Audit Checklist For ISO 13485

Diunggah oleh

EdJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Audit Checklist For ISO 13485

Diunggah oleh

EdHak Cipta:

Format Tersedia

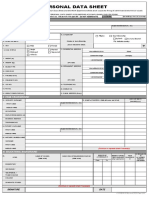

Form No.

MR17002/B

Audit Checklist

Exporting

Storing

/20

Marketing sales

ResourcesHuman

Quality

Purchasing

Maintenance

Questions

Production

DirectorManaging

Date

/

Evaluation

ISO 13485-2003 Specific Requirement

1.

Review the Technical file and its contents. (Ref. MRI-05-D01.)

2.

Review the Document Change Procedure, Confirm that the changes to

documents are reviewed and approved either by the original approving

authority. (Ref. MRP-05-01 : MRP-05-04)

3.

Does at least one copy of obsolete controlled documents shall be retained.

(Ref. MRP-05-01 : MRP-05-04)

4.

Review retention period the records and is it equivalent to the lifetime of the

product? (Ref. MRP-16-01)

5.

Management review meetings included the following: (Ref. SCP-01-02)

Regulatory Requirements and its impact,

6.

Review the maintenance plan and its execution (Ref. FCP-09-02) specifically:

Sterilization Unit

Air Handling Units

Remarks :

.

.

.

Fill in remarks and evidence for each item audited, if needed attach separate pages

* Evaluation:

0:N/A

1:Conforming

2:Non-conforming,

3:Observation

Form No. MR17002/B

Audit Checklist

7.

Review the Hygiene work instruction (Ref. FCI-09-A05)

8.

Check the adherence to the cleaning instructions of the used products (Ref.

MK03009)

9.

Check the monitoring program of ALL clean rooms (Ref. FCI-09-A01)

specifically:

P in the clean room and its adjacent sections

Temperature and RH%

Maintenance Condition of the AHUs

Microbiological Controls of the production areas and the PRODUCTS

10.

Review the current risk analysis and its update status (Ref. MRI-05-D01)

specifically:

Microbiological failures,

All relevant usability aspects.

11.

Review the advisory notice and recall system (Ref. MKP-03-03 and SCP-1401)

12.

Review the retention of at least one copy of the material relevant purchase

orders (Ref. PRP-06-02 and MRP-16-01)

Exporting

Storing

/20

Marketing sales

ResourcesHuman

Quality

Purchasing

Maintenance

Questions

Production

DirectorManaging

Date

/

Evaluation

Remarks :

.

.

.

Fill in remarks and evidence for each item audited, if needed attach separate pages

* Evaluation:

0:N/A

1:Conforming

2:Non-conforming,

3:Observation

Form No. MR17002/B

Audit Checklist

13.

Review the presence of the relevant work instructions and/or other activity

related documents (including labeling instructions)

14.

Review the Batch file and its contents (Ref. FCP-08-01)

15.

Review the Sterilization Process Records and Sterilization Process

Parameters

(Ref. FCI-09-A04, FCI-09-V01, FCI-09-V02 and QCI-10-S16)

16.

Review the sterilization process validation (Ref. FCI-09-A04, FCI-09-V01, FCI09-V02, QCI-10-S16 and sterilizer validation protocol)

17.

Review the records of the calibration (Ref. FCP-11-01)

18.

Review the action if the measuring equipment was found not to conform to

requirements (Ref. FCP-11-01)

Exporting

Storing

/20

Marketing sales

ResourcesHuman

Quality

Purchasing

Maintenance

Questions

Production

DirectorManaging

Date

/

Evaluation

Remarks :

.

.

.

Fill in remarks and evidence for each item audited, if needed attach separate pages

* Evaluation:

0:N/A

1:Conforming

2:Non-conforming,

3:Observation

Form No. MR17002/B

Audit Checklist

19.

Review the customer feedback results and its impact (Ref. MKP-03-03)

20.

Review the measurement conducted on the product to verify that the

product requirements have been met. (Ref. QCP-10-03)

21.

Review that the nonconforming product is accepted by concession only if

regulatory requirements are met. (Ref. QCP-13-01)

22.

Review that the product needs to be reworked has a documented rework

instruction (Ref. QCP-13-01)

23.

Review the Data Analysis Procedure and its output records (Ref. QCP-20-01.)

24.

Review the evidence of the suitability and effectiveness of the quality

system (Ref. SCP-01-02)

Exporting

Storing

/20

Marketing sales

ResourcesHuman

Quality

Purchasing

Maintenance

Questions

Production

DirectorManaging

Date

/

Evaluation

Remarks :

.

.

.

Fill in remarks and evidence for each item audited, if needed attach separate pages

* Evaluation:

0:N/A

1:Conforming

2:Non-conforming,

3:Observation

Form No. MR17002/B

Audit Checklist

25.

Review Customer Complaints records (Ref. MKP-03-03) specifically check

that any complaint which was not followed by a PCAR the reason should be

stated

26.

Review Preventive/Corrective Action and its linked investigation records

(Ref. SCP-14-01)

Exporting

Storing

/20

Marketing sales

ResourcesHuman

Quality

Purchasing

Maintenance

Questions

Production

DirectorManaging

Date

/

Evaluation

MDD 93/42/EEC Specific Requirement

27.

Review the current risk analysis and its update status (Ref. MRI-05-D01)

specifically:

Microbiological failures,

All relevant usability aspects.

28.

Review the current Annex I Essential Requirements Checklist (Ref. MRI-05D01)

29.

Review the vigilance system procedure and records. (Ref. MKP-03-01.)

Check the presence of the competent authorities addresses

30.

Check for the availability of the Technical File for at least 5 years after the

last product is produced.

Remarks :

.

.

.

Fill in remarks and evidence for each item audited, if needed attach separate pages

* Evaluation:

0:N/A

1:Conforming

2:Non-conforming,

3:Observation

Form No. MR17002/B

Audit Checklist

31.

Review the advisory notice and recall system (Ref. MKP-03-03 and SCP-1401)

32.

Review

33.

Review the NB notification process (Ref. MRI-05-D01)

34.

Review the Post-Production experience records (Ref. MKP-03-03)

Exporting

Storing

/20

Marketing sales

ResourcesHuman

Quality

Purchasing

Maintenance

Questions

Production

DirectorManaging

Date

/

Evaluation

the contents of the technical file and its contents (Ref. MRI-05-D01)

EC Declaration of Conformity,

Risk Analysis,

Classification, etc.

35.

36.

Remarks :

.

.

.

Fill in remarks and evidence for each item audited, if needed attach separate pages

* Evaluation:

0:N/A

1:Conforming

2:Non-conforming,

3:Observation

Anda mungkin juga menyukai

- Audit Checklist - IsO 13485 and MDDDokumen6 halamanAudit Checklist - IsO 13485 and MDDMarcos Poffo100% (2)

- ISO 13485 2016 Documentation Manual Clause Wise RequirementsDokumen15 halamanISO 13485 2016 Documentation Manual Clause Wise Requirementsqmicertification100% (1)

- 2016 StandardDokumen39 halaman2016 StandardAnkur Dhir100% (4)

- Medical Device Quality Management Systems: Strategy and Techniques for Improving Efficiency and EffectivenessDari EverandMedical Device Quality Management Systems: Strategy and Techniques for Improving Efficiency and EffectivenessBelum ada peringkat

- ISO 13485 Documentation RequirementsDokumen2 halamanISO 13485 Documentation Requirementsalexrferreira67% (3)

- ISO 13485 Audit ChecklistDokumen38 halamanISO 13485 Audit ChecklistRRR1Belum ada peringkat

- Technical FilesDokumen15 halamanTechnical Fileshitham shehataBelum ada peringkat

- ISO 13485 Quality Management System A Complete Guide - 2020 EditionDari EverandISO 13485 Quality Management System A Complete Guide - 2020 EditionBelum ada peringkat

- Medical Device Design Verification SOPDokumen1 halamanMedical Device Design Verification SOPqmdocs0% (1)

- Iso 13485 Webinar SlidesDokumen50 halamanIso 13485 Webinar SlidesFBASTOSEQ100% (3)

- Cracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsDari EverandCracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsBelum ada peringkat

- 410 09e Checkliste For Assessment 13485 MDDDokumen51 halaman410 09e Checkliste For Assessment 13485 MDDeko Setyawan100% (1)

- ISO 13485 Operational Procedure QOP-73-02 (A) Design Risk ManagementDokumen4 halamanISO 13485 Operational Procedure QOP-73-02 (A) Design Risk Managementtahir_rizvi1569Belum ada peringkat

- ISO 13485 2003 Audit ChecklistDokumen38 halamanISO 13485 2003 Audit Checklisttousifaslam100% (1)

- Comparison Chart of ISO 13485 and FDA QSR RequirementsDokumen4 halamanComparison Chart of ISO 13485 and FDA QSR RequirementsjvivoloBelum ada peringkat

- ISO 13485 Internal Audit ChecklistDokumen23 halamanISO 13485 Internal Audit ChecklistGary Jheferson Salazar Rondon60% (5)

- Bsi MD Risk Management For Medical Devices Webinar 131119 Uk enDokumen29 halamanBsi MD Risk Management For Medical Devices Webinar 131119 Uk enrakesh marwahBelum ada peringkat

- Iso 13485 Medical Devices 2016Dokumen12 halamanIso 13485 Medical Devices 2016Anusha Fotedar67% (9)

- Understanding Iso 13485Dokumen12 halamanUnderstanding Iso 13485valfunmor100% (2)

- 2016 Ia Sample ChecklistDokumen5 halaman2016 Ia Sample ChecklistMiss BreedloveBelum ada peringkat

- Iso 13485 & 21 CFR 820 Template Documentation Operational Procedure Qop 42 01 Control of DocumentsDokumen9 halamanIso 13485 & 21 CFR 820 Template Documentation Operational Procedure Qop 42 01 Control of DocumentsfattuatiBelum ada peringkat

- Standard Awareness Training 13485Dokumen21 halamanStandard Awareness Training 13485Jeelani BashaBelum ada peringkat

- Design Controls For Medical Devices - Part 1Dokumen15 halamanDesign Controls For Medical Devices - Part 1Quality JiveBelum ada peringkat

- MDR Readiness Checklist: Prepared by Cite Medical SolutionsDokumen37 halamanMDR Readiness Checklist: Prepared by Cite Medical SolutionsBeal100% (1)

- ISO 13485 FDA PackageDokumen2 halamanISO 13485 FDA PackageNirav Desai100% (2)

- Post-Market Surveillance - VigilanceDokumen40 halamanPost-Market Surveillance - VigilanceSergio Mosa100% (1)

- Design Transfer ChecklistDokumen1 halamanDesign Transfer Checklistdavid proctor100% (1)

- Guidance On The Application of ISO 14971 PDFDokumen22 halamanGuidance On The Application of ISO 14971 PDFPravin Sasatte0% (1)

- ISO TR 20416-2020 Medical Devices-Post-Market Surveillance For ManufacturersDokumen50 halamanISO TR 20416-2020 Medical Devices-Post-Market Surveillance For ManufacturersQas Wei100% (4)

- ISO 13485 Gantt Chart - May 2020Dokumen4 halamanISO 13485 Gantt Chart - May 2020Rohini Gadhawe100% (4)

- Quality Manual ExampleDokumen32 halamanQuality Manual ExamplesaiaviBelum ada peringkat

- Checklist of Mandatory Documentation Required by Iso 13485 2016Dokumen3 halamanChecklist of Mandatory Documentation Required by Iso 13485 2016Ami Jariwala100% (1)

- Medical Device Risk Management - IsO 14971Dokumen86 halamanMedical Device Risk Management - IsO 14971novdic71% (7)

- Checklist of Mandatory Documentation Required by ISO 13485:2016Dokumen15 halamanChecklist of Mandatory Documentation Required by ISO 13485:2016LiliBelum ada peringkat

- Iso 13485 Manual DocumentsDokumen14 halamanIso 13485 Manual DocumentsRRR1100% (1)

- ISO 13485 QMS manual indexDokumen5 halamanISO 13485 QMS manual indexQuality and Safety Consultants Co.Belum ada peringkat

- Medical Device Design Validation SOPDokumen1 halamanMedical Device Design Validation SOPqmdocs0% (1)

- Design History File - Final PDFDokumen5 halamanDesign History File - Final PDFDarcy Chadwick Sheerin100% (1)

- Post Market Surveillance System SOPDokumen8 halamanPost Market Surveillance System SOPstevekent40% (5)

- ISO 14971 RISK Management For Medical Devices: The Definitive GuideDokumen41 halamanISO 14971 RISK Management For Medical Devices: The Definitive GuideOrielson Cruz100% (2)

- 7 steps CAPA medical devicesDokumen7 halaman7 steps CAPA medical devicesShantha Kumar ParameswaranBelum ada peringkat

- Device Master RecordsDokumen70 halamanDevice Master Recordsmogluk100% (3)

- FDA Medical Device Complaint FormDokumen2 halamanFDA Medical Device Complaint Formclayton51175% (4)

- Post-Market Surveillance of MOWOOT II Medical DeviceDokumen4 halamanPost-Market Surveillance of MOWOOT II Medical DeviceMarcBenetPozo100% (1)

- Preparation of A Technical FileDokumen5 halamanPreparation of A Technical FileV R33% (3)

- Step-By-Step Guide To Preparing Your FDA 510 (K) SubmissionDokumen25 halamanStep-By-Step Guide To Preparing Your FDA 510 (K) SubmissionRajesh100% (1)

- Medical Device Iso 13485Dokumen25 halamanMedical Device Iso 13485rwillestone100% (2)

- 93-42-EC ER Checklist ExampleDokumen16 halaman93-42-EC ER Checklist Exampledulichsinhthai100% (2)

- ISO13645 RequirementsDokumen22 halamanISO13645 RequirementsBalaji S100% (1)

- BS ISO 20417-2021 Medical Devices - Information To Supplied by The ManufacturerDokumen82 halamanBS ISO 20417-2021 Medical Devices - Information To Supplied by The ManufacturerKabomed QA92% (13)

- Mandatory Documents and Records Required by ISO 13485Dokumen7 halamanMandatory Documents and Records Required by ISO 13485Ricky MarkBelum ada peringkat

- Checklist of Mandatory Documentation Required by Iso 13485 2016 enDokumen18 halamanChecklist of Mandatory Documentation Required by Iso 13485 2016 enjmittal75% (4)

- Final ReportDokumen62 halamanFinal Reportapi-438611633100% (1)

- Study - ISO 13485 PDFDokumen15 halamanStudy - ISO 13485 PDFAnonymous 78Ezy46qvBelum ada peringkat

- 0.016 USL Process Is NOT StableDokumen5 halaman0.016 USL Process Is NOT StableEdBelum ada peringkat

- Book of ExperimentsDokumen79 halamanBook of ExperimentssonatagpBelum ada peringkat

- Conflict PDFDokumen7 halamanConflict PDFArif KhanBelum ada peringkat

- Manual de Autocad BasicoDokumen17 halamanManual de Autocad Basicoinfected521Belum ada peringkat

- Survival of The Fittest - The Process Control ImperativeDokumen10 halamanSurvival of The Fittest - The Process Control ImperativeEdBelum ada peringkat

- Quality improvement through human performance enhancement in manufacturingDokumen8 halamanQuality improvement through human performance enhancement in manufacturingEdBelum ada peringkat

- Applied Technology: by John J. Flaig, PH.DDokumen2 halamanApplied Technology: by John J. Flaig, PH.DEdBelum ada peringkat

- Zed Charts Compare Apples and Oranges: Wheeler's WorkshopDokumen4 halamanZed Charts Compare Apples and Oranges: Wheeler's WorkshopEdBelum ada peringkat

- Present With PassionDokumen90 halamanPresent With Passiondnguyen_252544Belum ada peringkat

- Blind IdentDokumen6 halamanBlind IdentEdBelum ada peringkat

- Conflict PDFDokumen7 halamanConflict PDFArif KhanBelum ada peringkat

- A3 Simple ChartDokumen1 halamanA3 Simple ChartEdBelum ada peringkat

- Entropy: Increasing The Discriminatory Power of DEA Using Shannon's EntropyDokumen15 halamanEntropy: Increasing The Discriminatory Power of DEA Using Shannon's EntropyEdBelum ada peringkat

- AutocorrelationDokumen25 halamanAutocorrelationAnonymous xeirMaAHBelum ada peringkat

- A Study of Q Chart For Short Run PDFDokumen37 halamanA Study of Q Chart For Short Run PDFEd100% (1)

- Short Run Statistical Process ControlDokumen21 halamanShort Run Statistical Process ControlEdBelum ada peringkat

- Being in Control: The Fact That Variation Exists Means SPC Is Critical To Monitor Process BehaviourDokumen2 halamanBeing in Control: The Fact That Variation Exists Means SPC Is Critical To Monitor Process BehaviourdumbledoreaaaaBelum ada peringkat

- Conjoint AnalysisDokumen12 halamanConjoint AnalysisEd0% (1)

- Working in TeamsDokumen24 halamanWorking in TeamsEdBelum ada peringkat

- BSC (Hons) Finance Ii/ BSC (Hons) Finance With Law IiDokumen49 halamanBSC (Hons) Finance Ii/ BSC (Hons) Finance With Law IiSunny SinghBelum ada peringkat

- Ordinal Categorical Data AnalysisDokumen34 halamanOrdinal Categorical Data AnalysisEdBelum ada peringkat

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Forecasting MethodsDokumen30 halamanForecasting MethodsEdBelum ada peringkat

- Tolerance Design Using Taguchi MethodsDokumen30 halamanTolerance Design Using Taguchi MethodsEdBelum ada peringkat

- Lean Six SigmaDokumen7 halamanLean Six SigmaJEFFSOTOBelum ada peringkat

- Statistical Process Control FundamentalsDokumen32 halamanStatistical Process Control FundamentalsEd100% (1)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Audit Checklist For ISO 13485Dokumen6 halamanAudit Checklist For ISO 13485EdBelum ada peringkat

- 1 N 2Dokumen327 halaman1 N 2Muhammad MunifBelum ada peringkat

- Harry Styles: The Rise of a Pop StarDokumen9 halamanHarry Styles: The Rise of a Pop StarBilqis LaudyaBelum ada peringkat

- PDF Reply Position Paper For ComplainantDokumen4 halamanPDF Reply Position Paper For ComplainantSheron Biase100% (1)

- Organization Structure GuideDokumen6 halamanOrganization Structure GuideJobeth BedayoBelum ada peringkat

- UNIT: 01 Housekeeping SupervisionDokumen91 halamanUNIT: 01 Housekeeping SupervisionRamkumar RamkumarBelum ada peringkat

- Tutorial Manual Safi PDFDokumen53 halamanTutorial Manual Safi PDFrustamriyadiBelum ada peringkat

- PDS-1st PageDokumen1 halamanPDS-1st PageElmer LucreciaBelum ada peringkat

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDokumen1 halamanPass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaBelum ada peringkat

- Macdonald v. National City Bank of New YorkDokumen6 halamanMacdonald v. National City Bank of New YorkSecret SecretBelum ada peringkat

- 【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1Dokumen36 halaman【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1RioNorte LojaBelum ada peringkat

- Forecasting AssignmentDokumen1 halamanForecasting AssignmentVarun Singh100% (1)

- Keynes Presentation - FINALDokumen62 halamanKeynes Presentation - FINALFaith LuberasBelum ada peringkat

- HSPA+ Compressed ModeDokumen10 halamanHSPA+ Compressed ModeAkhtar KhanBelum ada peringkat

- A CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHDokumen9 halamanA CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHprajakta shindeBelum ada peringkat

- SINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORDokumen3 halamanSINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORElias EliasBelum ada peringkat

- Lirik and Chord LaguDokumen5 halamanLirik and Chord LaguRyan D'Stranger UchihaBelum ada peringkat

- Micro Controller AbstractDokumen6 halamanMicro Controller AbstractryacetBelum ada peringkat

- Entrepreneurship and EconomicDokumen2 halamanEntrepreneurship and EconomicSukruti BajajBelum ada peringkat

- PaySlip ProjectDokumen2 halamanPaySlip Projectharishgogula100% (1)

- Racial and Ethnic Challenges in the UAE vs UKDokumen16 halamanRacial and Ethnic Challenges in the UAE vs UKATUL KORIBelum ada peringkat

- CLC Customer Info Update Form v3Dokumen1 halamanCLC Customer Info Update Form v3John Philip Repol LoberianoBelum ada peringkat

- BIU and EU functions in 8086 microprocessorDokumen12 halamanBIU and EU functions in 8086 microprocessorDaksh ShahBelum ada peringkat

- EDP/LRP Well Intervention System OverviewDokumen22 halamanEDP/LRP Well Intervention System OverviewJerome LIKIBIBelum ada peringkat

- The Earthing of Zenner BarrierDokumen4 halamanThe Earthing of Zenner BarrierFatholla SalehiBelum ada peringkat

- BCM Risk Management and Compliance Training in JakartaDokumen2 halamanBCM Risk Management and Compliance Training in Jakartaindra gBelum ada peringkat

- Personal InsuranceDokumen11 halamanPersonal InsuranceSumit Kumar SharmaBelum ada peringkat

- Youtube AlgorithmDokumen27 halamanYoutube AlgorithmShubham FarakateBelum ada peringkat

- SIWES Report Example For Civil Engineering StudentDokumen46 halamanSIWES Report Example For Civil Engineering Studentolayinkar30Belum ada peringkat

- nrcs143 009445Dokumen4 halamannrcs143 009445mdsaleemullaBelum ada peringkat

- SQL-Problems Solutions PDFDokumen11 halamanSQL-Problems Solutions PDFManpreet Singh100% (1)