Diunggah oleh

Juanjo SolanoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Diunggah oleh

Juanjo SolanoHak Cipta:

Format Tersedia

Home

Search

Collections

Journals

About

Contact us

My IOPscience

Hybrid printing of mechanically and biologically improved constructs for cartilage tissue

engineering applications

This content has been downloaded from IOPscience. Please scroll down to see the full text.

2013 Biofabrication 5 015001

(http://iopscience.iop.org/1758-5090/5/1/015001)

View the table of contents for this issue, or go to the journal homepage for more

Download details:

IP Address: 186.176.90.127

This content was downloaded on 22/10/2015 at 13:59

Please note that terms and conditions apply.

IOP PUBLISHING

BIOFABRICATION

doi:10.1088/1758-5082/5/1/015001

Biofabrication 5 (2013) 015001 (10pp)

Hybrid printing of mechanically and

biologically improved constructs for

cartilage tissue engineering applications

Tao Xu 1 , Kyle W Binder 1 , Mohammad Z Albanna, Dennis Dice,

Weixin Zhao, James J Yoo and Anthony Atala 2

Wake Forest Institute for Regenerative Medicine, Wake Forest University Health Sciences,

Medical Center Blvd, Winston-Salem, NC 27157, USA

E-mail: aatala@wakehealth.edu

Received 27 April 2012

Accepted for publication 18 October 2012

Published 21 November 2012

Online at stacks.iop.org/BF/5/015001

Abstract

Bioprinting is an emerging technique used to fabricate viable, 3D tissue constructs through the

precise deposition of cells and hydrogels in a layer-by-layer fashion. Despite the ability to

mimic the native properties of tissue, printed 3D constructs that are composed of

naturally-derived biomaterials still lack structural integrity and adequate mechanical properties

for use in vivo, thus limiting their development for use in load-bearing tissue engineering

applications, such as cartilage. Fabrication of viable constructs using a novel multi-head

deposition system provides the ability to combine synthetic polymers, which have higher

mechanical strength than natural materials, with the favorable environment for cell growth

provided by traditional naturally-derived hydrogels. However, the complexity and high cost

associated with constructing the required robotic system hamper the widespread application of

this approach. Moreover, the scaffolds fabricated by these robotic systems often lack

flexibility, which further restrict their applications. To address these limitations, advanced

fabrication techniques are necessary to generate complex constructs with controlled

architectures and adequate mechanical properties. In this study, we describe the construction

of a hybrid inkjet printing/electrospinning system that can be used to fabricate viable tissues

for cartilage tissue engineering applications. Electrospinning of polycaprolactone fibers was

alternated with inkjet printing of rabbit elastic chondrocytes suspended in a fibrincollagen

hydrogel in order to fabricate a five-layer tissue construct of 1 mm thickness. The

chondrocytes survived within the printed hybrid construct with more than 80% viability one

week after printing. In addition, the cells proliferated and maintained their basic biological

properties within the printed layered constructs. Furthermore, the fabricated constructs formed

cartilage-like tissues both in vitro and in vivo as evidenced by the deposition of type II collagen

and glycosaminoglycans. Moreover, the printed hybrid scaffolds demonstrated enhanced

mechanical properties compared to printed alginate or fibrincollagen gels alone. This study

demonstrates the feasibility of constructing a hybrid inkjet printing system using off-the-shelf

components to produce cartilage constructs with improved biological and mechanical

properties.

(Some figures may appear in colour only in the online journal)

1

2

These authors contributed equally to this work.

Author to whom any correspondence should be addressed.

1758-5082/13/015001+10$33.00

2013 IOP Publishing Ltd

Printed in the UK & the USA

Biofabrication 5 (2013) 015001

T Xu et al

1. Introduction

transfection of living cells [17]. These experiments support

the use of inkjet bioprinting as a low cost fabrication method

and provide a glimpse of its future potential.

However, like many other bioprinting approaches, inkjet

bioprinting technology utilizes hydrogels as the primary

scaffold materials for printed cells [18]. Although a variety

of tissue constructs can be fabricated with these gel-based

scaffolds, these gels often have limited structural integrity

due to their low mechanical strength [19, 20]. This limitation

hinders development of printed constructs for use in loadbearing tissue engineering applications, such as those designed

to repair or replace cartilage and bone.

We hypothesized that these mechanical limitations

associated with printed hydrogel constructs could be overcome

by using inkjet printing techniques in conjunction with

electrospinning, which is another fabrication technique that

can create nanofibrous scaffolds of synthetic polymer. By

combining flexible mats of electrospun synthetic polymer

with traditional inkjet printing in a layer-by-layer fashion,

functional tissue constructs with enhanced mechanical

properties could be fabricated. In this study, we first

determined whether electrospinning could be employed

in conjunction with inkjet-based cell printing to produce

constructs with enhanced mechanical properties that would

be suitable for cartilage tissue engineering in a proofof-concept design. We then evaluated the functionality of

the resulting constructs in terms of four parameters: cell

survival, maintenance of the layered structure, mechanical

properties, and formation of cartilage-specific extracellular

matrix. Generation of organized layered cartilage constructs

with improved biological and mechanical properties would

have numerous applications clinically. In particular, to meet

the depth-dependent cellular and matrix properties properties

of articular cartilage, biomimetic zonal cartilage repair and

regeneration using modular hydrogel systems has been

envisioned [21]. Our hybrid method allows for control over

construct organization and might have potential to these

applications involving complex zonal properties to tissueengineered constructs for cartilage repair.

Naturally-derived hydrogels such as collagen, fibrin and elastin

have advanced the field of biomaterials in tissue engineering

and regenerative medicine because their composition and

structure resembles that of native tissue [1, 2]. Organ/tissue

printing using inkjet technology is evolving into a practical

method to fabricate viable 3D tissue constructs and has found

widespread applications in the field of tissue engineering and

regenerative medicine [3, 4]. The bioprinting approach often

utilizes naturally-derived hydrogels as cell-printing solutions

to construct tissues in layer-by-layer fashion due to their

superior biocompatibility and low toxicity on the cells [5].

However, the low to moderate mechanical properties of

these hydrogels hinder their utility in load-bearing tissue

engineering applications, such as cartilage, because they are

unable to provide proper 3D structural integrity during surgical

procedures and the regenerative process [6].

Fabrication methods such as solid free form technology,

which is based on computer-aided design/computer-aided

manufacturing, has been employed to fabricate 3D scaffolds

[7]. Despite its ability to control the scaffold porosity, the

scaffold, which often is made of a synthetic polymer, does not

provide the proper affinitive environment to the cells due to the

polymer hydrophobicity properties [8]. Multi-head deposition

systems (MHDS) offer the ability to fabricate hybrid scaffolds

using both synthetic polymers and hydrogel materials. The

hybrid scaffold provides a favorable environment within the

hydrogel for the cells to grow and can possess adequate

mechanical properties that can be altered depending on the

synthetic polymer used during fabrication. Recently, MHDS

was employed to fabricate hybrid scaffolds using synthetic

polymers such as PCL and polyglycolic acid incorporated

within hydrogels such as alginate, gelatin, and hyaluronic

acid as a cell-printing solution [6, 8, 9]. While the ability to

precisely deposit cells and materials has been well-established,

most robotic precision deposition machines are often complex,

expensive to manufacture and require special skills to operate.

By combining synthetic polymers and natural hydrogels, these

systems can offer a hybrid scaffold system, but the main

frame of the scaffold, composed of bulk synthetic polymers,

is very rigid and lack of flexibility, which might not be

suitable for cartilage tissue engineering. Deposition of these

components can also be achieved by inkjet printing system

using off-the-shelf components and provides a platform in

which multiple cell types can be deposited into a construct.

This technique can provide many of the similar functions as

a robotic deposition system but can be effectively utilized

with little specialized equipment [10, 11]. Inkjet technology

has been used in many applications to produce high density

patterns of DNA for microarrays [12], microdepositions of

proteins for enzyme assays [13] and high density arrays of

bacterial colonies [14]. The technique has also been applied

to high-throughput patterning of mammalian cells, including

Chinese hamster ovary cells [15] and hippocampal cells [16].

Even more recently, it has been shown that the environmental

conditions generated during the printing process, such as heat

and shear stress, can be used to perform high-throughput

2. Materials and methods

2.1. Materials

Poly(-caprolactone) (PCL) (704105, average Mn 42,500),

Pluronic F-127 (P2443), fibrinogen from bovine plasma

(F8630) and thrombin from bovine plasma (T4648) were all

purchased from Sigma-Aldrich (St. Louis, MO). Collagen

type I derived from rat tail (354236) was purchased from

BD Biosciences (Billerica, MA). All reagents were chemical

grade.

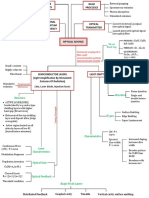

2.2. Construction of the hybrid printing system

To build cartilage constructs, we developed a novel hybrid

printing system by incorporating an electrospinning apparatus

into an inkjet printing platform. Figures 1(A) and (B) show

the schematic drawing of this hybrid printing system and the

actual hybrid printing system after construction, respectively.

2

Biofabrication 5 (2013) 015001

T Xu et al

(A)

(B)

Figure 1. (A) Schematic representation of the hybrid printing system shows the inkjet printhead and the electrospinning printhead. (B) The

actual prototype of the hybrid printing system after construction.

The inkjet printing platform is composed of a customized

XYZ plotter driven by step motors. The printhead was

equipped with a dc solenoid inkjet valve (Offshore Solutions

Inc, Beaverton, OR). Reservoirs for loading the cell suspension

to be printed were connected to the inkjet valve. The cellprinting solution was supplied to the inkjet valve from the

reservoirs using pressurized air. The printhead was mounted

over a XYZ plotter platform to allow deposition of cells

onto the scaffold generated by electrospinning. The XYZ

plotter was positioned under the printhead via a customized

controller. The controller acquires the positioning information

from custom software built on the .NET Framework 2.0

(Microsoft Corp, Redmond, WA). The software converts the

image of the target to a special four byte protocol, which is

used to activate a specific inkjet valve and coordinate XYZ

position.

In this hybrid system, the electrospinning apparatus

is used to generate a polymeric fiber-based scaffold. An

electrospinning head, in tandem with the inkjet head, was

also mounted over the XYZ plotter. The power supply, which

is used to provide a high voltage field for electrospinning,

was modulated by the same customized controller. To prevent

the potential adverse effects of static discharge on the logic

circuitry of the customized controller, the controller was

conductively isolated from the high voltage power supply

through fiber optics.

2.4. Isolation and culture of rabbit articular chondrocytes

Chondrocytes were obtained from rabbit ear cartilage as

described previously [23]. Briefly, the rabbit was sedated

and the ear was shaved, cleaned with povidone-iodine, and

draped. A pocket was resected under sterile conditions at the

subperichondrial level and an approximately 2 2 cm piece

of cartilage was removed. Biopsy specimens were washed

in phosphate-buffered saline (PBS) and finely minced under

sterile conditions. To disassociate chondrocytes from the

cartilage tissue, the minced cartilage was incubated in Hams

F12 medium with glutamine/bicarbonate supplemented with

10% fetal bovine serum (FBS), 100 U ml1 penicillin,

100 g ml1 streptomycin, 2.5 g ml1 amphotericin B

(Gibco-BRL), and 1 mg ml1 collagenase type B (Boehringer

Mannheim GmbH, Germany) at 37 C on an orbital shaker.

After 24 h, the undigested pieces were discarded and the

supernatant was collected and distributed onto fresh tissue

culture dishes. Every dish was filled with 20 ml of fresh

Dulbeccos modified Eagles medium (DMEM) supplemented

with 10% FBS, 1% antibiotic-antimycotic (ABAM) and 1%

L-glutamine. Cell cultures were incubated in a humidified

incubator in 5% CO2 at 37 C. Culture media was changed

every three to four days. To prepare the cell printing solution,

cell pellets at passage 6 were re-suspended in a mixture of

fibrinogen (10 mg ml1) and rat tail collagen type I (1.5 mg

ml1) in PBS at a concentration of 34 106 cells ml1 and

loaded into cell reservoirs.

2.3. Preparation of polymer solution

2.5. Fabrication of cartilage constructs

PCL (10% wt/vol) and Pluronic F-127 (5% wt/vol) were

dissolved in acetone under gentle stirring in a warm water bath

(50 C). Acetone was used as a solvent because it is a natural

byproduct of ketone body synthesis in the liver. Pluronic F-127

was added to the polymer solution to reduce the viscosity of

molten PCL and also improve the hydrophilicity properties of

the resulting electrospun PCL scaffold [22]. The final polymer

solution was loaded into the polymer reservoirs of the printing

system.

A layer of PCL was electrospun for 30 min at 3 ml h1 at

20 kilovolts (KV) through an 18.5 gauge blunt needle syringe.

The syringe was placed 8 cm above a sterile 10 cm petri

dish containing sterile PBS. A sheet of aluminum foil was

placed directly under the petri dish and to act as the ground

for the system and force the PCL to spin directly into

the PBS. Wet electrospinning was necessary because dry

PCL/F-127 rapidly absorbs water from printed constructs

and leads to desiccation of the cells. After spinning a

3

Biofabrication 5 (2013) 015001

T Xu et al

layer of PCL, 3 ml of the cell-printing solution containing

chondrocytes/fibrinogen/collagen was printed through the

inkjet valve onto the electrospun PCL fibrous scaffold layer

to form a cell/matrix layer. The cell-printing solution was

allowed to gel through subsequent printing of 1.5 ml thrombin

(20 UI ml1 dissolved in PBS) on the cell/matrix layer to

create a transient clot for structural integrity while spinning.

The thrombin layer was allowed to react with the fibrinogen

for 15 min. Subsequently, PCL was spun again for another

10 min at 3 ml h1 followed by inkjet printing of the cellprinting solution and thrombin. A final layer of PCL was spun

for 30 min at 3 ml h1. The final construct consisted of five

alternating layers of PCL/F-127 (three electrospun layers) and

chondrocytes (two gel layers) with an approximate thickness

of 1 mm. Each of the two gel layers was approximately

150 m, and the central electrospun layer was about 100 um,

and the top and bottom electrospun layers were approximately

300 m thick. The design that central layer of PCL/F-127 was

thinner than the outer electrospun layers was to facilitate more

communication of the cells in the two gel layers and subsequent

integration of the cells upon the degradation of the electrospun

layers. The top and bottom electrospun layers were designed

to provide the mechanical property of the hybrid construct. It

was observed that the thickness of the constructs was reduced

to approximately 0.4 mm as the fibrin degraded and left the

collagen matrix behind. Each construct was square with a

10 cm diagonal. Cartilage constructs were then incubated in

DMEM medium supplemented with 10% FBS, 1% ABAM

and 1% L-glutamine in 5% CO2 at 37 C.

Constructs without cells were fabricated using the same

method of alternating PCL/F-127 and the fibrinogen/collagen

mixture. PCL/F-127 control constructs were fabricated

using the same electrospinning method without the

fibrinogen/collagen mixture. For the purpose of comparing

the printed-electrospun constructs with commonly used

hydrogels, alginate and fibrin/collagen hydrogels were used

as controls. Alginate controls were prepared by mixing 2%

wt/vol sodium alginate (MVG; Pronova Biomedical, Oslo,

Norway) with an overall gluronic acid (G-block) content

of 70% (as recommended by the manufacturer) with PBS.

Solution was gelled by mixing with 0.25 M CaCl2 and

pulled through an even diameter tube before gelling was

complete to ensure a uniform thickness through the construct.

Collagen/fibrin hydrogels were fabricated by plating the

mixture of collagen and fibrin without cells in a petri dish

marked to 0.4 mm to ensure an even thickness and measuring

the resulting gel with digital calipers.

Constructs were then rinsed with PBS and viewed using a

fluorescent microscope at 200 magnification. Cell viability

was assessed by randomly examining five representative fields

per sample with a minimum of 50 cells per field, counting

the number of live cells stained with calcein AM (green) and

comparing this number to the total number of cells.

2.7. Microstructure of cartilage constructs

The microstructure of the cartilage constructs was evaluated

using scanning electron microscopy (SEM). Samples were

lyophilized and sputter coated with gold. Cross-sectional

electron-micrographs were obtained at 200, 500, and

4000 magnification at 20.0 kV and 50 Pa using a

Hitachi S-2600 scanning electron microscope (Hitachi High

Technologies America, Pleasanton, CA).

2.8. Mechanical properties of printed hybrid constructs and

other hydrogel constructs

Mechanical properties of hybrid constructs without cells,

pure PCL/F-127, alginate, and collagen/fibrin gel were

evaluated in fully hydrated conditions using an Instron uniaxial

load frame (Instron Corporation, Issaquah, WA). Rectangular

samples (n = 3) of 6 mm long and 4 mm wide were

prepared from each construct. The thickness of each sample

was measured separately using digital caliper and reported

as average standard deviation (SD). Hybrid samples

had a thickness of 0.38 0.055 mm, alginate samples

0.36 0.05 mm, PCL samples 0.29 0.05 mm and

collagen/fibrin samples 0.4 mm. The samples were allowed to

stretch at 0.2 mm s1 crosshead speed until failure. Ultimate

tensile strength (UTS) was calculated at the maximum load

immediately before breaking. Youngs modulus was calculated

from the slope of the linear segment of the stressstrain curve.

Values were presented as average SD.

2.9. In vitro evaluation of hybrid cartilage constructs

Hybrid printed cartilage constructs were cultured in vitro to

evaluate the cellular organization and proliferation within

each construct. In addition, extracellular matrix deposition and

organization were observed over time. Hybrid constructs were

fabricated as described and cultured in DMEM supplemented

with 10% FBS, 1% ABAM and 1% L-glutamine in 5% CO2 at

37 C for four weeks. Printed hybrid constructed without cells

were used as controls.

2.10. In vivo evaluation of hybrid cartilage constructs

2.6. Evaluation of cell viability

All animal procedures were approved by the Wake Forest

University Health Sciences Animal Care and Use Committee.

For the in vivo assessment, printed hybrid constructs were

prepared, cultured in vitro for two weeks and implanted

subcutaneously in immunodeficient mice (nu/nu) (Charles

River Laboratories). An unseeded control hybrid scaffold

also was implanted in each mouse. The constructs were

implanted in the mice for two, four, and eight weeks. Six

animals were used to evaluate the performance of the hybrid

The viability of chondrocytes within the fabricated cartilage

constructs was evaluated at one week after printing by a twocolor fluorescence live/dead assay (Molecular Probes, OR)

following the manufacturers protocol. Briefly, triplicates of

printed cartilage constructs were rinsed with PBS to remove

residual serum and incubated for 30 min in 5% CO2 at

37 C with 2 ml of 2 M calcein AM and 4 M ethidium

homodimer (EthD-1) dissolved in 10 ml PBS solution.

4

Biofabrication 5 (2013) 015001

T Xu et al

cartilage constructs with two at each time point. Each mouse

was anesthetized with isoflurane and two small incisions

were created on the dorsa. Hybrid cartilage constructs were

subcutaneously inserted in the first incision. The control hybrid

constructs without cells were similarly inserted in the second

incision. After two, four, and eight weeks of implantation, the

incisions were closed and mice were examined. At the end of

study, constructs with 6 of the 12 experimental groups were

explanted from the mice and prepared for histological analysis.

polymers to be easily controlled to produce highly organized

porous structures that encourage cellular infiltration and

integration into the surrounding tissue [2426]. Furthermore,

manipulation of the electrospinning technique can produce

highly aligned fibers [27] that can be used to direct the growth

of muscle [28], nerves [29], and cartilage [30]. Like inkjet

printing, electrospinning is a low cost fabrication technique

with immense potential for tissue engineering. By combining

electrospinning with inkjet printing, we were able to obtain a

tissue construct consisting of layers of electrospun PCL and

printed hydrogels containing cells. This layered structure could

have been achieved by alternating electrospinning and inkjet

printing in separate machines. However, the combined hybrid

system allows production of extremely thin patterns in the

electrospun and cellular layers that would not survive repeated

movements between machines. In addition, the hybrid system

maintains the sterility of the printing field by eliminating

transfers between machines. Together, the electrospinning and

printing apparatuses create a system with greater capabilities

than either apparatus alone.

The printed hybrid constructs produced using our system

had adequate mechanical integrity to maintain the structure

of the five printed layers as shown in figures 2(A) and

(B). Microstructural analysis of the printed hybrid constructs

using SEM demonstrated the presence of intact layers of

cell/collagen matrix between the sheets of PCL as shown in

figure 2(C). Measurements of the electrospun fibers showed

an average fiber diameter of 422 62 nm and a pore size

smaller than 5 m. The microstructure of the PCL at high

magnification appeared fibrous, and occasional beads were

present (figure 2(D)). Formation of beads occurs when the

extruded polymer fails to form fibers and instead clusters on

the collection screen. This phenomenon is directly related to

the viscosity and surface tension of the polymer solution and is

inversely related to the charge density of the solution. However,

this can be avoided by increasing the concentration of polymer

in the solution and slowing the flow rate of the solution through

the needle tip. Beading can be controlled to generate structures

with porous membranes and cups [31]. Thus, this technique

may be used to finely tune the scaffold architecture for different

tissue types.

To visualize the attachment of chondrocytes to the

collagen matrix, the top layer of PCL was removed from

the construct and the cells were visualized under SEM.

Chondrocytes appeared to be firmly attached and spread out on

the matrix as shown in figure 2(E). SEM demonstrated that the

layered structure of the construct could be maintained in vitro.

However, we experienced layer separation in two constructs

immediately after printing because the electrospun and printed

layers were not well anchored to each other.

Our approach is very similar to recent work performed

by Yang et al [32], in which skin constructs were produced

by manually seeding fibroblasts and keratinocytes on wet

electrospun layers. Other similar studies have been performed

using electrosprayed cells and fibers, which allow a better

infiltration of cells into the scaffold [33, 34]. In our technique,

direct encapsulation of cells between fiber mats ensures that

cells are evenly distributed through the gel layers within the

2.11. Histological evaluation

Samples from printed hybrid constructs with cells and without

cells from in vitro and in vivo experiments were processed

for histological analyses. Samples were fixed overnight with

10% formalin. Fixed samples were then embedded in paraffin

and cut into 35 m thick sections. Massons Trichrome

(MT) staining for collagen and Safranin O (Saf O) staining

for glycosaminoglycans were performed to evaluate the

deposition and organization of extracellular matrix in the

printed hybrid constructs.

To distinguish collagen that had been deposited by

chondrocytes in the hybrid constructs from the collagen used

to print the constructs, sections were immunostained with antitype II collagen antibodies (Dako, Denmark). Immunostaining

was performed using a DakoAutostainer Universal Staining

System (Dako, Denmark). Slides were rinsed with Dako Wash

Buffer and incubated in 100 l of 3% hydrogen peroxide for

30 min. After rinsing twice in buffer, sections were incubated

with 100 l of 10% Dako ready-to-use protein block serumfree for 30 min and samples were left to air dry. Sections were

then incubated with 100 l of mouse anti-type II collagen

antibody at 1:200 dilution for 90 min, and this was followed

by two washes in buffer. Sections were incubated again

with blocking solution for 30 min and then incubated with

100 l of biotin-labeled rabbit anti-mouse antibody at a 1:200

dilution for 30 min. Sections were rinsed twice with buffer and

biotin was detected using streptavidin-conjugated horseradish

peroxidase (Vector Laboratories, Burlingame, CA).

2.12. Statistical analysis

Statistical analysis was performed using the Student t-test.

Values were represented as average SD where applicable

and p <0.05 was considered to be significant.

3. Results and discussion

3.1. Morphology and microstructure of hybrid

electrospun/inkjet printed constructs

We have developed a novel hybrid fabrication system that

combines both electrospinning and inkjet bioprinting to

achieve simultaneous high throughput cell patterning and

controlled scaffold production, thus overcoming one of the

major limitations of inkjet printing alone. Electrospinning

of PCL was incorporated in this hybrid printing system

because PCL scaffolds have excellent mechanical properties

and because electrospinning allows the composition of the

5

Biofabrication 5 (2013) 015001

T Xu et al

(B)

(A)

(C)

(D)

(E )

Figure 2. (A) Macroscopic view of the printed construct in culture media, scale bar 2 cm. (B) Schematic representation of the five-layer

printed constructs of PCL and chondrocytes. (C) Cross-sectional SEM at 200 magnification shows the layered structure of the scaffold.

PCL can be seen at the left and right with cells and collagen in the middle, scale bar 100 m. (D) 4000 magnification showing the

microstructure of the PCL, scale bar 10 m. (E) 500 magnification shows the chondrocytes attaching to the collagen matrix, scale bar

10 m.

scaffold, but the cell growth, tissue formation, mechanical

properties and functional expression are difficult to control due

to the limitations of this technology. These constructs could

be adequate for use in engineering some tissues, but the cell

placement is not specific enough to build tissues and organs

with complex structural and functional requirements. The

major advantage of our technique over previous work is that we

are using inkjet printing to precisely control deposition of cells

in complex patterns within the layers. This is an ability that no

other system has been able to demonstrate and illustrates the

power of this novel system. The architecture of electrospun

scaffolds could already be controlled by manipulating the

polymer flow rate, needle size, voltage, and electric field

to organize layered tissue constructs in the Z direction. The

current prototype we used for this study needed lengthy time

to fabricate the constructs. This is mostly due to the time

required to electrospin the PCL scaffolds. Further development

is necessary to build a high-throughput system that could

fabricate constructs in a reasonably acceptable time.

The live/dead assay indicated that after one week in culture,

81.58 3.46% of the chondrocytes in the printed hybrid

constructs were viable. This suggests that the combined

electrospinning/printing process did not affect the viability of

the cells, which showed similar viabilities at similar time points

in previous experiments [15]. The electrospinning process did

not significantly affect the printed cells, likely because the

collection plate acted as the ground and prevented the cells

from being directly exposed to the voltage. Furthermore, other

studies have shown that cells can be directly deposited at high

voltage with no apparent detrimental effects [30, 31].

3.3. Mechanical testing

To evaluate the structural and mechanical properties of the

constructs, we examined the Youngs modulus and UTS

of each construct and compared these to the values for

constructs fabricated with PCL alone by electrospinning and

for constructs produced with alginate, the scaffolding material

typically used in bioprinting. Mechanical testing demonstrated

that the printed hybrid constructs were stiffer and were able to

withstand greater tensile stress than alginate, collagen/fibrin or

electrospun PCL/F-127-only constructs (table 1). The Youngs

modulus of the printed hybrid constructs (1.76 MPa) was four

3.2. Cell viability

Printed hybrid constructs with chondrocytes were analyzed

using the Molecular ProbesTM viability/cytotoxicity assay.

6

Biofabrication 5 (2013) 015001

T Xu et al

(hyaluronan, chondroitin sulfate, and keratin sulfate), and

elastin. Of these, type II collagen and the glycosaminoglycans

were expected to be most visible in the fabricated constructs.

Analysis of sections after two weeks in vitro showed the

initiation of cartilage tissue formation, but there was very little

cartilage tissue visible. We hypothesize that the lack of ECM

deposition at two weeks in vitro was due to lack of nutrient

diffusion within the constructs. However, histological analysis

confirmed that the chondrocytes were producing the matrix

components of cartilage tissue after four weeks of in vitro

culture (figure 3). When printed hybrid constructs containing

cells were compared to printed hybrid constructs without

cells at four weeks, H&E staining showed that a significant

population of homogenously organized chondrocytes existed

within the matrix of the printed hybrid constructs with cells

(figure 3(B)) compared to the negative control constructs

(figure 3(A)). MT staining demonstrated the clear presence

of well-dispersed collagen bands accumulated around the

cells (figure 3(D)). Immunohistochemical analysis revealed

formation of type II collagen in the printed hybrid constructs.

This was not present in the print mixture and is a major

component of cartilage (figures 3(G) and (H)). Saf O staining

demonstrated the presence of GAGs only in the printed hybrid

constructs with cells (figures 3(F) and (E)). Interestingly,

glycosaminoglycans and type II collagen, the two important

components of cartilage, seemed to be concentrated at the

edges of the constructs at four weeks in vitro, suggesting that

the cells in the center of the construct were less functionally

active, possibly due to limited diffusion of nutrients and

growth factors from the media to the center of the construct

[32, 38]. The parameters of the electrospinning in this

experiment generated nanofibers with very low porosity,

which may have prevented nutrients in the media from

diffusing through these pores. Altering the parameters of the

electrospinning would change the porosity of the layers, but a

very dense lower layer of PCL should be maintained to prevent

the cells from falling through the construct. Alternatively, a

mixture of nano- and microfibers may be useful to enhance

the diffusion of nutrients and growth factors at the core of the

constructs.

In vivo evaluation of explanted tissues after 8 weeks

showed dense and well organized collagen formation in the

printed hybrid constructs compared to very minimal formation

of collagen in the controls (figures 4(A) and (B)). The structure

of the GAGs appears to resemble typical elastic cartilage with

areas of dense GAGs interspersed with areas of little deposition

(figure 4(D)). Most importantly, constructs recovered from

mice showed rounded chondrocytes with lacunae that are

typical of normal elastic cartilage. Type II collagen was

also visible in the printed constructs (figure 4(F)). Control

constructs showed no presence of collagen type II or GAGs

after eight weeks of implantation (figures 4(C) and (E)).

Constructs retrieved after eight weeks in vivo had large

amounts of collagen and GAGs deposited throughout the entire

construct and appeared histologically similar to normal elastic

cartilage. This demonstrates that the cells were able to maintain

their normal phenotype and produce ECM in vivo despite the

in vitro limitations.

Table 1. Youngs modulus and UTS of pure alginate gel,

electrospun pure PCL, hybrid PCL/collagen/fibrin scaffolds, and

collagen/fibrin matrix. Data were presented as average SD

(n = 3).

Youngs modulus (MPa)

Alginate

PCL

Scaffold

Matrix

0.41 0.06a

0.77 0.22

1.76 0.71a

b

UTS (MPa)

0.26 0.11a

0.92 0.20

1.11 0.12a

b

p < 0.05 versus hybrid scaffold by

two-sample t-test.

b

Mechanical strength of collagen/fibrin

matrix was too low to be distinguished

from random noise.

a

times higher than that of alginate constructs (0.41 MPa) (n

= 4, p = 0.008)). Similarly, the UTS of the printed hybrid

constructs (1.11 MPa) was five times higher than the UTS

of the alginate constructs (0.26 MPa) (n = 4, p = 0.003).

Neither the strength nor the stiffness of the printed hybrid

constructs was significantly different from those measured

for pure PCL/F-127 electrospun fibers (n = 4, p = 0.067).

This observation was expected, as the collagen/fibrin gel

has very low mechanical strength and generally does not

contribute to the combined mechanical properties of the

construct. When tested, collagen/fibrin constructs indeed

displayed such low tensile strength that the stress-strain

profile was indistinguishable from the noise signal generated

by the testing machine. These mechanical testing results

confirmed our hypothesis that the hybrid constructs would

demonstrate increased structural stability over the alginate

or fibrin/collagen hydrogels. Both Youngs modulus and the

UTS of the constructs were significantly greater than alginate

because the constructs took on the structural properties of

the PCL. While the observed beading in the PCL reduced

the tensile strength of woven electrospun fibers by forming

stress defects [35], the hybrid structures still showed better

mechanical properties over the alginate controls. Boland

et al evaluated the Youngs modulus and UTS of printed

alginate constructs to be 89 47 KPa and 56 12 KPa,

respectively and were comparable to our alginate mechanical

values [36]. The mechanical properties of the hybrid cartilage

constructs were lower than those reported for native human

cartilage (Youngs modulus 4.1 MPa) [37]. These properties

are expected to improve during the tissue regeneration process

as cells deposit and align their own ECM. Moreover, the initial

mechanical properties of the printed hybrid constructs can be

easily improved by changing the diameter, porosity and/or

orientation of electrospun PCL fibers.

3.4. Histological analysis

Having demonstrated that cells were able to survive the

printing process and that the printed hybrid constructs were

indeed stronger than standard alginate scaffolds, we examined

ECM production by the printed chondrocytes in order to

determine if the cells retained some or all of their functional

characteristics. The main components of elastic cartilage are

collagen (types II, VI, IX, X, and XI), glycosaminoglycans

7

Biofabrication 5 (2013) 015001

T Xu et al

(A)

(C )

(E)

(G )

(B)

(D)

(F )

(H )

Figure 3. Histological analysis of in vitro printed constructs with cells (printed) and without cells (control) at four weeks. Printed samples

are five layer constructs alternating PCL and cells in a collagen/fibrin gel. Control samples are five layer constructs alternating PCL and

collagen/fibrin gel. (A) Control sample stained with H&E shows no presence of cells. (B) H&E staining of the printed constructs after four

weeks in culture. Dark blue staining indicates cell nuclei. (C) Control sample stained with MT shows no blue collagen. (D) MT staining of

the printed constructs after four weeks in culture. Dark staining shows cell nuclei. Blue staining demonstrates presence of collagen. (E)

Control sample stained with Saf O shows only green counterstain and no red GAGs. (F) Saf O staining of the printed constructs after four

weeks in culture. Dark staining indicates cell nuclei and red shows production of GAGs. (G) Control sample labeled with anti-type II

collagen antibody demonstrating only counterstain. (H) Anti-type II collagen antibody labeling a section after four weeks in culture. Brown

staining indicates production of type II collagen. Magnification: 200 . Scale bars: 100 m.

(A)

(C )

(E )

(B)

(D)

(F )

Figure 4. Histological analysis of in vivo printed constructs with cells (printed) and without cells (controls) at eight weeks after implantation.

Printed samples are five layer constructs alternating PCL and cells in a collagen/fibrin gel. Control samples are five layer constructs

alternating PCL and collagen/fibrin gel. All samples were cultured for two weeks prior to implantation. (A) Control sample stained with MT

shows no blue collagen. (B) MT staining of constructs implanted in vivo for eight weeks demonstrating large bands of collagen. (C) Control

sample stained with Saf O shows no red GAGs. (D) Saf O staining of in vivo constructs shows significant GAG production. (E) Control

sample labeled with anti-type II collagen antibody demonstrating only counterstain. (F) Anti-type II collagen antibody labeling a section

after eight weeks in vivo. Brown staining indicates production of type II collagen. Magnification: 200. Scale bars: 100 m.

Careful selection of scaffold material for each patients

construct would allow the implant to withstand mechanical

forces while encouraging new cartilage to organize and fill

the defect. This technique can also be extended to other tissue

types. Although electrospun scaffolds can direct chondrocytes

3.5. Future direction

Cartilage constructs similar to those created in this experiment

could be applied clinically by using MRI images of a defect in

the knee as a blueprint to bioprint a matching construct.

8

Biofabrication 5 (2013) 015001

T Xu et al

growth [30], they can also direct the formation of myotubes to

enhance strategies for muscle tissue engineering [28]. The use

of hybrid system allows creation of highly aligned electrospun

fibers and targeted application of myotubes. This technique can

then be used to layer patterns of endothelial cells and nerve

cells on the aligned myotubes to create functional muscle.

By overcoming one of the major obstacles associated with

conventional bioprinting, we have expanded the utility of

biofabrication technology.

[9]

[10]

[11]

[12]

Conclusions

This study demonstrates the feasibility of generating layered

cartilage constructs using a combination of electrospinning

and inkjet printing. The hybrid scaffold demonstrated

enhanced mechanical properties compared to conventional

hydrogel constructs generated using inkjet printing alone.

Printed cells maintained their viability and produced cartilagespecific ECM both in vitro and in vivo. Further refinement of

the technique could produce functional cartilage constructs by

using oriented fibers to direct chondrocyte growth. Combining

this tight control of scaffold properties with the precise cell

delivery of the printing process, as well as with advances

in hydrogel technology, will enable production of highly

functional tissue constructs. This work indicates that the hybrid

electrospinning/inkjet printing technique is a promising new

technology that could simplify production of complex tissues.

[13]

[14]

[15]

[16]

[17]

[18]

Acknowledgments

[19]

The authors would like to thank Cathy Mathis for assistance

with histology and Dr Jennifer Olson for editorial assistance

with this manuscript.

[20]

[21]

References

[1] Slaughter B V, Khurshid S S, Fisher O Z, Khademhosseini A

and Peppas N A 2009 Hydrogels in regenerative medicine

Adv. Mater. 21 330729

[2] Mather M L and Tomlins P E 2010 Hydrogels in regenerative

medicine: towards understanding structure-function

relationships Regen. Med. 5 80921

[3] Chung B G, Lee K H, Khademhosseini A and Lee S H 2012

Microfluidic fabrication of microengineered hydrogels and

their application in tissue engineering Lab Chip 12 4559

[4] Huang G Y et al 2011 Microfluidic hydrogels for tissue

engineering Biofabrication 3 012001

[5] Reichert J C, Heymer A, Berner A, Eulert J and Noth U 2009

Fabrication of polycaprolactone collagen hydrogel

constructs seeded with mesenchymal stem cells for bone

regeneration Biomed. Mater. 4 065001

[6] Schuurman W, Khristov V, Pot M W, van Weeren P R,

Dhert W J and Malda J 2011 Bioprinting of hybrid tissue

constructs with tailorable mechanical properties

Biofabrication 3 021001

[7] Hutmacher D W, Sittinger M and Risbud MV 2004

Scaffold-based tissue engineering: rationale for

computer-aided design and solid free-form fabrication

systems Trends Biotechnol. 22 35462

[8] Shim J H, Kim J Y, Park M, Park J and Cho D W 2011

Development of a hybrid scaffold with synthetic

[22]

[23]

[24]

[25]

[26]

[27]

biomaterials and hydrogel using solid freeform fabrication

technology Biofabrication 3 034102

Shim J H, Lee J S, Kim J Y and Cho DW 2012 Bioprinting of

a mechanically enhanced three-dimensional dual cell-laden

construct for osteochondral tissue engineering using a

multi-head tissue/organ building system J. Micromech.

Microeng. 22 085014

Wilson W C Jr and Boland T 2003 Cell and organ printing 1:

protein and cell printers Anat. Rec. 272A 4916

Roth E A, Xu T, Das M, Gregory C, Hickman J J

and Boland T 2004 Inkjet printing for high-throughput cell

patterning Biomaterials 25 370715

Okamoto T, Suzuki T and Yamamoto N 2000 Microarray

fabrication with covalent attachment of DNA using bubble

jet technology Nature Biotechnol. 18 43841

Roda A, Guardigli M, Russo C, Pasini P and Baraldini M 2000

Protein microdeposition using a conventional ink-jet printer

Biotechniques 28 (3) 4926

Xu T et al 2004 Construction of high-density bacterial colony

arrays and patterns by the ink-jet method Biotechnol.

Bioeng. 85 2933

Xu T, Jin J, Gregory C, Hickman J J and Boland T 2005 Inkjet

printing of viable mammalian cells Biomaterials 26 939

Xu T, Gregory C A, Molnar P, Cui X, Jalota S, Bhaduri S B

and Boland T 2006 Viability and electrophysiology of

neural cell structures generated by the inkjet printing

method Biomaterials 27 35808

Xu T, Rohozinski J, Zhao W, Moorefield E C, Atala A

and Yoo J J 2009 Inkjet-mediated gene transfection into

living cells combined with targeted delivery Tissue Eng. A

15 95101

Boland T, Mironov V, Gutowska A, Roth E A

and Markwald R R 2003 Cell and organ printing 2: fusion

of cell aggregates in three-dimensional gels Anat. Rec.

272A 497502

Tanaka Y, Gong J P and Osada Y 2005 Novel hydrogels with

excellent mechanical performance Prog. Polym. Sci. 30 19

Bonn D, Kellay H, Prochnow M, Ben-Djemiaa K

and Meunier J 1998 Delayed fracture of an inhomogeneous

soft solid Science 280 2657

Klein T J, Rizzi S C, Reichert J C, Georgi N, Malda J,

Schuurman W, Crawford R W and Hutmacher D W 2009

Strategies for zonal cartilage repair using hydrogels

Macromol. Biosci 9 104958

Lee S J and Yoo J J 2012 Guidance of cell adhesion,

alignment, infiltration, and differentiation on electrospun

nanofibrous scaffolds Handbook of Intelligent Scaffold for

Tissue Engineering and Regenerative Medicine ed G Khang

(Singapore: Pan Stanford Publishing) pp 20112

Sanz E, Penas L and Lequerica J L 2007 Formation of

cartilage in vivo with immobilized autologous rabbit

auricular cultured chondrocytes in collagen matrices Plast.

Reconstr. Surg. 119 170713

Ekaputra A K, Prestwich G D, Cool S M and Hutmacher D W

2008 Combining electrospun scaffolds with electrosprayed

hydrogels leads to three-dimensional cellularization of

hybrid constructs Biomacromolecules 9 2097103

Lee Y H et al 2005 Electrospun dual-porosity structure and

biodegradation morphology of Montmorillonite reinforced

PLLA nanocomposite scaffolds Biomaterials 26 316572

Kim T G, Chung H J and Park T G 2008 Macroporous and

nanofibrous hyaluronic acid/collagen hybrid scaffold

fabricated by concurrent electrospinning and

deposition/leaching of salt particles Acta Biomater.

4 16119

Li D, Ouyang G, McCann J T and Xia Y 2005 Collecting

electrospun nanofibers with patterned electrodes Nano Lett.

5 9136

Biofabrication 5 (2013) 015001

T Xu et al

[28] Choi J S, Lee S J, Christ G J, Atala A and Yoo J J 2008 The

influence of electrospun aligned poly(epsiloncaprolactone)/collagen nanofiber meshes on the formation

of self-aligned skeletal muscle myotubes Biomaterials

29 2899906

[29] Wang H B et al 2009 Creation of highly aligned electrospun

poly-L-lactic acid fibers for nerve regeneration applications

J. Neural Eng. 6 016001

[30] Wise J K, Yarin A L, Megaridis C M and Cho M 2009

Chondrogenic differentiation of human mesenchymal stem

cells on oriented nanofibrous scaffolds: engineering the

superficial zone of articular cartilage Tissue Eng. A

15 91321

[31] Eda G and Shivkumar S 2006 Bead structure variations

during electrospinning of polystyrene J. Mater. Sci.

41 57048

[32] Yang X, Shah J D and Wang H 2009 Nanofiber enabled

layer-by-layer approach toward three-dimensional tissue

formation Tissue Eng. A 15 94556

[33] Stella J A, Liao J, Hong Y, David Merryman W, Wagner W R

and Sacks M S 2008 Tissue-to-cellular level deformation

[34]

[35]

[36]

[37]

[38]

10

coupling in cell micro-integrated elastomeric scaffolds

Biomaterials 29 322836

Townsend-Nicholson A and Jayasinghe S N 2006 Cell

electrospinning: a unique biotechnique for encapsulating

living organisms for generating active biological

microthreads/scaffolds Biomacromolecules 7 33649

Cha D I, Kim H Y, Lee K H, Jung Y C, Cho J W

and Chun B C 2005 Electrospun nonwovens of

shape-memory polyurethane block copolymers J. Appl.

Polym. Sci. 96 4605

Boland T, Xu T, Damon B and Cui X 2006 Application of

inkjet printing to tissue engineering Biotechnol. J. 1 9107

Woodfield T B, Malda J, de Wijn J, Peters F, Riesle J and van

Blitterswijk C A 2004 Design of porous scaffolds for

cartilage tissue engineering using a three-dimensional

fiber-deposition technique Biomaterials 25 414961

Wang H J, Bertrand-De Haas M, Riesle J, Lamme E and Van

Blitterswijk C A 2003 Tissue engineering of dermal

substitutes based on porous PEGT/PBT copolymer

scaffolds: comparison of culture conditions J. Mater. Sci.

Mater. Med. 14 23540

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Maths Question of The DayDokumen162 halamanMaths Question of The DayGaurav YadavBelum ada peringkat

- The Neurohistological TechniquesDokumen4 halamanThe Neurohistological Techniquesapi-3846255100% (2)

- DST 60 IFT MeasurementDokumen12 halamanDST 60 IFT Measurement김동완Belum ada peringkat

- C12HDokumen129 halamanC12Hkhudhayer1970Belum ada peringkat

- Task 3 - New Research Proposal, C Vides o ZamudioDokumen3 halamanTask 3 - New Research Proposal, C Vides o ZamudioOctavio LópezBelum ada peringkat

- Pages From SAES-H-001-19Dokumen1 halamanPages From SAES-H-001-19mohammed s fawabBelum ada peringkat

- Bm101: Biology For Engineers: Instructor: Yashveer Singh, PHDDokumen15 halamanBm101: Biology For Engineers: Instructor: Yashveer Singh, PHDhimanshu singhBelum ada peringkat

- Chemistry Final Cheat SheetDokumen1 halamanChemistry Final Cheat SheetScott Allred100% (2)

- Pamphlet TG-X SeriesDokumen2 halamanPamphlet TG-X SeriesrajeshBelum ada peringkat

- Dna Repair MechanismsDokumen49 halamanDna Repair MechanismsayeshaBelum ada peringkat

- Marine Science Semester 1 ReviewDokumen18 halamanMarine Science Semester 1 ReviewJoe Xavier ReidyBelum ada peringkat

- Din 50942-96Dokumen13 halamanDin 50942-96RONALD100% (2)

- Redox ExerciseDokumen4 halamanRedox ExerciseHau Hei, Matthew LinBelum ada peringkat

- In-Line Pulsation Dampeners For Bredel 25-100, APEX 28 and APEX 35 PumpsDokumen2 halamanIn-Line Pulsation Dampeners For Bredel 25-100, APEX 28 and APEX 35 PumpsVruno Velasquez LBelum ada peringkat

- CBSE Class 11 and 12 Chemistry Notes The P-Block ElementsDokumen45 halamanCBSE Class 11 and 12 Chemistry Notes The P-Block ElementsPrabhuPalanichamy50% (2)

- Ultimate Cheatcode CematconDokumen82 halamanUltimate Cheatcode CematconJulian Deleon100% (1)

- Copper Filling of Blind Micro Vias and Through Holes Using Reverse Pulse PlatingDokumen4 halamanCopper Filling of Blind Micro Vias and Through Holes Using Reverse Pulse PlatingteehoweBelum ada peringkat

- Sika®-1: Product Data SheetDokumen2 halamanSika®-1: Product Data SheetKhin Sandi KoBelum ada peringkat

- An Overview of Traditional Fish Smoking in Africa PDFDokumen20 halamanAn Overview of Traditional Fish Smoking in Africa PDFBzmania SlimnzieBelum ada peringkat

- Duplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Dokumen11 halamanDuplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Mathew CherianBelum ada peringkat

- Suitable dimensions, performance requirements, and processes for optical transmittersDokumen1 halamanSuitable dimensions, performance requirements, and processes for optical transmittersshruti soniBelum ada peringkat

- Assignment 5: Unit 7 - Week 5Dokumen1 halamanAssignment 5: Unit 7 - Week 5atulBelum ada peringkat

- Efficient H2S Scavenger Glyoxal Outperforms TriazineDokumen8 halamanEfficient H2S Scavenger Glyoxal Outperforms TriazineMo OsBelum ada peringkat

- Udel PSU Design Guide - EN v5.0 - 0 - 0 PDFDokumen84 halamanUdel PSU Design Guide - EN v5.0 - 0 - 0 PDFReza Pencinta AL HadadBelum ada peringkat

- Carbonate Acidizing Design PDFDokumen15 halamanCarbonate Acidizing Design PDFNelson PuentsBelum ada peringkat

- GraniteDokumen4 halamanGranitequsaiBelum ada peringkat

- OzonolysisDokumen1 halamanOzonolysisThu NguyenBelum ada peringkat

- Metabolisme ImmunometabolismDokumen25 halamanMetabolisme ImmunometabolismOKE channelBelum ada peringkat

- Reinforcing Low-Grade Glulam Beams with GFRP RodsDokumen12 halamanReinforcing Low-Grade Glulam Beams with GFRP RodsCălin MartonBelum ada peringkat

- Important Aspect of Viscosity in Gravure Printing ProcessDokumen18 halamanImportant Aspect of Viscosity in Gravure Printing ProcessMakarand Dole100% (1)