In Pulse™ II: Applications

Diunggah oleh

Fabio JuniorJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

In Pulse™ II: Applications

Diunggah oleh

Fabio JuniorHak Cipta:

Format Tersedia

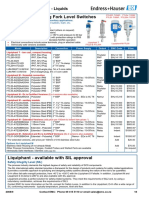

ProductSpecification03315

(Rev.D,11/2012)

InPulseII

FuelInjectionControl

Applications

The Woodward

In-Pulse ll fuel

injection control

manages and

controls

electronically fuel

injected (EFI)

reciprocating

engines (gas,

diesel, or dual

fuel) used in

power

generation,

marine propulsion, locomotive and industrial engine, and process markets.

The In-Pulse ll manages the core fuel system and injection events for many EFI fuel

systems, including electronic unit injectors and pumps (EUI/EUP), common rail

systems (C-R), SOGAV Solenoid Operated Gas Admission Valves, micro pilot

injection systems, and electronic rail valves (ERV).

The In-Pulse ll can mount directly on the engine, withstanding the high temperature

and vibration environment. The In-Pulse ll can also be mounted inside nearby control

cabinets if required.

The In-Pulse ll, with the addition of an 18-channel driver board, uses the same

packaging, digital core, software tools, communication ports, I/O, and features of the

733 Digital Control (see product specification 03304). Therefore where common

engine types utilize different fuel systems, seamless interchangeability of the core

fuel control can be easily accomplished without redesigning the complete engine

management system.

If required, the In-Pulse ll can be used as the main control unit within an engine

management system. The control is designed for network connectivity to other

Woodward or customer-selected devices, such as remote I/O modules, actuators,

ignition controls, air/exhaust and fuel flow control valves, and power management

controls. It may be programmed to perform all engine functions such as speed, air

and fuel control, monitoring, alarms, engine protection, and sequencing.

The In-Pulse II improves engine management or plant control system reliability by

offering many redundant options, including redundant networks, redundant speed

and position sensors, redundant power supply inputs, and a second In-Pulse ll wired

as a hot stand-by for critical applications or where marine classification requires it.

Because of the many philosophies with respect to sensing speed and crank position,

the control incorporates multiple sensing algorithms that include missing tooth and

pin detection on the crank or cam for sensing speed and crank position. If sensor

failure protection is required, redundant sensors can be employed.

On-engine

mounting

Controls up to 18

outputs

Processor

technology and I/O

is based on the

733 digital control

Multiple sensor

detection options

Redundant speed

sensor options

Up to 7 injection

events per cylinder

Programmable

current profiles for

each injection

event

Woodward GAP

programming

environment

Redundant single

propulsion marine

configurations

CSA and CSAUL

listed

CE Compliant

Woodward 03315 p.2

Programming

The In-Pulse ll is programmed using Woodwards proven GAP Graphical Application Programmer. GAP is a

dedicated, high-level, block-oriented programming language specifically designed for simple and quick

implementation of difficult engine control strategies. GAP functions are easily modified and expanded, allowing fast

creation of new applications.

Adjustments

Adjustments can be made quickly and easily through the Woodward Watch Window or Control View PC configuration

interfaces. Both adjustment methods are menu-driven. The control saves all set points to non-volatile memory upon

command. More information is on our website (www.woodward.com).

Communications

The In-Pulse ll provides two isolated serial interfacesone RS-232 and the other RS-485. Both ports feature an

industry-standard Modbus * protocol (ASCII or

RTU) that can interface to a Modbus master or slave device such as a Human/Machine Interface (HMI). These ports

also support Woodward ServLink protocol for a Watch Window or Control View PC interface. Baud rates are tunable

to meet specific user requirements.

The In-Pulse ll also provides three CAN ports, one of which is isolated if requested. All ports feature J1939 and

CANOpen protocols. These ports can be used for distributed control with other devices such as actuators, valves,

other In-Pulse ll controls and 733s (to load share for example), and to communicate with other on-engine devices

such as I/O modules and displays. The isolated port is well suited for communication to off-engine components like

PLCs, ship and building systems.

* Modbus is a trademark of Schneider Automation Inc.

SelfDiagnostics

The In-Pulse ll has integrated diagnostics to determine the control and IO integrity. Memories, processor, IO, and

baseline power supply monitoring are included in the diagnostic tests.

Load Share CAN bus

Gen Power Meter

Air Control Valve

Ignition Controller

CAN-Engine Level

Gen Protection Relay

CAN-guidance level

In-Pulse II

ProAct Actuator

PLC

RS232

Port

Building

MGMT

System

RS485

Port

Modbus

Remote

System

Alarm

System

Local Display

T/C & RTD Temperature Scanner

Expansion I/O Module(s)

Mains Protection Relay

Typical In-Pulse ll System Diagram

Woodward 03315 p.3

Specifications

Input Power

Voltage

Power Consumption

Speed Signal Inputs (2)

Speed Input Voltage

Speed Input Frequency

Proximity Input Duty Cycle

Magnetic Pickup Diagnostics

Discrete Inputs (8)

Type

Discrete Input

Impedance

Proximity Probe Frequency/Duty Cycle

PWM Frequency/Duty Cycle

Analog Inputs (4)

Type

Input Impedance

Resolution

Accuracy

Current Outputs, 420 mA (3)

Type

Accuracy

Resolution

Diagnostics

Current Outputs, 4-20/20-160 mA (1)

Type

Accuracy

Resolution

Diagnostics

Discrete/PWM Outputs (4)

Type

Max Output Current

PWM Frequency Range

Proximity Probe Power Output (1)

Voltage Level

Current Limit

Injector Outputs (18)

Voltage Level

Current Limit

Type

Max Operating Temperature

Storage Temperature

Humidity

Mechanical Vibration

Mechanical Shock

Enclosure Protection

70125 Vdc (110 Vdc nominal)

Application-specific

Magnetic Pickup: 1.470.0 V peak-to-peak

Proximity Probe: 528 Vdc

10 Hz to 25 kHz

1090% to 10 kHz, 2080% to 20 kHz

Open wire detection

4 isolated inputs can be configured for PWM, digital, or proximity probes

4 non-isolated inputs are dedicated discrete inputs

Sinking with internal pull-up

15 k

10 Hz 7 kHz / 1090% to 3 kHz, 2080% to 7 kHz

100 Hz 1 kHz / 1090% duty cycle

420 mA, transducers externally powered

200

12 bits

0.5% of full scale

420 mA

0.5% of full scale

14 bits

Current readback provided

420 mA or 20160 mA

0.8% of full scale (420 mA) or 1.1% of full scale (20160 mA)

14 bits

Current readback provided

Isolated outputs sinking to dedicated return

Each output can be configured as either a discrete or PWM output

500 mA (Boolean) or 150 mA (PWM)

501000 Hz (configurable)

15 Vdc, isolated

60 mA

70125 Vdc (as applied at input terminals)

20 A pull-in (configurable)

May also be configured as 6 PWM FCV drivers (3 A limit)

Environment

On-engine mounting with application-defined temperature limits

40 to +120 C (40 to +248 F)

95% at +60 C (+140 F)

US MIL-STD 202F, Method 214A, TC(B)

US MIL-STD 810C, Method 516.2, Procedure I

IP-66

Regulatory Compliance

North American:

CSA:

European Compliance for CE Marking:

EMC Directive:

ATEX Potentially Explosive

Atmospheres Directive:

CSA Certified for Class I, Division 2, Groups A, B, C, and D, T3C at 85 C ambient.

For use in Canada and the United States. Certificate 1718321

Declared to 2004/108/EC COUNCIL DIRECTIVE of 15 Dec 2004 on the

approximation of the laws of the Member States relating to electromagnetic

compatibility.

Declared to 94/9/EC COUNCIL DIRECTIVE of 23 March 1994 on the

approximation of the laws of the Member States concerning equipment and

protective systems intended for use in potentially explosive atmospheres.

Zone 2, Category 3, Group II G, Ex nA IIC T3 Gc X IP66

Woodward 03315 p.4

In-Pulse ll Outline Drawing

Loop Power

>

>

>

>

4-20mA

4-20mA

4-20mA

4-20mA

Off Engine

MPU/Prox Speed #2

CAN #2

On Engine

DI/PWM/Prox #1

CAN #3

On Engine

DI/PWM/Prox #2

RS232

Configuration

DI/PWM/Prox #3

RS485

Modbus

DI/PWM/Prox #4

Digital/PWM Output #1

Isol Return

Digital/PWM Output #2

Digital Input #5

Digital/PWM Output #3

Digital Input #6

Digital/PWM Output #4

Digital Input #7

Dout Power

Digital Input #8

Digital Output PS Ret.

MPU/Prox Speed #1

DC

I/O Return

Actuator Output #1

Analog Input #1

Actuator Output #2

Analog Input #2

Analog Output #3

Analog Input #3

Analog Output #4

Analog Input #4

Sensor Power Supply

18-32 Vdc

DC

In-Pulse II

CAN #1

Backup Power Supply

Fuel Injectors

4-20mA, 20-160mA

4-20mA

4-20mA

4-20mA

15Vdc, 60mA

36

18 inj. (6 FCV)

Common

DC

70-125 Vdc

Injector Power Supply

In-Pulse ll Control Block Diagram

For more information contact:

PO Box 1519, Fort Collins CO, USA 80522-1519

1000 East Drake Road, Fort Collins CO 80525

Tel.: +1 (970) 482-5811 Fax: +1 (970) 498-3058

www.woodward.com

Distributors & Service

Woodward has an international network of distributors and service facilities.

For your nearest representative, call the Fort Collins plant or see the

Worldwide Directory on our website.

This document is distributed for informational purposes only. It is not to be construed as

creating or becoming part of any Woodward contractual or warranty obligation unless

expressly stated in a written sales contract.

Copyright Woodward 20032012, All Rights Reserved

Anda mungkin juga menyukai

- Cicuit Temp Air y OleoDokumen12 halamanCicuit Temp Air y OleoFabio JuniorBelum ada peringkat

- K-Suite 1.89Dokumen3 halamanK-Suite 1.89Fabio JuniorBelum ada peringkat

- Drawings PO80335843Dokumen8 halamanDrawings PO80335843Fabio JuniorBelum ada peringkat

- F63 Series Liquid Level Float SwitchDokumen8 halamanF63 Series Liquid Level Float SwitchFabio JuniorBelum ada peringkat

- InteliGen 6.0 PDFDokumen19 halamanInteliGen 6.0 PDFFabio JuniorBelum ada peringkat

- F63 SeriesDokumen3 halamanF63 SeriesFabio JuniorBelum ada peringkat

- LINC L471manualDokumen20 halamanLINC L471manualFabio JuniorBelum ada peringkat

- InteliGen 6.0 PDFDokumen19 halamanInteliGen 6.0 PDFFabio JuniorBelum ada peringkat

- ELC Data SheetDokumen2 halamanELC Data SheetFabio Junior100% (1)

- 1117 RTDDokumen5 halaman1117 RTDNa Rukok Sibak JoeBelum ada peringkat

- Liquid Level Float Switch: Description AccessoriesDokumen1 halamanLiquid Level Float Switch: Description AccessoriesFabio JuniorBelum ada peringkat

- Emerson Thermowell Pressure RatingDokumen1 halamanEmerson Thermowell Pressure RatingFabio JuniorBelum ada peringkat

- Anzex 07 3081 VM WSVMDokumen14 halamanAnzex 07 3081 VM WSVMFabio Junior0% (1)

- NVS Needle ValveDokumen1 halamanNVS Needle ValveFabio JuniorBelum ada peringkat

- Farris 3800 ManualDokumen12 halamanFarris 3800 ManualNelson AlvarezBelum ada peringkat

- L471 VerDokumen18 halamanL471 VerFabio JuniorBelum ada peringkat

- Liquiphant Vibrating Fork Level SwitchesDokumen1 halamanLiquiphant Vibrating Fork Level SwitchesFabio JuniorBelum ada peringkat

- Asco - Iom 327 SeriesDokumen4 halamanAsco - Iom 327 SeriesFabio JuniorBelum ada peringkat

- LFR-D enDokumen16 halamanLFR-D enFabio JuniorBelum ada peringkat

- Mcm3320 Servico 2012 InglesDokumen312 halamanMcm3320 Servico 2012 InglesFabio Junior100% (2)

- An951 PDFDokumen14 halamanAn951 PDFFabio JuniorBelum ada peringkat

- Cat Electronic Tech Nician 2014A v1.0Dokumen27 halamanCat Electronic Tech Nician 2014A v1.0Fabio JuniorBelum ada peringkat

- Tle 6220 PDFDokumen17 halamanTle 6220 PDFFabio JuniorBelum ada peringkat

- Data Sheet PDFDokumen13 halamanData Sheet PDFFabio JuniorBelum ada peringkat

- MC68 Adm PDFDokumen128 halamanMC68 Adm PDFFabio JuniorBelum ada peringkat

- Tle 6220 PDFDokumen17 halamanTle 6220 PDFFabio JuniorBelum ada peringkat

- C-11, C-13, C-15 TS Manual 2006 PDFDokumen420 halamanC-11, C-13, C-15 TS Manual 2006 PDFFabio Junior83% (6)

- XC9572 In-System Programmable CPLD: Features DescriptionDokumen9 halamanXC9572 In-System Programmable CPLD: Features DescriptionManish PushkarBelum ada peringkat

- XC9572 In-System Programmable CPLD: Figure 1: Typical I vs. Frequency For XC9572Dokumen8 halamanXC9572 In-System Programmable CPLD: Figure 1: Typical I vs. Frequency For XC9572Siddhi Nitin MahajanBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- CFEExam Prep CourseDokumen28 halamanCFEExam Prep CourseM50% (4)

- BAR Digest MenuDokumen4 halamanBAR Digest MenuFloila Jane YmasBelum ada peringkat

- 4.5.1 Forestry LawsDokumen31 halaman4.5.1 Forestry LawsMark OrtolaBelum ada peringkat

- Ice Cream Cost Benefit AnalysisDokumen12 halamanIce Cream Cost Benefit AnalysischarlotteBelum ada peringkat

- Journal Publication FormatDokumen37 halamanJournal Publication FormatAbreo Dan Vincent AlmineBelum ada peringkat

- Death Without A SuccessorDokumen2 halamanDeath Without A Successorilmanman16Belum ada peringkat

- ASCE - Art Competition RulesDokumen3 halamanASCE - Art Competition Rulesswarup babalsureBelum ada peringkat

- Gattu Madhuri's Resume for ECE GraduateDokumen4 halamanGattu Madhuri's Resume for ECE Graduatedeepakk_alpineBelum ada peringkat

- Difference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDokumen2 halamanDifference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDharma Teja TanetiBelum ada peringkat

- CORE Education Bags Rs. 120 Cr. Order From Gujarat Govt.Dokumen2 halamanCORE Education Bags Rs. 120 Cr. Order From Gujarat Govt.Sanjeev MansotraBelum ada peringkat

- Gary Mole and Glacial Energy FraudDokumen18 halamanGary Mole and Glacial Energy Fraudskyy22990% (1)

- SE Myth of SoftwareDokumen3 halamanSE Myth of SoftwarePrakash PaudelBelum ada peringkat

- Haryana Retial GarmentsDokumen8 halamanHaryana Retial Garmentssudesh.samastBelum ada peringkat

- EWAIRDokumen1 halamanEWAIRKissy AndarzaBelum ada peringkat

- Part I-Final Report On Soil InvestigationDokumen16 halamanPart I-Final Report On Soil InvestigationmangjuhaiBelum ada peringkat

- Cars Should Be BannedDokumen3 halamanCars Should Be BannedIrwanBelum ada peringkat

- FEM Lecture Notes-2Dokumen18 halamanFEM Lecture Notes-2macynthia26Belum ada peringkat

- SyllabusDokumen4 halamanSyllabusapi-105955784Belum ada peringkat

- Introduction To Elective DesignDokumen30 halamanIntroduction To Elective Designabdullah 3mar abou reashaBelum ada peringkat

- An Overview of Tensorflow + Deep learning 沒一村Dokumen31 halamanAn Overview of Tensorflow + Deep learning 沒一村Syed AdeelBelum ada peringkat

- Hardened Concrete - Methods of Test: Indian StandardDokumen16 halamanHardened Concrete - Methods of Test: Indian StandardjitendraBelum ada peringkat

- Enerflex 381338Dokumen2 halamanEnerflex 381338midoel.ziatyBelum ada peringkat

- Top Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Dokumen1 halamanTop Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Surya JamesBelum ada peringkat

- Conplast SP430 0407Dokumen4 halamanConplast SP430 0407Harz IndBelum ada peringkat

- Simplex Addressable Breakglass PDFDokumen12 halamanSimplex Addressable Breakglass PDFNurrul Ahmad Hidayat100% (1)

- 1LE1503-2AA43-4AA4 Datasheet enDokumen1 halaman1LE1503-2AA43-4AA4 Datasheet enAndrei LupuBelum ada peringkat

- Week 3 SEED in Role ActivityDokumen2 halamanWeek 3 SEED in Role ActivityPrince DenhaagBelum ada peringkat

- Software EngineeringDokumen3 halamanSoftware EngineeringImtiyaz BashaBelum ada peringkat

- AnkitDokumen24 halamanAnkitAnkit MalhotraBelum ada peringkat

- PS300-TM-330 Owners Manual PDFDokumen55 halamanPS300-TM-330 Owners Manual PDFLester LouisBelum ada peringkat