Transmoto Gearing

Diunggah oleh

rockydog360Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Transmoto Gearing

Diunggah oleh

rockydog360Hak Cipta:

Format Tersedia

On The Tools

TECH SERIES

In coming issues:

1

2

3

4

Suspension MODS

How to get the most from

your suspension budget.

GEARING

Understanding sprocket combos

and optimising gear ratios.

CARBS & EFI

Clever tuning tips to get

your air/fuel ratio right.

NUTS & BOLTS

How to remove broken bolts &

get the right torque settings.

GEARING

and how to make it work for you

The right gearing can transform the way your bike drives and handles. We take

the mystique out of the sprocket math to help you tailor your ride.

NICK DOLE

Transmoto Expert

dirt bikes chain and sprockets operate in a nasty,

open-to-the-elements environment, and yet

wed be lost without them. Over the years, weve

tried shaft-drives, hydraulics and belt-drives, but we keep

coming back to the humble roller drive-chain invented by

a Greek around 300BC. Why? Because they suit dirt bikes

perfectly. Theyre tough, simple, light, create minimal

power loss and theyre cheap.

Sure, shaft-drives are quieter and require far less

maintenance, but theyre heavy in an unsprung mass kind

iKAPTURE

of way, plus they make gearing changes difficult.

And while belt-drives are quieter and more efficient

than shafts, sand, rocks and mud make very short work

of their lifespan.

So what makes this world of chains and sprockets

tick? How can you alter you bikes power and handling

characteristics with different gearing combinations?

And how can gearing changes make life in the saddle

more enjoyable? Youre a few toothy pages away from

enlightenment.

GEARING GLOSSARY

Countershaft sprocket the countershaft

delivers the power out of the gearbox, and

the front/drive/countershaft sprocket is

attached to it.

WHO DA DOLE?

Cush-drive (hub) a rear hub designed to

have a carrier mounted to it so the engines

drive or torque pulsations are dampened

by large rubber blocks. This saves the

gearbox from shock-loading. There are

also aftermarket cush sprockets available.

Low-noise sprocket has a ring of

rubber bonded to it so the chain runs

on it. Theyre common on trailbikes,

and can be replaced with a non-rubber

type with accompanying noise.

Gear up/taller/higher gearing the drive

ratio is numerically decreased by fitting

a smaller rear sprocket and/or a larger

front sprocket.

Gear down/shorter/lower gearing

the drive ratio is numerically increased

by fitting a larger rear sprocket and/or

a smaller front sprocket.

Loctite proprietary name (eponym)

for an anaerobic thread-locking agent.

That is, it hardens in the absence of air.

Final drive chain and sprockets

in combination as a gearing set.

Nick Dole owns and operates Sydney-based

suspension business, Teknik Motorsport.

In the past decade, the man has tuned

suspension for the Ballards Offroad

team, performed engine and suspension

work on Australian Safari-winning GHR

Honda XR650s, run a Kawasaki Pro Lites

team in the Aussie MX Nats, worked as

an independent technical consultant for

magazine test programs, and dealt with

just about every punter and butchered

dirt bike to ever roll into a workshop.

We reckon that qualifies him to offer up

credible advice about how to get the most

out of your spend at the local workshop.

Tech Savvy?

Log onto www.transmoto.com.au for more detailed

information, and an archive of tech features.

116

117

hy do we have a gearbox at all? Why

not just run in a single gear? After

all, gear changes cost you time on the track,

right? Well, if we were punting a go-kart

running around a flat course, not changing

gears is a practical way to go faster. Unlike

go-karts, dirt bikes need to start from a

standstill, climb hills and have a broad speed

range. This is why many enduro bikes have

six-speed gearboxes, why most motocross

and how to make it work for you

GEARING

and how to make it work for you

GEARING

WHY

GEARING

Tech

IS IMPORTANT...

Gearing changes can make

the one bike versatile in

a variety of situations.

bikes have five-speed boxes, and why bigbore machines with oodles of torque can get

away with four-speed transmissions.

So, for a given gearbox, how do we tailor

the final drive to suit us? That all depends

on where you use the bike and how you like

to ride it. Do you ride to work and rev the

engine hard at 110km/h? Gearing can solve

that. Do you struggle to get up big hills?

Gearing can help there, too.

HOW GEARING

AFFECTS...

MOTOR

Back in the pre power-valve days, where

125s produced 30hp between 10,400 rpm

and 10,500rpm and 15hp either side of it,

gearing was critical for keeping an engine

on the pipe. These days, user-friendly twostrokes and new-generation four-strokes

have made life easier with their flatter

and more forgiving torque curves. But we

still have the same objective: to utilise the

engines torque to pull us around. Underrevving (labouring) and over-revving an

engine have never been ways to extract its

best. So whether you want some more snap

off the bottom, less gear changes per lap,

or a higher top-speed, gearing changes can

achieve this for you.

MX/SX

you can comfortably grab third earlier for

a smoother drive? Is there a long straight

that you are grabbing a gear on towards the

end and wasting time? Are you forced to

upshift dangerously close to the upramp of

a big jump? These are the key questions to

think about to ensure your gearing is not

unnecessarily costing you precious seconds

around each lap. With many different corners

on any given track, there will ultimately be

some sort of compromise. But changing one

or two teeth on the rear sprocket will usually

be enough to sort most issues.

When changing sprockets and making

corresponding changes to the rear axle

position, also consider the implications of

the effective change in swingarm length.

Generally speaking, a longer swingarm (or

wheelbase) creates a more stable chassis

that is less inclined to wheelstand. A shorter

swingarm allows the bike to turn quicker,

but it also creates a firmer feel from the rear

suspension because of the decreased leverage.

Enduro

Not many off-road riders count gears; were

usually too busy with fistfuls of throttle,

dodging trees and bashing away at the gear

lever to notice. So next time you ride, take

some time to think about it. How often do

you use first gear? Is the gap from first to

second too big? Can you make a gearing

change to effectively create a gear between

first and second, or to never use first at all?

New-model four-stroke enduro bikes

generally have a broad spread of useable

power and wide-ratio gearboxes, which

makes final gearing less critical. But that

doesnt mean gearing changes cant reap

benefits. If youre having trouble taming

a two-stroke for the bush, for instance,

taller gearing can help smooth the power

delivery. And finding the right gear for tight

singletrack can be the difference between

flowing through the trees and kissing one on

a missed shift.

Bear in mind what you do at the bottomend will affect the top. If you shorten the

gearing for more snap at slow speeds, you

will lose some top-speed. Carefully consider

the terrain type, and aim for a final gearing

combination that offers you the most

versatility.

Trail/Desert

Desert is easy run the tallest gearing

your engine can pull. Machine the rear hub

down if required! Then, let natural fear

regulate your decision and put a few teeth

back on the rear. The Honda CR500s that

dominated the Finke Desert Race in the

1990s ran a 15/36 final drive, while the newgen CRF450s run a 15/44 or 14/42 gearing

combo at Finke much taller than the bikes

118

standard 13/48 motocross gearing.

Trailriders can use the easy-to-swap

nature of the countershaft sprocket to have

ride-to-work road gearing and off-road

gearing. One tooth will usually do it with no

chain length changes needed. For example,

you could use a 13-tooth in the bush and 14or 15-tooth for the road, with that one tooth

transforming the bike for each application.

A smaller countershaft

sprocket will accelerate

wear on the chain slider.

SUSPENSION

The most obvious change gearing makes to

suspension is swingarm length. With the

rear axle back as far as itll go, the swingarm

is at its longest and has the most leverage

over the shock. This effectively makes the

shock softer. Moving the wheel forward

reduces the swingarms leverage, and the

shock becomes stiffer.

Chain torque is another matter and could

easily fill up a book with formulas and

algebra. Put simply, chain torque occurs

because the countershaft sprocket is in

front of the swingam pivot on the majority

of motorcycles. Chain torque opposes the

downward force the rider puts on the rear

suspension. Dont believe it? Put your front

wheel against a tree and let the clutch out.

The rear of the bike rises. This lift helps

you to clear obstacles in the same way prejumping does.

SPROCKETS

WHY CHANGE GEARING?

Below is a simple chart for gearing. The ratio

is simply the rear sprocket divided by the

countershaft. For example, if your bike is

running a fairly common 14/48 combination,

that will give you 3.43. Notice that 13/45 or

15/52 will give a similar result at 3.46 and

3.47, respectively, just slightly shorter.

Numerically higher numbers will make the

engine turn faster for a given speed, giving

faster take-off and a lower top-speed. Higher

numbers will give a slower take-off and a

higher top-speed. Note that shortening the

gearing will effectively close the gearbox

ratios up, giving a closer-ratio feel.

COUNTERSHAFT SPROCKET

REAR SPROCKET

How many times do you change gears around

the average motocross or supercross lap?

Twenty, thirty times? When you shift, youre

not accelerating; youre revving the engine

near peak horsepower and shifting back into

an RPM band with peak torque to start the

acceleration curve again. What happens if

you miss a shift or hit a false neutral? Do

you let a rider by as you lose forward drive

or case a jump and crash? By thinking about

your shift points and whether youre in the

right portion of the power curve through

the fastest corner on the track the corner

we traditionally gear for substantial

improvements in lap times can be made.

When you drive out of a corner, are you

usually in second gear and struggling to grab

third on the exit? Is third too tall for the

engine to pull through several corners and

you find youre using a lot of clutch to keep it

in the meat of the power? Could you gear up

and use second until the bike is straight and

not bouncing off the limiter, or gear down so

Always replace the chain

and sprockets as a set to

avoid premature wear.

TEETH

12

13

14

15

16

17

39

3.25

3.00

2.79

2.60

2.44

2.29

40

3.33

3.08

2.86

2.67

2.50

2.35

41

3.42

3.15

2.93

2.73

2.56

2.41

42

3.50

3.23

3.00

2.80

2.63

2.47

43

3.58

3.31

3.07

2.87

2.69

2.53

44

3.67

3.38

3.14

2.93

2.75

2.59

45

3.75

3.46

3.21

3.00

2.81

2.65

46

3.83

3.54

3.29

3.07

2.88

2.71

47

3.92

3.62

3.36

3.13

2.94

2.76

48

4.00

3.69

3.43

3.20

3.00

2.82

49

4.08

3.77

3.50

3.27

3.06

2.88

50

4.17

3.85

3.57

3.33

3.13

2.94

51

4.25

3.92

3.64

3.40

3.19

3.00

52

4.33

4.00

3.71

3.47

3.25

3.06

Steel or alloy? A steel/alloy combo? Self

cleaning? Whats best? In general terms, if you

are all about saving weight, buy alloy. Note

that there are many varieties of alloy, and

a quality English-brand sprocket will outlast

a cheap no-name brand many times over.

There are a few self-cleaning types around

and everyone has their own miraculous cure.

Personally, Im more interested in the quality

of the aluminium. However, even a cheap steel

sprocket will outlast an alloy unit, so trailriders

are best to go with steel. Enduro guys will have

to decide where they sit on the weight versus

wear trade-off, and perhaps go for one of the

steel-toothed alloy sprockets or a lightweight

steel unit.

Quality sprockets can cost more than $100

each, so building a collection for gearing

Its possible to bend rear

sprockets, so always check

them for any damage.

choices can start to blow the parts budget

out. Be sure what you want gearing-wise

before splashing out. The best thing about

a collection is that all major manufacturers

have not changed their sprocket bolt-patterns

in years.

So how do you know when your sprocket

has had the sword? Youll see most of the

wear on the drive-side. The teeth will start

to hook over, before the hooks themselves

begin to break clean off. The stumpy little

teeth that remain will soon let the chain spin

and ruin your day. As a rule, replace chain

and sprockets as a set, as a worn chain will

quickly ruin new sprockets and vice-versa.

Once you see hooking, its game over for the

sprocket. Although not immediately obvious,

sprocket wear costs power. Nothing absorbs

Once teeth begin to hook

over, the sprocket is worn out

and will begin to sap power.

less power than a brand new sprocket, and once

your sprocket teeth begin to hook, it takes

more energy to drive them.

Keep in mind that the fewer teeth on the

countershaft sprocket will accelerate wear on

both the sprocket and the chain buffer on top

of the swingarm, as it will have more sliding

friction on it. So with your gearing choices, try

to keep the countershaft size up to 13 or above

as a 12-tooth wears too fast to keep in check.

Note also that some engine cases or case

savers dont allow the fitment of a 15-tooth

sprocket unless modified.

The chain guide often limits rear sprocket

size. A 52-tooth unit is normally about as big as

you can go without mods to the guide. Always

inspect sprockets for damage as it is possible

to bend the rears, most likely when the chain

guide is bent with a rock.

119

Tech

DRIVE CHAINS

Thirty years ago, drive chains were a curse.

They stretched faster than you could adjust

them, and broke so often that you were wise

to carry a few spare links, spare section of

chain, a chain breaker and a countershaft

sprocket just in case. The advent of the O-ring

chain in the 80s changed all that. The O-rings

fit into the gap between the rollers and the

links and help trap the lubricant in the pins.

Mind you, the chains still need lubricating on

the rollers. The early O-ring chains were bulky

affairs that sapped power, but the reliability

A gold-plated chain is less

likely to rust and is well

worth the extra coin.

was worth it. As we got into the 90s, the

O-rings were replaced by X-rings. The X refers

to the cross-sectional shape of the ring, much

like an O is the cross-section. The advantage

of the X is not being crushed between the

rollers, as the X has two contact points per

face. It also meant the sealing lasted longer

as the O-rings did wear out.

An unexpected benefit was that O- and

X-ring chains ran cooler due to reduced

friction. On high-powered machines, this

meant the X-ring chains absorbed less power

than a conventional chain. We now have a few

manufacturers making sealed chains for low

power applications, like 250Fs, in the form

of U-rings and T-rings, all with seals that

bear some resemblance to the letter that

defines them. Only in high-level competition

is a non-sealed chain still worth some power

advantage. But as the non-sealed chain wears,

it absorbs more power as heat loss, and the

advantage disappears.

Joining links can still cause headaches.

Unless you have a good reason to remove the

chain frequently for cleaning, Id suggest a

Regular application of

chain lube will extend

the life of the rollers

and hence your chain.

rivet link is the best insurance. They take a

little extra effort to put on, but theres little

need to break modern chains again until

theyre worn and ready to be replaced.

As for chain quality, let price be your

guide. The O-ring chain you buy for $89 is

a nasty piece of power-robbing, sprocketwearing work compared to the lightweight

long-lasting joy of a $180 X-ring. Given the

choice, always buy a gold chain. They are

usually only 10 to 15 bucks more, but the

plating prevents rust and makes cleaning

easier as a result.

GO ON, CHANGE IT!

Swapping sprockets is a simple enough job

with few basic tools. The most difficult part is

removing the countershaft sprocket nut, and

avoiding losing skin on the rear sprocket.

There are two common ways to remove the

countershaft nut. The old method was to have

an assistant stand on the rear brake while you

used a long bar and socket. The folding tab

needs to be knocked back with a cold chisel

and if there is Loctite, some heating will help

to make the nut shift. You need to stand on the

rear brake quite hard to make this work. The

advent of cheap air compressors and impact

(rattle) guns from hardware stores means

there is now an easier method. Leave the chain

on and have an assistant stand on the top of

the chain to keep it tight while you loosen

the nut. Its only the shock of the hammering

action that loosens the nut. So by keeping the

chain taught, all of the impact is acting on

the nut. Dont be tempted to put the machine

in gear as the rotating hammering action will

be lost on the gearbox gears, not on the nut.

And using a section of chain curled up and

jammed into the cases is also a good way to

break a case.

While the rear wheel is out, remove the

chain adjusters that run into the swingarm

and apply some anti-seize. Theres no telling

when they will be out again.

Use Loctite on the sprocket

bolts, as loose bolts can

destroy a rear hub.

Sprocket bolts dont take kindly to being over

tightened, even a small amount. Put a set of

high-quality replacements on your shopping list

when you buy a sprocket.

Loose sprocket bolts will destroy a rear hub

faster than you know how to spend $400-$800

on a replacement. It doesnt take long to check

the bolts before each ride, so get into the habit

of it.

Some type of mechanical self-locking nut is a

must for rear sprockets. Be aware that selflocking nuts do wear out after

two or three tightenings.

For the few bikes that still use a circlip to retain

the countershaft sprocket, a bead of silicone will

provide cheap insurance against the clip being

flicked off.

Replace the folding tab that mechanically locks

the countershaft nut rather than relying solely

on Loctite. Its such a critical fastener, overkill

does not exist here.

Use a long ring-spanner to loosen the sprocket

bolts nuts before you start turning the Allenhead. The Allen-head is only for holding and

loosening, not tightening.

TOOLS

If you have an Allen key set, ring

spanner, Loctite and a 24, 27 or 30mm

socket to suit your rear axle nut and

countershaft nut, then theres no

excuse for you not to experiment

with different gearing combos.

120

DIY

TIPS

Look for blackening around the bolt heads

during your post-ride wash. If you can see it,

chances are the bolts are loose and fretting.

Placing silicone on the circlip

that retains the countershaft

nut will prevent it flicking off.

The sidewall height of a tyre will affect gearing.

A 110/80-19 will have a smaller rolling diameter

than a 110/90-19, thus shortening the gearing.

Conversely, the 90-profile is taller and will

require you to gear up to counteract its affect.

Anda mungkin juga menyukai

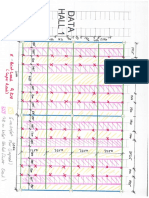

- Notes For Drawings For Data CentreDokumen1 halamanNotes For Drawings For Data Centrerockydog360Belum ada peringkat

- Tekla Structural Designer: BoosterDokumen1 halamanTekla Structural Designer: Boosterrockydog360Belum ada peringkat

- Notes From Tekla Model DesignDokumen1 halamanNotes From Tekla Model Designrockydog360Belum ada peringkat

- This Is A SampleDokumen1 halamanThis Is A Samplerockydog360Belum ada peringkat

- Lights Shower Sockets 1 Sockets 2Dokumen1 halamanLights Shower Sockets 1 Sockets 2rockydog360Belum ada peringkat

- CPD MMMR FlyerDokumen1 halamanCPD MMMR Flyerrockydog360Belum ada peringkat

- To The World I Will NeverDokumen1 halamanTo The World I Will Neverrockydog360Belum ada peringkat

- Data Hall 1 LoadsDokumen1 halamanData Hall 1 Loadsrockydog360Belum ada peringkat

- Calculation Control FormDokumen1 halamanCalculation Control Formrockydog360Belum ada peringkat

- BHDSBCSD SDJKSDLCF SD Lksjdkjkdcs SDJJFCDSKLJCSD KCDokumen1 halamanBHDSBCSD SDJKSDLCF SD Lksjdkjkdcs SDJJFCDSKLJCSD KCrockydog360Belum ada peringkat

- DsgdsiahdisalDokumen1 halamanDsgdsiahdisalrockydog360Belum ada peringkat

- Ref. Calculations Output: ContractDokumen1 halamanRef. Calculations Output: Contractrockydog360Belum ada peringkat

- Hip Roof Load TakedownDokumen1 halamanHip Roof Load Takedownrockydog360Belum ada peringkat

- Project Completion Structural ChecklistDokumen4 halamanProject Completion Structural Checklistrockydog360Belum ada peringkat

- (08!11!14) Domestic House Design Updated Version 7Dokumen67 halaman(08!11!14) Domestic House Design Updated Version 7rockydog360Belum ada peringkat

- Catalogo Pirelli 2014Dokumen198 halamanCatalogo Pirelli 2014Andre Soares MotaBelum ada peringkat

- Catalogo Pirelli 2014Dokumen198 halamanCatalogo Pirelli 2014Andre Soares MotaBelum ada peringkat

- Yamaha FZ6 2007 ALL VERSIONS Service ManualDokumen538 halamanYamaha FZ6 2007 ALL VERSIONS Service Manualm.kelleci7248100% (7)

- 2D Linpro Analysis Fixed-Pinned Support ConditionsDokumen3 halaman2D Linpro Analysis Fixed-Pinned Support Conditionsrockydog360Belum ada peringkat

- 3 Day SplitDokumen1 halaman3 Day Splitrockydog360Belum ada peringkat

- Insanity Is Doing The Same Thing Over and Over Again and Expecting A Different ResultDokumen5 halamanInsanity Is Doing The Same Thing Over and Over Again and Expecting A Different Resultrockydog360Belum ada peringkat

- Protein Other: Chicken Turkey Beef Ham Eggs Protein Powder Milk Coleslaw Red Sauce Butter Fitness FibreDokumen1 halamanProtein Other: Chicken Turkey Beef Ham Eggs Protein Powder Milk Coleslaw Red Sauce Butter Fitness Fibrerockydog360Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Top Survival Tips - Kevin Reeve - OnPoint Tactical PDFDokumen8 halamanTop Survival Tips - Kevin Reeve - OnPoint Tactical PDFBillLudley5100% (1)

- Uxc01387a PDFDokumen16 halamanUxc01387a PDFmahesh123Belum ada peringkat

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIDokumen9 halamanJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidBelum ada peringkat

- JSA FormDokumen4 halamanJSA Formfinjho839Belum ada peringkat

- HW Chapter 25 Giancoli Physics - SolutionsDokumen8 halamanHW Chapter 25 Giancoli Physics - SolutionsBecky DominguezBelum ada peringkat

- Piston Master PumpsDokumen14 halamanPiston Master PumpsMauricio Ariel H. OrellanaBelum ada peringkat

- CFodrey CVDokumen12 halamanCFodrey CVCrystal N FodreyBelum ada peringkat

- Dreizler EDokumen265 halamanDreizler ERobis OliveiraBelum ada peringkat

- Kpolovie and Obilor PDFDokumen26 halamanKpolovie and Obilor PDFMandalikaBelum ada peringkat

- Qualification of Class Y Flip Chip Cga Package Technology For SpaceDokumen8 halamanQualification of Class Y Flip Chip Cga Package Technology For SpacePepe ChorizoBelum ada peringkat

- Agreement - IDP - Transformation Institute - 2023Dokumen16 halamanAgreement - IDP - Transformation Institute - 2023Elite ProgramBelum ada peringkat

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDokumen2 halamanN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueBelum ada peringkat

- Group 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasDokumen12 halamanGroup 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasSeyell DumpBelum ada peringkat

- Embedded System Lab ManualDokumen67 halamanEmbedded System Lab Manualsaim100% (1)

- Lab Activity 5Dokumen5 halamanLab Activity 5Jasmin CeciliaBelum ada peringkat

- MJDF Mcqs - Mixed - PDFDokumen19 halamanMJDF Mcqs - Mixed - PDFAyesha Awan0% (3)

- Chapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDokumen123 halamanChapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjBelum ada peringkat

- AnkitKumar InternshalaResume PDFDokumen2 halamanAnkitKumar InternshalaResume PDFkusha010Belum ada peringkat

- Xbox One S Retimer - TI SN65DP159 March 2020 RevisionDokumen67 halamanXbox One S Retimer - TI SN65DP159 March 2020 RevisionJun Reymon ReyBelum ada peringkat

- State Common Entrance Test Cell: 3001 Jamnalal Bajaj Institute of Management Studies, MumbaiDokumen9 halamanState Common Entrance Test Cell: 3001 Jamnalal Bajaj Institute of Management Studies, MumbaiSalman AnwarBelum ada peringkat

- 02 Laboratory Exercise 1Dokumen2 halaman02 Laboratory Exercise 1Mico Bryan BurgosBelum ada peringkat

- C7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesDokumen13 halamanC7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesBhat SaqibBelum ada peringkat

- Detailed Lesson Plan in Mathematics (Pythagorean Theorem)Dokumen6 halamanDetailed Lesson Plan in Mathematics (Pythagorean Theorem)Carlo DascoBelum ada peringkat

- Marketing Plan Nokia - Advanced MarketingDokumen8 halamanMarketing Plan Nokia - Advanced MarketingAnoop KeshariBelum ada peringkat

- Unit 6B - PassiveDokumen18 halamanUnit 6B - PassiveDavid EstrellaBelum ada peringkat

- Fractional Differential Equations: Bangti JinDokumen377 halamanFractional Differential Equations: Bangti JinOmar GuzmanBelum ada peringkat

- Market Structure and TrendDokumen10 halamanMarket Structure and TrendbillBelum ada peringkat

- Lesson 3 - Adaptation AssignmentDokumen3 halamanLesson 3 - Adaptation AssignmentEmmy RoseBelum ada peringkat

- Prosocial Behaviour: Hans W. BierhoffDokumen20 halamanProsocial Behaviour: Hans W. BierhoffSahil Mushaf100% (1)

- 2002 CT Saturation and Polarity TestDokumen11 halaman2002 CT Saturation and Polarity Testhashmishahbaz672100% (1)