Fe04a PDF

Diunggah oleh

vette512Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fe04a PDF

Diunggah oleh

vette512Hak Cipta:

Format Tersedia

7

HOME

SPECIFICATIONS

4.1

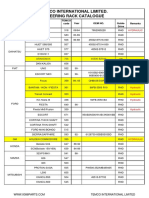

Table 4-1. Spark Specifications

Table 4-3. Charging Specifications

DATA

IGNITION

Ignition timing range

TDC - 50 BTDC

Spark plug size

12 mm

Battery

28 amp hour/300 CCA

Alternator AC voltage output

0.038-0.043 in

Spark plug gap

0.97-1.09 mm

Harley-Davidson

No. 6R12 (no substitute)

Spark plug type

DATA

ITEM

FLHR, FLHR-I, FLHRC-I,

FLHT, FLHTC, FLTR

(38 Amp)

16-20 VAC per 1000 RPM

FLHT-I, FLTR-I, FLHTC-I,

FLHTCU-I (45 Amp)

19-26 VAC per 1000 RPM

Ignition coil primary

resistance at room temperature

0.3-0.5 ohms

Alternator stator coil

resistance

0.1-0.3 ohms

Ignition coil secondary

resistance at room temperature

2750-3250 ohms

Regulator voltage

output @ 3000 RPM

14.4-14.6 volts

Regulator amperes @ 3000 RPM

Table 4-2. Circuit Breaker/Fuses

FLHR, FLHR-I, FLHRC-I,

FLHT, FLHTC, FLTR

(38 Amp)

34-40 Amps

Color

Terminal

Type

40

Threaded

Posts

FLHT-I, FLTR-I, FLHTC-I,

FLHTCU-I (45 Amp)

41-48 Amps

Radio Power

10

Red

Blade

Brakes/Cruise

15

Blue

Blade

P&A

10

Red

Blade

Circuit

Main

Rating

(Amperes)

System Fuses

Radio Memory

15

Blue

Blade

Security System

(Hazard 4-Way Flasher)

15

Blue

Blade

Accessory

15

Blue

Blade

Instruments

15

Blue

Blade

Ignition

15

Blue

Blade

Lighting

15

Blue

Blade

Headlamp

15

Blue

Blade

Radio

Radio Memory

Power

Instruments

Security

System

Brake Light

Relay

4-Way Flasher

Spare

Fuses

Brakes/

Cruise

Headlamp

P&A

Accessory

NOTE

See Figure 4-1. The fuse labeled Security provides basic turn

signal functionality on vehicles without a factory-installed

security system. Do not remove this fuse or use it as a

replacement fuse for other systems.

f2023x9x

Lighting

Ignition

Figure 4-1. Fuse Locations (FLTR, FLHT/C)

2003 Touring: Engine Management (Carbureted)

4-1

HOME

DIAGNOSTIC INTRODUCTION

4.2

SYSTEM PROBLEMS

s0520xtm

All system problems fall into at least one of three general categories.

40

30

20

10

0

No Start

The engine cranks over freely, but will not start. This does not

include situations where the engine will not crank, such as a

bad starter, dead battery, etc., and assumes that all obvious

checks are made- there is sufficient fuel in the tank, etc.

50 60 70

MPH

80

90

100

110

120

C

LE Y - D A V I D S O N

H AR ER T I F I E D

Poor Performance

The engine starts but there are performance problems, such

as poor fuel economy, rough idle, engine misfire, engine hesitation, severe spark knock, etc.

Check Engine Lamp

Figure 4-2. Check Engine Lamp (FLHR)

d0543x8x

The lamp indicates the existance of a fault condition. There

may also be starting or performance problems. See Figure 42.

RESOLVING PROBLEMS

To resolve system problems, five basic steps are involved. In

order of occurrence, they are:

1.

Check for trouble codes through observation of the

check engine lamp. See Section 4.3 CHECKING FOR

TROUBLE CODES.

2.

Retrieve trouble codes with the SCANALYZER (Part No.

HD-41325) or the check engine lamp diagnostics. See

Section 4.4 SCANALYZER: CARB, Section 4.5 CHECK

ENGINE LAMP DIAGNOSTICS: CARB and Figure 4-3.

3.

Diagnose problems relating to current trouble codes

using the diagnostic flow charts, Scanalyzer and other

special tools.

4.

Correct problems through replacement and/or repair of

faulty components.

5.

Validate repairs. Clear trouble codes and confirm proper

vehicle operation without recurrence of the fault condition, as indicated by the behavior of the check engine

lamp.

4-2

2003 Touring: Engine Management (Carbureted)

Figure 4-3. Scanalyzer

HOME

CHECKING FOR TROUBLE CODES

4.3

CHECK ENGINE LAMP

To diagnose system problems, start by observing the behavior of the Check Engine Lamp. See Figure 4-5.

1.

At Key On, the Check Engine Lamp will illuminate for

approximately four seconds and then turn off.

NOTES

References to Key ON or Ignition Switch ON in this

document means that the Ignition/Light Key Switch is

turned to IGNITION and the handlebar Engine Stop/Run

Switch is in the RUN position (although the engine is not

running). See Figure 4-4.

If the Check Engine Lamp is not illuminated at Key ON or

if it fails to go OFF after the initial four second ON period,

then a problem exists in the lamp circuit. See Section 4.9

NO CHECK ENGINE LAMP AT KEY ON or Section 4.10

CHECK ENGINE LAMP ON CONTINUOUSLY.

2.

When the lamp turns off after being illuminated for the

first four second period, it will:

a.

Remain off if there are no fault conditions or trouble

codes currently detected by the ignition module. See

A of Figure 4-5.

b.

Come back on for an 8 second period if only historic

codes exist. See B of Figure 4-5.

c.

Come back on, and remain on, if a current trouble

code exists. See C of Figure 4-5.

ON

f1240x2x

Figure 4-4. Ignition Switch (FLTR, FLHT/C/U)

3.

See CODE TYPES which follows for a complete description of trouble code formats.

NOTE

Trouble codes relating to the ignition coil can only be fully

diagnosed during actuation. For example, a problem with an

ignition coil will be considered a current fault even after the

problem is corrected, since the ignition module will not know

of its resolution until after the coil is exercised by a vehicle

start sequence. In this manner, there may sometimes be a

false indication of a current trouble code.

4 Sec.

Lamp OFF: No Current or Historic Trouble Codes

OFF

Key On

Lamp ON 8 Seconds:

Only Historic Trouble Codes Exist

ON

8 Sec.

4 Sec.

B

OFF

Lamp OFF

4 Sec.

Key On

Lamp Remains ON: Current Trouble Code *

ON

4 Sec.

C

OFF

4 Sec.

Key On

* Historic Trouble Codes May Also Exist

Figure 4-5. Check Engine Lamp Operation

2003 Touring: Engine Management (Carbureted)

4-3

HOME

CODE TYPES

RETRIEVING TROUBLE CODES

There are three types of diagnostic trouble codes (DTCs),

current, historic and functional.

The system provides three levels of diagnostics.

The most sophisticated level uses a computer based

diagnostic package called the DIGITAL TECHNICIAN

(Part No. HD-44750).

At the second level, a portable Scan Tool called a Scanalyzer (HD-41325) plugs into the Data Link Connector

and facilitates the diagnosis of system problems through

a direct interface with the ignition module. Using a special programmable application cartridge, the Scanalyzer

offers data displays and menu selections that allow for

quick and easy retrieval of data and enables the user to

perform a variety of diagnostic tests while monitoring

inputs and outputs. See Section 4.4 SCANALYZER:

CARB.

At the third level, the Check Engine Lamp is observed by

the user after being placed in the diagnostic mode. The

lamp blinks a code which correlates to a particular problem area. See Section 4.5 CHECK ENGINE LAMP

DIAGNOSTICS: CARB.

Current

Current trouble codes are those which presently disrupt

motorcycle operation. When current trouble codes are stored,

they can be read using either the Scanalyzer or the Check

Engine Lamp Diagnostics. A current trouble code resides in

the memory of the ignition module until the problem is corrected, at which point it becomes a historic, rather than a

current fault.

Historic

If a particular problem happens to resolve itself, the active or

current status is dropped and it also becomes a historic code.

Historic trouble codes are stored for a length of time to assist

in the diagnosis of intermittent faults. While historic trouble

codes are stored, they can be read using the Scanalyzer only.

The Check Engine Lamp will not indicate the existence of

historic trouble codes.

A historic trouble code resides in the memory of the ignition

module until the code is cleared by use of the Scanalyzer or a

total of 50 trips has elapsed. A trip consists of a start and

run cycle, the run cycle lasting at least 30 seconds. After the

50 trip retention period, the trouble code is automatically

erased from memory (that is, assuming no subsequent faults

of the same type are detected in that period).

It is important to note that historic trouble codes may also be

present whenever the system indicates the existence of a

current code. See MULTIPLE TROUBLE CODES for more

information.

Functional

A functional trouble code indicates an internal problem that

requires replacement of the ignition module (trouble codes 52

through 55).

4-4

2003 Touring: Engine Management (Carbureted)

MULTIPLE TROUBLE CODES

While it is possible for more than one fault to occur and set

more than one trouble code, there are several conditions

which may result in one fault setting multiple trouble codes:

If one of the primary side coil lines becomes grounded it

will also ground the Bank Angle Sensor resulting in multiple trouble codes being set (DTC 24 and/or 25 and 44).

Always start with the trouble code having the lowest numerical value. In the case of multiple trouble codes, the second

code should be resolved when the first code is corrected. For

a priority ranking, see list of fault conditions in Table 4-8.

HOME

SCANALYZER: CARB

4.4

SCANALYZER DIAGNOSTICS

Ignition

Module

Data Link

Connector [91A]

f1968x9x

Scanalyzer Cartridge

See Figure 4-7. Through a special programmable application

cartridge, the Scanalyzer offers data displays and menu

selections that allow for quick and easy retrieval of data. The

device enables the user to perform a variety of diagnostic

tests while monitoring inputs and outputs. For Scanalyzer

menu selections see Figure 4-8.

INSTALLATION

SPECIALTY TOOL

PART NO.

HD-41325

Scanalyzer

HD-41325-95C

Scanalyzer Cartridge

HD-42921A

Cable

Figure 4-6. Right Side Cover Removed

d0279x8x

The behavior of the check engine lamp as described under

Section 4.3 CHECKING FOR TROUBLE CODES indicates

the existence of a trouble code. Proceed as follows:

1.

Turn the Ignition/Light Key Switch to OFF.

2.

Remove right saddlebag and side cover to access data

link connector. See Figure 4-6.

3.

Remove rubber protective plug from data link connector.

Plug the Scanalyzer into the data link connector.

4.

Turn the Ignition/Light Key Switch to IGNITION. Turn the

handlebar mounted Engine Stop/Run Switch to RUN (but

do not start the engine).

5.

6.

Insert the diagnostic application cartridge into the Scanalyzer. During the next few seconds, the Scanalyzer

sequences through a series of screens that reflect a

power-on self test, the system copyright, and then an

attempt at communications with the ignition module.

Once communications is established, the Diagnostic

Menu appears. See Figure 4-8.

Cartridge

(Part No. HD-41325-95C)

Figure 4-7. Scanalyzer (Part No. HD-41325)

Continue with the instructions under USAGE which follows.

2003 Touring: Engine Management (Carbureted)

4-5

HOME

DIAGNOSTIC MENU

f1657x8x

1- System ID

2- Trouble Codes

3- Data Monitor

4- Active Diagnostic

5- Special Tests

6- Tool Setup

Main Menu

TOOL SETUP MENU

1- General Setup

2- Save Setup

3- Restore Setup

SPECIAL TEST MENU

1- Wiggle Test

2- Data Capture

3- File Manager

ACTIVE TEST MENU

1- Front Coil

2- Rear Coil

3- Tachometer

MODE

Secondary

Menus

DATA MONITOR MENU

RPM

MAP

MAP

ADVANCE

B+

Dwell

BAS Mode

BAS

Check Eng

=1000

=14.8 in. Hg

=2.10 V

=20.0 DEG

=13.20 V

=1800 uSec

=Run Mode

=0.62 V

=Lamp ON

MODE

TROUBLE CODE MENU

1- Display Current

2- Display Historic

3- Clear Historic

MODE

SYSTEM ID

P/N 32479-99

CAL ID

HD32ER0K0

MODE

Figure 4-8. Scanalyzer Menus

4-6

2003 Touring: Engine Management (Carbureted)

MODE

MODE

HOME

USAGE

d0543x8x

See Figure 4-8. The Diagnostic Menu, which consists of six

items, is the primary system menu (main menu) through

which all other secondary menus and displays are accessed.

Since the screen may not be large enough to display all line

items at any given time, use the up and down arrow keys to

scroll through the list.

Checking/Clearing Trouble Codes

1.

2.

3.

See Figure 4-9. From the diagnostic menu, press the

number 2 to access the Trouble Codes Menu.

At this point, the operator may:

a.

Press number 1 to display current trouble codes.

b.

Press number 2 to display historic trouble codes.

c.

Press number 3 to clear trouble codes. Note that

the Scanalyzer is the only method by which the

operator can display and manually clear historic

trouble codes.

After reading trouble codes, simply press the Mode key

to return to the Trouble Codes Menu. Press the Mode key

again to return to the Diagnostic Menu. In this manner,

regardless of where the operator is in the program, the

Mode key need only be pressed once or twice to return

to the Main Menu.

Figure 4-9. Scanalyzer Diagnostic Menu

NOTE

For more detailed instructions, refer to the literature provided

with the Scanalyzer.

REMOVAL

4.

1.

Turn the Ignition/Light Key Switch to OFF. Set the Engine

Stop/Run Switch to STOP.

2.

Unplug the Scanalyzer from the Data Link Connector.

Install protective plug.

3.

Install right side cover and saddlebag.

4.

Road test the vehicle and observe the check engine

lamp to confirm proper operation without the reoccurrence of trouble codes. See Section 4.3 CHECKING

FOR TROUBLE CODES.

5.

Write down all trouble codes on a piece of paper. If a current trouble code exists, place it at the top of the list.

a.

If current trouble codes are present, see Table 4-8.

to identify the source of the fault condition and then

see the applicable flow chart.

b.

If only historic trouble codes are present, then a fault

condition does not currently exist. If you wish, look

for an intermittent in the appropriate circuit.

c.

If trouble codes are NOT present, but starting or

driveability problems are evident, see symptoms

charts under Section 4.8 INITIAL DIAGNOSTIC

CHECK.

After correcting system problems, clear trouble codes

using the Trouble Codes Menu of the Scanalyzer.

NOTE

Trouble codes cannot be cleared while the engine is running.

Turn the engine off, but leave the Ignition/Light Key Switch in

the IGNITION position and return the handlebar Engine Stop/

Run Switch to RUN.

2003 Touring: Engine Management (Carbureted)

4-7

HOME

CHECK ENGINE LAMP DIAGNOSTICS: CARB

ACTIVATION

d0278x8x

Use of check engine lamp diagnostics assumes that the

SCANALYZER (Part No. HD-41325) is not available.

1.

Access the data link connector [91] under the right side

cover.

2.

Activate the diagnostic feature of the check engine lamp

as follows:

a.

b.

c.

3.

This intermission is followed by a 2 second pause

in which the lamp is off.

b.

The lamp will then flash one or more times to indicate the first digit of the trouble code. The length of

time the lamp is illuminated and the length of time in

which it is off are each about 1 second in duration.

2003 Touring: Engine Management (Carbureted)

1.

2.

3.

4.

5.

Terminal 1: receive data line (Lt GN/R)

Terminal 2: ground (BK)

Terminal 3: transmit data line (V/R)

Terminal 4: power (W/BK)

Protective cap

Figure 4-11. Installing Diagnostic Test Wire

The lamp will then flash one or more times to indicate the second digit of the trouble code. Count the

number of times the lamp flashes to retrieve the second digit.

Following transmission of the second digit of the first

code, there is a third 2 second pause in which the

lamp is off.

Following transmission of the first digit, there is

another 2 second pause in which the lamp is off.

If more than one trouble code is sent:

a.

4-8

The second digit follows:

a.

5.

6924

Turn the Ignition/Light Key Switch to IGNITION and

wait approximately eight seconds for the check

engine lamp to start flashing.

b.

Figure 4-10. Diagnostic Test Wire

See Figure 4-11. Install diagnostic test wire across

Terminal 1 and Terminal 2 on the data link connector

[91A].

The transmission of a trouble code is always preceded by six rapid flashes (about 3 per second).

Part number 72191-94 (2)

2.0 inch (51 mm) 18 gauge wire

See Figure 4-12. All trouble codes are sent out as a

series of flashes. To retrieve the first digit of the trouble

code simply observe the number of times the lamp

flashes.

c.

4.

1.

2.

See Figure 4-10. Create diagnostic test wire from

parts shown.

a.

4.5

6.

b.

After the pause comes the intermission, which is followed by transmission of the next recorded trouble

code.

c.

All subsequent codes are sent in the same manner,

each separated from the next by the intermission.

Once all codes have been sent, the data string is

repeated. When you have recorded the same trouble

code twice, it is an indication that the transmission has

been restarted and that all trouble codes have been

retrieved.

HOME

Intermission

1st Digit

ON

2nd Digit

1

Sec.

OFF

3 Flashes

per Second

1

Sec.

2 Sec.

2 Sec.

Pause Before

1st Digit

Pause Before

2nd Digit

Start of

Intermission

1

Sec.

1

Sec.

2 Sec.

Pause After

2nd Digit

NOTE

Looking at the above transmission, we can see that the trouble code is 12.

Now reference Table 4-8. The source of the fault condition is identified as the

Manifold Absolute Pressure (MAP) Sensor.

Figure 4-12. Check Engine Lamp Diagnostics

NOTE

If the lamp flashes at a rate faster than normal, then you are

observing the Intermission only, which means that no trouble codes are present.

7.

When examining trouble codes, write down all codes on

a piece of paper. If a current trouble code exists, place it

at the top of the list.

a.

If trouble codes are present, see Table 4-8. Follow

the applicable flow charts for each code.

b.

If trouble codes are NOT present, but starting or

driveability problems are evident, see symptoms

charts under Section 4.8 INITIAL DIAGNOSTIC

CHECK.

8.

Turn the Ignition/Light Key Switch to OFF.

9.

Remove diagnostic test wire from connector. Install protective plug in data link connector.

IMPORTANT NOTE

If diagnostic test wire is installed across Pins 1 and 2 on

connector [91A] in lieu of a Scanalyzer, the ignition module is placed in a diagnostic test mode and the engine

will start. The test wire must be removed from the data

link connector and the ignition switch turned OFF or the

check engine lamp will continue to flash codes.

10. Install right side cover and saddlebag.

2003 Touring: Engine Management (Carbureted)

4-9

HOME

BREAKOUT BOX: CARB

4.6

GENERAL

See Figure 4-13. The BREAKOUT BOX (Part No. HD-42682),

used in conjunction with a DVOM, allows circuit diagnosis

without having to probe connectors with sharp objects.

INSTALLATION

1.

Remove the right saddlebag and side cover.

2.

Remove connector [10] and connector [11] to release

ignition harness from ignition module. See Figure 4-14.

3.

Install Breakout Box connectors to ignition module and

ignition harness connectors of the same color.

f2001x8x

f1998x9x

Figure 4-13. Breakout Box (Part No. HD-42682)

REMOVAL

f1876xtm

1.

Separate connectors to remove Breakout Box between

ignition module and ignition harness.

2.

To connect ignition harness, install connector [10] and

connector [11] to ignition module connectors of the same

color. See Figure 4-14.

3.

Install the right side cover and saddlebag.

Connector [10]

(Black)

Connector [11]

(Gray)

Figure 4-14. Ignition Module

4-10

2003 Touring: Engine Management (Carbureted)

HOME

WIGGLE TEST

4.7

GENERAL

d0544x8x

The wiggle test indicates the presence of intermittents in a

wiring harness. Depending upon the availability of diagnostic

tools, either version of this test may be used.

PROCEDURE

Using Scanalyzer (Part No. HD-41325)

1.

Connect Scanalyzer to vehicle. See Section 4.4 SCANALYZER: CARB.

2.

Start motorcycle and allow to idle.

3.

Enter wiggle test mode.

4.

a.

Press 5 from the Diagnostic Menu to enter the

Special Tests menu.

b.

Press 1 from the Special Tests menu to enter the

Wiggle Test.

1.

2.

Minus sign

Corner LED (4)

Figure 4-15. Wiggle Test Indicators

hd39978

Shake or wiggle harness to detect intermittents. If intermittents are present the Scanalyzer will beep, light the

four corner LEDs and display a minus sign when a current trouble code is detected. See Figure 4-15.

NOTE

If a current trouble code is present when the wiggle test is

entered, the Scanalyzer will respond as described immediately upon entering the wiggle test mode. With key ON and

engine off, clear trouble codes and then perform wiggle test

with vehicle running.

Figure 4-16. Fluke 78 Multimeter (DVOM)

(Part No. HD-39978)

Using DVOM (Part No. HD-39978)

1.

2.

See Figure 4-16. Connect DVOM to wiring harness

between the suspect connections. When diagnosing ignition module connections, a BREAKOUT BOX (Part No.

HD-42682) may be used to simplify the procedure. See

Section 4.6 BREAKOUT BOX: CARB.

3.

Start motorcycle and allow to idle.

4.

Shake or wiggle harness to detect intermittents. If intermittents are present, radical voltage changes will register

on the DVOM.

Set DVOM to read voltage changes.

2003 Touring: Engine Management (Carbureted)

4-11

HOME

INITIAL DIAGNOSTIC CHECK

4.8

GENERAL

Diagnostic Tips

To locate faulty circuits or other system problems, follow the

diagnostic flow charts in this chapter. Read the general information and then work your way through the flow chart box by

box. For a systematic approach, always begin with INITIAL

DIAGNOSTICS below.

If the Scanalyzer is not working properly, check operation

on another vehicle.

If proper Scanalyzer function is verified, check data link

connector [91A] for 12 volts (Terminal 4) and proper

ground (Terminal 2). See Figure 4-17.

Diagnostic Notes

If a numbered circle appears adjacent to a box of the flow

chart, then more information is offered in the Diagnostic

Notes. Many diagnostic notes contain supplemental information, descriptions of various diagnostic tools or references to

other parts of the manual.

See Figure 4-11. If Scanalyzer reads No Response

with the ignition switch turned to IGNITION (engine stop

switch at RUN with the engine off), check serial receive

data wire for an open or short to ground between data

link Terminal 1 and ignition module.

Check for an open diagnostic test terminal between data

link Terminal 3 and ignition module. With ignition switch

turned to IGNITION, transmit data line and receive data

line should have 5 volts.

Scanalyzer Icon

The Scanalyzer icon appears at those points in the flow chart

where the Scanalyzer may be used.

Circuit Diagram/Connector Location Table

When working through a flow chart, refer to the illustrations,

the associated Circuit Diagram and the Wire Harness Connector Table as necessary. The wire harness connector table

opposite each flow chart identifies the connector number,

description, type and general location.

In order to perform most diagnostic routines, a Breakout Box

and a DVOM are required. See Section 4.6 BREAKOUT BOX:

CARB. To perform the circuit checks with any degree of efficiency, a familiarity with the various wire connectors is also

necessary.

IMPORTANT NOTE

If diagnostic test wire is installed across Pins 1 and 2 on

connector [91A] in lieu of a Scanalyzer, the ignition module is placed in a diagnostic test mode and the engine

will start. The test wire must be removed from the data

link connector and the ignition switch turned OFF or the

check engine lamp will continue to flash codes.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the diagnostic check flow charts. See page 4-15.

1.

Job/Time Code Values

When filing warranty claims, dealer technicians should use

the numeric job/time codes printed below the appropriate box

of the flow chart.

INITIAL DIAGNOSTICS

General

The diagnostic check is an organized approach to identifying

a system problem. If no problems are found after completion

of the diagnostic check, a comparison of Scanalyzer parameters may be used to help locate intermittents and out-of-specification sensors. See Table 4-4.

4-12

2003 Touring: Engine Management (Carbureted)

Compare engine behavior to symptoms tables.

a.

Starts hard. See Table 4-5.

b.

Hesitates, stumbles, surges, misfires and/or sluggish performance. See Table 4-6.

c.

Engine exhaust emits black smoke or fouls plugs.

See Table 4-7.

2.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), black socket probes and patch cord.

3.

Connect BREAKOUT BOX (Part No. HD-42682) to ignition module. See Section 4.6 BREAKOUT BOX: CARB.

HOME

Table 4-4. Typical Scan Values

ITEM

MAP sensor

MIN.

VALUE

MAX.

VALUE

HOT

IDLE

0.1 V

(high

vacuum)

4.96 V

(atmospheric

pressure)

1.5-3.0 V

Table 4-6. Engine Performance Problems

SYMPTOM

SOLUTION

Spray water around induction module seals with

engine idling. If RPM

changes, change seals.

Manifold leak

10-15

MAP sensor plugged or not

operating properly

Section 4.14 DTC 12.

5600

1000

Water or dirt in fuel system

Drain and refill with fresh

fuel.

Run mode

0.45-1.1 V

Disable

1.8-3.2 V

Run mode

0.45-1.1 V

960 uSec

8100 uSec

1600-2400

uSec

Spark advance

while running

50

RPM

Bank angle

sensor

Dwell

Table 4-5. Engine Starts Hard

Section 4.13 MISFIRE.

EVAP hose disconnected

from induction module (CA)

Connect.

Throttle plates not opening

fully

See throttle cable adjustment in 2003 FLT Service

Manual (Part Number

99483-03),

SOLUTION

SYMPTOM

Battery discharged

Spark plugs

See charging system troubleshooting in this section.

Spark plugs

Section 4.13 MISFIRE.

Spark plug wires

Section 4.13 MISFIRE

Ignition coil

Section 4.13 MISFIRE.

Valve sticking

See Section 3 in 2003 FLT

Service Manual (Part Number

99483-03).

Water or dirt in fuel system

Drain and refill with fresh fuel.

Table 4-7. Engine Exhaust Emits

Black Smoke or Fouls Plugs

SYMPTOM

SOLUTION

See Section 1 in 2003 FLT

Service Manual (Part Number 99483-03).

Clogged air filter

MAP sensor plugged or not

operating properly

Section 4.14 DTC 12.

Table 4-8. Diagnostic Trouble Codes (DTC) and Fault Conditions

FAULT CONDITION

DTC

RELEVANT SECTION

12

Map Sensor

4.14 DTC 12

16

Battery Voltage

4.15 DTC 16

24

Front Ignition Coil

4.16 DTC 24, 25

25

Rear Ignition Coil

4.16 DTC 24, 25

35

Tachometer

4.17 DTC 35

41

Crank Sensor

4.18 DTC 41

44

Bank Angle Sensor (Within TSM/TSSM) Detects Possible Theft Attempt

4.19 DTC 44

52

RAM Failure

4.20 DTC 52, 53, 54, 55

53

ROM Failure

4.20 DTC 52, 53, 54, 55

54

EEPROM Failure

4.20 DTC 52, 53, 54, 55

55

Ignition Module Failure

4.20 DTC 52, 53, 54, 55

2003 Touring: Engine Management (Carbureted)

4-13

HOME

f1973t9s

Data

Link

Power Wire

V/R

Lt GN/R

W/BK

BK

V/R

Lt GN/R

[91A]

[10B]

[10A]

[11B]

[11A]

Ignition Module

Figure 4-17. Diagnostic Check

Table 4-9. Wire Harness Connectors in Figure 4-17.

NO.

4-14

DESCRIPTION

TYPE

LOCATION

[10]

Ignition Module (Black)

12-Place Deutsch

Under Right Side Cover

[11]

Ignition Module (Gray)

12-Place Deutsch

Under Right Side Cover

[91]

Data Link

4-Place Deutsch

Under Right Side Cover

2003 Touring: Engine Management (Carbureted)

HOME

Diagnostic Check (Part 1 of 2)

Turn Ignition Switch to IGNITION. Set

Engine Stop Switch to RUN. Do not start engine.

Does check engine lamp illuminate?

YES

NO

Does light go off after

four seconds?

See Section 4.9 NO CHECK

ENGINE LAMP AT KEY ON.

YES

NO

Does engine

start?

See Section 4.10

CHECK ENGINE LAMP

ON CONTINUOUSLY.

YES

NO

Does Scanalyzer or check engine

lamp display ignition module

data? See Section 4.3 CHECKING FOR TROUBLE CODES.

See Section 4.11

ENGINE CRANKS, BUT

WILL NOT START.

YES

NO

Are any trouble

codes displayed?

STOP

YES

NO

Refer to applicable trouble code flow

chart. Start with lowest trouble code. All

diagnostic codes are listed in Table 4-8.

Compare scan data with

Table 4-4. Are values normal

or within typical ranges?

Go to Diagnostic

Check (Part 2 of 2).

YES

NO

See Section 4.7 WIGGLE

TEST. If Wiggle Test does

not recreate condition,

refer to symptoms tables.

Refer to diagnostic

tips in related trouble

code chart (even if

no code is set).

7110

2003 Touring: Engine Management (Carbureted)

4-15

HOME

Diagnostic Check (Part 2 of 2)

Continued from Diagnostic Check (Part 1 of 2).

Remove ignition module connectors [10B]

(BK) and [11B] (GY). Check for continuity to

ground at Pins 1 and 3 of Connector [91A].

Continuity to ground?

YES

NO

Locate and repair

short to ground.

7115

Test the four data link connector terminals against

their ignition module connector pins for continuity.

DATA LINK TERMINAL

IGNITION MODULE

TERMINAL

Pin

Wire Color

Pin

Connector

Lt. GN/R

11

[11B]

BK

11

[10B]

V/R

12

[11B]

W/BK

[10B]

Continuity present in all four circumstances?

YES

NO

Check Scanalyzer on

another vehicle.

Scanalyzer OK?

Inspect terminals

for damage or repair

opens as necessary.

7120

YES

NO

Replace ignition

module.

Scanalyzer

malfunction.

7125

4-16

2003 Touring: Engine Management (Carbureted)

HOME

NO CHECK ENGINE LAMP AT KEY ON

4.9

GENERAL

s0520xtm

If the Ignition/Light Key Switch is turned to IGNITION and the

Engine Stop/Run Switch is set to RUN (with the engine off),

the check engine lamp should illuminate for four seconds.

See Figure 4-18.

40

30

20

10

0

Battery voltage is supplied to the lamp bulb. The lamp bulb is

grounded by the ignition module through the BK/Y wire. A

lack of power to the ignition module will cause the check

engine lamp to be inoperative and also create a no start situation.

50 60 70

MPH

80

90

100

110

120

C

LE Y - D A V I D S O N

H AR ER T I F I E D

DIAGNOSTICS

Figure 4-18. Check Engine Lamp (FLHR)

Diagnostic Tips

f2023x9x

Check for the following conditions:

Check for open in BK/Y wire.

Check for blown accessory fuse. See Figure 4-19.

Diagnostic Notes

Accessory

Fuse

The reference numbers below correlate with the circled numbers on the Test 4.9 flow chart.

1.

Connect BREAKOUT BOX (Part No. HD-42682). See

Section 4.6 BREAKOUT BOX: CARB.

2.

Remove instrument console on FLHR models, outer fairing on FLHT/C, or instrument bezel on FLTR. See the

2003 FLT Service Manual (Part Number 99483-03).

3.

Leaving speedometer connector [39] connected, insert

probe into wire end of connector [39B] until contact is

made with backside of terminal. If necessary, use a fine

paper clip to avoid damage.

4.

5.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), purple pin probe and patch cord between Breakout Box and ground. Align blade with slot in terminal of

Breakout Box.

Figure 4-19. Left Side Cover Removed

(FLTR, FLHT/C)

6.

Assumes speedometer is functioning. If speedometer is

not functioning, see Section 2.2 SPEEDOMETER.

7.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), black pin or socket probe and patch cord.

8.

Check continuity.

a.

If continuity is present, most likely short to voltage;

b.

If no continuity present, then open.

LED failure requires speedometer replacement.

2003 Touring: Engine Management (Carbureted)

4-17

HOME

Ignition Module

[10B] [10A]

BK \ Y

[8B]

[8A]

Check Engine Lamp Ground Circuit

3 4 5 6 7 8 9 10 11 12

Ignition Module

Connector

Check Engine Lamp (LED)

1

2

3

4

5

6

BK \ Y

O\ W

+12V From Instruments

7

8

9

10

11

12

[39B] [39A]

Figure 4-20. Check Engine Lamp Circuit

Table 4-10. Wire Harness Connectors in Figure 4-20.

NO.

DESCRIPTION

MODEL

TYPE

LOCATION

[8]

Ignition Harness

All

12-Place Deutsch

Under Right Side Cover

[10]

Ignition Module

All

12-Place Deutsch (Black)

Under Right Side Cover

FLHT/C

12-Place Packard

Inner Fairing (Back of Speedometer)

[39]

Speedometer

FLTR

12-Place Packard

Under Bezel (Back of Speedometer)

FLHR/C

12-Place Mini-Deutsch

Under Console (Back of Speedometer)

4-18

2003 Touring: Engine Management (Carbureted)

HOME

Test 4.9

NO CHECK ENGINE LAMP AT KEY ON

Turn Ignition Switch to

IGNITION. Turn Engine Stop

Switch to RUN. Does the

Engine Start?

YES

NO

Turn Ignition Switch OFF. Disconnect Connector [10] (BK)

and Connect Breakout Box.

Did No Check Engine

Lamp and No Start

Conditions Occur

Simultaneously?

Check Continuity Between

Socket 4 of Connector [39B]

and Terminal 4 of Connector

[10] (BK) on Breakout Box.

Continuity Present?

2

3

NO

YES

4

2

7

NO

YES

Replace

Ignition

Module.

Replace

Speedometer.

7143

7130

NO

No Ignition Module

power. See Section

4.12 NO IGNITION

MODULE POWER.

See Section 4.11

ENGINE CRANKS, BUT

WILL NOT START for No

Start Condition and then

Return to Section 4.9 NO

CHECK ENGINE LAMP

AT KEY ON to Resolve

No Check Engine Lamp.

Disconnect Connector

[8]. Check Continuity of

BK/Y Wire Between Connectors [8A] and [39B].

Continuity Present?

Place Jumper Between

Terminal 4 of Connector

[10] (BK) on Breakout Box

to Ground. Check Engine

Lamp Should Be On.

Is It?

YES

YES

NO

Locate and Repair

Open on BK/Y Wire

Between Connectors [8B] and [10B].

Locate and Repair

Open on BK/Y Wire

Between Connectors [8A] and [39B].

7135

7145

2003 Touring: Engine Management (Carbureted)

4-19

HOME

CHECK ENGINE LAMP ON CONTINUOUSLY

4.10

GENERAL

s0520xtm

If the Ignition/Light Key Switch is turned to IGNITION and the

Engine Stop/Run Switch is set to RUN (with the engine off),

the check engine lamp should illuminate for four seconds.

See Figure 4-21.

40

30

20

10

0

Following the initial period of illumination, the lamp should go

off for four seconds. It may then come back on for an eight

second period or remain on continuously.

50 60 70

MPH

80

90

100

110

120

C

LE Y - D A V I D S O N

H AR ER T I F I E D

Battery voltage is supplied to the lamp bulb. The lamp bulb is

grounded by the ignition module through the BK/Y wire. A

steady light may indicate a short to ground on the black wire.

DIAGNOSTICS

Diagnostic Notes

Figure 4-21. Check Engine Lamp (FLHR)

3.

Remove instrument console on FLHR models, outer fairing on FLHT/C, or instrument bezel on FLTR. See the

2003 FLT Service Manual (Part Number 99483-03).

4.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), black pin probe and patch cord.

The reference numbers below correlate with the circled numbers on the Test 4.10 flow chart.

1.

If the lamp goes OFF when ignition module connector is

unplugged, BK/Y wire is shorted to ground.

2.

Check for trouble codes. See RETRIEVING TROUBLE

CODES under Section 4.3 CHECKING FOR TROUBLE

CODES.

4-20

2003 Touring: Engine Management (Carbureted)

HOME

Ignition Module

[10B] [10A]

BK \ Y

[8B]

[8A]

Check Engine Lamp Ground Circuit

3 4 5 6 7 8 9 10 11 12

Ignition Module

Connector

Check Engine Lamp (LED)

1

2

3

4

5

6

BK \ Y

O\ W

+12V From Instruments

7

8

9

10

11

12

[39B] [39A]

Figure 4-22. Check Engine Lamp Circuit

Table 4-11. Wire Harness Connectors in Figure 4-22.

NO.

DESCRIPTION

MODEL

TYPE

LOCATION

[8]

Ignition Harness

All

12-Place Deutsch

Under Right Side Cover

[10]

Ignition Module

All

12-Place Deutsch (Black)

Under Right Side Cover

FLHT/C

12-Place Packard

Inner Fairing (Back of Speedometer)

FLTR

12-Place Packard

Under Bezel (Back of Speedometer)

FLHR/C

12-Place Mini-Deutsch

Under Console (Back of Speedometer)

[39]

Speedometer

2003 Touring: Engine Management (Carbureted)

4-21

HOME

Test 4.10

CHECK ENGINE LAMP ON CONTINUOUSLY

Turn Ignition/Light Key Switch to IGNITION and Engine

Stop/Run Switch to RUN. Verify that there is NOT a 4

second lamp OFF period. Is there a lamp OFF period?

YES

NO

Check engine lamp function

OK. Check for trouble codes.

Turn ignition switch OFF. Disconnect

ignition module connector [10] (black).

Turn ignition switch to IGNITION.

Is the check engine lamp OFF?

YES

NO

Replace

ignition module.

7150

Disconnect connector [39].

Check for continuity to

ground on Pin 4 (BK/Y wire)

of connector [10] (black).

Continuity present?

YES

NO

Disconnect connector [8].

Does check engine

light illuminate?

Replace

speedometer.

7148

YES

NO

Locate and repair short

to ground on BK/Y wire

between Connectors

[8A] and [39B].

Locate and repair short

to ground on BK/Y wire

between Connectors

[8B] and [10B].

7160

4-22

2003 Touring: Engine Management (Carbureted)

7165

HOME

ENGINE CRANKS, BUT WILL NOT START

4.11

GENERAL

d0273x8x

If starter will not crank engine, the problem is not ignition

related. Refer to Starting/Charging in Section 1 of this manual.

Engine can be started with diagnostic test wire installed or if

the receive data line is grounded. The ignition switch must be

turned OFF after test wire is removed or check engine lamp

will continue to flash stored codes.

DIAGNOSTICS

Figure 4-23. Spark Tester

Diagnostic Notes

d0275x8x

The reference numbers below correlate with the circled numbers on the Test 4.11 flow charts.

1.

Check for trouble codes. See RETRIEVING TROUBLE

CODES under Section 4.3 CHECKING FOR TROUBLE

CODES.

2.

Check the condition of the battery. Perform a voltage test

and recharge if below 12.60V. Check battery connections

and perform load test. Replace the battery if necessary.

3.

Remove spark plug cable from spark plug.

a.

Visually check condition of plug.

b.

Attach cable to SPARK TESTER (Part No. HD26792). Clip tester to cylinder head bolt. See Figure

4-23.

c.

C B

Battery

While cranking engine, look for spark. Repeat procedure on other spark plug cables.

Figure 4-24. Ignition Coil Test

NOTE

Engine will not spark with both spark plugs removed.

When checking for spark, use SPARK TESTER with both

spark plugs installed.

4.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404) gray pin probes and patch cords.

5.

Gently use test lamp as shown in Figure 4-24. Inserting

the test lamp forcefully into the connector will damage

the terminal and require its replacement.

6.

Connect BREAKOUT BOX (Part No. HD-42682). See

Section 4.6 BREAKOUT BOX: CARB.

7.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray pin probe and patch cord.

8.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), brown socket probe and patch cord.

2003 Touring: Engine Management (Carbureted)

4-23

HOME

[79A] [79B]

Crank

Position

Sensor

(CKP)

R

BK

[11B] [11A] GY

1

2

BK

Ignition Module

Connectors

[83B]

A

B

C

Y \ BE

BE \ O

1

2

3

1

To

Data Link

[10B] [10A] BK

9

10

11

12

6-Place on FLHR

3 4 5 6 7 8 9 10 11 12

Key ON Power

7

8

Engine Stop Switch

4

5

6

3 4 5 6 7 8 9 10 11 12

FLHT/C

and FLTR Only

Rear Coil

W

\

B

K

Ignition

Coil

[1B]

[1A]

Front Coil

[22B]

[22A]

[8B] [8A]

To TSM/TSSM

GY

15 Amp

Ignition Fuse

R/BK To Ignition Switch

Figure 4-25. Ignition Circuit Diagram

Table 4-12. Wire Harness Connectors in Figure 4-25.

NO.

DESCRIPTION

MODEL

TYPE

LOCATION

[1]

Main to Interconnect Harness

FLHT/C

12-Place Deutsch

Inner Fairing- Right Fairing Bracket

FLTR

12-Place Deutsch

Inner Fairing- Below Radio (Right Side)

[8]

Ignition Harness

All

12-Place Deutsch

Under Right Side Cover

[10]

Ignition Module

All

12-Place Deutsch (Black)

Under Right Side Cover

[11]

Ignition module

All

12-Place Deutsch (Gray)

Under Right Side Cover

[79]

CKP Sensor

All

2-Place Mini-Deutsch

Under Right Side Cover

(Behind Electrical Bracket)

[83]

Ignition Coil

All

3-Place Packard

Below Fuel Tank (Left Side)

4-24

2003 Touring: Engine Management (Carbureted)

HOME

Test 4.11 (Part 1 of 3)

ENGINE CRANKS, BUT WILL NOT START

Is Fresh Gasoline in Tank?

Are Spark Plug Wires in

Correct Coil Towers?

YES

NO

Check for

Trouble Codes.

Codes Found?

Fill Tank With Fresh

Gasoline or Route Spark

Plug Wires Correctly.

YES

NO

Refer to Applicable Trouble

Code Chart.

Start With

Lowest Code.

Place Scanalyzer

in Data Monitor

Mode. Does

BAS MODE=RUN?

YES

NO

Check Battery

Connections. Perform

a Voltage Test. Is

Voltage Above 12.60?

Go to Section

4.19 DTC 44.

YES

NO

Does Battery

Pass Load

Test?

Recharge

Battery.

YES

NO

Check Spark Plug

Condition. Replace,

If Fouled. Check

Spark at Both Plugs

While Cranking.

Spark Present?

Replace

Battery.

7180

7185

YES

NO

Check Compression.

If Compression is

Good, Check Fuel

System.

Turn Ignition/Light Key

Switch to IGNITION and

Engine Stop Switch to

RUN. Check Engine

Lamp Should Illuminate

for 4 Seconds. Does it?

7210

YES

NO

Using DVOM, Check for

Battery Voltage at Socket

B of Connector [83B].

Battery Voltage Present?

See Section 4.12 NO

IGNITION MODULE

POWER.

YES

NO

STOP

Locate and

Repair Open

in W/BK Wire

to Coil.

Go to Test 4.11

(Part 2 of 3).

7215

2003 Touring: Engine Management (Carbureted)

4-25

HOME

Test 4.11 (Part 2 of 3)

ENGINE CRANKS, BUT WILL NOT START

Continued From Test 4.11 (Part 1 of 3).

Disconnect Connector [83]. Gently Connect Test Lamp to Sockets C (Front Cylinder) or A (Rear Cylinder) of Connector

[83B]. Crank Engine. Does Light Flash?

NO

YES

Check Coil Connections. Are

Connections OK?

6

7

YES

NO

Test Spark Plug

Cable Resistance.

See Section 4.13

MISFIRE.

Resistance OK?

Repair.

Connect Breakout Box. Check Continuity Between Socket A of Connector

[83B] and Terminal 7 of Connector

[10] (BK) on Breakout Box. Measure

Resistance Between Socket C of

Connector [83B] and Terminal 6 of

Connector [10] (BK) on Breakout Box.

Resistance Should be Less than 1.0

Ohm. Is it?

7226

YES

NO

Connect DVOM to Terminals 5 and 6

of Connector [11] (GY) on Breakout

Box and Set It for AC Volts. Crank

Engine. Meter Should Read 1 VAC

Minimum. Does it?

YES

NO

Plug Wires in

Correct Coil

Towers?

Replace

Spark Plug

Cables.

Locate and Repair

Poor Connection

at Connector [10B]

(BK) or Open in

Harness Between

Coil and Ignition

Module.

7225

7227

YES

YES

NO

8

NO

STOP

Replace

Coil.

7228

Route

Correctly.

Disconnect Connector [79].

Check Connector for Moisture

and Corrosion. Check Wires for

Chafing.

Connect DVOM to Pins 1 and 2

of Connector [79A]. Crank

engine. Meter Should Read 1

VAC Minimum. Does it?

Go to Test 4.11

(Part 3 of 3).

YES

NO

Check for Continuity

Between Socket 1 of

Connector [79B] and Terminal 5 of Connector [11]

(GY) on Breakout Box.

Continuity Present?

With Meter Still Connected, Check for

Resistance. Should

be Between 600-1200

Ohms. Is it?

YES

NO

Locate and Repair

Open on BK Wire

Between Socket 2 of

Connector [79B] and

Socket 6 of Connector [11B] (GY).

Locate and Repair

Open on R wire

Between Socket 1

of Connector [79B]

and Socket 5 of

Connector [11B]

(GY).

7231

7231

4-26

2003 Touring: Engine Management (Carbureted)

YES

NO

Loose Sensor

at Crankcase.

Tighten Sensor.

Replace

Crank

Position

Sensor.

7235

7230

HOME

Test 4.11 (Part 3 of 3)

ENGINE CRANKS, BUT WILL NOT START

Continued from Test 4.11 (Part 2 of 3).

Replace Ignition Module. Does Vehicle Start?

YES

NO

System OK.

Check For Improper Cam

Timing, Sprocket Failure,

Failed Timing Chain or Other

Mechanical Problem.

7250

7255

2003 Touring: Engine Management (Carbureted)

4-27

HOME

NO IGNITION MODULE POWER

4.12

GENERAL

DIAGNOSTICS

No Spark/No Check Engine

Lamp At Key ON

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.12 flow chart.

The ignition module turns on when power is applied to Pin 1

of Connector [10], black. The ignition module goes through an

initialization sequence every time power is removed and reapplied to Pin 1. The only visible part of this sequence is the

check engine lamp. Upon starting, the check engine lamp will

illuminate for 4 seconds and then (if parameters are normal)

go out.

1.

See Section 4.1 SPECIFICATIONS.

2.

Connect BREAKOUT BOX (Part No. HD-42682). See

Section 4.6 BREAKOUT BOX: CARB.

3.

Use HARNESS CONNECTOR TEST KIT (Part No. HD4104), black pin probe and patch cord.

4.

Remove headlamp assembly on FLHR models or outer

fairing on FLHT/C and FLTR. See the 2003 FLT Service

Manual (Part Number 99483-03).

R/BK To Ignition Switch

[83B]

11

A

B

C

15 Amp

Ignition Fuse

GY

Y \ BE

BE \ O

W

\

B

K

Ignition

Coil

[1B]

[1A]

4

5

6

3 4 5 6 7 8 9 10 11 12

FLHT/C

and FLTR Only

To

Data Link

7

8

Engine Stop Switch

9

10

11

12

6-Place on FLHR

[22B]

[22A]

3 4 5 6 7 8 9 10 11 12

[8B] [8A]

Ground Stud

Figure 4-26. Ignition Coil Circuit Diagram

4-28

Rear Coil

BK

1

2

3

To TSM/TSSM

Front Coil

2003 Touring: Engine Management (Carbureted)

[10B] [10A] BK

Ground

Key ON Power

HOME

Test 4.12

NO IGNITION MODULE POWER

1

Check Ignition

Fuse. Is Fuse

OK?

YES

NO

Replace Fuse

and Find

Source of Fault.

2

3

7270

Connect Breakout Box. With Ignition

ON, Place Multimeter Red Wire to

Terminal 1 of Connector [10] (BK)

on Breakout Box, Multimeter Black

Wire to Terminals 2 and 11 on Connector [10] (BK) on Breakout Box.

Is Voltage 12V 1.0V.?

NO

YES

Replace

Ignition

Module.

7305

Using a Breakout Box, Check Continuity Between Terminals on Breakout Box and Ground and Terminal 11

of Connector [10] (BK) on Breakout

Box and Ground. Continuity Present

in Both Places?

NO

YES

3

Repair Open in BK

Wire (Pin 2 or Pin

11) to Ground.

Check Continuity Between Pin

4 (W/BK) of Connector [22A]

and Terminal 1 of Connector

[10] (BK) on Breakout Box.

Is Continuity Present?

7310

YES

NO

Check Continuity

Between Sockets 4

(W/BK) and 3 (GY) of

Connector [22B]. With

Engine Stop Switch

ON, Is Continuity

Present?

Locate and Repair

Open in W/BK Wire

Between Connectors

[22] and [10].

7285

YES

NO

Locate and Repair

Open in GY Wire

Between Connector

[22A] and Fuse Block.

Replace

Engine Stop

Switch.

7295

7291

Table 4-13. Wire Harness Connectors in Figure 4-26.

NO.

DESCRIPTION

[1]

Main to Interconnect Harness

MODEL

TYPE

LOCATION

FLHT/C

12-Place Deutsch

Inner Fairing- Right Fairing Bracket

FLTR

12-Place Deutsch

Inner Fairing- Below Radio (Right Side)

[8]

Ignition Harness

All

12-Place Deutsch

Under Right Side Cover

[10]

Ignition Module

All

12-Place Deutsch (Black)

Under Right Side Cover

FLHT/C

12-Place Deutsch

Inner FairingRight Fairing Support Brace

FLTR

12-Place Deutsch

Inner Fairing Right Side of Radio Bracket

FLHR

6-Place Deutsch

Inside Headlamp Nacelle

[22]

Interconnect to Right

Handlebar Switch Controls

2003 Touring: Engine Management (Carbureted)

4-29

HOME

MISFIRE

4.13

GENERAL

d0273x8x

Misfire at Idle or Under Load

Battery condition and connections may also cause misfires.

Fuel system problems may also cause misfires. See

Table 4-6.

DIAGNOSTICS

Figure 4-27. Spark Tester

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 4.13 flow chart.

c.

1WARNING

Any open spark around gasoline or other combustibles

may result in fire or explosion. Thoroughly wipe up any

spilt fuel and dispose of rags in a suitable manner. Inadequate safety precautions could result in death or serious

injury.

1.

See Figure 4-27. Use the SPARK TESTER (Part No. HD26792) to verify adequate secondary voltage (25,000

volts) at the spark plug.

a.

Turn Ignition/Light Key Switch to IGNITION.

b.

Remove spark plug cable from spark plug. Visually

check plug condition.

c.

Attach cable to SPARK TESTER. Clip tester to cylinder head bolt.

d.

e.

2.

Reinstall and repeat procedure on other spark plug

cable.

Perform spark plug cable resistance test.

a.

Remove spark plug cable from spark plug and ignition coil. For best results, use a needle nose pliers

for removal/installation on coil. Gently grasp cable

as close to terminals as possible.

b.

Using an ohmmeter, touch probes to terminals on

each end plug wire.

4-30

Table 4-14. Spark Plug Cables

LOCATION

Front/Rear

2003 Touring: Engine Management (Carbureted)

LENGTH

RESISTANCE

20 inch

5,000-11,666

3.

If carbon tracking is evident, replace ignition coil and

inspect spark plug wires. Wires must be clean and tight.

Excessive wire resistance or faulty connections can

cause coil damage.

4.

This test can also be performed by substituting a known

good coil for one causing the no spark condition. The coil

does not require full installation to be functional. Verify

faulty coil by performing resistance test.

5.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray pin probe and patch cord to the coil connector [83B].

6.

Inspect for corrosion at battery terminals, main circuit

breaker, ignition fuse terminals GY and R/BK, right handlebar switch controls connector [22], and ignition coil

connector [83].

While cranking engine, watch for spark to jump

tester gap on leads.

IMPORTANT NOTE

Engine will not spark with both spark plugs removed.

When checking for spark, use SPARK TESTER with both

spark plugs installed.

Compare resistance values to Table 4-14. Replace

cables not meeting specifications. Reinstall and

repeat procedure on other spark plug cable.

HOME

[83B]

R/BK To

Ignition Switch

15 Amp

Ignition Fuse

A

B

C

Y \ BE

BE \ O

1

2

3

GY

Key ON Power

[1B]

[1A]

3 4 5 6 7 8 9 10 11 12

FLHT/C

and FLTR Only

To

Data Link

7

8

9

10

11

12

6-Place on FLHR

2

[10B] [10A] BK

Engine Stop Switch

Front Coil

W

\

B

K

Ignition

Coil

[22B]

[22A]

Rear Coil

3 4 5 6 7 8 9 10 11 12

[8B] [8A]

Figure 4-28. Ignition Coil Circuit Diagram

Table 4-15. Wire Harness Connectors in Figure 4-28.

NO.

[10]

[22]

[83]

DESCRIPTION

Ignition Module

Interconnect to Right

Handlebar Switch Controls

Ignition Coil

MODEL

TYPE

LOCATION

All

12-Place Deutsch (Black)

Under Right Side Cover

FLHT/C

12-Place Deutsch

Inner FairingRight Fairing Support Brace

FLTR

12-Place Deutsch

Inner Fairing Right Side of Radio Bracket

FLHR

6-Place Deutsch

Inside Headlamp Nacelle

All

3-Place Packard

Below Fuel Tank (Left Side)

2003 Touring: Engine Management (Carbureted)

4-31

HOME

Test 4.13

MISFIRE AT IDLE OR UNDER LOAD

Is Fuel

Contaminated?

NO

YES

Drain and

Flush Tank.

Refill With

Fresh Fuel.

Turn Ignition Switch OFF.

Disconnect One Spark Plug Lead

at a Time and Install Spark Tester

(HD-26792). See Figure 4-27.

Crank Engine to Induce Spark.

Observe Spark Tester During Test.

Spark Should Jump Tester Gap on

Both Leads During Test. Did It?

NO

YES

2

Check For:

Faulty, Worn or Cracked

Spark Plug(s).

Plug Fouling Due to

Engine Mechanical Fault.

See ENGINE TROUBLESHOOTING.

Faulty or Poor Connection at Plug.

Check the Resistance of Each Spark

Plug Cable That Did Not Fire the Spark

Tester. Also Check for Faulty Plug Wire

Connections and Wire Boots for Carbon Tracking. Are Wires OK?

YES

NO

Coil Should Be

Free of Carbon

Tracking. Is It?

Replace Faulty

Wire(s).

YES

NO

Switch Coil With Unit

Known to be Good.

Replace

Ignition Coil.

3

7520

7525

Spark Should Jump Tester

Gap While Cranking.

Did It?

7535

NO

YES

Original Ignition

Coil is Faulty.

Finish Installing

New Coil.

7535

Remove Test Coil. Disconnect

Negative (-) Battery Cable. Measure Resistance Between Battery

Positive and Socket B (W/BK) of

Connector [83B]. Wiggle Harness.

Resistance Should Be Less Than

1.0 Ohm Continuously. Is It?

YES

NO

Replace

Ignition

Module.

Find Source

of Intermittent

and Repair.

7541

4-32

2003 Touring: Engine Management (Carbureted)

7540

Anda mungkin juga menyukai

- CIRCUIT DIAGRAMSDokumen89 halamanCIRCUIT DIAGRAMSSean OsborneBelum ada peringkat

- Engine Control (7A-Fe) : System OutlineDokumen10 halamanEngine Control (7A-Fe) : System OutlineNguyễn Duy HoàngBelum ada peringkat

- Steering RackDokumen8 halamanSteering RackhidraulicBelum ada peringkat

- Auto DataDokumen2 halamanAuto DataOana CocârleaBelum ada peringkat

- ECM I/O Signals DiagnosticsDokumen5 halamanECM I/O Signals Diagnosticskofo3000Belum ada peringkat

- Pioneer Avh-X5500 Avh-X5550 Avh-X5590 SM PDFDokumen190 halamanPioneer Avh-X5500 Avh-X5550 Avh-X5590 SM PDFCarlos Alonso Gonzalez VazquesBelum ada peringkat

- MG100 Series Owners Manual5. Clean Channel VOLUME control1715. Overdrive Channel VOLUME controlDokumen6 halamanMG100 Series Owners Manual5. Clean Channel VOLUME control1715. Overdrive Channel VOLUME controlALBelum ada peringkat

- Kdfi V1.4: User Manual (English)Dokumen13 halamanKdfi V1.4: User Manual (English)Dot3xe Nicolas100% (1)

- AUTOMATICDokumen15 halamanAUTOMATICmacciastarBelum ada peringkat

- 94 Mazda B2300 or B3000 or B4000 or Navajo 4Dokumen3 halaman94 Mazda B2300 or B3000 or B4000 or Navajo 4Lotfi Ben SlimBelum ada peringkat

- Tektronix 576 Curve Tracer Operation and Service ManualDokumen251 halamanTektronix 576 Curve Tracer Operation and Service Manualmunnizza64100% (3)

- How To Reset An Acer BIOS Password PDFDokumen5 halamanHow To Reset An Acer BIOS Password PDFrahul2222222Belum ada peringkat

- PAL MaintenanceDokumen4 halamanPAL MaintenanceLucas PrimaniBelum ada peringkat

- BMW Connection DiagramDokumen4 halamanBMW Connection DiagramPakeTataNkisiMalongoBelum ada peringkat

- Group 5 Presentation: Hybrid CarDokumen48 halamanGroup 5 Presentation: Hybrid CarRuzaini ZaiBelum ada peringkat

- Sony Service Manual KLV-40V410A-BrazilDokumen88 halamanSony Service Manual KLV-40V410A-Brazilgimenes_r0% (1)

- 2008-11-14 003029 Es Code CheckDokumen6 halaman2008-11-14 003029 Es Code CheckRaysian K. SetoBelum ada peringkat

- Saw Filter (Siemens)Dokumen350 halamanSaw Filter (Siemens)Luiz059100% (1)

- HS402 DIY Oscilloscope Components List: Designator Quantity Value Description Footprint Comment PhotoDokumen5 halamanHS402 DIY Oscilloscope Components List: Designator Quantity Value Description Footprint Comment PhotoИльнур ТагировBelum ada peringkat

- 1 - Overview of CTC and PALs 10-23-11Dokumen30 halaman1 - Overview of CTC and PALs 10-23-11Khoa Nam NguyenBelum ada peringkat

- ADAS Description enDokumen10 halamanADAS Description enIonut-alexandru IordacheBelum ada peringkat

- BYPASS Map SENSORDokumen3 halamanBYPASS Map SENSORKushal ExpertBelum ada peringkat

- rr322404 Automotive Electrical and AutotronicsDokumen4 halamanrr322404 Automotive Electrical and AutotronicsSRINIVASA RAO GANTABelum ada peringkat

- E Prog Sin FotoDokumen16 halamanE Prog Sin FotoGasper CeballosBelum ada peringkat

- MST 9000 PDFDokumen12 halamanMST 9000 PDFJorge Alberto Barbosa Perez100% (1)

- CamRoad 6.1 User ManualDokumen17 halamanCamRoad 6.1 User ManualSean CrossBelum ada peringkat

- Typical LED SymbolDokumen4 halamanTypical LED Symbolthy thy thyBelum ada peringkat

- Philips Az787-61 Ver 1 0Dokumen26 halamanPhilips Az787-61 Ver 1 0Roman servisBelum ada peringkat

- DC Voltage Testing: Nodal AnalysisDokumen7 halamanDC Voltage Testing: Nodal Analysisseshubabu_999Belum ada peringkat

- Pro Acoustimass PDFDokumen19 halamanPro Acoustimass PDFFrancisco Coayo Matos100% (1)

- Buk9222 55aDokumen13 halamanBuk9222 55aAnthony AndreyBelum ada peringkat

- Panasonic Lumix DMC-FZ50 Service ManualDokumen69 halamanPanasonic Lumix DMC-FZ50 Service Manualdasxax100% (1)

- Cutting-Edge Automotive Diagnostic Equipment Functions ManualDokumen4 halamanCutting-Edge Automotive Diagnostic Equipment Functions ManualRichard Andrianjaka LuckyBelum ada peringkat

- Inverter - English 2022Dokumen17 halamanInverter - English 2022Dudes and ToolsBelum ada peringkat

- 2008 Mazda MPV - Brake - Conventional Brake SystemDokumen28 halaman2008 Mazda MPV - Brake - Conventional Brake Systemlo mio es mio100% (1)

- Ec PDFDokumen1.290 halamanEc PDFMayobanex Moya MartinezBelum ada peringkat

- EEC IV Self Test - Ford Fuel Injection and EEC IV Electronic Engine Control - EEC 4Dokumen9 halamanEEC IV Self Test - Ford Fuel Injection and EEC IV Electronic Engine Control - EEC 4Juan Pablo Rey BravoBelum ada peringkat

- 4TWX4036 Service FactsDokumen4 halaman4TWX4036 Service FactsAlejandro OrdoñezBelum ada peringkat

- Bosch DME Circuits InfoDokumen8 halamanBosch DME Circuits InfoDanno NBelum ada peringkat

- Alternator Troubleshooting With An OscilloscopeDokumen4 halamanAlternator Troubleshooting With An OscilloscopeVyas SrinivasanBelum ada peringkat

- Automatic Transmission Troubleshooting GuideDokumen754 halamanAutomatic Transmission Troubleshooting GuideElias SerranoBelum ada peringkat

- 968 Fuse Box ChartDokumen1 halaman968 Fuse Box Chartdamon wBelum ada peringkat

- SM 55.c PDFDokumen339 halamanSM 55.c PDFjorge Angel Lope100% (1)

- Rebuild Yamaha Vision Motorcycle TCI Electronic Ignition ModuleDokumen11 halamanRebuild Yamaha Vision Motorcycle TCI Electronic Ignition Modulexplod11Belum ada peringkat

- 9619 LG 42LE5500 42LE5500-UA Chassis LA02E Televisor LED-LCD Manual de Entrenamiento+diagramas PDFDokumen108 halaman9619 LG 42LE5500 42LE5500-UA Chassis LA02E Televisor LED-LCD Manual de Entrenamiento+diagramas PDFaldo50% (2)

- Motorbike anti-theft alarm with spark cut off and tilt sensor circuitDokumen9 halamanMotorbike anti-theft alarm with spark cut off and tilt sensor circuitArjun H NambiarBelum ada peringkat

- ECU PINS - MALE PIN VIEWDokumen1 halamanECU PINS - MALE PIN VIEWPaul LuczonBelum ada peringkat

- 1.8T Engine Fuel SupplyDokumen1 halaman1.8T Engine Fuel SupplyJZBelum ada peringkat

- smps1000 EltekDokumen2 halamansmps1000 Elteksebax123Belum ada peringkat

- Prius CodesDokumen2 halamanPrius Codeskde148100% (1)

- E46 BMW DIY 02 SimulatorsDokumen24 halamanE46 BMW DIY 02 SimulatorsbokileeBelum ada peringkat

- Drive Technology Connection DiagramsDokumen30 halamanDrive Technology Connection DiagramsSimon Tolomeo100% (1)

- Topswitch - GX: Flyback Quick Selection CurvesDokumen12 halamanTopswitch - GX: Flyback Quick Selection Curvessteviej85Belum ada peringkat

- Different Types of VVT VTECDokumen12 halamanDifferent Types of VVT VTECshahrizalBelum ada peringkat

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideDari EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideBelum ada peringkat

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualDari EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualBelum ada peringkat

- Chassis Dynamometer Testing: Addressing the Challenges of New Global LegislationDari EverandChassis Dynamometer Testing: Addressing the Challenges of New Global LegislationBelum ada peringkat

- Spa07 TC PDFDokumen2 halamanSpa07 TC PDFvette512Belum ada peringkat

- Spa02 TC PDFDokumen2 halamanSpa02 TC PDFvette512Belum ada peringkat

- Electrical 8: Subject Page NoDokumen2 halamanElectrical 8: Subject Page Novette512Belum ada peringkat

- Spa06 TC PDFDokumen2 halamanSpa06 TC PDFvette512Belum ada peringkat

- Spa03 TC PDFDokumen2 halamanSpa03 TC PDFvette512Belum ada peringkat

- Appendices: Subject Page NoDokumen2 halamanAppendices: Subject Page Novette512Belum ada peringkat

- Spa02a PDFDokumen12 halamanSpa02a PDFvette512Belum ada peringkat

- Maintenance Schedule 1.1: Maintenance Task and Service DataDokumen6 halamanMaintenance Schedule 1.1: Maintenance Task and Service Datavette512Belum ada peringkat

- Spa05 TC PDFDokumen2 halamanSpa05 TC PDFvette512Belum ada peringkat

- SM Appa PDFDokumen18 halamanSM Appa PDFvette512Belum ada peringkat

- Spa04 TC PDFDokumen2 halamanSpa04 TC PDFvette512Belum ada peringkat

- Maintenance 1: Subject Page NoDokumen2 halamanMaintenance 1: Subject Page Novette512Belum ada peringkat

- Sm07a PDFDokumen32 halamanSm07a PDFvette512Belum ada peringkat

- Induction Module Assembly 9.5: GeneralDokumen10 halamanInduction Module Assembly 9.5: Generalvette512Belum ada peringkat

- Sm09a PDFDokumen30 halamanSm09a PDFvette512Belum ada peringkat

- Sm08a PDFDokumen46 halamanSm08a PDFvette512Belum ada peringkat

- SM Appb1 PDFDokumen48 halamanSM Appb1 PDFvette512Belum ada peringkat

- sm08b PDFDokumen50 halamansm08b PDFvette512Belum ada peringkat

- Fuel Injection 9: Subject Page NoDokumen2 halamanFuel Injection 9: Subject Page Novette512Belum ada peringkat

- sm08c PDFDokumen36 halamansm08c PDFvette512Belum ada peringkat

- Electrical 8: Subject Page NoDokumen2 halamanElectrical 8: Subject Page Novette512Belum ada peringkat

- Sm06a PDFDokumen32 halamanSm06a PDFvette512Belum ada peringkat

- Sm03a PDFDokumen32 halamanSm03a PDFvette512Belum ada peringkat

- Sm04a PDFDokumen30 halamanSm04a PDFvette512Belum ada peringkat

- Specifications 5.1: Starter Torque ValuesDokumen14 halamanSpecifications 5.1: Starter Torque Valuesvette512Belum ada peringkat

- Engine 3: Subject Page NoDokumen2 halamanEngine 3: Subject Page Novette512Belum ada peringkat

- Sm02a PDFDokumen76 halamanSm02a PDFvette512Belum ada peringkat

- sm03b PDFDokumen44 halamansm03b PDFvette512Belum ada peringkat

- sm02 TC PDFDokumen2 halamansm02 TC PDFvette512Belum ada peringkat

- sm01b PDFDokumen19 halamansm01b PDFvette512Belum ada peringkat

- 87Dokumen5 halaman87vinay kumarBelum ada peringkat

- Next-Gen Compact Digital Multimeter PRO-11/12BDokumen4 halamanNext-Gen Compact Digital Multimeter PRO-11/12BRaghava AkshintalaBelum ada peringkat

- Pulse Analog ConverterDokumen4 halamanPulse Analog ConverterAishiteruBelum ada peringkat

- EL600 Single Rudder Redundancy Setup v1.11Dokumen30 halamanEL600 Single Rudder Redundancy Setup v1.11RomanBelum ada peringkat

- Calculation of The Power FactorDokumen50 halamanCalculation of The Power FactorAurobindo MandalBelum ada peringkat

- Single Phase Overhead Transformers Catalog Ca201001enDokumen4 halamanSingle Phase Overhead Transformers Catalog Ca201001enShung Tak ChanBelum ada peringkat

- Alarmas Omron SigmaII SGDHDokumen3 halamanAlarmas Omron SigmaII SGDHDiego DiegoBelum ada peringkat

- Yawar Khan: Career ObjectiveDokumen3 halamanYawar Khan: Career ObjectiveYawarBelum ada peringkat

- Digital to Analogue Conversion ExplainedDokumen18 halamanDigital to Analogue Conversion ExplainedGopu G NairBelum ada peringkat

- Panel - LPB: Approvals: Type: Job: NotesDokumen3 halamanPanel - LPB: Approvals: Type: Job: NotesEduardo martinezBelum ada peringkat

- VX3 RmodDokumen2 halamanVX3 RmodBambang KaryantoBelum ada peringkat

- CNAV - C-Nav 1PPSIDokumen2 halamanCNAV - C-Nav 1PPSILapatechBelum ada peringkat

- Contactores Ls Possenti Heat Contactors RelaysDokumen120 halamanContactores Ls Possenti Heat Contactors Relaysapi-28269646Belum ada peringkat

- 3-Phase control relay data sheetDokumen7 halaman3-Phase control relay data sheetlorentz franklinBelum ada peringkat

- Project: ETAP Ground Grid Input DataDokumen2 halamanProject: ETAP Ground Grid Input DataCarlos CastilloBelum ada peringkat

- 580N 580SN WT 580SN 590SN Tier 3 Tractor Loader BackhoeDokumen337 halaman580N 580SN WT 580SN 590SN Tier 3 Tractor Loader BackhoeMedi TakapenteBelum ada peringkat

- PR5597 Rev11 CPX Quick Start EngDokumen2 halamanPR5597 Rev11 CPX Quick Start EngTony Brooke-TaylorBelum ada peringkat

- 2 EcesyllDokumen91 halaman2 Ecesyllchavanakshay1812Belum ada peringkat

- Lesson Plan: Institute of Space TechnologyDokumen3 halamanLesson Plan: Institute of Space TechnologyShahZaib AnwarBelum ada peringkat

- CIGRE A3 - ps2 - q2.19 - Back-To-Back Capacitor Bank SwitchingDokumen2 halamanCIGRE A3 - ps2 - q2.19 - Back-To-Back Capacitor Bank Switchinglbk50Belum ada peringkat

- Schematic Diagram of Unit Auxiliary Transfer SchemeDokumen8 halamanSchematic Diagram of Unit Auxiliary Transfer Schemerashm006ranjanBelum ada peringkat

- Iec Standard / Normal Inverse Iec Long Time Inverse: Iec Characteristics Curve For IdmtDokumen2 halamanIec Standard / Normal Inverse Iec Long Time Inverse: Iec Characteristics Curve For IdmtSoumik KarBelum ada peringkat

- Project Report For GurusonsDokumen21 halamanProject Report For GurusonsNitin RoyBelum ada peringkat

- Ordering Spare PartsDokumen5 halamanOrdering Spare PartsPeryna WstydBelum ada peringkat

- Spring Reverb - Tank Technical ExplanationDokumen12 halamanSpring Reverb - Tank Technical ExplanationjustinBelum ada peringkat

- Frecuencia Alta ODI4-065R18J02-GQDokumen2 halamanFrecuencia Alta ODI4-065R18J02-GQcarlosconstructor1Belum ada peringkat

- Boya By-M1000 ManualDokumen2 halamanBoya By-M1000 ManualLuis Otavio TrindadeBelum ada peringkat

- Over Under Voltage ProtectionDokumen49 halamanOver Under Voltage ProtectionChandra Shekhar100% (1)

- Lp.. IctDokumen5 halamanLp.. Ictjoan dialogoBelum ada peringkat

- Brochure TWR H - B TWRHNN 300 ENDokumen4 halamanBrochure TWR H - B TWRHNN 300 ENEl INGEBelum ada peringkat