What Designers Should Know About Thermal Analysis - Archive Content From Machine Design

Diunggah oleh

Sargunam SankaravadivelJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

What Designers Should Know About Thermal Analysis - Archive Content From Machine Design

Diunggah oleh

Sargunam SankaravadivelHak Cipta:

Format Tersedia

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

WhatdesignersshouldknowaboutThermalAnalysis

Whatyouknowaboutstructuralanalysiswillhelprunanaccuratethermalanalysis.Ofcourse,there

areafewvariations.

|MachineDesign

Jun7,2007

SHARE

Tweet

COMMENTS 0

PaulKurowskiPresident

DesignGeneratorInc.

London,Ontario,Canada

EditedbyPaulDvorak

Heatflowsthroughasolidrodfromhotfacetocoldintheabsenceofconvection(noheatescapesalong

theway).

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

1/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

Vectors(bottom)showheatflowinabarafteraddingconvection.

Conductioncoefficientsshowthatthermalconductivitiesvarywidelyamongmaterials.

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

2/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

Plotscomparetemperaturedistributionsinthemicrochipassemblywithout(top)andwith(bottom)a

thermalresistancelayerseparatingthechipfromtheradiator.Outsidefaceshavethesametemperature

butthechipsurroundedbyathermalresistancelayerrunshotter.

Reflectorandlightbulbareexposedtovacuum.Theyellowsideofhousingisexposedtoair.Theblue

sideisexposedtovacuum.

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

3/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

Thearrowpointstoasensorinacoffeepot.Coffeetemperatureoscillatesastheheater(notshown)

cyclesonandoff.Theplotshowsatemperaturecycle.

Theplotshowsthetemperatureatthetopofthecoolingfin(arrow)afterthepoweristurnedonat

timet=0.Everytransientthermalanalysisrequiresaninitialtemperatureandtimeduration.

Ringsaresupportedontheinnercircumferenceandloadeddownwardontheirouteredges.

Displacementsforthemodelwithaconstantmodulusofelasticity(left)significantlydifferfromthe

modelwithatemperaturedependentmodulus(right).

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

4/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

Correctheatfluxcomesfrommodelswithfillets(left).Incorrectvaluesareduetosharpreentrantcorners

whichmakeheatfluxresultssingular(right).

Thermalandstructuralanalysesarethemostfrequentlyperformedfiniteelementanalyses.Bothusethe

sametypeofpartialdifferentialequationsandareanalogousinotherwaysaswell.

SIMILARITIES

Let'sstartwiththermalanalyses.Theprimaryunknownsaretemperaturesatnodesofthefiniteelement

mesh.Temperatureisscalarsoitneedsonlyonedegreeoffreedomateachnode,whetherthemodelis2D

or3Dandregardlesswhatelementsmeshthemodel.Oncetemperaturesarefoundatthenodes,theyare

interpolatedoverelementstocalculatetemperaturesintheentiremodel.Temperaturesarethen

differentiatedtofindthetemperaturegradients.Finally,thesoftwarecalculatesheatfluxbasedonthe

temperaturegradientandthermalconductivityofthematerial.

Thisismuchlikestructuralanalysisinwhichprimaryunknowns,displacements,arefirstfoundfornodes

thenareinterpolatedoverelements.Adisplacementfieldisthendifferentiatedtofindstrains,andstresses

arecalculatedbasedonstrainandmaterialelasticity.

However,displacementsarevectorsandsoaredefinedbymorethanonecomponent.Ittakestwo

components(twodegreesoffreedom)todescribenodaldisplacementsin2Dmodels,threecomponents

(threedegreesoffreedom)in3Dmodelsmeshedwithsolidelements,andsixcomponents(sixdegreesof

freedom)in3Dmodelswithshellelements.Sinceeachnodaldegreeoffreedomisanunknownittakes

morecomputingpowerforstructuralanalysisbecauseithasmoreunknowns.

Resultsfromstaticstructuralanalysisdescribeadeformedstructureinequilibriumbetweenappliedloads

andreactionsprovidedbysupports.Asteadystatethermalanalysisprovidesananalogyinwhichheat

flowsataconstantrate.It'salsoinequilibrium.

Thermalanalysisdealswithheatflowinasolidbody,sotheremustbeawayforheattoenterandtoexit

thatsolidbody.Ifheatentersabodywithnowaytoexit,thebody'stemperaturewouldtheoreticallyrise

toinfinity.Thisisanalogoustoapplyingastructuralloadtoanunsupportedmodel.Theresult:infinite

displacements.

Heatflowinginsideasolid,andheatenteringandleavingthesolid,aregovernedbydifferent

mechanisms.Heatinsidemovesbyconduction,whileheatenteringorescapingthesolidmovesby

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

5/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

convection,orradiation,orboth.

Heattransferbyconduction,forexample,isheatflowingthroughawall.Itisdescribedby:

Qconduction=KA(ThotTcold)/LwhereQconduction=rateofheatflow,K=thermalconductivity,A=

areaofthewall,Thot=temperatureonthehotside,Tcold=temperatureonthecoldside,andL=wall

thickness.

Heattransferbyconvectionmovesheattoorfromanexternalfaceofasolidbodyandsurrounding

fluid,suchasair,water,oroil.Theheatmovedbyconvectionisdescribedby:Qconvection=hA(TsTf)

whereQconvection=flowratebyconvection,h=convectioncoefficient,Ts=surfacetemperature,

andTf=fluidtemperature.

Theconvectioncoefficient,h,stronglydependsonwhetherconvectionisnaturalorforced.Natural

convectiontakesplaceonlyinthepresenceofgravitybecausefluidmovementdependsonthedifference

inthespecificgravitybetweencoldandhotfluid.Forcedconvection,suchasforcingairaroundawarm

solidwithafan,doesnotneedgravity.Convectioncoefficientsalsostronglydependonthetypeof

mediumsuchasair,steam,water,oroil,whichsurroundsthesolidbody.

Nowconsiderasolidbarinwhichoneendiskeptat300Kandtheotherat600K.Thisisanalogousto

prescribeddisplacementsinstructuralanalysis.Thetemperaturedifferencebetweentheendscreatesheat

flow.Theheatflowstabilizesafteraninitialtransientperiod.

Assumethebarisinsulatedsonoheatescapesthroughthesides.Allheatenteringonefacemustexit

throughtheother.Heatfluxisavectorandcanbeplottedusingarrows(besidecommonlyusedfringe

plots).Allheatfluxvectorsaretangenttotheoutsidefacesofthebar,becauseintheabsenceof

convection,noheatmovesacrosstheboundaries.

Addingconvectionsignificantlychangesheattransfer.Forexample,makethesurroundingfluidawater

temperaturebelow300K.Thetwoendsmaintaintheirprescribedtemperatures,butheatenteringthe

modelthroughthehotfacenowdoesnotmakeittotheotherend.Itallgetsdissipatedbyconvection.In

fact,thedirectionofheatflownearthecoldfacereverses.Definingalowerconvectioncoefficientwould

eliminatethisbackflowofheat.

Consideraheatsinkinwhichaceramicmicrochipgeneratesheatthroughoutitsentirevolume.Heat

travelstothealuminumradiatorbyconduction,thendissipatestoambientairbyconvection.

Addingacoolingfanorimmersingtheradiatorinwaterdoesnotchangethenatureofheartransferin

theheatsink.Theradiatorstillremovesheatbyconvection.FromanFEApointofview,theonly

differencebetweenair,water,oroilascoolingmediumandbetweennaturalandforcedconvectionsare

differentconvectioncoefficients.

Convectionrateontheoutsidefacesoftheradiatordeterminesthetemperatureofthosefaces,even

thoughthemicrochipproducesthesameamountofheat.Incaseofnaturalconvectionandalow

convectioncoefficient,theoutsidefinsgethotterbecauseofasteepertemperaturegradientbetweenthe

radiatorandambientair(TsTa)isrequiredtomovethegivenamountofheat.Incaseofforced

convection,(ahighervalueofconvectioncoefficient)theradiatorstayscoolerbecauseasmaller

temperaturegradientmovesthesameamountofheatfromsolidbodytosurroundingfluid.Plottingheat

fluxasvectorsletsanalystsseeheatmovementfromradiatortoambientair.

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

6/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

There'sonemoreimportantissue:thermalresistanceattheboundarybetweenthemicrochipand

radiator.Notwosolidsurfacesareeverinperfectcontact.Therearealwaystinyairgapsbetweenthem.

Therearetwomodesofheattransferthroughtheboundarybetweentwocontactingfaces.Thefirstis

conductionthroughpointsofsolidtosolidcontact,whichworkswell.Thesecondisconductionthrough

thegaps,whichispoor.Toaccountforthis,userscanaddathermalresistancelayertotheFEAmodel.

Thermalresistancelayersdonotchangehowmuchheatisgeneratedorchangetheoutsidetemperature

oftheradiator.However,inthepresenceofathermalresistancelayer,themicrochipmustrunhotter

becauseahighertemperaturegradientacrossthethermalresistancelayerisrequiredtopushheatacross

it.

Heattransferbyradiationcanbeignoredbecauseattheworkingtemperaturesoftheheatsink,it's

negligible,althoughtherearetimeswhenitisnot.

HEATTRANSFERBYRADIATION

Radiationmovesheatbetweenasolidbodyanditssurroundingsbycarryingitoffaselectromagnetic

radiation.

Heatexchangebyradiationalwaystakesplace,regardlessoftemperatureandwhetherbodiesareina

fluidorvacuum.Atroomtemperatures,however,radiationislowcomparedtoconvectiveheattransfer.

Hence,it'softenignored.

Allbodiesradiatethermalenergy.Radiationmovesheatbetweenbodiesofdifferenttemperaturesand

cansendheatawayintospace.Theheatexchangedbyradiationbetweenfacesoftwosolidbodieswith

temperaturesT1andT2isdescribedby:

Qradiation=s(T14T24)

whereQradiation=heatflowbyradiation,s=StefanBoltzmanconstant,and=emissivityofthe

radiatingface.Becauseheattransferbyradiationisproportionaltothefourthpoweroftheabsolute

temperature,theamounttransferredbecomessignificantathighertemperatures.

Forexample,consideraspotlightilluminatingalargevacuumchamber.Thechamberissolargewecan

ignoreheatreflectedfromchamberwallsbacktothelight.Thelightbulbandreflectorareinavacuum,

whilethebackofthealuminumhousingissurroundedbyroomtemperatureair.

Heatradiatesfromthelightbulbtotheoutsidespaceandtheparabolicreflector.Onlyasmallportionof

heatentersthehousingdirectlybyconductionwherethebulbcontactsthehousing.Conductionmoves

heatinsidethehousingfromvacuumsidetoairside.Convectiondissipatesheatfromfacesexposedto

air.

Becauseradiationbecomeseffectiveonlyathightemperatures,thelightbulbmustgethottodissipatethe

generatedheat.Thetemperatureofthealuminumhousingispracticallyuniformbecauseheatconducts

easilyinaluminum.

Thisexampleillustratesthatcoolinginvacuumisamajorchallengeforspacecraftdesigners.Even

thoughspacevehiclesoperateinnear0K,electroniccomponentscaneasilyoverheatbecauseradiation,

theonlycoolingmechanism,iseffectiveonlyathightemperatures.Toreachsteadystate,wheretheheat

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

7/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

generatedequalstheheatdissipatedbyradiation,anelectronicdevicemustreachhighertemperatures

thanthesamedevicecooledbyconvection,whichiseffectiveatlowertemperatures.

Theheatsinkandspotlightdealtwithheattransferinsteadystateandwithenoughtimetostabilizeheat

flow.Ananalysisofsteadystateheattransferisnotbasedontheinitialtemperaturesorhowlonga

systemtooktoreachasteadystate.Thatcouldtakesecondsordays.

TRANSIENTTHERMAL

Acoffeepotandtheheateritsitsonprovideanexampleoftransientthermalanalysis.Theheaterturns

onwhencoffeetemperaturedropsbelow88Candturnsoffwhenitreaches93C.Becauseofthermal

inertia,coffeetemperaturesoscillateoutsideofthisrange.

Twoheattransfermechanismsareatworkinthepot.Acombinationofconvectionandconduction(the

pot'sbottomdoesnotcompletelycontacttheheater)movesheatfromheatertoglass.Conductionmoves

heatacrosstheglasstosurroundingairandtothecoffee.Convectionmovesheatfromthecoffee'stop

surfaceandfromexternalsurfacesofthepot.Animportantconsiderationinthecoffeepotmodelisthe

definitionoftheconductioncoefficientforcoffee.Inreality,heattransferincoffeetakesplace

predominantlybyconvectionduetofluidmovementinducedbyheating.InanFEAmodel,however,

coffeemustbemodeledasasolidbodybecausethesoftwarecannotsimulatefluidflow.Allheattransfer

incoffeemustbemodeledbyconduction,soanartificiallyhighconductivitymustbeassignedtocoffeeto

compensateforthelackofconvectiveheattransfer.Also,nophasechangeeffects(boiling)canbe

modeledeither.Infact,FEAisnotrecommendedtosolvethisproblem,whichwouldbebetterhandled

usingComputationalFluidDynamics(CFD)tools.Showingthisproblemprovidesanopportunityto

emphasizethefactthatFEAisatoolforanalysisofheattransferinsolids,notinfluids.

Asolidbodywithheatflowingthroughitwillnotallbeatonetemperature.Consequently,different

portionsofthebodyexpandandshrinkatdifferentrates.Stressescausedbythisexpansionorshrinkage

arecalledthermalstresses.

Supposehotcoffee(93C)ispouredintoaporcelainmug.Whatarethethermalstressesinthemug?To

findout,runathermalanalysisthatrevealsthetemperaturedistribution.Applyatemperatureof93Cto

theinsidefacesofthemuganddefineconvectioncoefficientsfortheoutsidefaces.Becausecoolingis

relativelyslow,useasteadystatethermalanalysistocalculatethetemperaturedistributioninthecoffee

mug.Itwon'tbeuniform,sotherewillbethermalstresses.Havingfoundatemperaturefieldinthemug,

calculatethermalstressesbyexportingthetemperaturefieldfromthermalanalysistostructuralstatic

analysis.

NONLINEARTHERMALANALYSIS

Allexamplessofarinvolvedpropertiescharacterizingheattransfermaterialconductivity,convection

coefficients,emissivity,andheatpowerthatremainconstantandindependentoftemperature.These

assumptionsareoftenacceptablefortraditionalengineeringmaterialssuchassteelandaluminum,which

areoftensubjectedtoanarrowrangeofoperatingtemperatures.

Thermalanalysisofadvancedmaterialssuchascomposites,mayrequireanonlinearapproachwhenconductivity

isafunctionoftemperature,whileheatloadandconvectioncoefficientsarefunctionsoftemperatureandtime.

Furthermore,propertiesthatdeterminestructuralresponse,suchasthemodulusofelasticity,mayalsobe

functionsoftemperature.

Toillustrate,consideracomponentheatedsoastocauseanonuniformtemperaturedistribution.Also

makethematerial'smodulusofelasticitytemperaturedependent.Resultsfromsuchastructuralstatic

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

8/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

analysisunderabendingloadshowthatignoringtheeffectoftemperatureonthemodulusofelasticity

producesa40%displacementerror.

MOREMODELINGCONSIDERATIONS

Similaritiesbetweenthermalandstructuralanalysismeanmostmodelingtechniquesareidenticaland

thatskillsacquiredinonetypeofanalysisareusefulintheother.Thedifferenceinmodelingtechniques,

however,beginswiththermalboundaryconditions.Thedefinitionofsymmetricboundaryconditionsin

thermalanalysisisbasedontheobservationthatifgeometryandboundaryconditionsaresymmetrical,

noheatflowsthroughtheplaneofsymmetry.Therefore,aftersimplifyingthemodelto12(or14incaseof

adoublesymmetry),nothingmustbedonetothefacesexposedbycuts.Aconvectioncoefficientofzero

forthosefacesmeansnoheatflowsacrossthem.

Analysisofheatfluxrequiresadetailededgemodel.Sharpreentrantcornersthosenotblendedwith

joiningsurfacesarenotsuitableforheatfluxanalysesnearcorners.Heatfluxishighandmeaningless,

asingularity,insharpinsidecorners.Thisisdirectlyanalogoustosharpinsidecornersthatgenerate

stresssingularitiesinstructuralmodels.

Heatconvectioncoefficientsvaryamongdifferentmedia.

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

9/10

8/10/2016

WhatdesignersshouldknowaboutThermalAnalysis|ArchivecontentfromMachineDesign

http://machinedesign.com/archive/whatdesignersshouldknowaboutthermalanalysis

10/10

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Green Hydrogen GuidebookDokumen52 halamanGreen Hydrogen GuidebookWilliam Chang82% (11)

- Python Notes For ProfessionalsDokumen814 halamanPython Notes For ProfessionalsNemani100% (11)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Isogen InfoDokumen34 halamanIsogen InfoNagarajan100% (1)

- SPECON Reference ManualDokumen67 halamanSPECON Reference ManualNewuman MonteroBelum ada peringkat

- Microsoft SQ L Server Notes For ProfessionalsDokumen286 halamanMicrosoft SQ L Server Notes For ProfessionalsEribertMarquezBelum ada peringkat

- C#Dokumen338 halamanC#bebikash011100% (3)

- Nima Thesis-Last VersionDokumen110 halamanNima Thesis-Last VersionSargunam SankaravadivelBelum ada peringkat

- AutoCAD 2017 TipsnTricksDokumen23 halamanAutoCAD 2017 TipsnTricksDeepak SavantBelum ada peringkat

- Using OpenSTAAD Application ObjectDokumen7 halamanUsing OpenSTAAD Application ObjectRobert RayBelum ada peringkat

- Documents For Export ImportDokumen1 halamanDocuments For Export ImportSargunam SankaravadivelBelum ada peringkat

- Yield StressDokumen2 halamanYield StressSargunam SankaravadivelBelum ada peringkat

- FEA Failure TheoryDokumen3 halamanFEA Failure TheoryRamesh BammankattiBelum ada peringkat

- Finite Element Analysis of The Fatigue Strength of A Big End BoltDokumen136 halamanFinite Element Analysis of The Fatigue Strength of A Big End BoltSargunam SankaravadivelBelum ada peringkat

- Flow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFDokumen12 halamanFlow and Accoustically Induced Vibrations A Real Problem For LNG Facilities PDFSargunam SankaravadivelBelum ada peringkat

- Pdmstocaesarii PDFDokumen0 halamanPdmstocaesarii PDFshaffetiBelum ada peringkat

- Creating Optical Character Recognition (OCR) Applications Using Neural Networks - CodeProjectDokumen7 halamanCreating Optical Character Recognition (OCR) Applications Using Neural Networks - CodeProjectSargunam SankaravadivelBelum ada peringkat

- Budstikka - Dette Er Våre Vanskeligste KryssDokumen10 halamanBudstikka - Dette Er Våre Vanskeligste KryssSargunam SankaravadivelBelum ada peringkat

- Initiate A Stress-Intensity Factors CalculationDokumen9 halamanInitiate A Stress-Intensity Factors CalculationSargunam SankaravadivelBelum ada peringkat

- Fatigue Life EstimationDokumen7 halamanFatigue Life EstimationJomer J SimpsonBelum ada peringkat

- Acoustically Induced Piping Vibration in PDFDokumen13 halamanAcoustically Induced Piping Vibration in PDFSargunam Sankaravadivel100% (1)

- Bolt Length Calculation For Standard Flange-Gasket-Flange - PDMS MacroDokumen1 halamanBolt Length Calculation For Standard Flange-Gasket-Flange - PDMS MacroSargunam SankaravadivelBelum ada peringkat

- Windows OOPS Principles (SOLID Principles) Sample in C# For Visual Studio 2010Dokumen7 halamanWindows OOPS Principles (SOLID Principles) Sample in C# For Visual Studio 2010Sargunam SankaravadivelBelum ada peringkat

- Fatigue Analysis GuideDokumen12 halamanFatigue Analysis GuideSargunam SankaravadivelBelum ada peringkat

- What Is Poisson Ratio - What's It Application - QuoraDokumen2 halamanWhat Is Poisson Ratio - What's It Application - QuoraSargunam SankaravadivelBelum ada peringkat

- Edge Detection-Shetty PrajwalDokumen63 halamanEdge Detection-Shetty PrajwalSargunam SankaravadivelBelum ada peringkat

- Requirement of Flexibility in Piping Design - An Overview - What Is Piping PDFDokumen8 halamanRequirement of Flexibility in Piping Design - An Overview - What Is Piping PDFSargunam SankaravadivelBelum ada peringkat

- C# ProgramingDokumen117 halamanC# ProgramingSargunam SankaravadivelBelum ada peringkat

- Array Collection and Appending - Page 2Dokumen4 halamanArray Collection and Appending - Page 2Sargunam SankaravadivelBelum ada peringkat

- Three Layer Architecture in C#Dokumen11 halamanThree Layer Architecture in C#Sargunam SankaravadivelBelum ada peringkat

- How Does The Material Properties Affect Stress Results in FEA - QuoraDokumen3 halamanHow Does The Material Properties Affect Stress Results in FEA - QuoraSargunam SankaravadivelBelum ada peringkat

- FEA Failure TheoryDokumen3 halamanFEA Failure TheoryRamesh BammankattiBelum ada peringkat

- A2 - Workbook 3 Updated PDFDokumen276 halamanA2 - Workbook 3 Updated PDFMaham Furqan 1737934Belum ada peringkat

- Ita Wegman The Mystery of The EarthDokumen6 halamanIta Wegman The Mystery of The Earthjaguba100% (1)

- Koalatext Reference 230Dokumen20 halamanKoalatext Reference 230jauBelum ada peringkat

- ProbSet 1 Chap 1Dokumen2 halamanProbSet 1 Chap 1Joseph FlorBelum ada peringkat

- The Correlation Between The CBR and Shear Strength in Unsaturated Soil ConditionsDokumen13 halamanThe Correlation Between The CBR and Shear Strength in Unsaturated Soil ConditionsVetriselvan ArumugamBelum ada peringkat

- AMNS IIT Gandhinagar PPT - Formatted 1Dokumen15 halamanAMNS IIT Gandhinagar PPT - Formatted 1Arjun ChouhanBelum ada peringkat

- Cambridge O Level: Physics 5054/12Dokumen16 halamanCambridge O Level: Physics 5054/12dxD.T.C.dxBelum ada peringkat

- Saturated Steam Table by TemperatureDokumen1 halamanSaturated Steam Table by TemperatureAhmad FauzanBelum ada peringkat

- Simple Harmonic Motion (Practice Questions)Dokumen29 halamanSimple Harmonic Motion (Practice Questions)SakshamBelum ada peringkat

- F1 05 C MatterDokumen7 halamanF1 05 C MatterToh Tze LeaBelum ada peringkat

- Energy and Exergy Analysis of A Steam Power Plant in EgyptDokumen13 halamanEnergy and Exergy Analysis of A Steam Power Plant in EgyptaliBelum ada peringkat

- AC Part 3Dokumen9 halamanAC Part 3Norman Ace AndresBelum ada peringkat

- Introduction To Green Roofs: Brought To You byDokumen28 halamanIntroduction To Green Roofs: Brought To You byOnur Olguner100% (1)

- REMF-193 Design and Fabrication of Mini Refrigerator and HeaterDokumen4 halamanREMF-193 Design and Fabrication of Mini Refrigerator and HeaterretechBelum ada peringkat

- Escuela Normal "Gendarmería Nacional" - La QuiacaDokumen7 halamanEscuela Normal "Gendarmería Nacional" - La QuiacaRa MenBelum ada peringkat

- Cot - Science 5Dokumen13 halamanCot - Science 5Sotto Mary Jane100% (3)

- Edvantage The TenDokumen76 halamanEdvantage The Tenapi-683027695Belum ada peringkat

- Pengumuman DPT Vendor Komponen TrafoDokumen3 halamanPengumuman DPT Vendor Komponen Trafodenny yusufBelum ada peringkat

- Mud ConstructionDokumen35 halamanMud ConstructionPaulBelum ada peringkat

- Chem ReviewerDokumen18 halamanChem ReviewerMariz del RosarioBelum ada peringkat

- ZGE 4301 CSAH - M10 Activity No. 1 FT Climate ChangeDokumen10 halamanZGE 4301 CSAH - M10 Activity No. 1 FT Climate ChangeMark Joshua PasicolanBelum ada peringkat

- Experiment 1Dokumen13 halamanExperiment 1許書僑(乂傳說x飛龍乂)Belum ada peringkat

- Report in Meteorology (Structure of Depressions)Dokumen16 halamanReport in Meteorology (Structure of Depressions)Cecilia PicayoBelum ada peringkat

- Business Plan Majola Recycling V4Dokumen50 halamanBusiness Plan Majola Recycling V4Darlington DhanahBelum ada peringkat

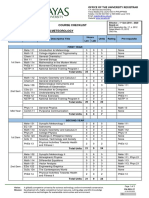

- FM-REG-27 Course Checklist - v.2 06-30-2020 - METEOROLOGYDokumen2 halamanFM-REG-27 Course Checklist - v.2 06-30-2020 - METEOROLOGYKevin CordovizBelum ada peringkat

- Science CFA - Energy TransferDokumen6 halamanScience CFA - Energy TransferHelina AmbayeBelum ada peringkat

- Grade 8 - SCIENCE - Final TestDokumen8 halamanGrade 8 - SCIENCE - Final TestAyu Yuniarti Sholehatun AmalBelum ada peringkat

- 2030 RIBA Climate ChallengeDokumen6 halaman2030 RIBA Climate ChallengeDiaconu FlorinBelum ada peringkat

- Chemistry f4 Mid-Year ExamDokumen13 halamanChemistry f4 Mid-Year ExamWindy SanBelum ada peringkat