Evaluation of Bubbler Irrigation System at Different Emission Flow Rates For Young Mango Orchard

Diunggah oleh

AJER JOURNALJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Evaluation of Bubbler Irrigation System at Different Emission Flow Rates For Young Mango Orchard

Diunggah oleh

AJER JOURNALHak Cipta:

Format Tersedia

American Journal of Engineering Research (AJER)

2016

American Journal of Engineering Research (AJER)

e-ISSN: 2320-0847 p-ISSN: 2320-0936

Volume-5, Issue-8, pp-35-42

www.ajer.org

Research Paper

Open Access

Evaluation of Bubbler Irrigation System at Different Emission

Flow Rates for Young Mango Orchard

Rajesh Kumar Soothar1*, Muhammad Saffar Mirjat1, Hafeez-ur-Rehman1, Velo

Suthar2, Shamim Ara Memon1 and Muhammad Aslam Samo1

1

Faculty of Agricultural Engineering, Sindh Agriculture University, Tandojam, Sindh, Pakistan.

2

Faculty of Social Science, Sindh Agriculture University, Tandojam, Sindh, Pakistan.

ABSTRACT: An experiment was conducted on evaluating performance of bubbler irrigation system under

young mango plant rows at the Higher Education Commission, research station at Sindh Agriculture University,

Tandojam. The experimental station possesses more than 70 mango plants, irrigated by micro and traditional

irrigation methods fed by tubewell with average water static level of 9 ft below ground surface. Bubbler

irrigation system was designed to irrigate 12 mango plants. The aim of study was to assess the performance of

the bubbler irrigation system at different emission flow rates with an installed bubbler irrigation system to

improve water distribution uniformity. The result of this study showed that the high pressure losses and the

system operated on one gallon per minute flow rate of each bubbler, water distribution uniformity was low, with

an average of 68 %. Other hand, comparison with emission (bubbler) flow rate was adjusted at half gallon per

minute has shown high water emission uniformity of system performed with an average of 92 % distribution

uniformity. The reasons for the minimum distribution uniformity of bubblers were observed at one gallon per

minute emission flow and this study recommended to improve the bubbler irrigation at dissimilar flow rates.

Keyword: Bubbler irrigation, flow rate, mango plant, water requirements

I. INTRODUCTION

Agriculture sector is considered as the principal and water resources consumer in the entire world.

However, Majority of population is directly or indirectly involved in agriculture sector and this sector

contributes about 22 % of Gross Domestic Product in the Pakistan (Agricultural Statistics of Pakistan, 2010-11)

but it is still lagging and steps for better land and water conservation management practices are needed to

effectively support sustainable agriculture.

In addition, agriculture could be the reason for water degradation because of the absence of proper

water management, therefore, there is an urgent need for optimum use of water for agriculture and an extra

emphasis should be given towards water management to prevent water pollution or deterioration of water

quality.

In that high opinion, modern irrigation system such as; trickle, sprinkler and pitcher irrigation methods

are considered as the most important practical and efficient for irrigation water application compared to

traditional irrigation practices and application.

Bubbler irrigation system is a modified version of trickle irrigation system, Bubbler irrigation system

was first time designed and introduced in orchard crops(Rawlins, 1977; Behoteguy & Thornton, 1980; Hull,

1981); Rawlins (1977) reported effective use of bubbler irrigation system in orchard fruits trees, many other

researchers continued research work to improve system design that can be adopted under different aspect like as

areas, weather climate, soil condition and water flow rate/ discharge on fruit trees (Behoteguy and Thornton,

1980; Hull, 1981). The system supplies water through a pumping unit, mixing chamber, mainline, sub main line,

laterals and bubblers etc. The specific bubbler flow rate range between 60-240 liter per hour (Nakayama, 1986).

In general, root development under trickle irrigation system is superiority constrained to the wetted soil volume

by the emission points, thereby roots are concentrated near the soil surface and their length is decreased

(Stevens and Douglas, 1994). The emission (bubbler) flow is controlled by pressure gauge and changing bubbler

diameter. Moreover, the relatively more bubbler flow compared to short emission flow (bubblers), under

bubbler irrigation system unlikely to be clogged in addition it requires minimum filtration and maintenance

energy. Many researchers confirmed that the modern irrigation systems produce high yield and reducing the cost

of labor and energy; similarly, modern irrigation system improves water application efficiency, uniformity

efficiency and reduces water losses in irrigation practices due to evaporation and deep percolation. Moreover, a

www.ajer.org

Page 35

American Journal of Engineering Research (AJER)

2016

poorly designed micro irrigation system does not cover entire canopy and it is unable to provide sufficient

moisture around the tree canopy hence plant remains stressed. Mirjat et al., (2011) observed that the plant

growth was almost similar; however, signs of leaf stress were observed under micro irrigated trees, while mango

trees irrigated by traditional basin method showed no wilting sign of leaves. Local farmer reported better yield

under traditional irrigated mango trees as compared to micro irrigation methods.

The Mango, (Mangifera indica L.) belonging to Family Anacardiaceae, is the most important

commercially grown fruit crop in over 90 countries of the World (Evans, 2008). About 77 percent of global

mango production occurs in Asia and mango cultivation is believed to have originated in South East part of the

earth and at present major mango producing countries include China, Thailand, Mexico, Pakistan, Philippines,

Indonesia, Brazil, Nigeria and Egypt. Among internationally traded tropical fruits, mango second ranks under

fruits quantity and value. Each exporting country has its own varieties, which differ in shape, colour and flavor;

Pakistan has Sindhri, Langro, Doshehri, Chaunsa, Kali Seroli, Bagan Pali, Swarnarika and Neelum varieties

(Al-Shareed, 2013). The biggest importer of mango is the United States of America that importing an average

of 1,85,000 MT annually (about 45% of the total world import volume). Mango tree is a non-drought resistant

that can withstand low soil salinity level without any reduction in yield. Although the trees root zone depth is

ranging between 2m to 2.5 m (MINFAL, 2005), the soil moisture is taken up by plants through their roots.

Therefore, it becomes necessary that sufficient moisture remains available in the root zone and it is possible to

estimate the crop water requirement for mango plant based on available literature information provided by

MINFAL (MINFAL, 2005).

Mango tree is usually irrigated by traditional surface method, delivering large volume of water based

primarily on farmers experience and enhanced by the availability of free irrigation water. But other hand

considering the economical importance of mango fruit, we need to enhance its production and improve the fruit

quality. The mango orchard is a long term investment and a tree continues to bear fruit for longer duration than

many other fruit trees. Beside other factors like soil, mango variety and environment, the water is also a key

player in the mango cultivation.

The results of a study on mango plant in Pakistan on irrigation frequency have shown that the best

period between irrigations intervals 7 day for young mango plant and average range of gross application depths

of irrigation water 75 to 100 mm with a good quality of irrigation water (MINFAL, 2005). However, the annual

water requirements demand for a mango plant may range between 500 to 750 mm and normal economic bearing

life 30 to 50 years (MINFAL, 2005). In the study, to evaluate the performance of bubbler irrigation systems at

emission flow rate on mango plants. Naimah, 1985 noted that, an accumulation of salts on the surface layer was

higher for trickle as compared to bubbler irrigation system. As the trend continued year to year reduce mango

yield due shortage of water and an abundant amount of water should be required for its irrigation, to maintain

and increased mango production. As the available fresh water resources in the Pakistan are limited, it is

necessary to control irrigation water through irrigation methods and soil conservation practices, such as modern

irrigation systems (trickle, bubbler, Sprinkler and pitcher) for enhancing mango production.

The evaluation of bubbler irrigation method, ensure uniformly water distribution application of

irrigation to avoid waste and conserve the precious water. Keeping the above fact in view this study was

conducted to investigate the performance of bubbler irrigation system at different emission flow rate and used

for irrigating young mango orchards.

II. MATERIALS AND METHODS

Description of the experimental area

Experimental study on mango plants were conducted at the experimental station located at Faculty of

Agricultural Engineering, Sindh Agriculture University Tandojam. The experimental site is situated at the

latitude of 250 25 28 N and longitude of 680 32 25 E; about 26 m above the mean sea level. One-year-old

mango plants trees were trans planted during 2012-13 at this site on 1.5ha area having two varieties of mango

were selected in this study that are suitable according to local climatic conditions and have the commercial value

in local and international market. A plot measuring 19200 ft2 was used in this experimental study. Mango plants

were irrigated with micro irrigation systems (Drip and Bubbler Irrigation Methods) established with the

financial assistant of the Higher Education Commission, Pakistan. The mango plants are irrigated from

centrifugal pump/ motor, with depth of ground water at 80 ft. Soil texture is characterized as clay loam soil, with

physical and chemical characteristics as summarized in Table 1.

The experimental site was selected in the second year of the HEC funded research project, the plot

consists of 12 mango plant trees out of 72 mango trees with distances of 40 ft between mango to mango plants

and row to row. For irrigating the young mango plant trees bubbler irrigation system, an irrigation pipe network

was made and normal designed according to the guidelines provided by Keller and Karmeli, 1975; Howel et al.,

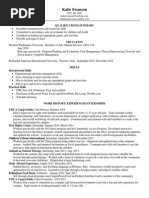

1992; Nakayama and Bucks, 1986; Al-Amoud, 1999.The layout plan of bubbler irrigation system is illustrated

in Figure 1.The irrigation network consists for whole plot of 2 inch main pipe line feeding 1 inch sub main pipe

www.ajer.org

Page 36

American Journal of Engineering Research (AJER)

2016

line, However, submain pipe line supplies to lateral (LDPE) distributing water for each mango plant tree

through bubbler that discharge into a basin around mango tree.

The bubbler irrigation network has included all the necessary units and parts such as; water source,

valves, filters, water meters, mixing chamber, mainline, sub main line, laterals and bubblers etc.as indicated in

the network scheme sketch in Figure 1. In experimental, the mango plants irrigated with water from a ground

water in the site with suitable water quality as present in Table 1. The experimental area climate is characterized

by high temperature in the May to August (summer season) with short amount of rain fall occurred as shown in

the climatic data (Table 2). The land preparation, irrigation scheduling and other agro-chemical practices for

young mango plant were followed as per guidelines by MINFAL (2005).

The irrigation scheduling is based on the soil moisture depletion. In this study, 50% soil moisture

depletion was fixed and next irrigation was applied when soil moisture deficit attained this criterion (MINFAL,

2005). Soil samples were collected at the vicinity of emission point under bubbler irrigated plots and soil

moisture contents were determined. Soil moisture content was determined by oven drying the soil sample for 24

hrs at a temperature of 105 0C and was calculated by using appropriate equation. Tensiometers were installed to

measure the soil moisture deficit. Once soil has attained the desired deficit, irrigation was applied to bring it at

the field capacity. The irrigation depths were calculated using equations given by Soomro et al., 1999; Soomro

et al., 2001:

SMD

(1)

x pb x dr

100

f -o

SMD

(W

-W d)

(2)

(3)

x 100

Wd

Where,

D

= Depth of water required (cm)

SMD = Soil moisture deficit level

pb

= Bulk density (grams cm-3)

= Moisture content at 50 % SMD

o

= Moisture content on dry weight basis (%)

= Wet weight of soil (g)

= Oven dry weight of soil (g)

Water was delivered to irrigation plots through motor pumps, installed to maintain required Pascal

operating pressure throughout the bubbler irrigation network system. The water delivery to system was installed

using pipes selected to minimize friction losses and ensure uniformity distribution in all selected plots of

research project. Mango plant trees in bubbler irrigation plot was designed to receive water from 1 bubbler at a

flow rate of 1 gallon per min. The system operating pressure was monitored throughout the experiment using

pressure gauge installed at main pipe line of the system in pumping station.

For comparison purpose, bubblers at a flow rate of 1 gallon per min in some experimental plot were

adjusting by 1bubbler at a flow rate of 0.5 gallon per min. Evaluation the performances of bubbler irrigation

systems were first made volume of water under each bubbler was measured and emission uniformity of water

application was determined. The containers were placed underneath each emission point and water flowing

through a bubbler, for a given time, was collected. After a given time, interval, the flow was disconnected and

the containers were removed. The volume of water collected in each container was measured using a graduated

cylinder. The recorded volume was divided by time to yield the discharge at each bubbler. The measured

discharge was used to calculate the uniformity coefficient, coefficient of variation (Cv) and distribution

uniformity were also calculated (Table 5) using the equations given by ASAE, 2002; Mosh, 2006; Mirjatet al.,

2010; Tagar et al. 2012 and the recommendations of Killer and Bliesner, 1990.

C

Sd

100 - 80

V avg

Cv

(4)

x 100

(5)

www.ajer.org

Page 37

V avg

American Journal of Engineering Research (AJER)

n

i 1

(V

LQ

- V avg )

2016

(6)

n

D

V LQ

100

V

avg

(7)

Where,

Cu

Uniformity coefficient (%)

Sd

Standard deviation of observations

V avg Average volume collected

Cv

Standard deviation

Uniformity variation (%)

V avg Average volume collected.

V LQ Average of the lowest volume of water relaxed

Du

Distribution uniformity (%)

V LQ Average of the lowest volume of water relaxed

V avg Average volume relaxed

Figure 1 Bubbler Irrigation System Layout

Table 1. Soil and water analysis results before experiment

Soil Characteristics

Values

Physical Properties

Sand (%)

41.4

Silt (%)

28.3

Clay (%)

30.3

Texture

Clay Loam

Bulk Density

1.17 g cm3

Infiltration Rate

8 mm hr-1

Chemical Properties

Depth at 0-15 cm

7.9

Soil pH

Depth at 15-30 cm

7.85

Depth at 30-45 cm

7.86

www.ajer.org

Page 38

American Journal of Engineering Research (AJER)

Soil ECe (dS/m)

Sodium

(SAR)

Adsorption

Ratio

Depth at 0-15 cm

Depth at 15-30 cm

Depth at 30-45 cm

Depth at 0-15 cm

Depth at 15-30 cm

Depth at 30-45 cm

Water Characteristics

pH

EC (micro-S/cm)

SAR

Month

September, 2012

October, 2012

November 2013

December, 2012

January, 2013

February, 2013

March, 2013

April, 2013

May, 2013

June, 2013

July, 2013

August, 2013

September, 2013

2016

1.06

0.86

0.69

5.6

5.6

6.5

7.7

1361

6.72

Table 2. Average weather parameters during the period of experiment

Temperature Co

Relative Humidity %

Pan Evap. 24hrs (mm)

Min.

Max.

Min.

Max.

26.65

34.25

62.67

86.57

6.88

21.55

35.63

43.33

87.23

5.27

16.37

30.95

42.13

80.40

3.53

12.50

25.50

52.10

78.90

3.64

10.25

24.82

43.47

84.23

3.41

12.87

23.72

46.43

70.50

3.72

16.92

33.77

38.57

76.53

6.09

22.25

36.20

38.57

68.63

7.29

27.37

42.03

32.33

64.03

10.40

29.37

38.13

48.80

73.03

10.27

29.65

37.53

58.33

81.03

9.95

28.08

35.03

65.50

88.20

7.75

26.63

35.60

57.13

84.60

7.39

Rain Fall

(mm)

4.71

00

0.08

00

1.00

3.50

00

00

00

0.17

00

5.99

0.75

III. RSEULTS AND DISCUSSIONS

Evaluating the performance of bubbler irrigation system at one gallon per minute emission (bubbler)

flow, was calculated noticeable variations in distribution uniformity of water in young mango plant lines as

shown in Figure 2 and 3, and details of each bubbler flow under bubbler system are presented in Table 3.It is

also clear from the Table 3that there is a decrease in emission flow with length of lateral of the system (i.e.

mango plant at the end less water received), this is possibly due to decrease in pressure in lateral line of system

caused by friction loss. Data revealed that the co-efficient of variation for lateral 1 and lateral 2 were 21.33 and

23.53, respectively. Likewise, the distribution uniformity of lateral 1 and lateral 2 were 73 % and 71 %,

respectively at one gallon per minute emission flow rate. As a result, the system was tested that low distribution

uniformity of system was 68 as shown in Table 4, these values may be below the accepted range of distribution

uniformities of system recommended by ASAE and ASABE standard (ASAE, 1987 and ASABE (1999).

Results of half gallon per minute of emission (bubbler) flow rate of lateral lines performance was

shown an improved distribution uniformity of water for young mango plants, as shown in Figure 3. The

horizontal trend line of emission flow distribution shown (Figure 4 and 5) and Table 4 indicates even

distribution of irrigation water to all plants in both line with an emission uniformity ranging from 92.52 % to

93.75 %, and co-efficient of variation are varied from 4.677 to 5.573 respectively. Al-Amoud (2008) who

reported the uniformity of distribution of bubbler system was low with drip irrigation system which is in

contradiction to our results. These results suggest that the system can be rated from good to excellent i.e.

satisfactory as mentioned by ASABE (1999).

The performance of bubbler system was low due to inadequate design under one gallon per minute

emission flow. The bubbler discharges an abundant amount of water; its total flow for each bubbler under plant

basin is one gallon per minute which is more than the capacity size of the lateral diameter. Results revealed that

high friction loss occurred in which turn reduces the flow in further sections on laterals. Bubbler flow rate is half

gallon per minute on the other hand marked a maximum distribution uniformity of system under both lateral

which is within the capacity of the lateral size. To sustain the present bubbler irrigation system, the existing

bubblers should be adjusted at half gallon per minute emission flow exceed. The existing bubbler irrigation

system may be also adjusted at half gallon per minute emission flow to reduce friction losses.

www.ajer.org

Page 39

American Journal of Engineering Research (AJER)

2016

Figure 2. Water distribution fluctuations through first bubbler lines and trend line at one gallon per minute

emission flow

Figure 3. Water distribution fluctuations through second bubbler lines and trend line at one gallon per minute

emission flow

Figure 4. Water distribution fluctuations through first bubbler lines and trend line at half gallon per minute

emission flow

Figure 5. Water distribution fluctuations through first bubbler lines and trend line at half gallon per minute

emission flow

www.ajer.org

Page 40

American Journal of Engineering Research (AJER)

2016

Table 3. Bubbler discharge at different emission flow rates

Discharge rate

Discharge rate

Bubbler System run at one System run at half Bubbler System run at one System run at half

No.

No.

gallon per minute gallon per minute

gallon per minute

gallon per minute

Lateral 01

Lateral 02

L1B1

0.889

0.493

L2B1

0.863

0.489

L1B2

0.823

0.489

L2B2

0.797

0.480

L1B3

0.744

0.484

L2B3

0.709

0.480

L1B4

0.735

0.471

L2B4

0.669

0.467

L1B5

0.577

0.445

L2B5

0.550

0.436

L1B6

0.445

0.436

L2B6

0.392

0.418

Total

4.214

2.818

Total

3.981

2.770

Average 0.702

0.470

Average

0.663

0.462

Note: L is lateral and B is Bubbler

Table 4. Minimum discharge, Average discharge, Standard deviation, Coefficient of variation, Uniformity

coefficient and Distribution uniformity of existing system

Sr. No

Min.

Av.

(q Standard

Coefficient of Uniformity

Distribution

discharge

discharge

qav)2

deviation variation (Cv)

coefficient

uniformity

qm (lit/hr)

qavg

(Cu)

(Du)

System run on one gallon per minute of emission flow

Lateral 1

101.000

159.500

6943.5 34.018

21.328

82.937

72.727

Lateral 2

89.000

150.667

7545.3 35.462

23.537

81.171

71.018

Entire

89.000

155.083

8734.7 26.979

17.397

86.083

67.706

System

System run on half gallon per minute of emission flow

Lateral 1

99.000

106.667

149.33 4.989

4.677

96.258

93.750

Lateral 2

95.000

104.833

204.83 5.843

5.573

95.541

92.528

Entire

95.000

105.750

181.94 3.894

3.682

97.054

92.356

System

IV. CONCLUSIONS AND RECOMMENDATIONS

It is evident from the above results that the evaluated performance of bubbler irrigation system at one

gallon per minute emission flow was inefficient for young mango plants as compared to same bubbler irrigation

system adjusted on half gallon per minute emission flow. The present study concluded that half gallon per

minute emission flow of system of each bubbler with proper design and management could satisfy water needs

for young mango plants.

ACKNOWLEDGEMENTS

The authors are thankful to Higher Education Commission, Pakistan for the financial support for the project

work.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

Agricultural Statistics of Pakistan. 2010-11. Government of Pakistan Statistics Division, Pakistan Bureau of Statistics.

www.pbs.gov.pk/content/agriculture-statistics(Visitedon 03-04-2013).

Al-Amoud, A.I. 2008. Performance of bubbler irrigation system as compared to trickle for large size date palm tree farm. The

Canadian Society for Bioengineering, Paper No. CSBE 08-172.

Al-Shareed Enterprises. 2013. Exporter of fresh fruits and vegetables. www.alshareed.pk/fruits/mango.html (Visited on 03-082013).

ASABE, 1999. Field evaluation of micro irrigation system. EP 485. St. Joseph, Mich., American Society of Agriculture and

Biology Engineers Standards. 46th Ed.

ASAE, 1987. Design, Installation, and Performance of Trickle Irrigation Systems. Standards. American Society of Agricultural

Engineers, 2950 Niles Road, St. Joseph, MI 49085-9659. pp 522-525.

Behoteguy, D. and J.R. Thornton. 1980. Operation and installation of a bubbler irrigation system. ASAE. Paper No. 60-2059. pp.

16.

Evans, E.A. 2008. Recent trends in world and US mango production, trade, and consumption. Florida Cooperative Extension

Service, Institute of Food and Agricultural Sciences, University of Florida. http://edis.ifas.ufl.edu/pdffiles/FE/FE71800.pdf,

(Visited on 24-03-2013).

Howell, T.A., R.H. Cuenca and K.H. Solomon. 1992. Crop Yield Response, pp 93-122, In: Management of Farm Irrigation

Systems, Ed. G.J. Hoffman, T.A. Howell and K.H. Solomon, American Society of Agricultural Engineers, Monogragh No. 9.

www.ajer.org

Page 41

American Journal of Engineering Research (AJER)

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

2016

Hull, P.J. 1981. A low pressure irrigation system for orchard tree and plantation crops. The Agricultural Engineer, Summer. pp.

55-58.

Keller, J. and D. Karmeli. 1975. Trickle irrigation design. Rain Bird Sprinkler Manufacturing Corporation, Azusa, California,

USA.

Killer and Bliesner, 1990. Sprinkler and Trickle Irrigation. Book Published by Van Nostrand Reinhold, New York. 652 pages.

MINFAL. 2005. Irrigation Agronomy Field Manual. Federal Water Management Cell, Ministry of Food, Agriculture and

Livestock, Government of Pakistan, Islamabad., 6: 289-292.

Mirjat, M.S., M.M. Jiskani, A.A. Siyal and M.U. Mirjat. 2011. Mango production and fruit quality under properly managed drip

irrigation system. Pak. J. Agri., Agril. Engg., Vet. Sci., 27(1): 1-12.

Mirjat, M.S., M.U. Mirjat and F.A. Chandio. 2010. Water distribution pattern, discharge uniformity and application efficiency of

locally made emitters used in a trickle subunit. Pak. J. Agri., Agril. Engg. Vet. Sci., 26(1): 1-15.

Mosh, S. 2006. Guidelines for planning and design of micro irrigation in arid and semi arid regions. Int. Comm. Irrig & Drain

(ICID).

Nakayama, F.S. and D.A. Bucks. 1986. Trickle irrigation for crop production. Design, operation and Management. Elsevier

Science Publishers B.V., Amsterdam, the Netherland. 383.

Nimah, M. 1985. Localized versus drip irrigation system. Proceedings of the third drip irrigation congress, Fresno, California,

USA., pp552-554.

Rawlins, S.L. 1977. Uniform irrigation with a low head bubbler system. Agric. Water Managem., 1: 167-178.

Soomro, A., M.S. Mirjat, H. Soomro and K.H. Bukhari. 1999. Effect of different irrigation frequencies on water use efficiency,

growth and cotton yield. Pak. J. Agril. Engg., Vet. Sci., 15(2).

Soomro, A., M.S. Mirjat, F.C. Oad, H. Soomro, M.A. Samo and N.L. Oad. 2001. Effect of irrigation intervals on soil salinity and

cotton yield. J. Biol. Sci., 1(6): 472-474.

Stevens, R.M. and T. Douglas. 1994. Distribution of grape vine roots and salt under drip and full-ground cover micro-jet

irrigation systems. Irri. Sci., 15: 147-152.

Tagar, A., F.A. Chandio, I.A. Mari and B. Wagan. 2012. Comparative study of drip and furrow irrigation methods at farmers

field in Umarkot. World Acad. Sci, Engg & Technol. vol: 69. http://www.waset.org/journals/waset/v69/v69-168.pdf

www.ajer.org

Page 42

Anda mungkin juga menyukai

- Effect of Drip and Furrow Irrigation Systems On Sunflower Yield and Water Use Efficiency in Dry Area of PakistanDokumen6 halamanEffect of Drip and Furrow Irrigation Systems On Sunflower Yield and Water Use Efficiency in Dry Area of PakistanZaheer AhmedBelum ada peringkat

- Water Management & Soil Water Conservation in CitrusDokumen15 halamanWater Management & Soil Water Conservation in CitrusAngela VargasBelum ada peringkat

- Overview of Project Work: "Design of Low Cost Terrace Shednet With Effective Cropping Pattern"Dokumen9 halamanOverview of Project Work: "Design of Low Cost Terrace Shednet With Effective Cropping Pattern"Avinash PandeBelum ada peringkat

- Sprinkler and Drip Irrigation Systems in PakistanDokumen21 halamanSprinkler and Drip Irrigation Systems in PakistanBilal GandapurBelum ada peringkat

- FIELD EVALUATION OF DRIP IRRIGATION SYSTEMDokumen8 halamanFIELD EVALUATION OF DRIP IRRIGATION SYSTEMHenry ChavezBelum ada peringkat

- Effect of Drip Irrigation and Plastic Mulch On Crop Yield and Yield Components of CantaloupeDokumen13 halamanEffect of Drip Irrigation and Plastic Mulch On Crop Yield and Yield Components of CantaloupePradhees BtechBelum ada peringkat

- Microirrigation of Few Crops With Limited Applications: Sept 10 - 16 2006, PWTC, Kuala LumpurDokumen14 halamanMicroirrigation of Few Crops With Limited Applications: Sept 10 - 16 2006, PWTC, Kuala LumpurfarhanBelum ada peringkat

- Amjad Wateruseefficiency 952 955 1Dokumen5 halamanAmjad Wateruseefficiency 952 955 1Angeline LaresmaBelum ada peringkat

- Thesis On Irrigation Water ManagementDokumen5 halamanThesis On Irrigation Water ManagementWhereToBuyResumePaperCanada100% (2)

- Water Balance Study of Plastic Lined Farm PondDokumen12 halamanWater Balance Study of Plastic Lined Farm PondNeel Praveen KulluBelum ada peringkat

- 01 2016 PAWEES Abstract Final PDFDokumen66 halaman01 2016 PAWEES Abstract Final PDFhirohiro8008Belum ada peringkat

- Research Article Effects of Subsurface Drip Irrigation On Water Consumption and Yields of Alfalfa Under Different Water and Fertilizer ConditionsDokumen12 halamanResearch Article Effects of Subsurface Drip Irrigation On Water Consumption and Yields of Alfalfa Under Different Water and Fertilizer ConditionsROHITHBelum ada peringkat

- Effect of Drip Fertigation and Plastic Mulching On Growth and Yield of TomatoDokumen4 halamanEffect of Drip Fertigation and Plastic Mulching On Growth and Yield of TomatoShailendra RajanBelum ada peringkat

- ARDUINO Based Automated Sprinkler Irrigation System With Soil Moisture Sensor and Notification System For Agricultural PurposesDokumen18 halamanARDUINO Based Automated Sprinkler Irrigation System With Soil Moisture Sensor and Notification System For Agricultural PurposesMichael DarmstaedterBelum ada peringkat

- 2015 - Yemaneh Et AlDokumen12 halaman2015 - Yemaneh Et AlMekonen AyanaBelum ada peringkat

- 74-The Gains To Obtained From National Subsurface Drip Irrigation Research Project in TurkeyDokumen6 halaman74-The Gains To Obtained From National Subsurface Drip Irrigation Research Project in TurkeySumit KumarBelum ada peringkat

- Clsu JournalDokumen10 halamanClsu JournalCURLS VINCENT AGANONBelum ada peringkat

- Water Conservation: Strategies and Solutions: January 2016Dokumen6 halamanWater Conservation: Strategies and Solutions: January 2016Bhushan ShilwarBelum ada peringkat

- Ijarr PDFDokumen6 halamanIjarr PDFKarbari MuskanBelum ada peringkat

- Summary of Kurukshetra: Theme: Irrigation and Water ConservationDokumen17 halamanSummary of Kurukshetra: Theme: Irrigation and Water ConservationRAJ STUDY WIZARDBelum ada peringkat

- Water Conservation: Strategies and Solutions: January 2016Dokumen6 halamanWater Conservation: Strategies and Solutions: January 2016Jean LykaBelum ada peringkat

- Agricultured Automatic Drip Irrigation System: Mr. S.G.Galande, Dr. G.H. AgrawalDokumen4 halamanAgricultured Automatic Drip Irrigation System: Mr. S.G.Galande, Dr. G.H. AgrawalInternational Organization of Scientific Research (IOSR)Belum ada peringkat

- Water Conservation: Strategies and Solutions: January 2016Dokumen6 halamanWater Conservation: Strategies and Solutions: January 2016ガルソン クリスティアンBelum ada peringkat

- Innovative Technologies For Water Saving in Irrigated AgricultureDokumen6 halamanInnovative Technologies For Water Saving in Irrigated AgricultureAvinash VasudeoBelum ada peringkat

- Water Conservation: Strategies and SolutionsDokumen6 halamanWater Conservation: Strategies and SolutionsHIMANSHUBelum ada peringkat

- Peanut - MilletDokumen8 halamanPeanut - Milletkoneti aravindBelum ada peringkat

- K.T. Jadhav, Et AlDokumen9 halamanK.T. Jadhav, Et AlHARANIBelum ada peringkat

- Netafim Important Research PaperDokumen13 halamanNetafim Important Research PaperperminderlbwBelum ada peringkat

- Chapter IDokumen50 halamanChapter ICarla Jean NIETOBelum ada peringkat

- Response of Rice To IrrigationDokumen14 halamanResponse of Rice To IrrigationjaypalagiriBelum ada peringkat

- Water 09 00003Dokumen15 halamanWater 09 00003Attina Balqin IzzahBelum ada peringkat

- Micro NanobubblewateroxygationsynergisticallyiDokumen9 halamanMicro NanobubblewateroxygationsynergisticallyiAshish SonawaneBelum ada peringkat

- Formet SynopsisDokumen7 halamanFormet Synopsisanushkat7347Belum ada peringkat

- 001 SP-8-2-202-869Dokumen4 halaman001 SP-8-2-202-869gthiyagu1977Belum ada peringkat

- Kinerja Irigasi Tetes Tipe Emiter Aries Pada Tanaman Pisang Cavendhis Di PT Nusantara Tropical FarmDokumen6 halamanKinerja Irigasi Tetes Tipe Emiter Aries Pada Tanaman Pisang Cavendhis Di PT Nusantara Tropical FarmYessi CarolineBelum ada peringkat

- Drip Irrigation Performance on Tomato PlantsDokumen14 halamanDrip Irrigation Performance on Tomato PlantsSagitan Putra La KimbiBelum ada peringkat

- Water Conservation in IndiaDokumen5 halamanWater Conservation in IndiaPONTIOUS TALLY100% (1)

- 1.... 1st ANNUAL RESSEARCH PROGRESS REPORT (PARB-945)Dokumen38 halaman1.... 1st ANNUAL RESSEARCH PROGRESS REPORT (PARB-945)Nabin YadavBelum ada peringkat

- Tomato IrrigationwaterDokumen7 halamanTomato IrrigationwaterPapoo YarBelum ada peringkat

- Agricultural Water Management: Kidane Welde, Hintsa Libsekal GebremariamDokumen6 halamanAgricultural Water Management: Kidane Welde, Hintsa Libsekal GebremariamKidaneBelum ada peringkat

- Micro IrrigationDokumen210 halamanMicro IrrigationChanako DaneBelum ada peringkat

- Fertigation in Sustainable Agricultural SystemsDokumen6 halamanFertigation in Sustainable Agricultural SystemsMuhammad AzrulBelum ada peringkat

- Soilless Culture System To Support Water Use Efficiency and Product Quality: A ReviewDokumen6 halamanSoilless Culture System To Support Water Use Efficiency and Product Quality: A Reviewgustavo dela espriellaBelum ada peringkat

- Effect of Water Stress On Crop Yield and Yield Components of CantaloupeDokumen3 halamanEffect of Water Stress On Crop Yield and Yield Components of CantaloupeيقسشةBelum ada peringkat

- IWTC16-Zarif Khero Research WorkDokumen15 halamanIWTC16-Zarif Khero Research WorkzarifkheroBelum ada peringkat

- Ijciet 08 02 033 PDFDokumen7 halamanIjciet 08 02 033 PDFIAEME PublicationBelum ada peringkat

- Argawal MicroirrigationDokumen8 halamanArgawal MicroirrigationgagassageBelum ada peringkat

- Design of Micro Irrigation System For Hilly Terraced Land: Sept 10 - 16 2006, PWTC, Kuala LumpurDokumen8 halamanDesign of Micro Irrigation System For Hilly Terraced Land: Sept 10 - 16 2006, PWTC, Kuala LumpurfarhanBelum ada peringkat

- Drip Irrigation Literature ReviewDokumen7 halamanDrip Irrigation Literature ReviewROHITHBelum ada peringkat

- Effect of Sprinkler Irrigation Systems and Irrigation Frequency On Water Use Efficiency and Economical Parameters For Wheat ProductionDokumen11 halamanEffect of Sprinkler Irrigation Systems and Irrigation Frequency On Water Use Efficiency and Economical Parameters For Wheat ProductionAmin MojiriBelum ada peringkat

- 2017 CWR AllDokumen9 halaman2017 CWR AllsabahparvazeBelum ada peringkat

- Water 12 01429 PDFDokumen21 halamanWater 12 01429 PDFsahil khanBelum ada peringkat

- Horticulturae 08 01059Dokumen14 halamanHorticulturae 08 01059Pepek beloangBelum ada peringkat

- Water 11 00035Dokumen16 halamanWater 11 00035Mohd Naqiuddin HusriBelum ada peringkat

- Mango production and quality under drip irrigationDokumen12 halamanMango production and quality under drip irrigationTrian TeeBelum ada peringkat

- Performance Evaluation of The Tanoso Irrigation Scheme in The Brong - Ahafo Region of GhanaDokumen8 halamanPerformance Evaluation of The Tanoso Irrigation Scheme in The Brong - Ahafo Region of GhanaInnovative Research Publications100% (1)

- Greenhouse Tomato Yield & Quality with Drip IrrigationDokumen5 halamanGreenhouse Tomato Yield & Quality with Drip IrrigationOana CorduneanuBelum ada peringkat

- Chapter 1 (Final)Dokumen12 halamanChapter 1 (Final)Nahzel Mae DulayBelum ada peringkat

- Comparative Study of Subsurface Drip IrrigationDokumen10 halamanComparative Study of Subsurface Drip Irrigationsunilpatil.043827Belum ada peringkat

- Agricultural Water Management : Efficient Water Use in Crop ProductionDari EverandAgricultural Water Management : Efficient Water Use in Crop ProductionBelum ada peringkat

- Performance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesDokumen6 halamanPerformance Analysis of LTE in Rich Multipath Environments Considering The Combined Effect of Different Download Scheduling Schemes and Transmission ModesAJER JOURNALBelum ada peringkat

- Switching of Security Lighting System Using Gsm.Dokumen12 halamanSwitching of Security Lighting System Using Gsm.AJER JOURNALBelum ada peringkat

- Pixel Based Off-Line Signature Verification SystemDokumen6 halamanPixel Based Off-Line Signature Verification SystemAJER JOURNALBelum ada peringkat

- The Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureDokumen7 halamanThe Differentiation Between The Turbulence and Two-Phase Models To Characterize A Diesel Spray at High Injection PressureAJER JOURNALBelum ada peringkat

- Comparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemDokumen6 halamanComparative Analysis of Cell Phone Sound Insulation and Its Effects On Ear SystemAJER JOURNALBelum ada peringkat

- Production and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.Dokumen6 halamanProduction and Comparartive Study of Pellets From Maize Cobs and Groundnut Shell As Fuels For Domestic Use.AJER JOURNALBelum ada peringkat

- Structure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesDokumen9 halamanStructure and Surface Characterization of Nanostructured Tio2 Coatings Deposited Via HVOF Thermal Spray ProcessesAJER JOURNALBelum ada peringkat

- Recycling of Scrapped Mating Rings of Mechanical Face SealsDokumen5 halamanRecycling of Scrapped Mating Rings of Mechanical Face SealsAJER JOURNALBelum ada peringkat

- Experimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungDokumen6 halamanExperimental Investigation On The Effects of Digester Size On Biogas Production From Cow DungAJER JOURNALBelum ada peringkat

- Minimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterDokumen11 halamanMinimizing Household Electricity Theft in Nigeria Using GSM Based Prepaid MeterAJER JOURNALBelum ada peringkat

- An Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaDokumen12 halamanAn Evaluation of Skilled Labour Shortage in Selected Construction Firms in Edo State, NigeriaAJER JOURNALBelum ada peringkat

- Improved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsDokumen7 halamanImproved RSA Cryptosystem Based On The Study of Number Theory and Public Key CryptosystemsAJER JOURNALBelum ada peringkat

- Utilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateDokumen4 halamanUtilization of "Marble Slurry" in Cement Concrete Replacing Fine AgreegateAJER JOURNALBelum ada peringkat

- Weighted Denoising With Multi-Spectral Decomposition For Image CompressionDokumen13 halamanWeighted Denoising With Multi-Spectral Decomposition For Image CompressionAJER JOURNALBelum ada peringkat

- A Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.Dokumen6 halamanA Concept of Input-Output Oriented Super-Efficiency in Decision Making Units.AJER JOURNALBelum ada peringkat

- WHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")Dokumen12 halamanWHY JESUS CHRIST CAME INTO THE WORLD?... (A New Theory On "TIE MINISTRY")AJER JOURNALBelum ada peringkat

- Experimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilDokumen6 halamanExperimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilAJER JOURNALBelum ada peringkat

- Statistical Method of Estimating Nigerian Hydrocarbon ReservesDokumen10 halamanStatistical Method of Estimating Nigerian Hydrocarbon ReservesAJER JOURNALBelum ada peringkat

- The Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)Dokumen6 halamanThe Role of Citizen Participant in Urban Management (Case Study: Aligudarz City)AJER JOURNALBelum ada peringkat

- Unmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentDokumen6 halamanUnmanned Aerial Vehicle and Geospatial Technology Pushing The Limits of DevelopmentAJER JOURNALBelum ada peringkat

- Eye State Detection Using Image Processing TechniqueDokumen6 halamanEye State Detection Using Image Processing TechniqueAJER JOURNALBelum ada peringkat

- Urbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleDokumen6 halamanUrbanization and The Risk of Flooding in The Congo Case of The City of BrazzavilleAJER JOURNALBelum ada peringkat

- An Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedDokumen12 halamanAn Exponent-Based Propagation Path Loss Model For Wireless System Networks at Vehicular SpeedAJER JOURNALBelum ada peringkat

- DMP Packet Scheduling For Wireless Sensor NetworkDokumen8 halamanDMP Packet Scheduling For Wireless Sensor NetworkAJER JOURNALBelum ada peringkat

- Distinct Revocable Data Hiding in Ciphered ImageDokumen7 halamanDistinct Revocable Data Hiding in Ciphered ImageAJER JOURNALBelum ada peringkat

- The Design and Implementation of A Workshop Reservation SystemDokumen7 halamanThe Design and Implementation of A Workshop Reservation SystemAJER JOURNALBelum ada peringkat

- Frequency Selective Fading in Wireless Communication Using Genetic AlgorithmDokumen6 halamanFrequency Selective Fading in Wireless Communication Using Genetic AlgorithmAJER JOURNALBelum ada peringkat

- Theoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesDokumen10 halamanTheoretical and Experimental Study of Cavitation Dispersing in "Liquid-Solid" System For Revelation of Optimum Influence ModesAJER JOURNALBelum ada peringkat

- Head Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaDokumen5 halamanHead Determination and Pump Selection For A Water Treatment Plant in Villages Around Maiduguri, Borno State, NigeriaAJER JOURNALBelum ada peringkat

- Risk Assessment and Risk MappingDokumen7 halamanRisk Assessment and Risk MappingAJER JOURNALBelum ada peringkat

- Section 9 - ProppantsDokumen18 halamanSection 9 - ProppantsIllimination Illuminated MinisatanBelum ada peringkat

- 8508A Reference Multimeter PDFDokumen7 halaman8508A Reference Multimeter PDFNicole FloydBelum ada peringkat

- Pratham Sutone: Academic Record Skill HighlightsDokumen1 halamanPratham Sutone: Academic Record Skill HighlightsMugdha KolheBelum ada peringkat

- Wiring 87T E01Dokumen4 halamanWiring 87T E01Hau NguyenBelum ada peringkat

- Gulfstream G550 Aircraft Maintenance ManualDokumen16 halamanGulfstream G550 Aircraft Maintenance ManualMorrisBelum ada peringkat

- Cabarroguis CLUP SEA ReportDokumen91 halamanCabarroguis CLUP SEA ReportAlvin Lee Cucio Asuro100% (3)

- DR Bob Jantzen's Differential GeometryDokumen485 halamanDR Bob Jantzen's Differential GeometryBGMoney5134Belum ada peringkat

- DevOps Overview PDFDokumen50 halamanDevOps Overview PDFSubba Rao KedarisettyBelum ada peringkat

- Polymer Solar Cells PDFDokumen19 halamanPolymer Solar Cells PDFJulio Andrés Casal RamosBelum ada peringkat

- Hafner - 1969 - The New Reality in Art and ScienceDokumen14 halamanHafner - 1969 - The New Reality in Art and ScienceEyeVeeBelum ada peringkat

- Wands and StavesDokumen4 halamanWands and StavesSarah Jean HEADBelum ada peringkat

- Approach To NEA V0.3Dokumen16 halamanApproach To NEA V0.3mohammedomar1974Belum ada peringkat

- Linux InstallationDokumen4 halamanLinux InstallationRayapudi LakshmaiahBelum ada peringkat

- ARNU15GL2G4Dokumen2 halamanARNU15GL2G4julioBelum ada peringkat

- Overview of Co-Operative BankingDokumen14 halamanOverview of Co-Operative BankingDr. Meghna DangiBelum ada peringkat

- An Evaluation of The Performance Contracting On Organisation Performance A Case of Kenyatta University, Kenya PDFDokumen15 halamanAn Evaluation of The Performance Contracting On Organisation Performance A Case of Kenyatta University, Kenya PDFAlexander DeckerBelum ada peringkat

- 007 Noverina Chaniago PDFDokumen9 halaman007 Noverina Chaniago PDFMega TesrimegayaneBelum ada peringkat

- Grade 2 math lesson plan compares mass in grams & kilogramsDokumen3 halamanGrade 2 math lesson plan compares mass in grams & kilogramskristine arnaiz80% (10)

- Consultancy Project Assessment SheetDokumen1 halamanConsultancy Project Assessment SheetSadeeqBelum ada peringkat

- Software Customisation Reference ManualDokumen269 halamanSoftware Customisation Reference ManualTonthat QuangBelum ada peringkat

- Katie SwansonDokumen1 halamanKatie Swansonapi-254829665Belum ada peringkat

- PTC Creo Elements/Direct Modeling ExpressDokumen5 halamanPTC Creo Elements/Direct Modeling ExpressladydaladyBelum ada peringkat

- Critical Success FactorsDokumen12 halamanCritical Success Factorsmoon1377Belum ada peringkat

- User Manual CCS-SeriesDokumen76 halamanUser Manual CCS-SeriesYaron David Haro VasseurBelum ada peringkat

- ENGB200 Unit 4 Selecting A Topic and PurposeDokumen12 halamanENGB200 Unit 4 Selecting A Topic and PurposeannehiewBelum ada peringkat

- PYZ IT StrategyDokumen56 halamanPYZ IT StrategyBen Van Neste100% (1)

- AL1-Module3-Desirable Characteristics of TestsDokumen4 halamanAL1-Module3-Desirable Characteristics of TestsNica HannahBelum ada peringkat

- LAB REPORT 2-HINGED ARCH (Reference)Dokumen11 halamanLAB REPORT 2-HINGED ARCH (Reference)jajenBelum ada peringkat

- Studies For HarpDokumen38 halamanStudies For HarpRodrigo Eduardo Gallegos MillánBelum ada peringkat

- Prosedur Penggajian: Payroll ProcedureDokumen5 halamanProsedur Penggajian: Payroll ProcedureVira TrianaBelum ada peringkat