S050 WTR C Eng 09

Diunggah oleh

thomasobur0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

40 tayangan2 halamanAir Release valve

Judul Asli

S050-WTR-C-ENG-09

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAir Release valve

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

40 tayangan2 halamanS050 WTR C Eng 09

Diunggah oleh

thomasoburAir Release valve

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

S050.WTR.CAT.

EN01

S-050

S-050-C

PN 16

PN 16

/S-052

Water Supply

PN 25

Automatic Air Release Valve

Description

The S-050 series Automatic Air Release Valve releases accumulated

air from the system while it is under pressure. The presence of air

in a water system can reduce the effective cross sectional flow area

resulting in increased head loss and deceased flow. Unwanted air

may also cause water hammer and metering inaccuracies, while

hastening corrosion. In spite of its compact and light weight

structure, the S-050 series Automatic Air Release Valve has a

12mm orifice that enables it to release air at high flow rates and is

not exposed to obstruction by debris.

Applications

- On most types of pumps.

- After filters, pressure reducers and fertilizer injection systems.

- On heads of landscape systems.

S-050-C, S-052 additional applications:

- Water pipelines vulnerable to vandalism and/or water theft.

- Water systems found in remote areas.

Operation

The automatic air release valve releases entrapped air from

pressurized systems.

Without air release valves, pockets of accumulated air may cause the

following hydraulic disturbances:

- Restriction of effective flow due to a reduction of the flow area. In

extreme cases this will cause complete flow stoppage.

- Obstruction of efficient hydraulic transmission due to air flow

disturbances.

- Acceleration of cavitation damages.

- Increase in pressure transients and surges.

- Internal corrosion of pipes, fittings and accessories.

- Dangerous high-energy bursts of compressed air.

- Inaccuracies in flow metering.

As the system fills and is pressurized, the automatic air release

valve functions according to the following stages:

1. Entrapped air, which accumulates at peaks and along the system,

rises to the top of the air valve, which in turn displaces the liquid in

the air valve body.

2. The float drops, unsealing the rolling seal. The automatic air

release orifice opens and the accumulated air is released.

3. Liquid enters the valve and the float rises, pushing the rolling seal

back to its sealing position.

Note: Automatic air release valves are designed to release air as it

accumulates at peaks in pressurized systems. They are not normally

recommended for vacuum protection or for discharging large

volumes of air, because of their inherently small orifices. For this

purpose, air & vacuum valves are recommended as they have much

larger orifices.

However, air release valves will permit air to enter the system under

vacuum conditions. If this is not desirable, specify the one-way out

check valve.

Main Features

- Working pressure range:

S-050 0.2 - 16 bar

S-050-C 0.2 - 16 bar

S-052 0.2 - 25 bar

- Test pressure for the air valve is 1.5 times its working pressure.

- Maximum working temperature: 60C.

- Maximum intermittent temperature: 90C.

- The body is made of high strength composite materials and all

operating parts are made of specially selected corrosion- resistant

materials.

- The larger than usual orifice enables it to release air at higher flow

rates than other automatic air release valves of its kind.

- The enlarged orifice and self cleaning rolling seal make it less

exposed to obstruction by debris.

- The valves rolling seal mechanism design is less sensitive to

different pressures than a direct float seal, thus enabling a one size

orifice for a wide pressure range (from 0.2 up to 25 bar).

- Lightweight, simple and reliable structure.

- A discharge outlet enables removal of excess fluids.

Valve Selection

- Available in male threaded sizes: 1/2, 3/4, 1 - BSP / NPT

- S-050 is rated for 16 bar.

- S-050-C vandalism protected by a metal shell covering the air

release component, rated for 16 bar.

- S-052 vandalism protected by a metal shell covering the air release

component, rated for 25 bar.

- SG-10 For low pressures (0.2-10 bar)

- S-050 LP For low pressures (0.05-6 bar)

- S-050 B With a brass base (0.2-16 bar)

- S-050 V, S-050-C-V Vacuum check valve - Available as a valve

that will only release air from the system and will not admit air

to the system when negative pressure conditions occur. This

characteristic is obtained by adding a check valve to the air outlet.

Note

For best suitability, it is recommended to send the fluid chemical

properties along with the valve request.

Upon ordering, please specify: model, size, working pressure, thread

and flange standard and type of liquid.

S-050 / S-050-C / S-052

S-050 / S-050 B

A

2

3

S-050

S-050 B

S-050-C

S-052

4

5

DIMENSIONS AND WEIGHTS

Model

Dimensions mm

Connection

Weight

Orifice Area

Kg.

S-050

87

143

1/8 BSP Female

0.3

12

S-050 B

87

143

1/8 BSP Female

0.65

12

S-050-C

85

148

1/8 BSP Female

1.65

12

S-052

85

148

1/8 BSP Female

1.65

mm2

8

9

10

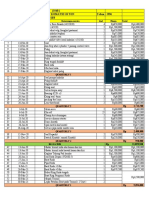

PARTS LIST AND SPECIFICATION

No.

Part

Material

1.

Shell

Ductile Iron

2.

Body

Reinforced Nylon

3.

Air Release Outlet

A

1

2

S-050

Polypropylene

S-050-C/S-052

Brass

4.

O-Ring

BUNA-N

5.

Rolling Seal

EPDM

6.

Clamping Stem

Reinforced Nylon

7.

Float

Foamed Polypropylene

8.

O-Ring

BUNA-N

9.

Base

10.

S-050-C / S-052

3

4

5

6

7

S-050

Reinforced Nylon / Brass

S-050-C/S-052

Brass

Strainer

Nylon

8

9

10

A.R.I. FLOW CONTROL ACCESSORIES Ltd. www.arivalves.com ari@ari.co.il Tel: 972-4-6761988

A.R.I. FLOW CONTROL ACCESSORIES Ltd. reserves the right to make productchanges without prior notice. To insure receivingupdated information on parts specifications, please call the export dept. atthe A.R.I.

factory. A.R.I. FLOW CONTROL ACCESSORIES Ltd. shall not be held liable for any errors. All rights reserved.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Torque Converter & Hydraulic Ratchet System - 4thDokumen18 halamanTorque Converter & Hydraulic Ratchet System - 4thfalconalnajjar0% (1)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- REE 6031 Tutorial 1Dokumen5 halamanREE 6031 Tutorial 1Eng Maboshe Charles Namafe0% (1)

- Design Calc Saud It SampleDokumen25 halamanDesign Calc Saud It SampleglazetmBelum ada peringkat

- FX 3900 PVDokumen194 halamanFX 3900 PVthomasoburBelum ada peringkat

- Military Standard: WL-S 2155 (A@Dokumen18 halamanMilitary Standard: WL-S 2155 (A@thomasoburBelum ada peringkat

- Bolting Torques - Spiral Wound GasketsDokumen1 halamanBolting Torques - Spiral Wound GasketsthomasoburBelum ada peringkat

- 3 - SFQ Corrosion Resistant Sump PumpsDokumen1 halaman3 - SFQ Corrosion Resistant Sump PumpsthomasoburBelum ada peringkat

- Steel Onesteel HandbookDokumen34 halamanSteel Onesteel HandbookjlolhnpBelum ada peringkat

- Auto Drain 70APADH4000Dokumen3 halamanAuto Drain 70APADH4000thomasoburBelum ada peringkat

- 3% Rule Sizing For PSV-Compressible FlowDokumen1 halaman3% Rule Sizing For PSV-Compressible FlowthomasoburBelum ada peringkat

- Engineering Competency StandardsDokumen11 halamanEngineering Competency StandardsRobbie van LeeuwenBelum ada peringkat

- Mack Ball ValvesDokumen10 halamanMack Ball ValvesthomasoburBelum ada peringkat

- Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")Dokumen2 halamanType A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")thomasoburBelum ada peringkat

- Varec 3650B 33-11518Dokumen15 halamanVarec 3650B 33-11518thomasoburBelum ada peringkat

- Parker 72 00DDokumen2 halamanParker 72 00DthomasoburBelum ada peringkat

- Bond Ek Design and Construction Manual June 2012Dokumen56 halamanBond Ek Design and Construction Manual June 2012rocketBelum ada peringkat

- Air Test Gun For Tube BundlesDokumen7 halamanAir Test Gun For Tube BundlesthomasoburBelum ada peringkat

- Atlas Metals - Carbon Steel Pipe Pressure Rating ChartDokumen4 halamanAtlas Metals - Carbon Steel Pipe Pressure Rating ChartthomasoburBelum ada peringkat

- Eaton Hydraulic Power PackDokumen6 halamanEaton Hydraulic Power PackthomasoburBelum ada peringkat

- Heat Transfer - Transient Hyperbolic Conduction in Hollow CylinderDokumen6 halamanHeat Transfer - Transient Hyperbolic Conduction in Hollow CylinderthomasoburBelum ada peringkat

- Metaland KYS CatalogueDokumen96 halamanMetaland KYS CataloguethomasoburBelum ada peringkat

- Weather Head E BRFI MC001 E3Dokumen159 halamanWeather Head E BRFI MC001 E3jeffls68688100% (1)

- 29 Life Expectancy of Piston Type Pumps and MotorsDokumen2 halaman29 Life Expectancy of Piston Type Pumps and Motorsbee140676Belum ada peringkat

- How To Prevent Pump Cavitation - EnggcyclopediaDokumen7 halamanHow To Prevent Pump Cavitation - EnggcyclopediaSurya DharmaBelum ada peringkat

- Model 1Dokumen68 halamanModel 1Prashanth Menon0% (1)

- Fluids Mechanics IiDokumen16 halamanFluids Mechanics IiJesús MorenoBelum ada peringkat

- Technical Service Manual: GeneralDokumen10 halamanTechnical Service Manual: GeneralmarceloieeeBelum ada peringkat

- Difference Between Pipeline, Piping, Tubing, Ducting & ConduitDokumen5 halamanDifference Between Pipeline, Piping, Tubing, Ducting & ConduitleepondiffBelum ada peringkat

- Gas LiftDokumen66 halamanGas LiftWahyu NugrahaBelum ada peringkat

- Affinity Laws For Variable Speed Centrifugal PumpsDokumen4 halamanAffinity Laws For Variable Speed Centrifugal PumpsSwapnil KadamBelum ada peringkat

- Experiment No. 2 Performance Test of Rotary Pump: GradeDokumen26 halamanExperiment No. 2 Performance Test of Rotary Pump: GradeAli Requiso MahmudBelum ada peringkat

- 05 Seat and o Ring TemperatureDokumen1 halaman05 Seat and o Ring TemperatureAndri AjaBelum ada peringkat

- Draft TubesDokumen11 halamanDraft TubesPrabath PereraBelum ada peringkat

- Arenado: Equipment DescriptionDokumen5 halamanArenado: Equipment DescriptionDiego GuajardoBelum ada peringkat

- Various Types of Faults in Turbine, GeneratorDokumen10 halamanVarious Types of Faults in Turbine, Generatorchanchalk007Belum ada peringkat

- Technical Information: Loop Flushing ValveDokumen8 halamanTechnical Information: Loop Flushing ValveanandsubbiahBelum ada peringkat

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe SpratDokumen2 halaman42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe Spratvelikimag87Belum ada peringkat

- Hydraulic System Introduction PDFDokumen13 halamanHydraulic System Introduction PDFPerrote Caruso PerritoBelum ada peringkat

- Auxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Dokumen81 halamanAuxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Arif MechanicalBelum ada peringkat

- Up6s 30 125Dokumen1 halamanUp6s 30 125Eddie SantillánBelum ada peringkat

- Milk Factory Visit ReportDokumen10 halamanMilk Factory Visit ReportshubhamrasalBelum ada peringkat

- Rotary Screw CompressorDokumen8 halamanRotary Screw Compressormanpreetsodhi08100% (2)

- ISO Standards For Oil & Gas IndustryDokumen5 halamanISO Standards For Oil & Gas Industrykaezzar10100% (2)

- PBFB en Us A4Dokumen1 halamanPBFB en Us A4operacion hydratekBelum ada peringkat

- Arv Facts PDFDokumen9 halamanArv Facts PDFReyBelum ada peringkat

- History Maintenance Forklift Dan Genset SRMDokumen24 halamanHistory Maintenance Forklift Dan Genset SRMGanong ZainalBelum ada peringkat

- Pressure Drop Calculation For EvaporatorDokumen5 halamanPressure Drop Calculation For EvaporatorCaleb FalcoteloBelum ada peringkat

- NETZSCH NEMO BY Pumps USADokumen2 halamanNETZSCH NEMO BY Pumps USAWawan NopexBelum ada peringkat

- Sullair 3009aDokumen72 halamanSullair 3009aveljim C.A67% (3)