Brazing

Diunggah oleh

Anonymous qRbPsLpuNHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Brazing

Diunggah oleh

Anonymous qRbPsLpuNHak Cipta:

Format Tersedia

Brazing.

Joining metals by flowing a thin capillary thickness layer, of nonferrous filler metal

into the space between them. Bonding results from the intimate contact produced by dissolution of

a small amount of base metal into the molten filler metal, without fusion of the base metal. The

term

brazing is used when the temperature exceeds some arbitrary value, typically 470C (880F).

Carbon Restoration. Heating and holding a metal above the critical temperature (Ac1) in contact

with a suitable carbonaceous atmosphere which may be solid, liquid, or gas for the purpose of

restoring carbon by adding it to the surface. The amount of carbon added is usually sufficient to

return

the material to the original carbon content prior to a heat treat operation that reduced this carbon

level.

Carbonitriding. The introduction of carbon and nitrogen into a solid ferrous alloy by holding

above the critical temperature (Ac1) in an atmosphere that contains suitable gases, such as

hydrocarbons,

carbon monoxide, and ammonia. The carbonitrided alloy is usually quench hardened. Other

common names and related subjects are case hardening, dry cyaniding, gas cyaniding, nicarbing,

and nitrocarburizing (obsolete).

Carburizing. The introduction of carbon into a solid ferrous alloy by holding above the critical

temperature (Ac1) in contact with a suitable carbonaceous atmosphere which may be solid, liquid,

or

gas. The carburized alloy is usually quench hardened. Other common names and related subjects

are

case hardening, gas carburizing, and cyaniding.

Cryogenic Treatment. The cooling of a material to a temperature low enough to promote the

transformation of phases. Other common names and related subjects are deep freezing, cold

treatment,

and subzero treatment.

Ferrous. A metal of, related to, or containing iron.

Hardening. An increase in the hardness of a material by suitable treatment usually involving

heating

and cooling. Other common names and related subjects are neutral hardening, quench hardening,

flame hardening, induction hardening, laser hardening, and surface hardening.

Homogenizing. Holding at high temperature to eliminate or decrease chemical segregation by

diffusion. The resultant composition is uniform with coring and concentration gradients eliminated.

Materials Science. The science and technology of materials. Metals and nonmetals are included

in this field of study.

Metals. (1) An opaque lustrous element that is a good conductor of heat and electricity and when

polished a good reflector of light. Most metals are malleable and ductile and, in general, heavier

than

other elemental substances. (2) Metals are distinguished from nonmetals by their atomic binding

and

electron availability. Metallic atoms tend to lose electrons from the outer shells. (3) An elemental

Anda mungkin juga menyukai

- Safety - Incident Rate: Causal Factors - All IncidentsDokumen1 halamanSafety - Incident Rate: Causal Factors - All IncidentsAnonymous qRbPsLpuNBelum ada peringkat

- Book 2Dokumen2 halamanBook 2Anonymous qRbPsLpuNBelum ada peringkat

- Operational Excellence ResumesDokumen26 halamanOperational Excellence ResumesAnonymous qRbPsLpuNBelum ada peringkat

- Resume PacketDokumen35 halamanResume PacketVishal IyerBelum ada peringkat

- DOE TerminologyDokumen1 halamanDOE TerminologyAnonymous qRbPsLpuNBelum ada peringkat

- Book 2Dokumen2 halamanBook 2Anonymous qRbPsLpuNBelum ada peringkat

- Brainstorming: Planning: Selection of The Right Team - PeopleDokumen1 halamanBrainstorming: Planning: Selection of The Right Team - PeopleAnonymous qRbPsLpuNBelum ada peringkat

- 3.2.2 Program Management Performance DomainsDokumen1 halaman3.2.2 Program Management Performance DomainsAnonymous qRbPsLpuNBelum ada peringkat

- Supplier DataDokumen1 halamanSupplier DataAnonymous qRbPsLpuNBelum ada peringkat

- Business Process Management SuiteDokumen1 halamanBusiness Process Management SuiteAnonymous qRbPsLpuNBelum ada peringkat

- 50 Topics of Interest To The SDokumen1 halaman50 Topics of Interest To The SAnonymous qRbPsLpuNBelum ada peringkat

- Table 15.2 10 Characteristics of Effective Information Technology (IT) DeploymentDokumen1 halamanTable 15.2 10 Characteristics of Effective Information Technology (IT) DeploymentAnonymous qRbPsLpuNBelum ada peringkat

- Developed 15 Supplier On Brakes Parts DevelopmentDokumen2 halamanDeveloped 15 Supplier On Brakes Parts DevelopmentAnonymous qRbPsLpuNBelum ada peringkat

- Management ProcessDokumen1 halamanManagement ProcessAnonymous qRbPsLpuNBelum ada peringkat

- Pre-Course Questionnaire APQP/ PPAP TrainingDokumen2 halamanPre-Course Questionnaire APQP/ PPAP TrainingAnonymous qRbPsLpuNBelum ada peringkat

- Early TQM FrameworksDokumen1 halamanEarly TQM FrameworksAnonymous qRbPsLpuNBelum ada peringkat

- Overview of Program ManagementDokumen1 halamanOverview of Program ManagementAnonymous qRbPsLpuNBelum ada peringkat

- Kanban CirculationDokumen1 halamanKanban CirculationAnonymous qRbPsLpuNBelum ada peringkat

- Perhaps The Most Visible Difference Between A Process Management Enterprise and A MoreDokumen1 halamanPerhaps The Most Visible Difference Between A Process Management Enterprise and A MoreAnonymous qRbPsLpuNBelum ada peringkat

- The Role of Operations StrategyDokumen1 halamanThe Role of Operations StrategyAnonymous qRbPsLpuNBelum ada peringkat

- Inventory and VariationDokumen1 halamanInventory and VariationAnonymous qRbPsLpuNBelum ada peringkat

- GANT: Creating Value Across A Virtual NetworkDokumen1 halamanGANT: Creating Value Across A Virtual NetworkAnonymous qRbPsLpuNBelum ada peringkat

- Source ToolingDokumen1 halamanSource ToolingAnonymous qRbPsLpuNBelum ada peringkat

- Relations Among Sales Price, Cost, and ProfitDokumen1 halamanRelations Among Sales Price, Cost, and ProfitAnonymous qRbPsLpuNBelum ada peringkat

- Types of EstimatesDokumen1 halamanTypes of EstimatesAnonymous qRbPsLpuNBelum ada peringkat

- Mutual Aid SystemDokumen1 halamanMutual Aid SystemAnonymous qRbPsLpuNBelum ada peringkat

- Individual Efficiency and Overall EfficiencyDokumen1 halamanIndividual Efficiency and Overall EfficiencyAnonymous qRbPsLpuNBelum ada peringkat

- Just in TimneDokumen1 halamanJust in TimneAnonymous qRbPsLpuNBelum ada peringkat

- Ten Arguments Against The JITDokumen1 halamanTen Arguments Against The JITAnonymous qRbPsLpuNBelum ada peringkat

- Code of Professional ConductDokumen1 halamanCode of Professional ConductAnonymous qRbPsLpuNBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rexnord Bearings Catalog: Download The Most Up-To-Date VersionDokumen530 halamanRexnord Bearings Catalog: Download The Most Up-To-Date VersionCelmira Borda AcuñaBelum ada peringkat

- Indian Standard: Guide For Lateral Dynamic Load Test On PilesDokumen21 halamanIndian Standard: Guide For Lateral Dynamic Load Test On PilesSubodh SontakkeBelum ada peringkat

- HEAVILY LOADED COLUMN - COLUMN 800x800 - AT BASEMENT LEVELDokumen1 halamanHEAVILY LOADED COLUMN - COLUMN 800x800 - AT BASEMENT LEVELRavi ShankarBelum ada peringkat

- Mary Beth D. Hueste, John B. Mander, and Anagha S. Parkar: Technical Report Documentation PageDokumen8 halamanMary Beth D. Hueste, John B. Mander, and Anagha S. Parkar: Technical Report Documentation Pagemohamed ahmedBelum ada peringkat

- Laser - WikipediaDokumen148 halamanLaser - WikipediaAnkur SinghBelum ada peringkat

- Advanced Quantum Physics: Lecture HandoutDokumen5 halamanAdvanced Quantum Physics: Lecture HandoutPhyo ThihaBelum ada peringkat

- FEM Question Bank PDFDokumen23 halamanFEM Question Bank PDFedla rajuBelum ada peringkat

- Voltas Product Presentation Chillers1Dokumen32 halamanVoltas Product Presentation Chillers1KamalMuralikumarBelum ada peringkat

- Name:Sajeel Khan Roll#:M.phil-SSP-03-F19 Class:M.phil-SSP (Morning) Subject: Defect in Solids Submitted TO:Dr. Ijaz Mujtaba Ghauri SBDokumen10 halamanName:Sajeel Khan Roll#:M.phil-SSP-03-F19 Class:M.phil-SSP (Morning) Subject: Defect in Solids Submitted TO:Dr. Ijaz Mujtaba Ghauri SBAnonymous f7wV1lQKRBelum ada peringkat

- 1 Introduction To Reservoir Rock PropertiesDokumen20 halaman1 Introduction To Reservoir Rock PropertiesAram RafiqBelum ada peringkat

- QUIZ 4 Disaster Readiness and Risk ReductionDokumen3 halamanQUIZ 4 Disaster Readiness and Risk ReductionRain GamboaBelum ada peringkat

- Empirical Solutions: Ozgur KisiDokumen73 halamanEmpirical Solutions: Ozgur Kisieko dateshidzeBelum ada peringkat

- Goodbye, Hazen Hello, Kozeny-CarmanDokumen3 halamanGoodbye, Hazen Hello, Kozeny-CarmanOscarBelum ada peringkat

- Lesson 6.2 Chemical ReactionsDokumen20 halamanLesson 6.2 Chemical Reactions16394-Karm M. Basel KabbaniBelum ada peringkat

- Mechanics of Deformable BodiesDokumen106 halamanMechanics of Deformable Bodiesgilbert casinoBelum ada peringkat

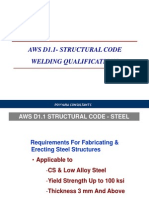

- Aws D1.1welding Qualification.Dokumen10 halamanAws D1.1welding Qualification.idealparrotBelum ada peringkat

- Pittcon TechnicalProgramDokumen68 halamanPittcon TechnicalProgramAyse Demir-KorkmazBelum ada peringkat

- Operating MicroscopeDokumen26 halamanOperating MicroscopeAlfred Fredrick0% (1)

- NSS Phy Curriculum (Notes For Teachers)Dokumen30 halamanNSS Phy Curriculum (Notes For Teachers)energy0124Belum ada peringkat

- ME 308 Machine Elements Ii: Spring Design - 2Dokumen50 halamanME 308 Machine Elements Ii: Spring Design - 2xxxBelum ada peringkat

- Lecture-05 Reservoir Pressure&TemperatureDokumen20 halamanLecture-05 Reservoir Pressure&TemperatureShuvro Aakash100% (1)

- Aakash Test Planner: Aiats Test For Class-Xi (Medical)Dokumen3 halamanAakash Test Planner: Aiats Test For Class-Xi (Medical)Bharat GelotBelum ada peringkat

- A Study On Mechanical Properties of Polydimethylsiloxane (PDMS) CompositesDokumen13 halamanA Study On Mechanical Properties of Polydimethylsiloxane (PDMS) Compositesacademic researchBelum ada peringkat

- PhysicsDokumen5 halamanPhysicsAnuBelum ada peringkat

- Finite Element Analysis of Soil Bearing Capacity Using PlaxisDokumen5 halamanFinite Element Analysis of Soil Bearing Capacity Using PlaxisRehan HakroBelum ada peringkat

- Chemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-605::aid-Cite6054444-3.0.Co 2-g) Görge Baltin Heinz Köser Klaus-Peter Wendlandt - Reactive DesorDokumen1 halamanChemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-605::aid-Cite6054444-3.0.Co 2-g) Görge Baltin Heinz Köser Klaus-Peter Wendlandt - Reactive Desorlili purwasihBelum ada peringkat

- Jurnal Dinding Penahan TanahDokumen11 halamanJurnal Dinding Penahan TanahAnonymous 7npIQ1kYDBelum ada peringkat

- Chemistry SM XI 2021-22Dokumen154 halamanChemistry SM XI 2021-22SHRUTI AGARWALABelum ada peringkat

- Automatic Transmission 42REDokumen121 halamanAutomatic Transmission 42REmtaylor030% (7)