SERIE C e PDF

Diunggah oleh

cochcorpJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SERIE C e PDF

Diunggah oleh

cochcorpHak Cipta:

Format Tersedia

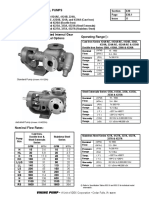

SPEC SHEET 1001-001 E

SECTION : 1001

Effective : January 2009

Replaces : September 2005

SERIE C Mouvex Technology

Eccentric disc pump

Seal free design

Seal free means leak free. Designed without mechanical

seal, packing or magnets, the C series eliminates

leakage and reduces maintenance time.

CIP & SIP abilities

The stainless steel version is designed to be flushed

and cleaned in place without disassembling.

Sanitary & Food applicable

The stainless steel models are ideal for sanitary

applications, carry 3A approval certification and are

designed per EHEDG recommendations.

I C

E Q U I P

M

H Y G

I E

N

D E S I G N

A N

U P

E U

R

Chemical applicable

The range of C pumps are in conformity with ATEX

certification.

II 2 G II B T4, T3

www.mouvex.com

SERIE C -

Mouvex Technology - Eccentric disc pump

Main advantages

Low pulsation effect

Self-priming with strong suction power

INLET

Ability to clear the pipes

Total flowrate

Ability to run dry

Low shear

Maintenance of the delivery/pressure performance

over time due to automatic disc/cylinder adjustment

Flowrate

Internal

flowrate

Outstanding volumetric efficiency

Pumped product constantly renewed

Ability to pump low and high viscosity products

Output not affected by viscosity variation

External

flowrate

OUTLET

Low linear speed

C SERIES (cross section)

0

50

100

Mouvex Technology

150

200

Angle ()

250

300

350

Pump without mechanical seal (seal free design)

Disc face to the cylinder (front view)

Disc (mobile)

Internal External

2 pumping chambers

Discharge port

400

Inlet port

Disc face to the cylinder (cross section)

Cylinder (stationary)

Low shearing

Disc

V

e

Displacement of the disc in the cylinder

The disc has an eccentric motion

(driven by an eccentric shaft).

Cylinder

Each point of the disc has the same linear speed.

We get a circular translation.

The mouvex technology allows a flowrate with low

linear speed.

V = .e

e : excentration of the shaft

V : linear speed

SERIE C -

Mouvex Technology - Eccentric disc pump

Stainless steel construction :

M3/h

36

C36i

BELLOWS :

316 Ti Stainless steel

DISC :

acton Stainless steel

CYLINDER : 316 L Stainless steel

BODYCASE : 316 L Stainless steel

24

C24i

18

SEAL :

FDA Viton (L gasket)

Viton ORing

C18i

Encapsulated teflon

Tflon (L gasket)

12

C12i

C8i

C4i

PORT :

SMS, DIN, CLAMP, IDF

Flanges PN16, PN20

C2i

C1i/C1i-VR

2

1

Rpm

450 500

750

1000

Stainless steel construction :

C Series Pump

Displacements (liters)

Max. outputs (m3/h)

Max. T (C) continuous

Max. pressure (bar)

C1i

C2i

(C1i-VR) (C2i-VR)

0,016

0,033

C4i

C8i

C12i

C18i

C24i

C36i

0,108

0,178

0,411

0,617

0,95

1,42

C4i-HT C8i-HT C12i-HT C18i-HT

0,108

0,178

0,411

12

18

24

36

12

18

100

100

100

100

100

100

100

100

150

150

150

150

1000

750

750

500

500

450

450

750

750

500

500

Particle passage* (mm3)

15

15

20

20

15

15

Opening size

(Suct/Disch) (mm)

40

40

50

50

60

60

70

70

50

50

60

60

CIP/SIP (120 C)

C1i

C2i

(C1i-VR) (C2i-VR)

C4i

C8i

C12i

C18i

C24i

C36i

20

20

35

35

38

38

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

Port (mm)

40

40

50

50

65

Weight (kg)

21 (24)

22 (25)

38

41

115

19

19

10

10

10

10

162

162

233

233

310,5

310,5

345,5

345,5

236

249,5

257

274

428

447,5

533,5

561,5

53

53

62

62

96,5

96,5

121

121

196

196

228

228

337

337

395

395

105

105

120

120

175

175

224

224

105,5

105,5

99

99

146,5

146,5

215

215

101

101

128,5

128,5

95,5

95,5

150

150

157

157

237,5

237,5

131,5

131,5

167

167

238

238

325,5

325,5

110

110

152

152

220

220

210

210

10

10

14

14

18

18

18

18

280

280

65

80

80

120

185

200

0,617

1000

Max. speed (Rpm)

C Series

Pump

YES (only with SS construction)

*no hard particles

Options

High temperature

Heating jacket

Mobile unit

Shroud

SERIE C -

Illustrations

Mouvex Technology - Eccentric disc pump

Stainless steel construction

Applications : varnish, painting, resin, glue,

isocyanate, oil, solvent

Applications :

isocyanate, polyol

C12i in painting industry

C 18a in chemical industry

Applications :

ointment, sirup, cream, suppository, shampoo

Applications :

flavour, sauce, chocolate, glucose

C18i in cosmetic/pharmaceutical industry

C1i-VR in food industry

Applications :

yeast, concentrate, glucose, flavour, alcohol

Applications :

yogurt, ferment, dessert, yolk

C4i in beverage industry

C2i in dairy industry

Cleaning recommandations

C1/C2

C4/C8

C12/C18

C24/C36

10

10

30/35

40/45

15

YES

NO

NO

NO

CIP outputs required (m /h) (maximum value)

3

Do we have to set up a bypass

CIP outputs (m3/h)

20

YES

NO

NO

NO

25

YES

YES

NO

NO

30

YES

YES

NO

NO

35

YES

YES

NO

NO

40

YES

YES

NO

NO

Setting without Bypass

Setting with Bypass

P maxi 3 bar

P maxi 3 bar

C Series

(Non driven pump)

C Series

(Non driven pump)

Cleaning in 2 steps (pump & installation)

3.1. Cleaning of the pump only

3.2. Cleaning of the installation

P maxi 6 bar

P maxi 3 bar

V1

C Series

(Non driven pump)

C Series

(Pump stopped)*

Return

towards CIP

or wasted water

V1 : 3 ways valve

(the pump is isolated)

Non driven pump = Pump no driven by the motor but could be driven by the CIP flush.

Pump stopped = Pump strictly stopped.

SERIE C -

Mouvex Technology - Eccentric disc pump

Ductile Iron

(Pump equipped with heating base and relief valve)

C Series Pump

C4a

C8a

C12a

C18a

Displacement (liters)

0,108

0,178

0,411

0,617

0,108

0,178

Max. flowrate (m3/h)

12

18

100

100

100

100

150

150

Max. T (C)

Max. pressure (bar)

Max. speed (Rpm)

C4a-HT C8a-HT

750

750

500

500

750

750

Particles passage* (mm3)

15

15

Opening size

(suct/dis) (mm)

50

50

60

60

50

50

*Pump equipped with flanges (PN16/20)

C Series Pump

C4a

C8a

C12a

C18a

20

233

242

67

254

120

20

233

259

67

254

120

35

10

310,5 384

109

363

175

12

35

10

310,5 384

109

363

175

172

C Series Pump

C4a

C8a

C12a

127

150

172

152

127

150

172

152

101

157

239

220

101

157

239

220

C18a

Port (mm)

50

50

65

65

Weignt (kg)

43

46

115

120

BELOWS :

DISC :

316 Ti

GS ductile

iron

CYLINDER : GS ductile

iron

BODYCASE : GS ductile

iron

RINGS :

Viton ORing

Encapsulated

teflon

FLANGES :

PN16, PN20

M3/h

18

C18a

12

C12a

C8a

C4a

Rpm

500

Mouvex reserves the right to modify the information and illustrations contained in this document

without prior notice. This is a non-contractual document. 01/09

Printed in FRANCE by Filigrane

2009 Mouvex

750

ZI la Plaine des Isles

rue des Caillottes

89000 AUXERRE - FRANCE

T + 33.3.86.49.86.30

F + 33.3.86.46.42.10

contact@mouvex.com

www.mouvex.com

Distributed by :

Anda mungkin juga menyukai

- My Grammar Booklet 2018Dokumen56 halamanMy Grammar Booklet 2018慈心100% (2)

- Blood Type "BDokumen2 halamanBlood Type "BBrenda Gutierrez100% (4)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDari EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceBelum ada peringkat

- Machines, Tools and Methods of Automobile ManufactureDari EverandMachines, Tools and Methods of Automobile ManufacturePenilaian: 4 dari 5 bintang4/5 (1)

- A New Extrusion ConceptDokumen18 halamanA New Extrusion ConceptLeonel VelasquezBelum ada peringkat

- Flygt PumpsDokumen104 halamanFlygt PumpsAchira Chanaka Peiris0% (1)

- Varun Beverage LTD: Strategy For Marketing Through Retail OutletsDokumen107 halamanVarun Beverage LTD: Strategy For Marketing Through Retail OutletsMunish SinghBelum ada peringkat

- Visual Flow Indicator Guide from Flow-MonDokumen12 halamanVisual Flow Indicator Guide from Flow-Mondhanu_aquaBelum ada peringkat

- Supplement ECD45Dokumen35 halamanSupplement ECD45Aprizal AzisBelum ada peringkat

- Under Her Towle Samantha 2017 Annas Archive Libgenrs Fic 2013042 PDFDokumen217 halamanUnder Her Towle Samantha 2017 Annas Archive Libgenrs Fic 2013042 PDFMaithri MurthyBelum ada peringkat

- How To French Polish Classical GuitarsDokumen29 halamanHow To French Polish Classical GuitarsMartin F. Martin100% (1)

- 20DIYBeautyRecipeseBook PDFDokumen28 halaman20DIYBeautyRecipeseBook PDFMaria100% (1)

- Lowara Multi-Stage Pumps CatalogueDokumen64 halamanLowara Multi-Stage Pumps Cataloguepinkypacho0% (1)

- Rotan Internal Gear Pumps: Desmi IncDokumen14 halamanRotan Internal Gear Pumps: Desmi IncVijay BhureBelum ada peringkat

- Diamec U4Dokumen2 halamanDiamec U4geovanny_ort100% (1)

- Pentax Cm50 PumpDokumen3 halamanPentax Cm50 Pumpvishal.nitham100% (1)

- KSB Centrifugal PumpsDokumen12 halamanKSB Centrifugal Pumpswoodywheel100% (1)

- A Comparative StudyDokumen40 halamanA Comparative StudyJaris Orobia100% (4)

- Volute Casing Pump Technical Data SheetDokumen11 halamanVolute Casing Pump Technical Data SheetAndresBelum ada peringkat

- IB English-PropagandaDokumen21 halamanIB English-PropagandaAna Ximena Trespalacios SilvaBelum ada peringkat

- Three Way Valve Technical OverviewDokumen8 halamanThree Way Valve Technical OverviewWalter JosephBelum ada peringkat

- HFENs ChallengeProgramme Week 2 Challenges Over25BMIDokumen18 halamanHFENs ChallengeProgramme Week 2 Challenges Over25BMISoftware NoxBelum ada peringkat

- Ricasoli Case StudyDokumen21 halamanRicasoli Case StudyRodianneBelum ada peringkat

- Catalogue HyvaDokumen222 halamanCatalogue HyvaEdgar Rojas Espejo100% (2)

- Product Training: DW - Rotary Lobe PumpDokumen48 halamanProduct Training: DW - Rotary Lobe PumpMantavya ShrimaliBelum ada peringkat

- Egger Impeller Brochure PDFDokumen10 halamanEgger Impeller Brochure PDFnbharath1988100% (1)

- Cargo Oil PumpDokumen17 halamanCargo Oil Pumpaloordominic100% (4)

- 2007 Danfoss CatalogueDokumen40 halaman2007 Danfoss CatalogueMiroslav AleksicBelum ada peringkat

- SPX Twin Screw Pumps PDFDokumen8 halamanSPX Twin Screw Pumps PDFarunkumar17Belum ada peringkat

- Instalasi POMPADokumen106 halamanInstalasi POMPAMeliaGrinaBelum ada peringkat

- Oi P 024 Tri Clover PumpDokumen9 halamanOi P 024 Tri Clover PumpGustavoBelum ada peringkat

- Bombas PCMDokumen12 halamanBombas PCMVictor ValdiviaBelum ada peringkat

- Esv Ie2 TD en PDFDokumen68 halamanEsv Ie2 TD en PDFCristian Muñoz AlarcónBelum ada peringkat

- PT - trasTI SUPPLIER (Pumps For Industry, Mining, Oil and Gas)Dokumen19 halamanPT - trasTI SUPPLIER (Pumps For Industry, Mining, Oil and Gas)Faturachman Reza100% (1)

- Vatech SB6-2YDokumen4 halamanVatech SB6-2YAlexander GuzmánBelum ada peringkat

- Catalogo Bomba Gabbioneta Modelo VBN PDFDokumen2 halamanCatalogo Bomba Gabbioneta Modelo VBN PDFPrabha KaranBelum ada peringkat

- Schwing SP 88Dokumen6 halamanSchwing SP 88Vittorio50% (2)

- Technical Focus: DG Ready Vane PumpDokumen6 halamanTechnical Focus: DG Ready Vane PumpJohnny Diaz VargasBelum ada peringkat

- KMT Aqua-Dyne Master CatalogDokumen36 halamanKMT Aqua-Dyne Master CatalogZeck100% (1)

- SchuF Valve Guide v6Dokumen57 halamanSchuF Valve Guide v6Adam Chapin100% (1)

- CP Range: Redefining Flow ControlDokumen8 halamanCP Range: Redefining Flow ControlSmootherBelum ada peringkat

- LOGICOSDokumen82 halamanLOGICOSManoloEskobarBelum ada peringkat

- Dosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)Dokumen8 halamanDosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)2009tamerBelum ada peringkat

- Submersible Drainage Pumps: For Clear WaterDokumen4 halamanSubmersible Drainage Pumps: For Clear Waternewaz2010Belum ada peringkat

- Alfa Laval Unique Mixproof Tank Outlet: Double Seat ValvesDokumen7 halamanAlfa Laval Unique Mixproof Tank Outlet: Double Seat Valvesمیلاد قاسمیBelum ada peringkat

- Check ValvesDokumen8 halamanCheck ValvesNilesh MistryBelum ada peringkat

- Ejector BrochureDokumen8 halamanEjector Brochurebabis1980Belum ada peringkat

- Grundfos LiteratureDokumen36 halamanGrundfos Literaturebenjiy80Belum ada peringkat

- MULTi-V NT ENG 50Hz PDFDokumen44 halamanMULTi-V NT ENG 50Hz PDFVíctor Fernández Narváez100% (1)

- LVH-C: Lowviscosity Housing-CoalescerDokumen5 halamanLVH-C: Lowviscosity Housing-CoalescerAzmi AhmadBelum ada peringkat

- Bombas Gorman RuppDokumen12 halamanBombas Gorman RuppRafael Hernández RcrewBelum ada peringkat

- Tapflo CT BrochureDokumen8 halamanTapflo CT BrochureСања БанковићBelum ada peringkat

- FlygtDokumen4 halamanFlygtToby Hopkins-AllanBelum ada peringkat

- KingLai Pump Catalogue 2009 10Dokumen24 halamanKingLai Pump Catalogue 2009 10aconibet9040100% (1)

- Ee Eipc3 5.englDokumen10 halamanEe Eipc3 5.englZoran JankovBelum ada peringkat

- BVA HydraulicsDokumen72 halamanBVA HydraulicsLeviBelum ada peringkat

- 05-Force Feed Lubrication SystemDokumen34 halaman05-Force Feed Lubrication SystemBookMaggotBelum ada peringkat

- Trailer Concrete PumpDokumen6 halamanTrailer Concrete Pumpmailme_vijuBelum ada peringkat

- CGL Centrifugal End Suction Pump O & M ManualDokumen6 halamanCGL Centrifugal End Suction Pump O & M ManualSaravanan ManiBelum ada peringkat

- 01 06 0013 PDFDokumen48 halaman01 06 0013 PDFoleg-spb100% (1)

- Bellin Catalogue PDFDokumen16 halamanBellin Catalogue PDFTC Mehmet ÖztürkBelum ada peringkat

- UC Series: Fire Fighting Equipments Designed According ToDokumen12 halamanUC Series: Fire Fighting Equipments Designed According ToJulio Acuña RBelum ada peringkat

- Motor PDFDokumen81 halamanMotor PDFmaungBelum ada peringkat

- Concrete Volute PumpsDokumen8 halamanConcrete Volute PumpsvijayunityBelum ada peringkat

- Dosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)Dokumen9 halamanDosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)jkhgvdj mnhsnjkhgBelum ada peringkat

- Sec 630Dokumen30 halamanSec 630cochcorpBelum ada peringkat

- TR 301 Temperature Range For ElastomersDokumen1 halamanTR 301 Temperature Range For ElastomerscochcorpBelum ada peringkat

- FAM - ADV - BRO - 05-BROUCHURE Advanced PDFDokumen32 halamanFAM - ADV - BRO - 05-BROUCHURE Advanced PDFcochcorpBelum ada peringkat

- Mine - Construction Pumps, Sandpiper Mine PumpsDokumen2 halamanMine - Construction Pumps, Sandpiper Mine PumpscochcorpBelum ada peringkat

- Specialdutydewatering Sma3adatasheetDokumen2 halamanSpecialdutydewatering Sma3adatasheetcochcorpBelum ada peringkat

- Why Choose Sandpiper Pumps: Double Diaphragm vs. OthersDokumen1 halamanWhy Choose Sandpiper Pumps: Double Diaphragm vs. OtherscochcorpBelum ada peringkat

- Course Guide Bar and BevDokumen6 halamanCourse Guide Bar and BevRoy CabarlesBelum ada peringkat

- Syrups Are Concentrated Aqueous Preparations of A Sugar or Sugar Substitute With or Without Flavoring Agents and Medicinal SubstancesDokumen2 halamanSyrups Are Concentrated Aqueous Preparations of A Sugar or Sugar Substitute With or Without Flavoring Agents and Medicinal SubstanceszuBelum ada peringkat

- MOOD CAFE'.BusinessPlan - DocsDokumen45 halamanMOOD CAFE'.BusinessPlan - DocsAshe'sha Kate VillaluzBelum ada peringkat

- Philippine Coffee Industry Roadmap 2017-2022: A Pathway to Global CompetitivenessDokumen63 halamanPhilippine Coffee Industry Roadmap 2017-2022: A Pathway to Global CompetitivenessNguyen Van KienBelum ada peringkat

- Icj 2013 05Dokumen48 halamanIcj 2013 05Tejas KotwalBelum ada peringkat

- Coffee Day Beverages - Sales Trainee 2022 BatchDokumen2 halamanCoffee Day Beverages - Sales Trainee 2022 Batchfaizan shaikhBelum ada peringkat

- h1n1 Master TonicDokumen2 halamanh1n1 Master TonicmmetaBelum ada peringkat

- Kellogg Company ReportDokumen32 halamanKellogg Company ReportRebekah KahaneBelum ada peringkat

- The Taste of Water in Japanese Garden Design by Wybe KuitertDokumen2 halamanThe Taste of Water in Japanese Garden Design by Wybe Kuitertjtuylvanrilland100% (1)

- Chinese Phrase GuideDokumen15 halamanChinese Phrase GuideNhel Crisostomo RoqueBelum ada peringkat

- Consumer Buying Behaviour Towards Pepsi and Coca-ColaDokumen11 halamanConsumer Buying Behaviour Towards Pepsi and Coca-ColaNeeru DhakaBelum ada peringkat

- Untitled DocumentDokumen3 halamanUntitled DocumentJBE legendsBelum ada peringkat

- The Five SensesDokumen8 halamanThe Five Sensesapi-300870263Belum ada peringkat

- Tjedan XXL Ušteda: Hit Cijena!Dokumen28 halamanTjedan XXL Ušteda: Hit Cijena!TomeBelum ada peringkat

- NIC CodesDokumen43 halamanNIC CodesSaurabh GuptaBelum ada peringkat

- A Look at Your Child's NutritionDokumen2 halamanA Look at Your Child's NutritionAslul KhitanBelum ada peringkat

- IBD Exam Booklet 2007Dokumen3 halamanIBD Exam Booklet 2007Adam MayBelum ada peringkat

- Liquid-Liquid Equilibria For The Water + Ethanol + Citral and Water + Ethanol + Limonene Systems at 293 KDokumen4 halamanLiquid-Liquid Equilibria For The Water + Ethanol + Citral and Water + Ethanol + Limonene Systems at 293 KpablobaladoBelum ada peringkat

- The Milk Teas Habits of 18 Year Onld Female Students in ISBADokumen23 halamanThe Milk Teas Habits of 18 Year Onld Female Students in ISBAQuang HuyBelum ada peringkat

- Nestlé: Usama AhmadDokumen26 halamanNestlé: Usama AhmadMuhammad Usama MunirBelum ada peringkat