Itp For Fabrication Steel Structure of Warehouse and Workshop

Diunggah oleh

Phong DoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Itp For Fabrication Steel Structure of Warehouse and Workshop

Diunggah oleh

Phong DoHak Cipta:

Format Tersedia

LP1PP

PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.:

LP1-PTSC-10USU-QAM14-ITP-0001

INSPECTION AND TEST PLAN

FOR FABRICATION STEEL STRUCTURE OF

WAREHOUSE AND WORKSHOP

Page 9 of 9

Revision No.: C

Date: 27-Sep-2016

VIETNAM OIL AND GAS GROUP

LONG PHU 1 POWER PROJECT MANAGEMENT BOARD

EPC CONSORTIUM:

POWER MACHINES PJSC;

PETROVIETNAM TECHNICAL SERVICES CORPORATION - PTSC

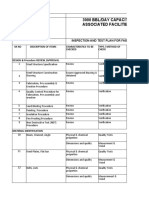

INSPECTION AND TEST PLAN

FOR FABRICATION STEEL STRUCTURE OF WAREHOUSE AND

WORKSHOP

Document No: LP1-PTSC-10USU-QA-M14-ITP-0001

Phn Approved

trng cho PTSC

approve

CONTRACTOR: PTSC

REV

NO.

PREPARED BY

REVIEWED BY

APPROVED BY

PTSC

LP1PP

REVIEWED BY

APPROVED BY

DATE

NAME

SIGN

DATE

NAME

SIGN

DATE

NAME SIGN

DATE

1.08.16 VDQK

1.0816

NTT

1.08.16

NVC

1.08.16

31.08.16 VDQK

31.0816

NTT

31.08.16

NVC

31.08.16

27.09.16 VDQK

27.0916

NTT

27.09.16

NVC

27.09.16

NAME

SIGN

DATE

NAME

SIGN

DATE

REVIEWED

CATEGORY

Thay th PTSC thnh PM

LP1PP

PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.:

LP1-PTSC-10USU-QAM14-ITP-0001

INSPECTION AND TEST PLAN

FOR FABRICATION STEEL STRUCTURE OF

WAREHOUSE AND WORKSHOP

Revision No.: C

Page 9 of 9

Date: 27-Sep-2016

REVISION RECORD SHEET

No.

Rev. No.

Content of revision

Date of Revision

Issue for Approval

1-Aug-2016

Issue for Approval

31-Aug-2016

Issue for Approval

27-Sep-2016

LP1PP

PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.:

LP1-PTSC-10USU-QAM14-ITP-0001

INSPECTION AND TEST PLAN

FOR FABRICATION STEEL STRUCTURE OF

WAREHOUSE AND WORKSHOP

Revision No.: C

Page 9 of 9

Date: 27-Sep-2016

TABLES OF CONTENTS

1.0

GENERAL ...................................................................................................................................... 3

2.0

REFERENCE DOCUMENTS ..................................................................................................... 3

3.0

INSPECTION NOTIFICATION................................................................................................. 4

4.0

QUALITY CONTROL FORMS.................................................................................................. 5

LP1PP

PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.:

LP1-PTSC-10USU-QAM14-ITP-0001

INSPECTION AND TEST PLAN

FOR FABRICATION STEEL STRUCTURE OF

WAREHOUSE AND WORKSHOP

Revision No.: C

1.0

Page 9 of 9

Date: 27-Sep-2016

GENERAL

This Inspection and Test Plan (ITP) is a plan for fabrication steel structure of Warehouse and

Workshop for Long Phu 1 Thermal Power Plant Project.

2.0

REFERENCE DOCUMENTS

ASTM E8/E8M 15: Standard Test Methods for Tension Testing of Metallic Materials.

ASTM A370 16: Standard Test Methods and Definitions for Mechanical Testing of Steel

Products.

ASTM A751 14a: Standard Test Methods, Practices, and Terminology for Chemical Analysis

of Steel Products.

ASTM E415 15: Standard Test Method for Analysis of Carbon and Low-Alloy Steel by

Spark Atomic Emission Spectrometry.

ASTM A 325/A325M 14: Standard Specification for Structural Bolts, Steel, Heat Treated

830 MPa Minimum Tensile Strength.

ASTM A490/ A490M 14a: Standard Specification for High-Strength Steel Bolts.

ASTM A307 14: Standard Specification for Carbon Steel Bolts, Studs, and Threaded Rod.

ASTM F1554 14 Grade 36 : Low carbon, 36 ksi yield steel anchor bolts.

AISC 303-10: Code of Standard Practice for Structural Steel Buildings and Bridges.

AISC 348-14: Specification for Structural Joints Using High-Strength Bolts.

AWS D1.1-2015: Structural Welding Code Steel 2015.

ISO 12944-5: Paints and varnishes Corrosion protection of steel structures by protective paint

systems Part 5: Protective paint systems.

SSPC :

Steel Structures Painting Council, USA

SSPC - PA1:

Shop, Field and Maintenance Painting

SSPC - PA2:

Measurement of Dry Paint Thickness with Magnetic Gauges

ISO 8501-1:1998: International Standard Organization

LP1-TKC-10XXX-C-C1-DRD-0002: Steel Structure General Note

LP1-TKC-10XX-M-G1-SPC-2022: Specification for Painting.

LP1PP

PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.:

LP1-PTSC-10USU-QAM14-ITP-0001

INSPECTION AND TEST PLAN

FOR FABRICATION STEEL STRUCTURE OF

WAREHOUSE AND WORKSHOP

Revision No.: C

3.0

Page 9 of 9

Date: 27-Sep-2016

INSPECTION NOTIFICATION

The inspection notification shall be made in the daily communication between the EPC

Contractor and PMC/Owner as per Inspection and Test Plan.

The interface points to be included in this ITP as follows:

I:

Verification of Inspection - Denotes the responsibility for implementing the verification of

the inspections required in the ITP and quality of the final product. These inspections are

carried out by the Subcontractor at the time of independent witness.

S:

Random Surveillance or Monitoring - Denotes the responsibility for inspecting work on a

random surveillance or monitoring basis and signing for that work. The Subcontractor will

ensure the QC forms applicable to the works are available at the work site for signatures. As

formal notification is not required for this designation the Subcontractor will submit a

weekly schedule of expected activities and assist with oral communication. The

Subcontractor will record the result before moving on to the next step.

R:

Review Point - Denotes the responsibility for review of relevant documents instead of

inspection/witness.

W: Witness Point - Denotes the responsibility for witnessing and signing for the work. Formal

notification must be given to the interested parties in a timely manner.

This would

generally be 24 hour for site activities. Attendance by interested parties is mandatory but, on

a case-by-case basis, the witness activity may be waived. Intention to waive must be by

written instruction (email acceptable). The Subcontractor must document the inspection and

endorse the record before moving on to the next step.

H:

Hold Point - Denotes the responsibility for witnessing and signing work to release Hold

Points in the work process. Attendance by interested parties is mandatory. Work may NOT

proceed beyond Hold Points without witness and sign off by the identified participants.

Generally, the formal notification for Hold Point witness will be delivered with at least 24

hour in advance for site activities to ensure availability of interested parties

A:

Denotes the responsibility of relevant parties to sign in acceptance record in accordance

with current regulation of Viet Nam Law in construction.

LP1PP

PTSC

LONG PHU 1 THERMAL POWER PLANT PROJECT

Document No.:

LP1-PTSC-10USU-QAM14-ITP-0001

INSPECTION AND TEST PLAN

FOR FABRICATION STEEL STRUCTURE OF

WAREHOUSE AND WORKSHOP

Revision No.: C

4.0

QUALITY CONTROL FORMS

1.

LP1-IMR-001_Input Material Inspection Report

2. LP1-S-001_Dimension Inspection Report

3. LP1-S-002_Daily visual Inspection report

4.

LP1-NDT-001 _Penetrant Testing Inspection Report

5. LP1-NDT-002_Magnetic Particle Examination Report

6. LP1-NDT-003_ Ultrasonic Testing Inspection Report

7. LP1-PA-001_ Release Note For Painting

8. LP1-PA-002_ Inspection Suface After Cleaning

9. LP1-PA-003_Dry Film Thickness Inspection

10. LP1-PA-004_Final Survey Inspection Report of Painting

11. LP1-GAL-001_ Release Note For Galvanizing

12. LP1-PL-001_Packing Inspection Release Note

13. LP1-PL-002 -a _Packing List

14. LP1-PL-002-b_Packing Inspection Report

15. LP1-IRC-001-a _Inspection Release Certificate

16. LP1-IRC-001-b_Delivery Notice

17. LP1-IRC-001-c _ Packing List

18. LP1-IRC-001-d _Packing List detail

Page 9 of 9

Date: 27-Sep-2016

Anda mungkin juga menyukai

- Steel Fabrication and Erection SOPDokumen8 halamanSteel Fabrication and Erection SOPMDhana SekarBelum ada peringkat

- Jabali Project Steel Structure ErectionDokumen26 halamanJabali Project Steel Structure ErectionNick LawBelum ada peringkat

- Steel Work Inspection ReportDokumen3 halamanSteel Work Inspection ReportAhmad Hasnan100% (1)

- Water Tank ItpDokumen5 halamanWater Tank ItpHgagselim SelimBelum ada peringkat

- Thrust Boring - Horizontal Directional DrillingDokumen6 halamanThrust Boring - Horizontal Directional Drillingsai_kukie100% (1)

- Elements of Pipe DesignDokumen49 halamanElements of Pipe DesignAnonymous 4rMVkArBelum ada peringkat

- Painting Procedures ADokumen7 halamanPainting Procedures AMaged Lotfy Abdel-aal100% (1)

- Inspection Test Plan For FabricationDokumen4 halamanInspection Test Plan For FabricationAshwani Dogra100% (9)

- ITP For Steel Structure1Dokumen3 halamanITP For Steel Structure1吴兴泊Belum ada peringkat

- Fit-Up Inspection ReportDokumen1 halamanFit-Up Inspection ReportAlfian ImaduddinBelum ada peringkat

- ITP C 005 (Structural Concrete)Dokumen4 halamanITP C 005 (Structural Concrete)segun ajibolaBelum ada peringkat

- Quality Control Procedure Strcture-SSDokumen16 halamanQuality Control Procedure Strcture-SSKamran AliBelum ada peringkat

- Msog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresDokumen5 halamanMsog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresMohd SaffririzalBelum ada peringkat

- Electrode Handling Procedure - Simple - SMAWDokumen7 halamanElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Itp For Steel Structure Erection (Content) Rev.1Dokumen3 halamanItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (5)

- ITP - Fabrication of Structural SteelDokumen2 halamanITP - Fabrication of Structural Steelsahad100% (6)

- ITP - OF - Structural Work FOR PARADEEPDokumen4 halamanITP - OF - Structural Work FOR PARADEEPRajeev KumarBelum ada peringkat

- Inspection Record and Report Master List As On 8.3.18Dokumen32 halamanInspection Record and Report Master List As On 8.3.18Gomathyselvi100% (1)

- Field ITP Civil Rev-8after Lump-Sump.Dokumen17 halamanField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- Structural Steel Inspection Report01Dokumen2 halamanStructural Steel Inspection Report01JM PerezBelum ada peringkat

- Inspection and Test Plan For Seel StructureDokumen3 halamanInspection and Test Plan For Seel StructureChris McNairBelum ada peringkat

- Iso 4624 PDFDokumen15 halamanIso 4624 PDFRajan Steeve50% (2)

- Fabrication Division QMDDokumen11 halamanFabrication Division QMDRakesh RanjanBelum ada peringkat

- Qms Form Arch & Civil ChecklistDokumen32 halamanQms Form Arch & Civil ChecklistMatt CerosBelum ada peringkat

- Structural Steel Inspection Report Checklist - SafetyCultureDokumen3 halamanStructural Steel Inspection Report Checklist - SafetyCultureMicheal raj ABelum ada peringkat

- Fit Up ReportDokumen41 halamanFit Up ReportFendik NewbieBelum ada peringkat

- CFD and Marine ApplicationsDokumen64 halamanCFD and Marine ApplicationsshahzBelum ada peringkat

- Itp For Storage TanksDokumen7 halamanItp For Storage TanksHamid MansouriBelum ada peringkat

- Structural Steel Checklist 17Dokumen2 halamanStructural Steel Checklist 17mgb2010hotmailcomBelum ada peringkat

- Fabrication of Steel Structure and Steel Equipment (Itp)Dokumen4 halamanFabrication of Steel Structure and Steel Equipment (Itp)Javed MABelum ada peringkat

- 027 ITP For Pre Cast Concrete PDFDokumen27 halaman027 ITP For Pre Cast Concrete PDFlinga2014Belum ada peringkat

- Boiler Erection ManualDokumen51 halamanBoiler Erection ManualPhong Do100% (1)

- HSTD-PTSCMC-TS-Q-PR-0001 Dimension Control Procedure For TOPSIDE FabricationDokumen19 halamanHSTD-PTSCMC-TS-Q-PR-0001 Dimension Control Procedure For TOPSIDE Fabricationngtchung100% (2)

- Car crushing hydraulic circuit analysisDokumen22 halamanCar crushing hydraulic circuit analysisphankhoa83100% (1)

- Itp For Structural Steel WorkDokumen12 halamanItp For Structural Steel Worknguyen thangBelum ada peringkat

- Astm 262 PDFDokumen19 halamanAstm 262 PDFiyam75% (4)

- Fabrication & Erection of Steel Works ChecklistDokumen1 halamanFabrication & Erection of Steel Works ChecklisttaghlubBelum ada peringkat

- Ibb Mcup & Modification of K-12 Building: Inspection and Test Plan FOR Architectural WorksDokumen19 halamanIbb Mcup & Modification of K-12 Building: Inspection and Test Plan FOR Architectural WorksShewale PravinBelum ada peringkat

- Inertia BaseDokumen2 halamanInertia BasePackiaraj KrishnasamyBelum ada peringkat

- Structural Steel Installation ChecklistDokumen1 halamanStructural Steel Installation Checklistboz vanduyn100% (1)

- ITP SampleDokumen2 halamanITP Sampleeiman_zerep50% (2)

- Structural Steel Inspection Report01Dokumen1 halamanStructural Steel Inspection Report01JobJob100% (1)

- Fit Up Inspection Report-10Dokumen57 halamanFit Up Inspection Report-10rizky youlandaBelum ada peringkat

- X6 Structural Steel Erection Inspection Test PlanDokumen11 halamanX6 Structural Steel Erection Inspection Test PlanNoor A Qasim100% (1)

- Inspection and Test Plan-Structural Steel C011Dokumen2 halamanInspection and Test Plan-Structural Steel C011FurqanBelum ada peringkat

- Erection Guidelines For 500 MW Boiler Pressure PartsDokumen150 halamanErection Guidelines For 500 MW Boiler Pressure Partsyanloyan80% (5)

- 2022-03-24 ITP For Fabrication and Erection of StructuralDokumen7 halaman2022-03-24 ITP For Fabrication and Erection of StructuraljaymarBelum ada peringkat

- Itp For InsulationDokumen14 halamanItp For InsulationHytham El-NoubyBelum ada peringkat

- Etp ListDokumen33 halamanEtp ListMohamed MostafaBelum ada peringkat

- Ibb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectDokumen19 halamanIbb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectShewale PravinBelum ada peringkat

- Punchlist: Punchlist No.: Rev.: Date: Page ..... of ....Dokumen1 halamanPunchlist: Punchlist No.: Rev.: Date: Page ..... of ....kerons100% (1)

- Steel Structure Fabric & Installation - Doc Rev01Dokumen7 halamanSteel Structure Fabric & Installation - Doc Rev01whah11Belum ada peringkat

- Torque ReportDokumen1 halamanTorque Reportjarofidz100% (1)

- JIS G 3106 - NewDokumen38 halamanJIS G 3106 - NewMani Ma100% (2)

- F462-79 (2007) Standard Consumer Safety Specification For Slip-Resistant Bathing FacilitiesDokumen7 halamanF462-79 (2007) Standard Consumer Safety Specification For Slip-Resistant Bathing FacilitiesPhong DoBelum ada peringkat

- Fabrication Method For HSM 2 ProjectDokumen14 halamanFabrication Method For HSM 2 ProjectMikiRoniWijayaBelum ada peringkat

- 026-Itp For Structural Steel PDFDokumen18 halaman026-Itp For Structural Steel PDFKöksal Patan100% (11)

- FM-D-01 Steel Structure ErectionDokumen1 halamanFM-D-01 Steel Structure ErectionG Vamsi ChandBelum ada peringkat

- Qcs 2010 Part 8.06 Metal WorksDokumen10 halamanQcs 2010 Part 8.06 Metal WorksRotsapNayrbBelum ada peringkat

- Gating System Design GuideDokumen11 halamanGating System Design GuideAshok Pradhan100% (1)

- 06 Fire Water Piping Welding ProcedureDokumen10 halaman06 Fire Water Piping Welding ProcedureAkhilesh Kumar100% (1)

- B2020-TDC-VF-009 Vessel Fabrication R0Dokumen5 halamanB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranBelum ada peringkat

- Structural Steel Inspection ReportDokumen2 halamanStructural Steel Inspection ReportAnnaBelum ada peringkat

- Mos Galvanizing ProceduresDokumen23 halamanMos Galvanizing ProceduresRajeswaran Rajachockalingam100% (1)

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dokumen16 halaman2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- ITP For CW and ACW Piping WorkDokumen8 halamanITP For CW and ACW Piping WorkPhong DoBelum ada peringkat

- ITP For CW and ACW Piping WorkDokumen8 halamanITP For CW and ACW Piping WorkPhong DoBelum ada peringkat

- RT ProcedureDokumen25 halamanRT ProcedurePhong Do100% (2)

- ITP Fencing Rev - 00 PDFDokumen3 halamanITP Fencing Rev - 00 PDFanon_987276020Belum ada peringkat

- Structural Steel Work Check ListDokumen1 halamanStructural Steel Work Check ListAhmad BilalBelum ada peringkat

- Quality Assurance in Buillding WorksDokumen8 halamanQuality Assurance in Buillding WorksAtish KumarBelum ada peringkat

- Weld Matrix Format 1Dokumen7 halamanWeld Matrix Format 1Arslan WaheedBelum ada peringkat

- Inspection Request - SampleDokumen1 halamanInspection Request - SampleMohd RashidBelum ada peringkat

- Painting & Inspection FormatDokumen1 halamanPainting & Inspection FormatABEC Trombay siteBelum ada peringkat

- 5) Economizer - Lifting SequencesDokumen1 halaman5) Economizer - Lifting SequencesPhong DoBelum ada peringkat

- Vv31b4-001-B-100!8!001 Method Statement For Fireproofing of Structural Steel Structures & Equipment With Interkote 1460Dokumen54 halamanVv31b4-001-B-100!8!001 Method Statement For Fireproofing of Structural Steel Structures & Equipment With Interkote 1460Phong DoBelum ada peringkat

- LP1 TKZ 10XXX M M1a Man 8405 CDokumen27 halamanLP1 TKZ 10XXX M M1a Man 8405 CPhong DoBelum ada peringkat

- KP2 Coalbunker SV Report For Week 48 Update On 30-NovDokumen246 halamanKP2 Coalbunker SV Report For Week 48 Update On 30-NovPhong DoBelum ada peringkat

- Presentation UzbekistanDokumen9 halamanPresentation UzbekistanPhong DoBelum ada peringkat

- LP1 TKZ 10XXX M M1a Man 8405 CDokumen27 halamanLP1 TKZ 10XXX M M1a Man 8405 CPhong DoBelum ada peringkat

- Approval Status of Steel Grades from Various Classification SocietiesDokumen9 halamanApproval Status of Steel Grades from Various Classification SocietiesPhong DoBelum ada peringkat

- Element Loading Sequence in Air PreheaterDokumen21 halamanElement Loading Sequence in Air PreheaterPhong DoBelum ada peringkat

- SmartControl Bathroom PlanDokumen19 halamanSmartControl Bathroom PlanashinataniBelum ada peringkat

- FEA of RC Slab With OpeningDokumen4 halamanFEA of RC Slab With OpeningMelkamu DemewezBelum ada peringkat

- AAnalyst 800 Detection Limits-Chromium DataDokumen2 halamanAAnalyst 800 Detection Limits-Chromium DataЂорђе РадојичићBelum ada peringkat

- Lesson 1.3: General Properties of Indefinite IntegralsDokumen6 halamanLesson 1.3: General Properties of Indefinite IntegralsMarkBelum ada peringkat

- Turbidites and Foreland Basins An Apenninic PerspectiveDokumen6 halamanTurbidites and Foreland Basins An Apenninic PerspectivekoloshrabeaaBelum ada peringkat

- Arduino Modules L298N Dual H Bridge Motor ControllDokumen7 halamanArduino Modules L298N Dual H Bridge Motor ControllMarius DanilaBelum ada peringkat

- Magnetism NotesDokumen4 halamanMagnetism NotesvenuBelum ada peringkat

- Introduction to Soil Moduli & Stress-Strain BehaviorDokumen45 halamanIntroduction to Soil Moduli & Stress-Strain BehaviorYassin Abd El AalBelum ada peringkat

- Online Courses From Top UniversitiesDokumen3 halamanOnline Courses From Top Universitiesephrem0% (2)

- Therm6.3 10211 ValidationDokumen7 halamanTherm6.3 10211 ValidationJavierBelum ada peringkat

- 3ap1 FG: High-Voltage Circuit-BreakerDokumen2 halaman3ap1 FG: High-Voltage Circuit-BreakerFernando VacaBelum ada peringkat

- Fishers LDADokumen47 halamanFishers LDABinduBelum ada peringkat

- A Ghost in The MachineDokumen7 halamanA Ghost in The MachineSicklslicerBelum ada peringkat

- Triple Deck Theory ExplainedDokumen18 halamanTriple Deck Theory ExplainedkrishnamurthyVishBelum ada peringkat

- Problems and Solutions For StudentsDokumen295 halamanProblems and Solutions For StudentsalsamixersBelum ada peringkat

- VTC 18MAT31 QP-Scheme-1Dokumen55 halamanVTC 18MAT31 QP-Scheme-1Maithira HBelum ada peringkat

- Topic 02 - Compound Semiconductor Growth TechnologyDokumen15 halamanTopic 02 - Compound Semiconductor Growth TechnologyIrum SabaBelum ada peringkat

- Sample Calculus Problems: Single Variable FunctionsDokumen155 halamanSample Calculus Problems: Single Variable Functionsmoustafa.mehanna7564Belum ada peringkat

- Construction Challenges in Hilly AreasDokumen24 halamanConstruction Challenges in Hilly AreasGhanashyam PuttaBelum ada peringkat

- IR Drop PDFDokumen3 halamanIR Drop PDFarammartBelum ada peringkat

- Thermodynamics of Phase TransformationDokumen20 halamanThermodynamics of Phase TransformationSaiCharan Dharavath100% (1)

- 9000 SPXDokumen220 halaman9000 SPXIsmael GraciaBelum ada peringkat

- 614460-Multi-Objective Material Selection For Wind Turbine Blade and Tower - Ashby's Approach - 10Dokumen12 halaman614460-Multi-Objective Material Selection For Wind Turbine Blade and Tower - Ashby's Approach - 10Erika Kawakami VasconcelosBelum ada peringkat