydrology1 - BY Civildatas - Blogspot.in PDFHimanshu sharmaBelum ada peringkat