Operation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw Crushers

Diunggah oleh

jlfyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Operation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw Crushers

Diunggah oleh

jlfyHak Cipta:

Format Tersedia

Operation & Maintenance Manual

Belt Drive Troubleshooting

Table B - 1 Belt Drive Troubleshooting

Trouble

Cause

Correction

Belt Slip (sidewalls glazed)

Insufficient tension

Replace belts; increase tension

Drive squeals

Overloaded drive

Arc of contact too short

Heavy starting load

Find cause and correct

Increase distance between hubs

Increase tension

Broken cord caused by prying

Overloaded drive

Impulse loads

Replace belt correctly

Redesign drive

Apply proper tension

Misalignment

Worn sheave grooves

Flat idler sheave

Realign drive

Replace sheave

Align and reposition

Excessive vibration

Check drive design, mounting

Consider banded belts

New belts installed with old

Replace belts with matched set

Sheave grooves worn unevenly

Improper groove angle

Replace sheaves

Shafts not parallel

Align drive

Shock loads

Apply proper tension

Heavy starting load

Apply proper tension

Use compensator starting

Belt pried over sheaves

Foreign object in drive

Replace belt correctly

Determine source of object,

design guard to correct problem

Sheave grooves worn

Sheave diameter too small

Mismatched belts

Drive overloaded

Belt slips

Sheaves misaligned

Oil present

Excessive heat present

Replace sheaves

Redesign drive

Replace with matched set

Redesign drive

Increase tension

Align sheaves

Eliminate oil

Ventilate drive

Belts roll over

Mismatched belts

Belt breaks

Belt wears prematurely

CRSH-OM-0003ENG(OCT-2014)

B-3

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Maintaining V-Belt Tension

Maintaining V-Belt Tension

1/64 inch per each inch of span length.

Example:

For a 100 inch span, the deflection would be

100/64, or approximately 1-1/2 inches.

V-belt tension must be maintained to provide

proper drive effectiveness. The following method

of tensioning v-belts has been established as an

acceptable and preferred method.

4) Compare the force measurement to the

recommended ranges shown in (Table B - 2)

below for the appropriate belt cross section

type shown in.

Tension-Deflection Method

1) Place a straightedge across the top of both

sheaves. See (Figure B - 4)

5) Tighten or loosen belt to bring it into the

recommended range.

2) Measure the span length.

6) When installing new belts, tighten them to

Initial Installation tension. This tension will

drop during the run-in period.

3) Using a spring scale at right angle to belt at

1/2 of span length, apply a force to the scale

on one of the belts enough to deflect the belt

1

2

3

7

9

8

6

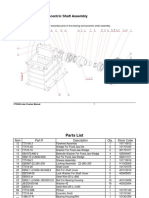

1 - Straightedge

5 - Motor Drive Sheave

2 - Span Length

6 - V-belt

3 - 1/2 Span

7 - Spring Scale

4 - Deflection Measurement - 1/64 Inch for each

Inch of Span Length

8 - Force Measurement

9 - Driven Sheave

Figure B - 4 Tension-Deflection Diagram

CRSH-OM-0003ENG(OCT-2014)

B-4

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Maintaining V-Belt Tension

Table B - 2 Belt Deflection Forces

Recommended Belt Deflection Force (Pounds)

V-Belt

Cross

Section

Smallest Sheave

Diameter Range

(Inches)

Initial

Installation

- 3.0

3.1 - 4.0

4.1 - 5.0

5.1 -

Retensioning

Maximum

Minimum

3.6

4.2

5.2

6.1

3.1

3.6

4.6

5.3

2.4

2.8

3.5

4.1

- 4.6

4.7 - 5.6

5.7 - 7.0

7.1 -

7.3

8.7

9.3

10.0

6.4

7.5

8.1

8.8

4.9

5.8

6.2

6.8

- 7.0

7.1 - 9.0

9.1 - 12.0

12.1 -

12.5

15.0

18.0

19.5

10.7

13.0

16.3

16.9

8.2

10.0

12.5

13.0

12.0 - 13.0

13.1 - 15.5

15.6 - 22.0

25.5*

30.0*

32.0*

22.1

26.0*

28.0*

17.0

20.0

21.5

18.0 - 22.0

22.1 -

45.0*

52.5*

39.0*

45.5*

30.0*

35.0*

AX

- 3.0

3.1 - 4.0

4.1 - 5.0

5.1 -

5.1

5.5

6.0

6.7

4.4

4.8

5.2

5.9

3.4

3.7

4.0

4.5

BX

- 4.6

4.7 - 5.6

5.7 - 7.0

7.1 - 12.0

10.0

11.0

11.5

10.1

8.7

9.5

9.9

7.8

6.7

7.3

7.6

CX

- 7.0

7.1 - 9.0

9.1 - 12.0

12.1 -

18.0

19.5

20.0

21.0

15.6

16.9

17.6

18.2

12.0

13.0

13.5

14.0

3V

2.65 - 3.35

3.65 - 4.50

4.75 - 6.0

6.5 - 10.6

4.6

5.5

6.4

7.3

4.0

4.8

5.6

6.4

3.1

3.7

4.3

4.9

5V

7.1 - 10.3

10.9 - 11.8

12.5 - 16.0

16.5

19.5

21.0

14.3

16.9

18.2

11.0

13.0

14.0

8V

12.5 - 16.0

17.0 - 20.0

21.2 - 24.4

39.0*

45.0*

51.0*

33.8*

39.0*

44.2*

26.0*

30.0*

34.0*

3VX

2.2 - 2.5

2.65 - 4.75

5.0 - 6.5

6.9 -

4.8

5.7

7.2

8.7

4.2

4.9

6.2

7.5

3.2

3.8

4.8

5.8

5VX

- 5.5

5.9 - 8.0

8.5 - 10.9

11.8 -

15.0

19.0

21.0

22.0

13.0

16.9

18.2

19.5

10.0

13.0

14.0

15.0

* Note: For banded belts, multiply the force in table by

the number of belts in the band.

CRSH-OM-0003ENG(OCT-2014)

B-5

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Belt Type Cross-Sections

Belt Type Cross-Sections

Backside Idler

A backside idler increases the arc of contact on

both sheaves. However, it forces a backward bend

in the v-belt that can contribute to premature

failure. The idler puts additional stress on the

bottom portion of the belt which will result in

bottom cracking. If a backside idler must be used,

the diameter should be at least 1 - 1/2 times the

diameter of the small sheave. It should also be

located as close as possible to the small sheave.

Figure B - 5 Belt Type Cross-Sections

Figure B - 7 Backside Idler

Belt Idlers

Kiss Idler

A properly designed v-belt drive does not require

and idler to deliver full horsepower if proper belt

tension can be maintained. Idlers should be

avoided if possible because it puts additional

bending stress points on the belt. Due to drive

design parameters, idlers are sometimes used. The

following are general descriptions of the types of

idlers that may be used.

A kiss idler differs from the backside idler because

the kiss idler does not penetrate the belt span and

create a backward bend on the belt. A kiss idler

does not contribute to premature belt failure. Use

of a kiss idler can help control belt vibration and

whip on drives subject to shock and pulsating

loads. If a kiss idler is used, the diameter should

be at least 1 - 1/2 times the diameter of the small

sheave.

Inside Idler

A v-grooved idler located on the inside of the belts

on the slack side of drive would be recommended

over a backside idler. The idler should be located

near the large sheave to minimize reduction of the

arc of contact on the small sheave. The diameter

should be equal to or larger than that of the small

sheave.

Figure B - 8 Kiss Idler

Figure B - 6 Inside Idler

CRSH-OM-0003ENG(OCT-2014)

B-6

Model CT-Series Jaw Crushers

Anda mungkin juga menyukai

- (Paper) (Balancing of Integral Gear-Driven Centrifugal Compressors)Dokumen8 halaman(Paper) (Balancing of Integral Gear-Driven Centrifugal Compressors)aref_tmuBelum ada peringkat

- Mitsubishi Air ConditionerDokumen68 halamanMitsubishi Air ConditionerbrianatburleighBelum ada peringkat

- J-Series IM20140521E TornilloDokumen210 halamanJ-Series IM20140521E TornilloFernando David RamirezBelum ada peringkat

- Radial Flow Gas TurbinesDokumen20 halamanRadial Flow Gas TurbinesAnggita Dwi LiestyosiwiBelum ada peringkat

- Axial Alignment and Thermal Growth Effects On Turbomachinery Trains With Double-Helical GearingDokumen12 halamanAxial Alignment and Thermal Growth Effects On Turbomachinery Trains With Double-Helical GearingAnton HidayatBelum ada peringkat

- "About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Dokumen165 halaman"About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Tun Lin AungBelum ada peringkat

- Ebae 161 92 Ram Pump JenningsDokumen6 halamanEbae 161 92 Ram Pump JenningsGaguk Triosona PraditaBelum ada peringkat

- Gear SGL San Metal Eom 05Dokumen23 halamanGear SGL San Metal Eom 05omaryehudeBelum ada peringkat

- Helical Gear Lubrication RequirementDokumen7 halamanHelical Gear Lubrication RequirementvenkateswaranBelum ada peringkat

- Compressor Divider Block InstructionDokumen19 halamanCompressor Divider Block InstructionDibyendu ChakrabortyBelum ada peringkat

- SKF MicrologDokumen52 halamanSKF MicrologJeffry KarundengBelum ada peringkat

- TEH-1109 - Parallel and Series Pump ApplicationDokumen20 halamanTEH-1109 - Parallel and Series Pump Applicationmngearhead100% (2)

- Force Couplings of Shafts With HubsDokumen23 halamanForce Couplings of Shafts With HubsParag NaikBelum ada peringkat

- PWV2Dokumen40 halamanPWV2Tony AppsBelum ada peringkat

- 1 Download Template (Free) 2 Start Download - View PDF: American Standard Steel ChannelsDokumen7 halaman1 Download Template (Free) 2 Start Download - View PDF: American Standard Steel ChannelsHiongyiiBelum ada peringkat

- Study, Analysis and Design of Automobile Radiator PDFDokumen10 halamanStudy, Analysis and Design of Automobile Radiator PDFRamón G. PachecoBelum ada peringkat

- Keyways ToleranceDokumen3 halamanKeyways ToleranceAkshay KakaniBelum ada peringkat

- Dry Gas Seal Failure and Trouble ShootingDokumen22 halamanDry Gas Seal Failure and Trouble ShootingDonBelum ada peringkat

- Selenoid eDokumen9 halamanSelenoid ejlfyBelum ada peringkat

- Trouble Shooting&SolutionsDokumen21 halamanTrouble Shooting&SolutionsBaran ShafqatBelum ada peringkat

- Steam Turbine Study Emg 32/25: Title: Document Code RevisionDokumen23 halamanSteam Turbine Study Emg 32/25: Title: Document Code RevisionUdhayakumar VenkataramanBelum ada peringkat

- Writing Emails Activities PDFDokumen3 halamanWriting Emails Activities PDFSara NewStein100% (1)

- 01 MidPoint Vs DewPointDokumen26 halaman01 MidPoint Vs DewPointpaldopalBelum ada peringkat

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDokumen4 halaman5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyBelum ada peringkat

- Gear Assembly Maintenance Techniques TurbogearsDokumen12 halamanGear Assembly Maintenance Techniques Turbogearshumayun121Belum ada peringkat

- Leveling 1Dokumen28 halamanLeveling 1Halina HamidBelum ada peringkat

- Amotcontrols ManualDokumen16 halamanAmotcontrols ManualIvaylo IvanovBelum ada peringkat

- MSZ Msy Ge06 24na - Service - Obh548a - 9 10Dokumen44 halamanMSZ Msy Ge06 24na - Service - Obh548a - 9 10tm5u2rBelum ada peringkat

- Tabla Tension Correas GatesDokumen4 halamanTabla Tension Correas Gatesvibrador0% (1)

- Jensen Mixer Series 600 IOM 2010Dokumen24 halamanJensen Mixer Series 600 IOM 2010SergioBelum ada peringkat

- Pumps in Parallel or Serial ConnectionDokumen7 halamanPumps in Parallel or Serial Connectionyarzar17Belum ada peringkat

- Recommended Initial Alram Ge - 872639Dokumen4 halamanRecommended Initial Alram Ge - 872639kjapasha100% (1)

- Rings and Packings KATALOG 2021 US-letterDokumen24 halamanRings and Packings KATALOG 2021 US-letterBHAVYA KHANNABelum ada peringkat

- Analysis and Enhancement of Hydraulic Ram Pump Using Computational Fluid Dynamics (CFD)Dokumen25 halamanAnalysis and Enhancement of Hydraulic Ram Pump Using Computational Fluid Dynamics (CFD)IJIRSTBelum ada peringkat

- Alineacion CopleDokumen20 halamanAlineacion CopleCarlos Roberto TamarizBelum ada peringkat

- Machinery Component Maintenance and RepairDokumen2 halamanMachinery Component Maintenance and Repairapi-3723333100% (1)

- 6177-4 Press and Shrink FitsDokumen11 halaman6177-4 Press and Shrink FitsRajesh RajwadeBelum ada peringkat

- LUBPROD - ENG.1910.LTR SMDokumen12 halamanLUBPROD - ENG.1910.LTR SMJeff LBelum ada peringkat

- Product Catalog - USDokumen166 halamanProduct Catalog - USamijoski6051Belum ada peringkat

- Integrally Geared CompressorDokumen4 halamanIntegrally Geared CompressorHieuBelum ada peringkat

- JBJ Techniques LTD Screw PumpsDokumen49 halamanJBJ Techniques LTD Screw Pumpsreach_arindomBelum ada peringkat

- Vacuum PumpDokumen10 halamanVacuum Pumptutuli1990Belum ada peringkat

- Dry Gas Seal System ManualDokumen44 halamanDry Gas Seal System ManualGeorge J AlukkalBelum ada peringkat

- 160 250VRDokumen51 halaman160 250VRWai LaiBelum ada peringkat

- Construction VocabularyDokumen6 halamanConstruction VocabularyraMunBelum ada peringkat

- Hydrocarbon Turbo ExpandersDokumen20 halamanHydrocarbon Turbo ExpandersPakde NdokBelum ada peringkat

- Valves Overview Service enDokumen12 halamanValves Overview Service enBalraj PadmashaliBelum ada peringkat

- ACHE Windmill DraftguardDokumen5 halamanACHE Windmill DraftguardTIKSHALABelum ada peringkat

- s33x UpgradeDokumen15 halamans33x UpgradeAlexandre Borges BorgesBelum ada peringkat

- Research Memorandum: National Advisory Committee For AeronauticsDokumen39 halamanResearch Memorandum: National Advisory Committee For Aeronauticshariprasadr5199Belum ada peringkat

- Kop Flex Turbomachinery Coupling CatalogDokumen116 halamanKop Flex Turbomachinery Coupling CatalogEdson França Rodrigues0% (1)

- 2016 Vol-2 3 OCTDokumen12 halaman2016 Vol-2 3 OCTsppramBelum ada peringkat

- Jurusan Teknik Mesin Universitas Diponegoro 2011Dokumen27 halamanJurusan Teknik Mesin Universitas Diponegoro 2011BaraSeptianKusumandanaBelum ada peringkat

- Larry E. Rocela Civil EngineerDokumen39 halamanLarry E. Rocela Civil EngineerJolly Rose GonzalesBelum ada peringkat

- Belt Selection ConsiderationsDokumen31 halamanBelt Selection Considerationsdivyaraghavaraju100% (1)

- FIXIE Inc Beltdrive Manual - pdffIXIE Inc Beltdrive ManualDokumen8 halamanFIXIE Inc Beltdrive Manual - pdffIXIE Inc Beltdrive Manualnangkarak8201Belum ada peringkat

- Flexible Mechanical ElementsDokumen10 halamanFlexible Mechanical ElementsJithesh GopalBelum ada peringkat

- Chapter 3Dokumen39 halamanChapter 3amiranurul50% (2)

- Recommendations For Constructing and Calculating Conveyors: Modular BeltsDokumen20 halamanRecommendations For Constructing and Calculating Conveyors: Modular BeltshimubuetBelum ada peringkat

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDari EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsPenilaian: 5 dari 5 bintang5/5 (1)

- The GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...Dokumen18 halamanThe GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...jlfyBelum ada peringkat

- Selenoid eDokumen9 halamanSelenoid ejlfyBelum ada peringkat

- GekkoDokumen6 halamanGekkojlfyBelum ada peringkat

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDokumen3 halaman2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyBelum ada peringkat

- Posibles Soluciones en La OperaciónDokumen3 halamanPosibles Soluciones en La OperaciónjlfyBelum ada peringkat

- Filtro de AireDokumen7 halamanFiltro de AirejlfyBelum ada peringkat

- GekkoDokumen6 halamanGekkojlfyBelum ada peringkat

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDokumen3 halaman2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyBelum ada peringkat

- Posibles Soluciones en La OperaciónDokumen3 halamanPosibles Soluciones en La OperaciónjlfyBelum ada peringkat

- Motor FalconDokumen4 halamanMotor FalconjlfyBelum ada peringkat

- Digital PresureDokumen11 halamanDigital PresurejlfyBelum ada peringkat

- Regulador de PrecionDokumen7 halamanRegulador de PrecionjlfyBelum ada peringkat

- Seguridad y TransporteDokumen6 halamanSeguridad y TransportejlfyBelum ada peringkat

- Falcon C ConcentradoDokumen6 halamanFalcon C ConcentradojlfyBelum ada peringkat

- C1000-R3.1 Installation, Operations, and Maintenance ManualDokumen8 halamanC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyBelum ada peringkat

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDokumen4 halaman5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyBelum ada peringkat

- Parametros OperativosDokumen5 halamanParametros OperativosjlfyBelum ada peringkat

- Condiciones de OperacionDokumen2 halamanCondiciones de OperacionjlfyBelum ada peringkat

- ComisionamientoDokumen2 halamanComisionamientojlfyBelum ada peringkat

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDokumen4 halaman5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyBelum ada peringkat

- Especificaciones 2Dokumen8 halamanEspecificaciones 2jlfyBelum ada peringkat

- C1000-R3.1 Installation, Operations, and Maintenance ManualDokumen8 halamanC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyBelum ada peringkat

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDokumen6 halamanRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyBelum ada peringkat

- C1000-R3.1 Installation, Operations, and Maintenance ManualDokumen6 halamanC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyBelum ada peringkat

- Descripcion FalconDokumen4 halamanDescripcion FalconjlfyBelum ada peringkat

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDokumen6 halamanRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyBelum ada peringkat

- C1000-R3.1 Installation, Operations, and Maintenance ManualDokumen6 halamanC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyBelum ada peringkat

- Falcon c1000Dokumen9 halamanFalcon c1000jlfyBelum ada peringkat

- Jaw Part3Dokumen6 halamanJaw Part3jlfy100% (1)

- Jaw Part2Dokumen6 halamanJaw Part2jlfyBelum ada peringkat

- Green ProtectDokumen182 halamanGreen ProtectLuka KosticBelum ada peringkat

- Chapter 3.seed CertificationDokumen9 halamanChapter 3.seed Certificationalemneh bayehBelum ada peringkat

- Demand, Supply, and Market EquilibriumDokumen15 halamanDemand, Supply, and Market EquilibriumAnonymous HBQ86kBelum ada peringkat

- Diagnostic Test Everybody Up 5, 2020Dokumen2 halamanDiagnostic Test Everybody Up 5, 2020George Paz0% (1)

- PUBLIC - Axie Origins Changelogs - Season 4Dokumen2 halamanPUBLIC - Axie Origins Changelogs - Season 4Alef CarlosBelum ada peringkat

- Angeles City National Trade SchoolDokumen7 halamanAngeles City National Trade Schooljoyceline sarmientoBelum ada peringkat

- 20150714rev1 ASPACC 2015Dokumen22 halaman20150714rev1 ASPACC 2015HERDI SUTANTOBelum ada peringkat

- Quality Assurance Plan - CivilDokumen11 halamanQuality Assurance Plan - CivilDeviPrasadNathBelum ada peringkat

- The Innovator - S SolutionDokumen21 halamanThe Innovator - S SolutionKeijjo Matti100% (1)

- Piston Master PumpsDokumen14 halamanPiston Master PumpsMauricio Ariel H. OrellanaBelum ada peringkat

- Quality Assurance Plan-75FDokumen3 halamanQuality Assurance Plan-75Fmohamad chaudhariBelum ada peringkat

- Python Programming Laboratory Manual & Record: Assistant Professor Maya Group of Colleges DehradunDokumen32 halamanPython Programming Laboratory Manual & Record: Assistant Professor Maya Group of Colleges DehradunKingsterz gamingBelum ada peringkat

- Venere Jeanne Kaufman: July 6 1947 November 5 2011Dokumen7 halamanVenere Jeanne Kaufman: July 6 1947 November 5 2011eastendedgeBelum ada peringkat

- July 2014Dokumen56 halamanJuly 2014Gas, Oil & Mining Contractor MagazineBelum ada peringkat

- Research in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDokumen13 halamanResearch in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDessy ParamitaBelum ada peringkat

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIDokumen9 halamanJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidBelum ada peringkat

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDokumen2 halamanN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueBelum ada peringkat

- 3114 Entrance-Door-Sensor 10 18 18Dokumen5 halaman3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaBelum ada peringkat

- A Wicked Game by Kate BatemanDokumen239 halamanA Wicked Game by Kate BatemanNevena Nikolic100% (1)

- Promoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefDokumen52 halamanPromoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefEduardo Antonio Molinari NovoaBelum ada peringkat

- Installation, Operation & Maintenance Manual - Original VersionDokumen11 halamanInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqBelum ada peringkat

- CMS156Dokumen64 halamanCMS156Andres RaymondBelum ada peringkat

- Trading Rules To Successful ProfitsDokumen89 halamanTrading Rules To Successful ProfitsOuattaraBelum ada peringkat

- FBISE Grade 10 Biology Worksheet#1Dokumen2 halamanFBISE Grade 10 Biology Worksheet#1Moaz AhmedBelum ada peringkat

- Astm C119-16Dokumen8 halamanAstm C119-16Manuel Antonio Santos Vargas100% (2)

- Nugent 2010 Chapter 3Dokumen13 halamanNugent 2010 Chapter 3Ingrid BobosBelum ada peringkat

- - Анализ текста The happy man для ФЛиС ЮФУ, Аракин, 3 курсDokumen2 halaman- Анализ текста The happy man для ФЛиС ЮФУ, Аракин, 3 курсJimmy KarashBelum ada peringkat

- Protected PCM USB Memory Sticks For Pa3X.Dokumen1 halamanProtected PCM USB Memory Sticks For Pa3X.mariuspantera100% (2)

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Dokumen8 halamanTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmBelum ada peringkat

- Yuzu InstallerDokumen3 halamanYuzu InstallerJohnnel PrietosBelum ada peringkat