SpiralHE-12 1 1-Rev8 PDF

Diunggah oleh

Teuku Husein FahsyaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SpiralHE-12 1 1-Rev8 PDF

Diunggah oleh

Teuku Husein FahsyaHak Cipta:

Format Tersedia

Optimize Heat Transfer

Efficiency and Space

Compact, Efficient Heat Exchanger

for Severe Service

Features

Description

Flow rates to 100 GPM (378 LPM)

A spiral tube heat exchanger is a coil assembly

fitted in a compact shell that optimizes heat transfer

efficiency and space. Every Sentry spiral coil assembly

has welded tube to manifold joints for durability and

strength. The coil assembly is welded to a head and

fitted in a compact shell. The spaces or gaps between

the coils of the spiral tube bundle become the shell

side flow path.

Sample conditions up to 5000 psi (345 bar) and up

to 1000F (540C)

Optimal design for corrosive fluid/gases

Vapor condensing/gas stripping capabilities

High flow in a small footprint

Highly resistant to thermal and hydraulic shock

Bolted or all welded shell

Numerous flow path and connection configurations

Compact and lightweight, easy to install

The spiral shape of the flow for the tubeside and

shellside fluids creates centrifugal force and secondary

circulating flow that enhances the heat transfer on both

sides in a true counterflow arrangement. Since there

are a variety of multiple parallel tube configurations

(diameter, number and length), efficiency is not

compromised by limited shell diameter sizes as it is in

shell and tube designs.

The profile of a spiral is very compact and fits in a

smaller footprint than a shell and tube design. Since

the tube bundle is coiled, space requirements for tube

bundle removal are significantly reduced.

When exotic material is required, a spiral tube heat

exchanger minimizes the material used since manifolds

replace the channels, heads and tubesheets of a

conventional shell and tube design. The shell side

is usually smaller than a comparable shell and tube

design and there are no requirements for tube supports

or pass dividers.

www.sentry-equip.com

12.1.1 Rev. 9 06/12

Spiral tube heat exchanger

spiral tube heat exchanger

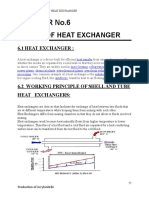

CROSS SECTION OF A SPIRAL TUBE HEAT EXCHANGER

Optimized Performance

Multiple tube side parameters (diameter, length, number

and material).

Variable shellside flow path gap and length.

Easy to Install

Simple piping and access.

Easy to remove shell for inspection, cleaning or replacement

of tube bundle. Virtually no tube bundle pull requirement.

SPECIFICATIONS

Materials:

Shellside

Carbon Steel & Stainless Steel

Tube Bundle

Stainless Steel, Hastelloy, Inconel and other alloys

Standard Pressure Rating:

Shellside

150 psig (10.3 barg) @ 400F (204C)

Tubeside

up to 5000 psig (345 barg) @ 1000F (540C)

Construction:

Shellside

Bolted or welded with NPT, FLG, SW or BW connections

Tubeside

Welded tube to manifold joints with NPT, FLG, SW or BW connections

Surface Area:

1 to 177 ft (0.1 to 16 m)

ASME Code Stamp available upon request

TYPICAL APPLICATIONS

Pump seal coolers

Inter / After coolers

Instant hot water heaters

Sample coolers

Acid heaters/coolers

Process condensers

It is solely the responsibility of the end-user, through its own analysis and testing, to select products and materials suitable for their specific

application requirements, ensure they are properly installed, safely applied, properly maintained, and limit their use to their intended purpose.

Improper selection, installation, or use may result in personal injury or property damage.

SENTRY EQUIPMENT CORP

For further information, contact:

966 Blue Ribbon Circle North

Oconomowoc, WI 53066 USA

Tel: 262-567-7256 Fax: 262-567-4523

E-mail:

sales@sentry-equip.com

Website:

www.sentry-equip.com

Sentry Equipment Corp 2006

12.1.1 Rev. 9 06/12

Anda mungkin juga menyukai

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Air Cooled Heat Exchangers - GEA BrochureDokumen16 halamanAir Cooled Heat Exchangers - GEA BrochurenorthstarleoBelum ada peringkat

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDari EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsPenilaian: 4 dari 5 bintang4/5 (6)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- Protec SPD BrochureDokumen4 halamanProtec SPD BrochureCrestBelum ada peringkat

- AUC-Knowledge QuestionsDokumen68 halamanAUC-Knowledge QuestionsFarhan SethBelum ada peringkat

- General CRT tester notesDokumen64 halamanGeneral CRT tester notesImran AliBelum ada peringkat

- Spiral Tube Heat ExchangerDokumen2 halamanSpiral Tube Heat ExchangerM AhmadBelum ada peringkat

- SpiralHE12 1 1 PDFDokumen2 halamanSpiralHE12 1 1 PDFaqibazizkhanBelum ada peringkat

- Air Fin CoolersDokumen43 halamanAir Fin Coolersbharatbellad100% (2)

- Sentry - Spiral Tube Heat Exchangers - 2016Dokumen2 halamanSentry - Spiral Tube Heat Exchangers - 2016Victor PomboBelum ada peringkat

- Air-Cooled Heat Exchangers Fin-Fan: by M.M.SorourDokumen64 halamanAir-Cooled Heat Exchangers Fin-Fan: by M.M.SorourNader GaafarBelum ada peringkat

- Heat Exchanger With Helical BafflesDokumen8 halamanHeat Exchanger With Helical BaffleshuangjlBelum ada peringkat

- ABC 200 Heat ExchangerDokumen200 halamanABC 200 Heat Exchanger전상문100% (2)

- Design Procedure For Pressure VesselDokumen200 halamanDesign Procedure For Pressure VesselSuryaprakash100% (1)

- Sample Coolers: Water - Steam - ProcessDokumen8 halamanSample Coolers: Water - Steam - ProcessSiriusAlazred100% (1)

- Shell-and-tube Heat Exchangers SolutionsDokumen24 halamanShell-and-tube Heat Exchangers SolutionsSubrata DasBelum ada peringkat

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDokumen18 halamaneBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xBelum ada peringkat

- How To Select Shell and Tube HEDokumen10 halamanHow To Select Shell and Tube HEgigihpradana100% (1)

- 112.09 Heat Exchangers BrochureDokumen4 halaman112.09 Heat Exchangers BrochureAlexandru DinaBelum ada peringkat

- Air-Cooled Heat ExchangersDokumen16 halamanAir-Cooled Heat Exchangersalex200301Belum ada peringkat

- SEC Spiral Heat Exchangers BrochureDokumen4 halamanSEC Spiral Heat Exchangers BrochureShrikant Nimbalkar100% (1)

- Hairpin heat exchanger design delivers high performance in a compact footprintDokumen1 halamanHairpin heat exchanger design delivers high performance in a compact footprint7761430Belum ada peringkat

- Application Note: Sentry Spiral Tube Heat Exchanger Vent Condenser ApplicationDokumen2 halamanApplication Note: Sentry Spiral Tube Heat Exchanger Vent Condenser ApplicationraritylimBelum ada peringkat

- Air-Cooled Heat Exchangers: LectureDokumen39 halamanAir-Cooled Heat Exchangers: LectureBaraa Shurbaji No 111Belum ada peringkat

- Basic Construction of Shell & Tube Heat ExchangersDokumen12 halamanBasic Construction of Shell & Tube Heat ExchangerslatshareBelum ada peringkat

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDokumen2 halaman01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoBelum ada peringkat

- Chemical Engineering Assignment SubmissionDokumen10 halamanChemical Engineering Assignment SubmissionFahad KamranBelum ada peringkat

- Presentation For Shell & Tub Heat ExchangerDokumen33 halamanPresentation For Shell & Tub Heat ExchangerHoa Hoang PhuBelum ada peringkat

- Sample Cooler Catalogue-SeplDokumen2 halamanSample Cooler Catalogue-SeplHANIF AKBARBelum ada peringkat

- LNG Applications of Diffusion Bonded HEXDokumen9 halamanLNG Applications of Diffusion Bonded HEXrowanlimBelum ada peringkat

- Chapter No.6: Design of Heat ExchangerDokumen35 halamanChapter No.6: Design of Heat ExchangerGlacier RamkissoonBelum ada peringkat

- 1 PBDokumen12 halaman1 PBscata1117Belum ada peringkat

- AH AV CatalogDokumen16 halamanAH AV CatalognomurapreBelum ada peringkat

- Heat Ex Changer Model Selection TypeDokumen10 halamanHeat Ex Changer Model Selection TypenoxleekBelum ada peringkat

- Cooling Tower SpecificationDokumen14 halamanCooling Tower SpecificationAmzad DPBelum ada peringkat

- Thermal Analysis of Tubular Heat Exchangers Using ANSYS: GANDHI .R - 51321340805Dokumen2 halamanThermal Analysis of Tubular Heat Exchangers Using ANSYS: GANDHI .R - 51321340805Anthoni RajBelum ada peringkat

- Basics of Double Pipe Heat Exchanger (Heat Transfer Slides)Dokumen38 halamanBasics of Double Pipe Heat Exchanger (Heat Transfer Slides)Asad Imran Munawwar100% (2)

- TEMA Type BEU or AEU Heat Exchanger GuideDokumen15 halamanTEMA Type BEU or AEU Heat Exchanger GuidemaruthigabbitaBelum ada peringkat

- Dezurik Valve Selection PDFDokumen28 halamanDezurik Valve Selection PDFnoklit15100% (1)

- DX Evaporator CoilsDokumen3 halamanDX Evaporator CoilsSME CoilsBelum ada peringkat

- Valve Selection GuideDokumen20 halamanValve Selection GuideGagandeep SinghBelum ada peringkat

- Shell and Tube SpecificationsDokumen7 halamanShell and Tube SpecificationsRenju AntonyBelum ada peringkat

- PHT Unit-5 (THEORY)Dokumen81 halamanPHT Unit-5 (THEORY)521 Balaji OBelum ada peringkat

- 400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Dokumen22 halaman400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Esteban CastellanoBelum ada peringkat

- Designing AND Optimization OF A Shell and Tube Heat ExchangerDokumen8 halamanDesigning AND Optimization OF A Shell and Tube Heat ExchangerAyush SinghBelum ada peringkat

- Air Fin Cooler CatalougeDokumen14 halamanAir Fin Cooler Catalougesammar_10Belum ada peringkat

- Air Cooled Screw Chiller R134aDokumen12 halamanAir Cooled Screw Chiller R134aamitbslpawar0% (1)

- 500mwboilermahagenco 140115124304 Phpapp02Dokumen38 halaman500mwboilermahagenco 140115124304 Phpapp02Lakshmi NarayanBelum ada peringkat

- Basco - Type - Es-Heat Exchangers BrochureDokumen8 halamanBasco - Type - Es-Heat Exchangers BrochureMarco Andrés Guevara LunaBelum ada peringkat

- Gem Chiller Catalogue Proof - 27 4 13Dokumen4 halamanGem Chiller Catalogue Proof - 27 4 13abianshbaralBelum ada peringkat

- NDE 2011 Proceedings Discusses Quality Control of Tube Joints in Fast Breeder ReactorsDokumen5 halamanNDE 2011 Proceedings Discusses Quality Control of Tube Joints in Fast Breeder ReactorsvaibraineaterBelum ada peringkat

- Capillary Evaporator DevelopmentDokumen13 halamanCapillary Evaporator DevelopmentArjun ChaliyathBelum ada peringkat

- Sanitary Dual Tube Coil: High Efficiency Tube-In-Tube Heat ExchangerDokumen2 halamanSanitary Dual Tube Coil: High Efficiency Tube-In-Tube Heat ExchangerparsmessengerBelum ada peringkat

- REMF-197 Design and Fabrication of Pulse Tube Refrigeration SystemDokumen4 halamanREMF-197 Design and Fabrication of Pulse Tube Refrigeration SystemretechBelum ada peringkat

- Especificaciones Blower CoilDokumen6 halamanEspecificaciones Blower CoilolivaresjhonBelum ada peringkat

- Boiler Pressure PartsDokumen3 halamanBoiler Pressure PartsBedabyas DehuryBelum ada peringkat

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDokumen6 halaman882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- Rod BaffelsDokumen2 halamanRod BaffelsVenkatesh SivarchanaBelum ada peringkat

- 4030 / 4280 Series: End Suction PumpsDokumen8 halaman4030 / 4280 Series: End Suction PumpsShrikant WalseBelum ada peringkat

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationDari EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationBelum ada peringkat

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDari EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesBelum ada peringkat

- Modules Test ReportDokumen4 halamanModules Test ReportprojectsBelum ada peringkat

- Maintain Safe Systems with Maintenance Free EarthingDokumen12 halamanMaintain Safe Systems with Maintenance Free EarthingRavi Shankar ChakravortyBelum ada peringkat

- Data FNC BatteriesDokumen20 halamanData FNC BatteriessalmanahmedmemonBelum ada peringkat

- Dyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.Dokumen10 halamanDyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.L.N.CHEMICAL INDUSTRYBelum ada peringkat

- Elizabeth Hokanson - Resume - DB EditDokumen2 halamanElizabeth Hokanson - Resume - DB EditDouglBelum ada peringkat

- Oops NotesDokumen79 halamanOops NotesaminBelum ada peringkat

- Ac Split Inverter PDFDokumen69 halamanAc Split Inverter PDFjewd100% (1)

- 2011 PG Parts CatalogDokumen181 halaman2011 PG Parts CatalogHaitem FarganiBelum ada peringkat

- Army C-sUAS Systems AssessmentDokumen4 halamanArmy C-sUAS Systems AssessmentArthur WongBelum ada peringkat

- Project Title: Hospital Management System Description: Hospital Management System Is A Web Based Project. It Consists of Client RegistrationDokumen68 halamanProject Title: Hospital Management System Description: Hospital Management System Is A Web Based Project. It Consists of Client Registrationshahid198950% (2)

- Mansoura University B07 Plumbing SubmittalDokumen139 halamanMansoura University B07 Plumbing SubmittalEslam MamdouhBelum ada peringkat

- Auto Parts Manufacturing in China: Ibisworld Industry ReportDokumen33 halamanAuto Parts Manufacturing in China: Ibisworld Industry ReportSaira BanuBelum ada peringkat

- Mechanical Advantage and EfficiencyDokumen16 halamanMechanical Advantage and EfficiencyYadana1Belum ada peringkat

- 1 Guntha Horizontal Green Poly House ProjectDokumen1 halaman1 Guntha Horizontal Green Poly House ProjectRajneeshBelum ada peringkat

- Session Plan (Julaps)Dokumen10 halamanSession Plan (Julaps)Wiljhon Espinola JulapongBelum ada peringkat

- Modern Control Technology Components & Systems (2nd Ed.)Dokumen2 halamanModern Control Technology Components & Systems (2nd Ed.)musarraf172Belum ada peringkat

- ME116P Weeks 1-4Dokumen243 halamanME116P Weeks 1-4Ska dooshBelum ada peringkat

- C++ FundamentalsDokumen207 halamanC++ Fundamentalsbrm1shubhaBelum ada peringkat

- Airbus A300-600/A310 Landing Gear SystemsDokumen190 halamanAirbus A300-600/A310 Landing Gear SystemsRaph 1123Belum ada peringkat

- Creative Photography Lab 52 Fun Exercises For Developing Self-Expression With Your CameraDokumen146 halamanCreative Photography Lab 52 Fun Exercises For Developing Self-Expression With Your Camerajwestmister100% (2)

- LSIS - Molded Case Circuit Breaker (MCCB) - CatalogDokumen140 halamanLSIS - Molded Case Circuit Breaker (MCCB) - CatalogNguyen LuongBelum ada peringkat

- Online Shopping RequirementsDokumen19 halamanOnline Shopping Requirementsbruh tesheme100% (1)

- Hi Tech ApplicatorDokumen13 halamanHi Tech ApplicatorSantosh JayasavalBelum ada peringkat

- Turan Balik - ResumeDokumen3 halamanTuran Balik - Resumeapi-250561031Belum ada peringkat

- Data Book: Automotive TechnicalDokumen1 halamanData Book: Automotive Technicallucian07Belum ada peringkat

- Netsh Wlan Start HostednetworkDokumen3 halamanNetsh Wlan Start HostednetworkM Nanda KumarBelum ada peringkat

- Isye6501 Office Hour Fa22 Week07 ThuDokumen10 halamanIsye6501 Office Hour Fa22 Week07 ThuXuan KuangBelum ada peringkat