PP Textile Belts: Polyamide / Polyamide

Diunggah oleh

Harish KumarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PP Textile Belts: Polyamide / Polyamide

Diunggah oleh

Harish KumarHak Cipta:

Format Tersedia

PP textile belts

ABRASION RESISTANCE

POLYAMIDE / POLYAMIDE

Areas of application

These PP textile belts are generally used in extraction and

transformation industries for conveying bulk material of large

grain size at temperatures between -25C and +60C.

Open-pit coal mines (conveying of overburden, coal and

aggregates)

Open-pit mineral mines (lime, phosphates, various ores)

Treatment of minerals

Iron and steel industries

Cement works (quarry materials and transformation)

Paper mills

Port installations

Public works

Agriculture

Sugar factories

Thermal power plants

Quarries and sand pits

Top cover

Our PP textile belt consists of rubber covers and moulded

edges and a textile carcass.

The carcass has a multiply structure comprising 2 to 5 plies

of PP (polyamide warp and weft) synthetic fabric. A layer of

skim gum covers each ply.

Textile carcass

Bottom cover

The covers protect the carcass against damage, adverse

weather conditions and biological and chemical

aggressions.

The role of the carcass is to transmit the longitudinal forces

and absorb the dynamic forces generated by the falling and

conveying of the material.

These PP textile belts are produced with cover grades W, X,

Y and Z complying with standard DIN 22102 or antiabrasive cover grade D.

IMPORTANT NOTICE: This brochure has been prepared carefully, to advise our

customers. The information stated therein is state of the art and the results of different tests

carried out over several years. Individual operating conditions affect any product, which

means that a product can only offer the safety that can be expected on the basis of the

data provided in our product information. In the event that the product is used otherwise

than in conformity with the specifications, such safety may not be assumed. Our

responsibility is limited exclusively to delivery of the conveyor belt in accordance with the

specifications.

Please note: Before using the product in new areas of application which are not covered

by the product information a Sempertrans engineer MUST be asked for advice.

Stocking, care and maintenance of all our products must be performed according to our

stocking, care and maintenance guidelines and according to ISO 5285 standard ;

Subject to errors and printing errors.

Reproduction of any kind - also of excerpts - only upon express written consent of

Sempertrans.

The brochure shall remain the property of Sempertrans and is the most recent version.

All transactions shall be exclusively subject to our general terms and conditions.

Date of publication 06/2007 1st edition

Subject to changes.

The figures stated in our documents are mean approximate values for information but

no specified or warranted values.

14

The usual designation of PP textile belts is as shown in the example below:

1800

2000/ 4 10+5 Y

Rated width of belt (mm)

Carcass (P = polyamide fabric in warp and in weft)

Rated breaking strength in warp direction (N/mm)

Number of plies of fabric

Thickness of top cover and bottom cover (mm)

Cover grade: W, X, Y or Z as per standard DIN 22102

The type of belt (rated breaking strength in N/mm) is obtained by superimposing plies of fabric:

TYPE N/mm

Number of plies

400

500

630

800 1000 1250 1400 1600 1800 2000 2500 3150 3500

2

IMPORTANT NOTICE: This brochure has been prepared carefully, to advise our

customers. The information stated therein is state of the art and the results of different tests

carried out over several years. Individual operating conditions affect any product, which

means that a product can only offer the safety that can be expected on the basis of the

data provided in our product information. In the event that the product is used otherwise

than in conformity with the specifications, such safety may not be assumed. Our

responsibility is limited exclusively to delivery of the conveyor belt in accordance with the

specifications.

4

5

Please note: Before using the product in new areas of application which are not covered

by the product information a Sempertrans engineer MUST be asked for advice.

Stocking, care and maintenance of all our products must be performed according to our

stocking, care and maintenance guidelines and according to ISO 5285 standard ;

Subject to errors and printing errors.

Reproduction of any kind - also of excerpts - only upon express written consent of

Sempertrans.

The brochure shall remain the property of Sempertrans and is the most recent version.

All transactions shall be exclusively subject to our general terms and conditions.

Date of publication 06/2007 1st edition

Subject to changes.

The figures stated in our documents are mean approximate values for information but

no specified or warranted values.

15

ABRASION RESISTANCE

Designation

ABRASION RESISTANCE

SEMPERTRANS standard RANGE, cover of grade W, X, Y or Z (as per DIN 22102) or D (anti-abrasive).

Belt

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

400/2

500/2

630/2

630/3

800/2

800/3

800/4

1000/2

1000/3

1000/4

1000/5

1250/2

1250/3

1250/4

1250/5

1400/3

1400/4

1500/5

1600/4

1600/5

1800/4

1800/5

2000/4

2000/5

2500/4

2500/5

3150/5

3500/5

Carcass

Carcass

construction weight

Kg/m2

2 P 200

2 P 250

2 P 315

3 P 200

2 P 400

3 P 250

4 P 200

2 P 500

3 P 315

4 P 250

5P 200

2 P 630

3 P 400

4 P 315

5 P 250

3 P 400

4 P 315

5 P 315

4 P 400

5 P 315

4 P 400

5 P 315

4 P 500

5 P 400

4 P 630

5 P 500

5 P 630

5 P 750

3.1

3.5

4.2

4.6

4.0

5.3

6.2

5.3

6.2

7.1

7.7

6.1

6.1

8.1

8.8

6.5

8.6

10.4

8.1

10.4

8.1

10.7

10.5

10.1

12.2

13.2

15.3

17.6

Carcass

thickness

mm

2.6

2.8

3.6

4.1

3.2

4.4

5.6

4.6

5.6

6.0

7.1

5.4

5.0

7.6

7.6

5.6

7.6

9.6

6.8

9.6

6.8

9.6

9.6

8.6

11.2

12.1

14.1

14.6

5

0

0

6

0

0

6

5

0

8

0

0

1

0

0

0

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

RATED WIDTH (mm)

1 1 1 1 2 2

2 4 6 8 0 2

0 0 0 0 0 0

0 0 0 0 0 0

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

2

2

5

0

2

4

0

0

2

5

0

0

2

8

0

0

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

The thicknesses and weights of the carcasses are given for information.

IMPORTANT NOTICE: This brochure has been prepared carefully, to advise our

customers. The information stated therein is state of the art and the results of different tests

carried out over several years. Individual operating conditions affect any product, which

means that a product can only offer the safety that can be expected on the basis of the

data provided in our product information. In the event that the product is used otherwise

than in conformity with the specifications, such safety may not be assumed. Our

responsibility is limited exclusively to delivery of the conveyor belt in accordance with the

specifications.

Please note: Before using the product in new areas of application which are not covered

by the product information a Sempertrans engineer MUST be asked for advice.

Stocking, care and maintenance of all our products must be performed according to our

stocking, care and maintenance guidelines and according to ISO 5285 standard ;

Subject to errors and printing errors.

Reproduction of any kind - also of excerpts - only upon express written consent of

Sempertrans.

The brochure shall remain the property of Sempertrans and is the most recent version.

All transactions shall be exclusively subject to our general terms and conditions.

Date of publication 06/2007 1st edition

Subject to changes.

The figures stated in our documents are mean approximate values for information but

no specified or warranted values.

16

THICKNESS AND WEIGHT

The thicknesses and weights can be evaluated from the table below for the thickness and weight of the carcass

and the table below gives the density of the standard covers.

Cover

Weight in Kg/m2

for 1 mm of gum

W

1.12

X

1.11

Y

1.12

Z

1.12

Values given for information

TECHNICAL SPECIFICATIONS

-

(see page 66)

Cover grade / resistance of covers to products conveyed

Pulley diameter

Tension travel

Trough transition lengths

Radius of curvature

Turnover

Station spacing

Roller skirt clearance

Splicing

IMPORTANT NOTICE: This brochure has been prepared carefully, to advise our

customers. The information stated therein is state of the art and the results of different tests

carried out over several years. Individual operating conditions affect any product, which

means that a product can only offer the safety that can be expected on the basis of the

data provided in our product information. In the event that the product is used otherwise

than in conformity with the specifications, such safety may not be assumed. Our

responsibility is limited exclusively to delivery of the conveyor belt in accordance with the

specifications.

Please note: Before using the product in new areas of application which are not covered

by the product information a Sempertrans engineer MUST be asked for advice.

Stocking, care and maintenance of all our products must be performed according to our

stocking, care and maintenance guidelines and according to ISO 5285 standard ;

Subject to errors and printing errors.

Reproduction of any kind - also of excerpts - only upon express written consent of

Sempertrans.

The brochure shall remain the property of Sempertrans and is the most recent version.

All transactions shall be exclusively subject to our general terms and conditions.

Date of publication 06/2007 1st edition

Subject to changes.

The figures stated in our documents are mean approximate values for information but

no specified or warranted values.

17

ABRASION RESISTANCE

For the possible cover thicknesses, please consult our technical department.

Manufacturing is possible with other cover grades. See cover range on pages 66 and 67 or consult our

technical department.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Trufrost Product RangeDokumen8 halamanTrufrost Product RangeHarish KumarBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- An Eco-Friendly Solution For Human Waste Management: Bio Digester - A DRDO PresentationDokumen29 halamanAn Eco-Friendly Solution For Human Waste Management: Bio Digester - A DRDO PresentationHarish KumarBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Trufrost Corporate Book NDokumen116 halamanTrufrost Corporate Book NHarish KumarBelum ada peringkat

- Flyer FicusDokumen2 halamanFlyer FicusHarish KumarBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- As4324 11Dokumen109 halamanAs4324 11Harish KumarBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Functional Analysis of Tube Chain Conveyors. Part 1: General Design and Calculation PrinciplesDokumen11 halamanFunctional Analysis of Tube Chain Conveyors. Part 1: General Design and Calculation PrinciplesHarish KumarBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Mannheim Full-Time Mba: Structure LocationsDokumen1 halamanMannheim Full-Time Mba: Structure LocationsHarish KumarBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Confederation of Indian Industry (CII) Contact Details PDFDokumen4 halamanConfederation of Indian Industry (CII) Contact Details PDFHarish Kumar0% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Essar Steel (Hazira) Limited: 5.0 Mtpa Integrated Steel PlantDokumen19 halamanEssar Steel (Hazira) Limited: 5.0 Mtpa Integrated Steel PlantHarish KumarBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Technical Datasheet of GearboxDokumen1 halamanTechnical Datasheet of GearboxHarish KumarBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Ficus IntroductionDokumen32 halamanFicus IntroductionHarish KumarBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Axle and Bogie Wheel AssemblyDokumen10 halamanAxle and Bogie Wheel AssemblyHarish KumarBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Confederation of Indian Industry (CII) Contact Details PDFDokumen4 halamanConfederation of Indian Industry (CII) Contact Details PDFHarish Kumar0% (1)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Infographics For PPT (Autosaved)Dokumen9 halamanInfographics For PPT (Autosaved)Harish KumarBelum ada peringkat

- Komljenovic DDokumen14 halamanKomljenovic DHarish KumarBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Automatic Samplers: Proven & DependableDokumen6 halamanAutomatic Samplers: Proven & DependableHarish KumarBelum ada peringkat

- Siwertell Ship Unloaders - Original - 33001 PDFDokumen6 halamanSiwertell Ship Unloaders - Original - 33001 PDFHarish KumarBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Handbook Setting Up Your Business in Flanders Update Jan 2018Dokumen44 halamanHandbook Setting Up Your Business in Flanders Update Jan 2018Harish KumarBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- S.No. Components Makes: 1 Grab Cranes - Gantry TypeDokumen4 halamanS.No. Components Makes: 1 Grab Cranes - Gantry TypeHarish KumarBelum ada peringkat

- Penden Cement Authority Limited: Daily Raw Material StockDokumen1 halamanPenden Cement Authority Limited: Daily Raw Material StockTenzin WangchukBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- BIG XI Hydrocarbons 7Dokumen87 halamanBIG XI Hydrocarbons 7JoshLeighBelum ada peringkat

- Jindal Steel and PowerDokumen3 halamanJindal Steel and PowerChandan SonyBelum ada peringkat

- Laporan Pengeboran PT ANSAFDokumen8 halamanLaporan Pengeboran PT ANSAFSetia WirawanBelum ada peringkat

- A Study On Receivable Management Its ImpactDokumen77 halamanA Study On Receivable Management Its ImpactVaibhav Badgi100% (3)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Capital Cost Scaling MethodologyDokumen45 halamanCapital Cost Scaling MethodologyManish ParetaBelum ada peringkat

- Waste Incineration TechnologyDokumen22 halamanWaste Incineration TechnologyJoao MinhoBelum ada peringkat

- Spectrum Resources Management: Consultant - Representative - TradingDokumen1 halamanSpectrum Resources Management: Consultant - Representative - Tradingadiekusumadewa 567Belum ada peringkat

- Hawassa University: Plant Design and Economics - ProjectDokumen64 halamanHawassa University: Plant Design and Economics - ProjectLove Is100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- VIU in Index-Priced WorldDokumen20 halamanVIU in Index-Priced WorldPaul VermeulenBelum ada peringkat

- Minerals and Energy Resources Class 10 Notes Geography Chapter 5Dokumen7 halamanMinerals and Energy Resources Class 10 Notes Geography Chapter 5sonamkheriaBelum ada peringkat

- Department/ Ministry Address State Mobile Telephone Number Email Address Mail Userst Atus Inet Userstat US Account Creation-Date DORDokumen31 halamanDepartment/ Ministry Address State Mobile Telephone Number Email Address Mail Userst Atus Inet Userstat US Account Creation-Date DORRashmi RanjanBelum ada peringkat

- Thermal Power PlantDokumen15 halamanThermal Power PlantMathes Mano100% (3)

- Energy Crisis in PakistanDokumen11 halamanEnergy Crisis in PakistanAhsan Ahmad100% (1)

- Air Polution and Air Pollution Control in Cement IndustryDokumen26 halamanAir Polution and Air Pollution Control in Cement IndustryPRAFULKUMAR PARMARBelum ada peringkat

- Coal Gasification: 1 HistoryDokumen9 halamanCoal Gasification: 1 HistoryErnesto GuevaraBelum ada peringkat

- Full Download Book Reservoir Development PDFDokumen41 halamanFull Download Book Reservoir Development PDFcarlotta.hernandez697100% (20)

- Term@ Basic of MiningDokumen3 halamanTerm@ Basic of MiningRahul kumarBelum ada peringkat

- DOK IV-ALL-139-3.7.1 - Daily ReportDokumen1 halamanDOK IV-ALL-139-3.7.1 - Daily ReportDale WearpackBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Project Report Pakistan Investigations (IR) PK-55Dokumen94 halamanProject Report Pakistan Investigations (IR) PK-55Ahsan AliBelum ada peringkat

- Evolution of RailwayDokumen16 halamanEvolution of RailwaytvjithinBelum ada peringkat

- Underwriters 76fh Woodstove UsMan (En)Dokumen52 halamanUnderwriters 76fh Woodstove UsMan (En)carlos diazBelum ada peringkat

- ME927 NotesDokumen451 halamanME927 Noteslpl bobalobBelum ada peringkat

- Coal Resources and Their Status in Nepal, BASKOTA, Shiv Kumar, NepalDokumen19 halamanCoal Resources and Their Status in Nepal, BASKOTA, Shiv Kumar, NepalSubash MahatBelum ada peringkat

- Mmbtu FundasDokumen18 halamanMmbtu FundasSambuddha BhattacharyaBelum ada peringkat

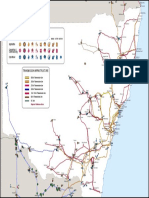

- NSW Generation MapDokumen1 halamanNSW Generation MapdsfsBelum ada peringkat

- Weekly Report 05-December-2022 Calendar YearDokumen8 halamanWeekly Report 05-December-2022 Calendar Yearzvishavane zvishBelum ada peringkat

- Boiler InspectionDokumen4 halamanBoiler InspectionyogeshthesiyaBelum ada peringkat

- Calorific ValuesDokumen2 halamanCalorific ValuesNaval LaddhaBelum ada peringkat

- List-of-Coal MinesDokumen17 halamanList-of-Coal Minesishtiaq ahmadBelum ada peringkat

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDari EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesBelum ada peringkat

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (242)