BOP Leave Behind For OIRA MTG

Diunggah oleh

Aulia Bimo AbmJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BOP Leave Behind For OIRA MTG

Diunggah oleh

Aulia Bimo AbmHak Cipta:

Format Tersedia

API Standard 53

API Standard 53 Blowout Equipment Systems

for Drilling Wells was developed using the API

ANSI accredited standards development

process based on openness, balance,

consensus and due process

The current edition was published November

2012

This Standard is the product of two plus years

of SMEs work and has now been in use for

nearly 3 years

Industry fully supports IBR of API 53 in its

entirety

16

Deviations from API 53

Accumulator Capacities

All at once inspection of the BOP

Hydraulic Locks on Surface Stacks

ROV Intervention Functions

Shear/Seal under flowing conditions

Shear Sequences

Testing

Training and Qualification

17

To comply with proposed rule,

one Drilling Contractors stack

would require :

33 additional subsea

accumulators

62 Surface accumulators

19 additional ROV panels

However, it is currently in

compliance with API specifications.

Typical Stack Today

Stack After Proposed Rule

After the proposed rule, BOP Stacks would be significantly heavier, more difficult to handle and

maintain, and have ROV visibility obscured. More importantly, they would not be any safer than the

ones used today and would become less reliable due to the additional components and leak points.

18

Accumulators store energy for use when power source is

unavailable or to assist rapid discharge. Basically they

compress gas against the power fluid which expands and

drives the power fluid to the selected application.

All BOP functions are normally powered from surface

supply by high pressure pumps that deliver fluid which is

stored in accumulator banks which supplement the

pumps when a function is operated such as closing a

pipe ram.

250.735(a) A surface accumulator system that provides

1.5 times the volume of fluid capacity necessary to close

and hold closed all BOP components against MASP.

Hydraulic Power Unit

19

The modern subsea BOP stack is fifty plus

feet tall, weighs 460 - 500 short tons and, in

2011, cost in the region of $40,000,000.

API S 53 section 7.6.9.3.1

At least every 5 years, the well control

system components shall be inspected for

repair or remanufacturing, in accordance

with equipment owner's PM program and

the manufacturer's guidelines.

250.739 What are the BOP maintenance and

inspection requirements?

A complete breakdown and detailed

physical inspection of the BOP and every

associated system and component must be

performed every 5 years. This complete

breakdown and inspection may not be

performed in phased intervals. A BSEEapproved verification organization is

required to be present during the

inspection

20

Diverter Housing

Riser joints are 75 90 feet long and with

buoyancy weigh up to 40 Tons each. A

Deepwater rig owns about 120 joints

Are all these associated systems to be removed and returned to

OEM every 5 years?

Choke & Kill Manifold

BOP Control Panel

Central Control Console

BOP control pods

distribute control fluid

with over 110

functions and weigh

about 27 tons each

21

Hydraulic Locks on Surface Stacks

Manual locks have been reliably and safely used for many years

The need for hydraulic locks was driven by the application of a subsea

BOP which doesnt lend itself to manual locks as it is physically located

subsea

During the latest revision of API 53, there was insufficient data to require

the use of hydraulic locks on surface BOPs

Manual locks are more reliable than hydraulic locks due to their simplified

design and inherent manual operation

Increase in control system complexity

Operating the equipment under high pressure has successfully been

accomplished using proven safe operational procedures

BOP with Manual Locks

BOP with Hydraulic Locks

22

API 53 identifies the critical functions which require ROV access

The BOP is equipped with accumulators for emergency functions such as Deadman and

Autoshear systems

ROV Panels are secondary control systems currently assigned to critical functions only

Many additional ROV panels would be required to comply to the proposed rule

This would result in additional leak paths, and require more space / real estate on the

stack

The additional equipment would obscure the ROVs view

Existing ROV Panels and Visibility

23

Existing Valve and Plumbing

BOP Equipment Summary

Industry fully supports the IBR of API 53, but does not

support those requirements that deviate from those

found in API 53

API 53 was developed and published in November 2012

through a comprehensive, accredited process to address

BOP equipment systems for drilling wells and should be

the basis of the new rule

Deviations from API 53 in the Proposed Rule may:

increase risk and complexity;

decrease overall system reliability and safety;

not be technically feasible; and

risk US global competitiveness

24

Anda mungkin juga menyukai

- OTC-23473-MS - New Generation Control System For 20ksi Subsea BOP - Shanks - 2012Dokumen12 halamanOTC-23473-MS - New Generation Control System For 20ksi Subsea BOP - Shanks - 2012Anonymous TYj74uwBelum ada peringkat

- Bright Boipuso Final Presentation-UpdatedDokumen27 halamanBright Boipuso Final Presentation-UpdatedBrightBelum ada peringkat

- Epa 40 CFR 112Dokumen32 halamanEpa 40 CFR 112Vlad420Belum ada peringkat

- BOP and Control SystemDokumen79 halamanBOP and Control SystemGonzalo Guzman Jaimes100% (1)

- 01 BOP and Control SystemDokumen79 halaman01 BOP and Control SystemAustin AsuquoBelum ada peringkat

- NORSOK D-SR-005 On Coiled TubingDokumen17 halamanNORSOK D-SR-005 On Coiled TubingJozsef MagyariBelum ada peringkat

- BOP Basic Safety FunctionsDokumen26 halamanBOP Basic Safety FunctionsMohamedSadekBelum ada peringkat

- Coiled Tubing EquipmentDokumen17 halamanCoiled Tubing EquipmentRombo RootBelum ada peringkat

- Nfpa - 1901-1906 Presentacion en Ingles PDFDokumen54 halamanNfpa - 1901-1906 Presentacion en Ingles PDFsantiagoBelum ada peringkat

- DETG 3-24-3011 Frank GallanderDokumen11 halamanDETG 3-24-3011 Frank GallanderidrisBelum ada peringkat

- Crown BlockDokumen6 halamanCrown BlockNigin ParambathBelum ada peringkat

- Wor-Ges-045 DD 8 8 23Dokumen7 halamanWor-Ges-045 DD 8 8 23reda rashwanBelum ada peringkat

- SOW For Stacker and Reclaimer - Inspection and EvaluationDokumen8 halamanSOW For Stacker and Reclaimer - Inspection and Evaluationriysall100% (1)

- Pump and Valve Requirements and Guidance For New ReactorsDokumen175 halamanPump and Valve Requirements and Guidance For New ReactorssivaramBelum ada peringkat

- ASME B31 1 Power Piping Inspection and Repair Updates Joe FreyDokumen32 halamanASME B31 1 Power Piping Inspection and Repair Updates Joe Freyvpsimbu86100% (1)

- ArtificialLiftSystem 16 PDFDokumen167 halamanArtificialLiftSystem 16 PDFchftBelum ada peringkat

- 30 Mainline Hydrotesting 111Dokumen25 halaman30 Mainline Hydrotesting 111rexBelum ada peringkat

- Technical Specification MRSDokumen14 halamanTechnical Specification MRSPrasanna kumar subudhiBelum ada peringkat

- Mooring Line and Vetting Requirements - Update - 03 May 2023Dokumen6 halamanMooring Line and Vetting Requirements - Update - 03 May 2023hugo YangBelum ada peringkat

- API 682 3rd For TrainingDokumen46 halamanAPI 682 3rd For TrainingJai-Hong Chung100% (3)

- Engineering Encyclopedia: Saudi Aramco Piping SystemsDokumen23 halamanEngineering Encyclopedia: Saudi Aramco Piping SystemsPrakhar KulshreshthaBelum ada peringkat

- ROIVsDokumen8 halamanROIVshamza shafiqBelum ada peringkat

- Operation and Maintenance of Hydropower Stations PDFDokumen26 halamanOperation and Maintenance of Hydropower Stations PDFtranhuutuongBelum ada peringkat

- Usdot Phmsa Update: 2015 API - AGA Joint Committee Oil & Gas Pipeline Welding PracticesDokumen17 halamanUsdot Phmsa Update: 2015 API - AGA Joint Committee Oil & Gas Pipeline Welding PracticesDiBelum ada peringkat

- 1 ScopeDokumen9 halaman1 ScopedownloadBelum ada peringkat

- 1 การตรวจสอบการสร้างหม้อน้ำตามมาตรฐานASME2013Dokumen24 halaman1 การตรวจสอบการสร้างหม้อน้ำตามมาตรฐานASME2013Surasan ThepsiriBelum ada peringkat

- Preliminary Design ReportDokumen7 halamanPreliminary Design ReportAhmed ShoeebBelum ada peringkat

- IFRDokumen27 halamanIFRneerajtrvBelum ada peringkat

- Chapter 5 Wellhead and Choke PerformanceDokumen35 halamanChapter 5 Wellhead and Choke PerformanceAbuzeidBelum ada peringkat

- Commissioning Chilled Water TES Tank Systems: Technical FeatureDokumen10 halamanCommissioning Chilled Water TES Tank Systems: Technical FeatureJuan Fernando AriasBelum ada peringkat

- Akpo Field Development Focus On Riser System: BY Omeoga Obinna OTI/MSC/PPE/2016/FT/013Dokumen11 halamanAkpo Field Development Focus On Riser System: BY Omeoga Obinna OTI/MSC/PPE/2016/FT/013obinnaBelum ada peringkat

- API 682 4th Edition Category 1 Configurations: 3CW-FBDokumen19 halamanAPI 682 4th Edition Category 1 Configurations: 3CW-FBtuliofilipeBelum ada peringkat

- DOP 206 - Rev 4Dokumen12 halamanDOP 206 - Rev 4Fernando AybarBelum ada peringkat

- Design PhilosophyDokumen9 halamanDesign Philosophyabet133100% (1)

- Section 5: Guidelines For Operation and Maintenance of Sub - Transmission and Distribution EquipmentDokumen29 halamanSection 5: Guidelines For Operation and Maintenance of Sub - Transmission and Distribution EquipmentNagesh ThombareBelum ada peringkat

- Hand Out API 510 - IBT Reg Class - Rev 7 - Aug 2019Dokumen41 halamanHand Out API 510 - IBT Reg Class - Rev 7 - Aug 2019Eddy Dwi CahyonoBelum ada peringkat

- Hydro Power MaintenanceDokumen26 halamanHydro Power Maintenancetrxrhcp50% (4)

- AL Selection - Draft of Document - 2d01 - Sucker RodDokumen20 halamanAL Selection - Draft of Document - 2d01 - Sucker RodRaymundo Leonardo Pérez SierraBelum ada peringkat

- Spec Clauses NotesDokumen4 halamanSpec Clauses NoteszohaBelum ada peringkat

- 12 13 2016 MA PowerpointDokumen32 halaman12 13 2016 MA PowerpointKyle LangsleyBelum ada peringkat

- Chevron Maintenance & Inspection ProceduresDokumen40 halamanChevron Maintenance & Inspection Procedureshazopman100% (3)

- 2017 RETA Conference RAGAGEPDokumen33 halaman2017 RETA Conference RAGAGEPArdago LenggaBelum ada peringkat

- 04 Moduspec Justin Nally PDFDokumen25 halaman04 Moduspec Justin Nally PDFmojtaba_m007Belum ada peringkat

- FS HpuDokumen11 halamanFS Hpuscribd_thakurBelum ada peringkat

- Chapter-8 Turbine and Governor TestingDokumen10 halamanChapter-8 Turbine and Governor Testingafru2000Belum ada peringkat

- Industry & Govt Changes Post MacondoDokumen27 halamanIndustry & Govt Changes Post Macondonam172Belum ada peringkat

- Al Murjan Palace (Family Complex 1) - Mothers Villa - Mep Comments - 2022.08.18Dokumen39 halamanAl Murjan Palace (Family Complex 1) - Mothers Villa - Mep Comments - 2022.08.18Ayman SaeedBelum ada peringkat

- API 570 Final Exam ClosedDokumen12 halamanAPI 570 Final Exam Closedtbmari100% (3)

- API 653 and New Storage Tank DesignDokumen2 halamanAPI 653 and New Storage Tank DesignNabil Al-KhirdajiBelum ada peringkat

- API 510 QuizDokumen8 halamanAPI 510 QuizJeremy CoussouBelum ada peringkat

- CRW Overview and Product OfferingDokumen32 halamanCRW Overview and Product OfferingDean ReinBelum ada peringkat

- Product Update Reverse Circulation PDFDokumen4 halamanProduct Update Reverse Circulation PDFYoko Golding0% (1)

- GAIL (India) Limited Compressor Station Hazira, PO ONGCL, Ichhapore - Magdhalla Road, District Surat (Gujarat) Pin 394 518Dokumen19 halamanGAIL (India) Limited Compressor Station Hazira, PO ONGCL, Ichhapore - Magdhalla Road, District Surat (Gujarat) Pin 394 518Mayavan ABelum ada peringkat

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDari Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsPenilaian: 4 dari 5 bintang4/5 (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDari EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazinePenilaian: 5 dari 5 bintang5/5 (1)

- Subsea Valves and Actuators for the Oil and Gas IndustryDari EverandSubsea Valves and Actuators for the Oil and Gas IndustryPenilaian: 5 dari 5 bintang5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- Textbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringDari EverandTextbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringBelum ada peringkat

- FIRST SUMMATIVE EXAMINATION IN ORAL COMMUNICATION IN CONTEXT EditedDokumen3 halamanFIRST SUMMATIVE EXAMINATION IN ORAL COMMUNICATION IN CONTEXT EditedRodylie C. CalimlimBelum ada peringkat

- Global Divides: The North and The South: National University Sports AcademyDokumen32 halamanGlobal Divides: The North and The South: National University Sports AcademyYassi CurtisBelum ada peringkat

- DBMS Lab ManualDokumen57 halamanDBMS Lab ManualNarendh SubramanianBelum ada peringkat

- QSP 04bDokumen35 halamanQSP 04bakrastogi94843Belum ada peringkat

- ML Ass 2Dokumen6 halamanML Ass 2Santhosh Kumar PBelum ada peringkat

- The Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermannDokumen15 halamanThe Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermanngeorgiescuBelum ada peringkat

- Microsmart GEODTU Eng 7Dokumen335 halamanMicrosmart GEODTU Eng 7Jim JonesjrBelum ada peringkat

- Bolt Grade Markings and Strength ChartDokumen2 halamanBolt Grade Markings and Strength ChartGregory GaschteffBelum ada peringkat

- How He Loves PDFDokumen2 halamanHow He Loves PDFJacob BullockBelum ada peringkat

- Applications SeawaterDokumen23 halamanApplications SeawaterQatar home RentBelum ada peringkat

- What's New in CAESAR II: Piping and Equipment CodesDokumen1 halamanWhat's New in CAESAR II: Piping and Equipment CodeslnacerBelum ada peringkat

- Listen and Arrange The Sentences Based On What You Have Heard!Dokumen3 halamanListen and Arrange The Sentences Based On What You Have Heard!Dewi Hauri Naura HaufanhazzaBelum ada peringkat

- Nadee 3Dokumen1 halamanNadee 3api-595436597Belum ada peringkat

- Acer N300 ManualDokumen50 halamanAcer N300 Manualc_formatBelum ada peringkat

- 22 Khan S.Dokumen7 halaman22 Khan S.scholarlyreseachjBelum ada peringkat

- UntitledDokumen216 halamanUntitledMONICA SIERRA VICENTEBelum ada peringkat

- An Evaluation of MGNREGA in SikkimDokumen7 halamanAn Evaluation of MGNREGA in SikkimBittu SubbaBelum ada peringkat

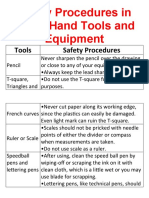

- Safety Procedures in Using Hand Tools and EquipmentDokumen12 halamanSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezBelum ada peringkat

- Siemens Make Motor Manual PDFDokumen10 halamanSiemens Make Motor Manual PDFArindam SamantaBelum ada peringkat

- Congenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementDokumen87 halamanCongenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementJZBelum ada peringkat

- English Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiDokumen4 halamanEnglish Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiMutiara siwa UtamiBelum ada peringkat

- Department of Education: Republic of The PhilippinesDokumen1 halamanDepartment of Education: Republic of The PhilippinesJonathan CayatBelum ada peringkat

- JIS G 3141: Cold-Reduced Carbon Steel Sheet and StripDokumen6 halamanJIS G 3141: Cold-Reduced Carbon Steel Sheet and StripHari0% (2)

- Patrick Meyer Reliability Understanding Statistics 2010Dokumen160 halamanPatrick Meyer Reliability Understanding Statistics 2010jcgueinj100% (1)

- Review On AlgebraDokumen29 halamanReview On AlgebraGraziela GutierrezBelum ada peringkat

- Delusion in SocietyDokumen2 halamanDelusion in SocietyGasimovskyBelum ada peringkat

- Modlist - Modlist 1.4Dokumen145 halamanModlist - Modlist 1.4Tattorin vemariaBelum ada peringkat

- Evolution Army 3 R DadDokumen341 halamanEvolution Army 3 R DadStanisław DisęBelum ada peringkat

- PresentationDokumen27 halamanPresentationMenuka WatankachhiBelum ada peringkat

- Rom 2 - 0-11 (En)Dokumen132 halamanRom 2 - 0-11 (En)Mara HerreraBelum ada peringkat