Croscheck PMS LSBL XIX Agustus 2015

Diunggah oleh

alsitorHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Croscheck PMS LSBL XIX Agustus 2015

Diunggah oleh

alsitorHak Cipta:

Format Tersedia

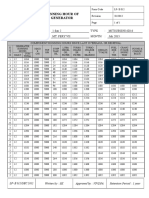

PMS CHECKLIST

NO.

ITEM

CHECK POINTS

VESSEL

LOCATION

PIC

Running

hours

Yes

No

Safety devices function properly.

Yes

No

Remote control function properly.

Yes

No

Check the alarm lamp operation

Yes

No

Oil pressure 0.49 to 0.64 Mpa / 5.0 to 6.5

kgf/cm2 ( during operation )

Yes

No

Yes

No

Yes

No

Water level at expansion tank

Yes

No

Check condition and level the Engine Oil

Yes

No

Yes

No

500

Yes

No

250

Yes

No

Measure Deflection of The V-Belt

( 10 to 15 mm)

250

Yes

No

The primary and secondary of fuel filter

500

Yes

No

Fuel injection nozzle opening pressure

( 34.3 Mpa / 350 kgf/cm2 )

1000

Yes

No

Injection timing ( BTDC 18 )

1000

Yes

No

Valve Clearance

( inlet : 0.6 mm, exhaust : 0.8 mm )

1000

Yes

No

Damper vibration

2000

Yes

No

Color of exhaust smoke

Yes

No

Sea water discharging volume

Yes

No

Tightening torque of bolts

Yes

No

Operate satisfactorily.

Yes

No

Oil pressure 4.0 to 5.0 bar

( Clutch disengaged )

Yes

No

Oil pressure appr. 22 bar

( Clutch engaged)

Yes

No

Yes

No

Yes

No

Yes

No

( during operation )

The oil filter and by pass oil filter

MAIN ENGINE

PORTSIDE

Condition of The Zinc Rods

(CUMMINS KTA 38 M2)

Condition of the V- Belt

Oil level ( between " Min " and " Max" )

and condition of The Oil

GEARBOX PORT

(REINTJES WAF

562)

SATISFACTORY

Operate satisfactorily.

Oil pressure 0.2 to 0.29 mpa / 2 to 3

kgf/cm2 ( standard pressure / no load )

Coolant temperature gauge 70 to 80 C

:

:

:

Oil temperature from the Thermometer

( 30 to 60 C and max 70 C )

Check the Contamination indicator for the

oil filter standard

( indicator red = filter contamination )

2000

2000

TB LSBL XIX

SUNGAI PITUNG

August 12, 2015

REMAKS

NO.

GEARBOX

PORT

ITEM

(REINTJES WAF

562)

CHECK POINTS

The contamination indicator for the oil filter

/ duplex filter

Running

hours

Yes

No

The Oil cooler Anodes

Yes

No

Leakage

Yes

No

Abnormal running

Yes

No

Abnormal opeating noises

Yes

No

Yes

No

Operate satisfactorily.

Yes

No

Safety devices function properly.

Yes

No

Remote control function properly.

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Water level at expansion tank

Yes

No

Check condition and level the Engine Oil

Yes

No

Yes

No

500

Yes

No

250

Yes

No

Measure Deflection of The V-Belt

(10 to 15 mm)

250

Yes

No

The primary and secondary of fuel filter

500

Yes

No

Fuel injection nozzle opening pressure

(34.3 Mpa / 350 kgf/cm2 )

1000

Yes

No

Injection timing ( BTDC 18 )

1000

Yes

No

Valve Clearance

( inlet : 0.6 mm, exhaust : 0.8 mm )

1000

Yes

No

Damper vibration

2000

Yes

No

Color of exhaust smoke

Yes

No

Sea water discharging volume

Yes

No

Tightening torque of bolts

Yes

No

Operate satisfactorily.

Yes

No

Oil pressure 4.0 to 5.0 bar

( Clutch disengaged )

Yes

No

Tightening torque of bolts

2000

5000

Check the alarm lamp operation

MAIN ENGINE

PORTSIDE

Oil pressure 0.49 to 0.64 Mpa / 5.0 to 6.5

(CUMMINS KTA 38 - kgf/cm2 ( during operation )

M2)

Oil pressure 0.2 to 0.29 mpa / 2 to 3

kgf/cm2 ( standard pressure / no load )

Coolant temperature gauge 70 to 80 C

( during operation )

SATISFACTORY

The oil filter and by pass oil filter

MAIN ENGINE

STARBOARD

Condition of The Zinc Rods

(CUMMINS KTA 38 M2)

Condition of the V- Belt

REMAKS

NO.

ITEM

CHECK POINTS

Running

hours

Oil pressure appr. 22 bar

( Clutch engaged)

Yes

No

Yes

No

Yes

No

2000

Yes

No

2000

Yes

No

The Oil cooler Anodes

Yes

No

Leakage

Yes

No

Abnormal running

Yes

No

Abnormal opeating noises

Yes

No

Yes

No

Yes

No

Safety devices function properly.

Yes

No

Water level at Expansion Tank

Yes

No

Condition of the V - Belt

Yes

No

Measure deflection of the V - Belt

(10 mm )

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Sea water discharging volume

Yes

No

Air Filter

Yes

No

Oil level ( between " Min " and " Max" )

and condition of The Oil

GEARBOX PORT

(REINTJES WAF

562)

Oil temperature from the Thermometer (

30 to 60 C and max 70 C )

Check the Contamination indicator for the

oil filter standard

( indicator red = filter contamination )

The contamination indicator for the oil filter

/ duplex filter

Tightening torque of bolts

MAIN ENGINE

PORTSIDE

(CUMMINS KTA 38 - Operate satisfactorily.

M2)

Condition of the Impeller water pump

1

2000

5000

400

Condition The Oil and Level Oil

GENERATOR

( Full mark )

ENGINES

PORTSIDE (

Lubricating Oil Filter

CUMMINS 6 BT5-9GM.83 )

Color of exhaust smoke

ALTERNATOR (

STAMFORD

UCM274E1 )

SATISFACTORY

The Valve tip Clearance

( inlet 0.2 mm and exhaust 0.45 mm )

2000

Yes

No

Condition of the Viscous Damper

2000

Yes

No

Lubricating Oil Pressure

( 280 kN/m2 / 2.5 kgf/cm2 )

Yes

No

Fuel injection nozzle opening pressure

(Mpa / kgf/cm2 )

Yes

No

Operate satisfactorily.

Yes

No

Abnormal vibration

Yes

No

Synchronasation system

Yes

No

Output voltage

Yes

No

REMAKS

NO.

ITEM

CHECK POINTS

Running

hours

Operate satisfactorily.

Yes

No

Safety devices function properly.

Yes

No

Water level at Expansion Tank

Yes

No

Condition of the V - Belt

Yes

No

Measure deflection of the V - Belt

(10 mm )

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

2000

Yes

No

2000

Yes

No

Lubricating Oil Pressure

( 280 kN/m2 / 2.5 kgf/cm2 )

Yes

No

Fuel injection nozzle opening pressure

( Mpa / kgf/cm2 )

Yes

No

Operate satisfactorily.

Yes

No

Abnormal vibration

Yes

No

Synchronasation system

Yes

No

Output voltage

Yes

No

Operate satisfactorily.

Yes

No

Check condition and level the Engine Oil

Yes

No

Water level at expansion tank

Yes

No

Condition of the V- Belt and tension of the

V- belt ( 10 -15 mm )

Yes

No

Oil filter element

Yes

No

Fuel filter element

Yes

No

Sea water discharging volume

Yes

No

Abnormal noise and vibrate

Yes

No

Exhaust color of smoke

Yes

No

Operate satisfactorily.

Yes

No

Condition of the Impeller water pump

400

Condition The Oil and Level Oil

GENERATOR

( Full mark )

ENGINES

STARBOARD (

Lubricating Oil Filter

CUMMINS 6 BT5-9GM.83 )

Color of exhaust smoke

4

Sea water discharging volume

MAIN ENGINE

PORTSIDE

(CUMMINS KTA 38 - Air Filter

M2)

The Valve tip Clearance

( inlet 0.2 mm and exhaust 0.45 mm )

Condition of the Viscous Damper

ALTERNATOR (

STAMFORD

UCM274E1 )

FIRE SISTEM

SATISFACTORY

REMAKS

NO.

ITEM

11

12

Running

hours

SATISFACTORY

Abnormal noise and vibrate

Yes

No

leakage from the pump casing

Yes

No

Greasing

Yes

No

All valves operate satisfactorily.

Yes

No

Piping in good order.

Yes

No

Operate satisfactorily.

Yes

No

leakage from the pump casing

Yes

No

All valves operate satisfactorily.

Yes

No

Piping in good order.

Yes

No

Yes

No

Yes

No

Yes

No

Piping in good order.

Yes

No

Bilge & GS Pump operate satisfactorily.

Yes

No

No heavy corrosion and leakage.

Yes

No

All valves operate satisfactorily.

Yes

No

Piping in good order.

Yes

No

Sea water cooling Pump operate

satisfactorily.

Yes

No

No heavy corrosion and leakage.

Yes

No

All valves operate satisfactorily.

Yes

No

Piping in good order.

Yes

No

Fuel oil Pump operate satisfactorily.

Yes

No

No heavy corrosion and leakage.

Yes

No

Yes

No

Piping in good order.

Yes

No

Emergency stop operating satisfactorily

Yes

No

Dirty oil Pump operate satisfactorily.

Yes

No

No heavy corrosion and leakage.

Yes

No

All valves operate satisfactorily.

Yes

No

REMAKS

FIRE PUMP

EMERGENCY FIRE

PUMP

Ballast pump Operate satisfactorily.

MAIN ENGINE

PORTSIDE

(CUMMINSSYSTEM

KTA 38 - No heavy corrosion and leakage.

BALLAST

M2)

PORT & STBD

All valves operate satisfactorily.

BILGE & GS

SYSTEM

10

CHECK POINTS

SEA WATER

COOLING SYSTEM

FUEL OIL SYSTEM All valves operate satisfactorily.

DIRTY OIL SYSTEM

Emergency Fire Pump

diturunkan ke darat

12

DIRTY OIL SYSTEM

NO.

ITEM

CHECK POINTS

Running

hours

SATISFACTORY

Piping in good order.

Yes

No

Operate satisfactorily.

Yes

No

Remote and control function properly.

Yes

No

Meters and gauges in good order.

Yes

No

Operate satisfactorily.

Yes

No

Remote and control function properly.

Yes

No

Meters and gauges in good order.

Yes

No

Operate satisfactorily.

Yes

No

Yes

No

Meters and gauges in good order.

MAIN ENGINE

PORTSIDE

(CUMMINS KTA 38 - No heavy corrosion and leakage.

PIPING

M2)

All valves operate satisfactorily.

Yes

No

Yes

No

Yes

No

17

BLOWER E/R

Operate satisfactorily.

Yes

No

18

EMERGENCY

STEERING

Operate satisfactorily.

Yes

No

19

CONTROL

CONSOL

Operate satisfactorily.

Yes

No

20

COMMUNICATION

SYSTEM

Operate satisfactorily.

Yes

No

21

1

CLEANLINESS of

E/R

Must be clean without rubbish or waste oil.

Yes

No

22

GUARDS AND

FENCING

Protection covers and/or guards in good

order.

Yes

No

QUICK CLOSING

VALVE

Operate satisfactorily.

Yes

No

23

All valves operate satisfactorily.

Yes

No

All lights in good order.

Yes

No

Protection covers or guards in good order

Yes

No

All lights in good order.

Yes

No

Protection covers or guards in good order

Yes

No

Lighting in working All lights in good order.

room, steering room

and other spaces

Protection covers or guards in good order

Yes

No

Yes

No

13

14

15

16

24

25

26

SEWAGE

TREATMENT

PLANT

OILY WATER

SEPARATOR

HYDRAULIC

POWER PACK AND Remote and control function properly.

CONTROL

Lighting in E/R

Lighting in Acc.

Spaces

27

Emergency cables

Condition in good order, no exposed wire,

heavy corrosion, especially on weather

deck.

Yes

No

28

Emergency lights

All lights in good order, no broken lights.

Yes

No

REMAKS

NO.

29

30

31

32

33

ITEM

Anti-explosion lights

in dangerous

spaces, pump room,

battery room, paint

locker etc.

Insulating mats

around MSB

Main Switch Board

CHECK POINTS

SATISFACTORY

All lights in good order, no broken covers

and guards, tightening handles available

on board.

Yes

No

Available on board or insulation cement

permanently laid up on the floor.

Yes

No

All gauges and indicating light are

functioning

Yes

No

The surface of panel for excessive

warmness

Yes

No

Unusual smell

Yes

No

All cable conncetion and bus

Yes

No

Gas detector at P.R

Yes

No

Fire detector

Yes

No

Yes

No

Yes

No

Bilges at Pump Room

Yes

No

Bilges at Steering Room

Yes

No

Daily Oil Tank

Yes

No

Fuel Oil Tank

Yes

No

Sewage tank

Yes

No

Sensor CO2

MAIN

AlarmsENGINE

operate

PORTSIDE

satisfactorily

(CUMMINS KTA 38 - Bilges at Engine Room

M2)

Level high / low

alarm operate

satisfactorily

Running

hours

REMAKS

Elvis Pangalo

Chief Engineers

Date : 12 AGUSTUS 2015

Hidayat Setiawan

Technical Superintendent

Date : 12 AGUSTUS 2015

Anda mungkin juga menyukai

- (782982478) Monthly Fuel, Lo Consumption Report - February 2016Dokumen1 halaman(782982478) Monthly Fuel, Lo Consumption Report - February 2016alsitorBelum ada peringkat

- 2016.04.13 S30 - Monitoring ROB (Dumai-Merak)Dokumen2 halaman2016.04.13 S30 - Monitoring ROB (Dumai-Merak)alsitorBelum ada peringkat

- Pms Engine TB Fery 03 LinsoDokumen15 halamanPms Engine TB Fery 03 LinsoalsitorBelum ada peringkat

- Pms June @LSBL XviiiDokumen32 halamanPms June @LSBL XviiialsitorBelum ada peringkat

- Pms Deck Nasyda LinsoDokumen21 halamanPms Deck Nasyda Linsoalsitor100% (1)

- DECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yrDokumen12 halamanDECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yralsitorBelum ada peringkat

- Pms Engine Lintas Ix LinsoDokumen27 halamanPms Engine Lintas Ix LinsoalsitorBelum ada peringkat

- Pms Deck Nasyda LinsoDokumen21 halamanPms Deck Nasyda Linsoalsitor100% (1)

- Pms Deck TB Fery 03 LinsoDokumen15 halamanPms Deck TB Fery 03 LinsoalsitorBelum ada peringkat

- Pms Engine Nasyda LinsoDokumen12 halamanPms Engine Nasyda LinsoalsitorBelum ada peringkat

- PMS Checklist for OB LSBL XVIIIDokumen5 halamanPMS Checklist for OB LSBL XVIIIalsitorBelum ada peringkat

- Monthly work reportDokumen11 halamanMonthly work reportalsitor100% (2)

- Tec-B 014 Running Hour Ae 1Dokumen2 halamanTec-B 014 Running Hour Ae 1alsitorBelum ada peringkat

- Maintenance Plan Bg. TaisirDokumen12 halamanMaintenance Plan Bg. TaisiralsitorBelum ada peringkat

- Technical Superintendent Visit: Superintendent'S Detailed ReportDokumen8 halamanTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorBelum ada peringkat

- Vessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmDokumen4 halamanVessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmalsitorBelum ada peringkat

- Technical Superintendent Visit: Superintendent'S Detailed ReportDokumen8 halamanTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorBelum ada peringkat

- TB SADP XXX Exhaust Vent Emergency Stop Test RecordsDokumen4 halamanTB SADP XXX Exhaust Vent Emergency Stop Test RecordsalsitorBelum ada peringkat

- LF - e 011 Inventory Spare Parts JuliDokumen1 halamanLF - e 011 Inventory Spare Parts JulialsitorBelum ada peringkat

- Technical Superintendent Visit: Superintendent'S Detailed ReportDokumen8 halamanTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorBelum ada peringkat

- Damage report formDokumen1 halamanDamage report formalsitor0% (1)

- Tec-B 028 Engine Room Critical Test B.indoDokumen13 halamanTec-B 028 Engine Room Critical Test B.indoalsitorBelum ada peringkat

- LF - e 012 Running Hour of GeneratorDokumen2 halamanLF - e 012 Running Hour of GeneratoralsitorBelum ada peringkat

- LF - e 011 Inventory Spare Parts JuliDokumen1 halamanLF - e 011 Inventory Spare Parts JulialsitorBelum ada peringkat

- MT FERY VII MAINTENANCE REPAIR REPORTDokumen1 halamanMT FERY VII MAINTENANCE REPAIR REPORTalsitorBelum ada peringkat

- Checklist Pms TB Tytyan Karimata 02Dokumen3 halamanChecklist Pms TB Tytyan Karimata 02alsitorBelum ada peringkat

- Standarisasi: Perawatan Generator AE (Cleaning) MT - Fery XVIDokumen2 halamanStandarisasi: Perawatan Generator AE (Cleaning) MT - Fery XVIalsitorBelum ada peringkat

- Monthly fuel and lube reportDokumen1 halamanMonthly fuel and lube reportalsitorBelum ada peringkat

- Tata Cara PengisiDokumen327 halamanTata Cara PengisialsitorBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- TDS-4S TDS-4H: Varco P/NDokumen21 halamanTDS-4S TDS-4H: Varco P/NEduardo BragaBelum ada peringkat

- Chery Amulet 1,6 Engine Service ManualDokumen76 halamanChery Amulet 1,6 Engine Service ManualG x HxhBelum ada peringkat

- GCAA Tier 4 Emissions StandardsDokumen18 halamanGCAA Tier 4 Emissions StandardsolguinrfBelum ada peringkat

- Arctic Cat 2010 700 Diesel Service ManualDokumen10 halamanArctic Cat 2010 700 Diesel Service Manualsusann100% (54)

- Transmissions For Off-Road Equipment (Construction Machinery, Special Vehicles, Lift Truck) List of Lubricants TE-ML 03Dokumen15 halamanTransmissions For Off-Road Equipment (Construction Machinery, Special Vehicles, Lift Truck) List of Lubricants TE-ML 03Mushhood SiddiquiBelum ada peringkat

- (Micfil) Produkt ModularDokumen9 halaman(Micfil) Produkt ModularAbdulrahman Al HuribyBelum ada peringkat

- Vento PHR4i REPAIR MANUAL PDFDokumen88 halamanVento PHR4i REPAIR MANUAL PDFErick HinojosaBelum ada peringkat

- Manual de Mantenimiento Cat 3500Dokumen46 halamanManual de Mantenimiento Cat 3500Kikemol Lv OBelum ada peringkat

- 02 Periodic MaintenanceDokumen23 halaman02 Periodic MaintenanceVincent RoyBelum ada peringkat

- DuBois Chemical - Lubricant Product GuideDokumen8 halamanDuBois Chemical - Lubricant Product GuideWMC_PM100% (1)

- 2ZZGE Engine - Part of ManualDokumen46 halaman2ZZGE Engine - Part of ManualDavide Faelli100% (2)

- Compare Non-Edible Oils and Engine Oils for LubricationDokumen15 halamanCompare Non-Edible Oils and Engine Oils for LubricationananthakumarBelum ada peringkat

- GPN SM Brochure Agriculture EN Preview 1Dokumen60 halamanGPN SM Brochure Agriculture EN Preview 1Hewa PCBelum ada peringkat

- XP13000EH Manual Rev06172022 WEBDokumen84 halamanXP13000EH Manual Rev06172022 WEBJose MoralesBelum ada peringkat

- AURTTA104 - Assessment 2 Practical Demonstration Tasks - V3Dokumen16 halamanAURTTA104 - Assessment 2 Practical Demonstration Tasks - V3muhammaduzairBelum ada peringkat

- King Engine Bearings Catalog 2015Dokumen552 halamanKing Engine Bearings Catalog 2015Walid Benazi50% (2)

- Technical Purchasing Specification: Technical Instruction 1CHE3272-001 (Ing)Dokumen10 halamanTechnical Purchasing Specification: Technical Instruction 1CHE3272-001 (Ing)Lorena HuebraBelum ada peringkat

- ESG Service Information: GeneralDokumen4 halamanESG Service Information: GeneralHectorFalconLlenderrozosBelum ada peringkat

- Suma de Demand Parts ListDokumen33 halamanSuma de Demand Parts ListTatiana Paucar RimacBelum ada peringkat

- BRBDokumen7 halamanBRBahmetBelum ada peringkat

- Cassida Fluid CR SeriesDokumen2 halamanCassida Fluid CR Seriescatch_samBelum ada peringkat

- Leichtlauf High Tech 5W-40 Engine OilDokumen2 halamanLeichtlauf High Tech 5W-40 Engine OilFlorin FloBelum ada peringkat

- Check Fluid Levels, Change Oil, Filters for Vehicle MaintenanceDokumen16 halamanCheck Fluid Levels, Change Oil, Filters for Vehicle Maintenancepapipapii100% (1)

- Dragflow - HYDRAULIC PUMP HY 35 A/BDokumen23 halamanDragflow - HYDRAULIC PUMP HY 35 A/BParviz Nasirov100% (1)

- Ventilação Do Carter ScaniaDokumen23 halamanVentilação Do Carter ScaniaAloisio RibeiroBelum ada peringkat

- Sym DD 50 (EN)Dokumen149 halamanSym DD 50 (EN)manualsymBelum ada peringkat

- Four Ball TestDokumen11 halamanFour Ball TestFaiz IslamBelum ada peringkat

- Injection Actuation Pressure - Test: TroubleshootingDokumen19 halamanInjection Actuation Pressure - Test: TroubleshootingMbahdiro KolenxBelum ada peringkat

- Synthetic Tractor Hydraulic/Transmission Oil SAE 5W-30 (ATH)Dokumen2 halamanSynthetic Tractor Hydraulic/Transmission Oil SAE 5W-30 (ATH)Bruce Wappman100% (5)

- General Installation, Operation, Maintenance and Troubleshooting Manual FOR Imo Pump Two Screw ProductsDokumen24 halamanGeneral Installation, Operation, Maintenance and Troubleshooting Manual FOR Imo Pump Two Screw ProductsJulio C. Sivira CallejaBelum ada peringkat