S CH English

Diunggah oleh

liviuppDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

S CH English

Diunggah oleh

liviuppHak Cipta:

Format Tersedia

Series S-CH

You get more ways to close a sack with MEYPACK, standard or customized to fit your

application:

Continuous band sealer

Series S-CH/S...

Series PTS...

Series D95HD...

for heat sealing of coated paper sacks

and SOS-bags

for the closure of Pinch Top sacks with or

without plastic inner liner or coating

for sewing closures, also with over-tape

or folding

Series FTS...

Series PT...

for fold, tape and seal closures of paper

sacks, with or without plastic inner liner

or coating

for the traditional triple closure of paper

sacks with plastic inner liner

MEYPACK supplies complete sack closing lines, beginning after the filling spout and

ending just before the palletizer. The program includes:

ASF Automatic stretcher/feeder

KGL Plastic open link conveyor

SB

Single belt conveyor

SWU Sack turning device

SAS Sack pusher

KSF Spreader/feeder for bag in box

SEG Sack folder for bag in box

ZU

Sack folder for secondary folding

FTS-based special machinery for air bag manufacture

For heat sealing of heavy duty

plastic sacks, light plastic sacks

and woven fabrics sacks with

plastic inner liner

Continuous process for highest

throughput

Combined sack closing line for FTS- and sewing closures

MEYPACK Verpackungssystemtechnik GmbH

Werk Schenefeld, DOBOY

Kiebitzweg 18

D-22869 Schenefeld

Telefon ++49-40-83902-0 Fax ++49-40-8309482

e-mail: sales.bag.closing@meypack.de

S-CH/W-3H with infeed from left to right with integrated conveyor SB and water refrigeration unit

Series S-CH...

Method of operation

MEYPACK offers continuous band sealers in a wide variety of

performance ranges for safe hermetically tight closures of

plastic sacks. The perfectly homogenous sealing with heater

bars and continuously moving bands is done under pressure.

On machines with water cooling bars the sealing seams are

cooled down under pressure between the steel bands. This

gives incomparable smooth seams. Otherwise, with the also

possible air cooling the seams get wrinkled due to free shrinking. Further optional equipment fits the machines to difficult

applications, e. g. dusty filling goods.

The bag closing machines series S-CH... use the continuous

sealing process. The bag is guided at the seal level by PTFEcoated steel bands through the heating section. This guarantees the most efficient heat transfer and avoids direct contact

of the plastic film with the heat source. Heavy duty carrier

chains running synchronously immediately below the steel

bands grip the bag top and maintain control through the entire

machine. At the same time the sack is supported by a conveyor

(additional equipment).

The heating section consists of heater bars, number depending

on machine type and required throughput. The automatic

temperature control of the heater bars enables the user to run

the machine constantly with a sealing process perfectly set to

the bag specification. After heat sealing the sack passes

cooling bars or air blowers to cool down the seam.

S-CH/D 95-3H

S-CH... -made seal

Machine data

Type

Features

rugged design for multi-shift operation

Machines S-CH/D95... which are equipped with swing needle

sewing heads D95 are used for the closure of woven fabrics

sacks with plastic inner liner. They heat seal the inner liner and

sew all layers of the sack.

high heat efficiency due to springloaded heater bars

simple operation and maintenance due to good

accessibility

a minimum of change-over time is required for

varying bag dimensions

manual or fully automatic sack feeding

compatible with any common open mouth sack

feeding system

Special options available

bag top trimmer

cleaning station

overtape applicator

emboss coder

sewing head

electromotive elevating device

water refrigeration unit

direction of feed from left to right

Eex-specification

not all options are compatible with every model

S-CH... -made seal with PE-overtape

BD-HD

Heating

section mm

200

Cooling

1 pair water cooling bars

vmax.

m/min

Pdrive

kW

Pheating

kW

0,55

0,9

2025

975

1910

450

Lenght Width Height Mass

mm

mm

mm ca. kg

S-CH/A-2H

2 x 200

air cooling tubes

19

0,55

1,8

2550

1080

1910

600

S-CH/W-2H

2 x 200

2 pairs water cooling bars

19

0,55

1,8

2550

1080

1910

600

S-CH/A-3H

3 x 200

air cooling tubes

19

0,55

2,7

2810

1045

1910

700

S-CH/W-3H

3 x 200

2 pairs water cooling bars

19

0,55

2,7

2810

1045

1910

700

S-CH/A-5H

5 x 200

air cooling tubes

22

1,1

4,5

3350

1045

1910

900

S-CH/W-5H

5 x 200

2 pairs water cooling bars

22

1,1

4,5

3350

1045

1910

900

S-CH/D95-2H

2 x 200

air cooling tubes

0,9

1,8

3185

1045

2800

650

S-CH/D95-3H

3x 200

air cooling tubes

13,5

0,9

2,7

3445

1045

2800

750

S-CH/D95-5H

5x 200

2 pairs water cooling bars

21

1,6

4,5

3985

1045

2800

950

Further types and variations are possible.

Pillow type sacks made from films 70...300 m are sealable, at gusseted sacks or with overtape the total thickness is limited

to 1000 m.

Anda mungkin juga menyukai

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Series S-CH/S : Continuous Crimp SealerDokumen2 halamanSeries S-CH/S : Continuous Crimp SealerliviuppBelum ada peringkat

- Series PTS : Sack Closing MachinesDokumen2 halamanSeries PTS : Sack Closing MachinesliviuppBelum ada peringkat

- Series PT : Sack Closing MachinesDokumen2 halamanSeries PT : Sack Closing MachinesliviuppBelum ada peringkat

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshDari EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshBelum ada peringkat

- Series FTS : Sack Closing MachinesDokumen2 halamanSeries FTS : Sack Closing MachinesliviuppBelum ada peringkat

- Illustrated Catalogue of Cotton MachineryDari EverandIllustrated Catalogue of Cotton MachineryBelum ada peringkat

- Series D95 HD : Sack Closing MachinesDokumen2 halamanSeries D95 HD : Sack Closing MachinesliviuppBelum ada peringkat

- Vacuum FormingDokumen4 halamanVacuum FormingAzizol WahabBelum ada peringkat

- Hot RunnerDokumen98 halamanHot RunnerSree Raj67% (3)

- Blown Film CoexDokumen4 halamanBlown Film CoexTaeng SoshiBelum ada peringkat

- Castflex EngDokumen12 halamanCastflex EngJuanBelum ada peringkat

- Extrusion InformationDokumen29 halamanExtrusion InformationNishant1993100% (1)

- Funke Semiwelded Cassette WarmtewisselaarDokumen4 halamanFunke Semiwelded Cassette Warmtewisselaaranilkumar995472Belum ada peringkat

- Anopack F11 DuplexDokumen15 halamanAnopack F11 DuplexRăzvan Dinu100% (1)

- ViFlow Funke GB PDFDokumen8 halamanViFlow Funke GB PDFukalBelum ada peringkat

- Thermo WaveDokumen127 halamanThermo WaveFernando Molina100% (2)

- TrayMfg ESD Catalog 2015Dokumen12 halamanTrayMfg ESD Catalog 2015Nicholas FlandinBelum ada peringkat

- CSI Bolt-On Heating SystemsDokumen12 halamanCSI Bolt-On Heating Systemspeubrandao100% (1)

- Raffia Tape Line ProcessDokumen20 halamanRaffia Tape Line ProcessSumeet Rathor100% (12)

- 2 Stage Wet LaminatingDokumen2 halaman2 Stage Wet LaminatingdanceBelum ada peringkat

- Samwoo Catalogue 2012Dokumen24 halamanSamwoo Catalogue 2012quyBelum ada peringkat

- Manual Uponor MeltawayDokumen12 halamanManual Uponor MeltawayUPOTERMBelum ada peringkat

- Packaging AssignmentDokumen11 halamanPackaging AssignmentAbhijeetKumarBelum ada peringkat

- Alfa Laval Astepo Combibox: Compact Cartoning System For Use in The Food and Beverage IndustriesDokumen2 halamanAlfa Laval Astepo Combibox: Compact Cartoning System For Use in The Food and Beverage IndustriesJosefina DiasBelum ada peringkat

- Cooling TunnelDokumen7 halamanCooling TunnelAmit Kumar OjhaBelum ada peringkat

- Plastic Extrusion ProcessDokumen8 halamanPlastic Extrusion ProcessAmir NawazBelum ada peringkat

- Steriline TunnelDokumen8 halamanSteriline TunnelHutHeoBelum ada peringkat

- Thermoforming EquipmentDokumen9 halamanThermoforming EquipmentA MahmoodBelum ada peringkat

- An Introduction To Single Screw Extrusion: Table of ContentsDokumen6 halamanAn Introduction To Single Screw Extrusion: Table of ContentsKuzhaliBelum ada peringkat

- Fls Ball MillDokumen8 halamanFls Ball Millrazen_inBelum ada peringkat

- Quang Minh Industrial Machinery Trading CoDokumen16 halamanQuang Minh Industrial Machinery Trading CoNgoc Phuc NguyenBelum ada peringkat

- TL90-1500M GB 01Dokumen4 halamanTL90-1500M GB 01salamrefighBelum ada peringkat

- Name:-Ebrahim Abd EL-Hadi Ebrahim Section: - 1 Department: - Mechatronics (4 Year)Dokumen22 halamanName:-Ebrahim Abd EL-Hadi Ebrahim Section: - 1 Department: - Mechatronics (4 Year)Ebrahim Abd El HadyBelum ada peringkat

- MMT BM 201 enDokumen2 halamanMMT BM 201 enValiBelum ada peringkat

- Kustner AV YH enDokumen2 halamanKustner AV YH enyasser0% (2)

- Pressofiltro Nutsche Filter / Filter DryerDokumen2 halamanPressofiltro Nutsche Filter / Filter Dryerviajes cdcBelum ada peringkat

- Compression and Transfer MoldingDokumen12 halamanCompression and Transfer MoldingpandalynaBelum ada peringkat

- Multipass Belt Tunnel FreezerDokumen11 halamanMultipass Belt Tunnel FreezerAbas S. AcmadBelum ada peringkat

- 9 4 Sludge DryingDokumen17 halaman9 4 Sludge Dryingkosmc123Belum ada peringkat

- Extrusion Blow MouldingDokumen13 halamanExtrusion Blow Mouldingkish007rdBelum ada peringkat

- Conveyor Ovens - Continuous ProcessDokumen2 halamanConveyor Ovens - Continuous ProcessAmalina SolahuddinBelum ada peringkat

- Alfa Laval PHEDokumen16 halamanAlfa Laval PHESergio SmithBelum ada peringkat

- P-Usg: Underwater Strand Pelletizing Systems For Cost-Eff Ective ProductionDokumen8 halamanP-Usg: Underwater Strand Pelletizing Systems For Cost-Eff Ective Productionruk1921Belum ada peringkat

- Tablet and Capsule Section EquipmentDokumen26 halamanTablet and Capsule Section EquipmentBhushan patilBelum ada peringkat

- Fastening White Paper SMDokumen10 halamanFastening White Paper SMxitta00Belum ada peringkat

- Preform MoldDokumen6 halamanPreform MoldMichelle IngramBelum ada peringkat

- Calander PDFDokumen14 halamanCalander PDFansari_poly5264100% (1)

- Tecpesa. BrochureDokumen54 halamanTecpesa. Brochureyiyita01Belum ada peringkat

- Drying CabinetDokumen6 halamanDrying CabinetMelindaTanudjajaBelum ada peringkat

- Heat ExchangerDokumen10 halamanHeat ExchangerTan Vu HoBelum ada peringkat

- En HSM Vertical Baling Presses 2012-04Dokumen16 halamanEn HSM Vertical Baling Presses 2012-04Rodrigo CerveiraBelum ada peringkat

- Differentiation Between Strand Pellet Is Ing & Die Phase Pellet Is IngDokumen22 halamanDifferentiation Between Strand Pellet Is Ing & Die Phase Pellet Is IngJohn Mathew100% (1)

- What Heat SealerDokumen14 halamanWhat Heat SealerAarajita ParinBelum ada peringkat

- Stenter & DryerDokumen18 halamanStenter & DryerMasud Rana100% (1)

- Calendering - 8Dokumen14 halamanCalendering - 8Muhammad ChawlaBelum ada peringkat

- Transfer MouldingDokumen20 halamanTransfer MouldingSuranjana MandalBelum ada peringkat

- Rama HotrunnerDokumen43 halamanRama Hotrunner1keyvan1Belum ada peringkat

- AASHTO Shear Calculator, No Stirrups: Code Values of Beta and ThetaDokumen6 halamanAASHTO Shear Calculator, No Stirrups: Code Values of Beta and ThetaAnantPawarBelum ada peringkat

- Diamond Like Carbon (DLC)Dokumen30 halamanDiamond Like Carbon (DLC)Agnivesh SharmaBelum ada peringkat

- Release Bearing Noise With Pedal UpDokumen2 halamanRelease Bearing Noise With Pedal UpKB JongBelum ada peringkat

- Robitic WeldingDokumen23 halamanRobitic Weldingkhaled osmanBelum ada peringkat

- SONY Radio ICF-SW1 Disassembly - RepairDokumen9 halamanSONY Radio ICF-SW1 Disassembly - RepairMicheal speedBelum ada peringkat

- Lecture07 Pipeflow HandoutDokumen3 halamanLecture07 Pipeflow Handoutgtarun22gupta50% (2)

- CEFIC Guidelines Transport Equipment Packed Cargo (2010)Dokumen7 halamanCEFIC Guidelines Transport Equipment Packed Cargo (2010)sl1828Belum ada peringkat

- Laticrete 325 SW AdhesiveDokumen4 halamanLaticrete 325 SW AdhesiveAmeya MungaleBelum ada peringkat

- Vol 6 Report 186-Coatings and Inks For Food Contact Materials PDFDokumen142 halamanVol 6 Report 186-Coatings and Inks For Food Contact Materials PDFvaducBelum ada peringkat

- English For Technical Students and Engineers - 1 PDFDokumen60 halamanEnglish For Technical Students and Engineers - 1 PDFMîndru LaraBelum ada peringkat

- MR366X8423A000Dokumen128 halamanMR366X8423A000Guillermo MV100% (1)

- Tank PDFDokumen7 halamanTank PDFCarlos Eduardo Cueva CallerBelum ada peringkat

- Steel Plates For Offshore StructuresDokumen8 halamanSteel Plates For Offshore StructuresYiengeChanYeeBelum ada peringkat

- Advanced Lattice Support Structures For Metal Additive ManufacturingDokumen8 halamanAdvanced Lattice Support Structures For Metal Additive Manufacturinghadi32Belum ada peringkat

- Water and Wastewater Treatment-Monroe EnvironmentalDokumen20 halamanWater and Wastewater Treatment-Monroe EnvironmentalHussein Ali Mahdi Al-ZubaidyBelum ada peringkat

- Asko D5424 ManualDokumen36 halamanAsko D5424 ManuallksmrBelum ada peringkat

- Product Catalogue (ARZTECH SOLUTION) PDFDokumen5 halamanProduct Catalogue (ARZTECH SOLUTION) PDFAzizy YusofBelum ada peringkat

- Cryogenics - in BriefDokumen4 halamanCryogenics - in BriefAnnamalai Ram JGCBelum ada peringkat

- Chapter 1 Part 1Dokumen80 halamanChapter 1 Part 1anil kumarBelum ada peringkat

- LG wd-1457rd 1458rdDokumen42 halamanLG wd-1457rd 1458rdGlen CastlemanBelum ada peringkat

- CTX510 - Eco TUE FA V1.1 EN - 000Dokumen104 halamanCTX510 - Eco TUE FA V1.1 EN - 000Miliano FilhoBelum ada peringkat

- Defects and CausesDokumen58 halamanDefects and CausesPrasannaVenkatesan100% (2)

- BodyDokumen69 halamanBodyRoi Benedict BuenaBelum ada peringkat

- Equilibrium Staged OperationsDokumen11 halamanEquilibrium Staged OperationsdeeptankBelum ada peringkat

- Final Report 3D Chocolate PrintingDokumen20 halamanFinal Report 3D Chocolate PrintingPrathamesh PatilBelum ada peringkat

- Aalco CatalogueDokumen37 halamanAalco CatalogueLLBelum ada peringkat

- Process Flow Chart of Knitting: A. Stitch LengthDokumen9 halamanProcess Flow Chart of Knitting: A. Stitch LengthAushru HasanBelum ada peringkat

- Polymer in Energy Conversion and StorageDokumen10 halamanPolymer in Energy Conversion and StorageinnocentBelum ada peringkat

- FS 608 Spec Guide V8Dokumen1 halamanFS 608 Spec Guide V8Irfan IceBelum ada peringkat

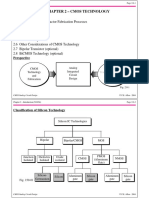

- Silicon Wafer and Ingot Preparation PDFDokumen23 halamanSilicon Wafer and Ingot Preparation PDFprinceBelum ada peringkat