Access Floor Schneider

Diunggah oleh

ben_splHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Access Floor Schneider

Diunggah oleh

ben_splHak Cipta:

Format Tersedia

Modular Access Floor

for Data Center

From Rack to Row to Room to Building

Why using Scneider Electric modular

access floor in Data Centers

The evolution of modern Data Centers emphasizes specific exigencies of security,

flexibility and modularity due to increasing thermal loads, data exchange capacities,

cable volumes and connections over the Data Center lifetime.

Schneider Electric access floor represents a reliable and efficient choice and provides

high performances at the lowest management costs.

Advantages of Schneider Electric

modular access floor

Adaptability to the various cooling solutions

Flexibility over time

Under floor space is ideal to place a range of cooling solutions,

from direct air distribution to the path for air or chilled water

cables.

In the under floor space, all systems necessary for the room

operation (from connection to energy supply network and from

direct air distribution system to the possible path for chilled

water cables) may be easily adapted and enhanced according to

future exigencies which may not be estimated at the Data Center

startup.

Lower initial investment

A Data Center layout requires flexibility in the use of space.

Areas which are designed today for treading may be used in the

future to accommodate heavy devices. The perfect modularity of

Uniflair access floor allows to replace the existing structure and

panels reducing the initial installation costs; performances will

always meet customers requirements, management costs will

be minimized and the available space will be exploited at best.

Security and reliability

The under floor plenum allows to distribute the chilled water

flows while keeping them physically separate from cables and

sensitive devices, minimizing the risks of damage in the event

of leakages or condensation, breakdowns or malfunctions.

Enhanced cooling capacity

Efficient systems arrangement

With heights up to 80-100 cm, the under floor plenum provides

virtually unlimited cabling and air flow capacity (even with high

density loads) and guarantees easy access.

The compact structure of modular access floor (the access floor

module includes a grid of vertical supports with side of 60 cm)

allows full flexibility and is the ideal solution to arrange the various

operational systems so that they may easily reach the points of

use, enabling layout variation over time.

Air handling optimization

The modular access floor structure and the space underneath

the panels provide the support for assembling completely

integrated modular equipments for air flow or pressure control.

Equipments may be installed - without layout restrictions - on the

designed strategic points.

Possibility to freely integrate

safe cooling systems

A modular access floor allows to easily integrate, without

additional costs, cooling systems intrinsically safe and redundant.

Minimal maintenance costs

Operating costs are minimized: access to the systems in case

of breakdowns or for ordinary maintenance is easy and direct.

The operator can enter the under floor plenum by almost every

part of the room, in a flexible and safe way, without the use of a

ladder or other devices.

3

4

Panels

Suction tools

Steel perforated panels

Support structure

Various solutions for the core

and for the back and upper

finishing.

Additional tools for hot air

suction improvement.

In steel, of the same

dimensions as a panel, the

upper finishing may be the

same as the other panels.

Made completely from steel,

characterized by a range

of heights from 5 cm up to

1 meter and above.

Panels

There are two options for the panel core material: high density wooden

clipboard (720 kg/m) or calcium sulphate. The first allows the best

combination of mechanical properties and contained weights for an economic

purchase with ease of working; the second possesses excellent mechanical

properties and fire resistance, greatly reduced sensitivity to humidity and

notable acoustic absorption for improved treading comfort. The back of

the core panel is covered to further improve mechanical characteristics and

increase thermal-hygrometric stability. The materials used are aluminium (0,05

mm thick) or galvanized steel (0,5 mm thick), depending on the protection

grade and resistance required. Finishes are normally made from hard plastic

laminate, vinyl or rubber (antistatic or conductive version).

Support structure

Uni8 Evolution pedestals are made completely from galvanized steel with

available heights from 5,5 cm. Supports are made of a tube secured to the

circular basis. The shaped head is connected to a threaded crossbar and a

regulation nut. The support head is shaped in order to position the stringers

not only around the perimeter of the panel but also on one or both of the

diagonals. Special versions of the support are also available in case particularly

high mechanical resistance is required. In galvanized steel, the stringers

permit to increase the mechanical resistance and the stability of the floor.

Special bridge stringers are also available which allow to connect the supports

at greater distances than those of a single module so as to exploit spaces

without limits as regards the installation of Data Center systems.

Self-extinguishing and sound-proofing gaskets protect the metallic components.

Tubular brace fixing

The use of tubular brace fixing, positioned according to the room layout,

absorbs the dynamic horizontal stress of the modular access floor. This

element is made of a tubular frame in galvanized steel with diameter of 25 mm

and thickness of 1,2 mm; the two ends are specifically shaped in order to

provide an optimal connection to the supports (by means of a connecting

metal ring) and to the slab (by means of brackets).

9

8

In row cooling systems

(alternate and at the back)

Units for cooling the Racks

placed inside the room.

Containment

A solution allowing to

completely separate hot

and cold air flows.

Chilled water production

system

Units for the production of

chilled water to the in row

conditioning units.

Linear grills

In room cooling system

In aluminium, available for air

transition, they are inserted

inside a panel.

Perimeter units for the

distribution of refrigerated air

underneath the floor.

Linear grills

Linear grills consist of a set of longitudinal fins in anodized aluminium joined together. They are normally

used where the free under floor plenum is used for distributing air. Various widths are available (95, 145,

195 and 295 mm) and they integrate completely into the panel module.

They guarantee an air flow of 650-2000 m/h a 20 Pa.

Steel perforated panel

It is made of a flat steel sheet secured to a frame consisting of metal grilles and it is used for under floor air

distribution. A covering perforated to the same geometry is glued on the upper side of the panel.

The 588 holes panel, for example, where 22% of the area is free, provides an air flow of 1200 m/h at 20 Pa.

Steel perforated panels equipped with an air-flow regulation device are also available.

High Density Server

Active Floor

Active Floor is a flexible and modular system for cooling Data Centers with medium and high density

loads. Integrated within a modular access floor in front of the intake section of the rack, the Uniflair Active

Floor fits exactly into a modular access floor panel. The cold air produced by the Close Control perimeter

units is directly channelled to the source of the thermal load thanks to the advanced adjustment of the

direction of the air flow. The Active Floor creates a high density bubble of air which is maintained at a

constant temperature along the whole intake section of the rack, guaranteeing operation at the nominal

design conditions. The air flow varies according to the actual thermal load and is detected by two sensors

placed on the discharge section of the server.

AFPS

AFPS is a control module that maintains a constant nominal pressure underneath the floor (from 20 up

to 80 Pa) and manages the fan speed in all operating conditions and for the entire lifetime of the room.

The system maintains a constant pressure underneath the floor even during standard and emergency

maintenance, thus avoiding the creation of hot spots. This system is also able to automatically adapt to

the addition of new equipment and increases in the thermal load of the room.

Ceiling / Duct

Suction plenum

Blade Server Rack

Hot Aisle

Blade Server Rack

Hot Aisle

AFPS integrates with the distribution systems (active and passive) maintaining a constant pressure

underneath the floor and optimizing the system efficiency.

Pressure Sensor

Pressure Sensor

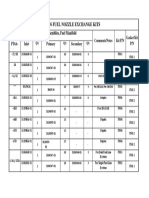

30KAL and 30KFL Panel 40LAL and 40LFL Panel

The panel 30KAL consists of a high density calcium sulphate

board core (1500 kg/m3) with nominal thickness 30 mm. It is

covered on the lower face with a 0,05 mm thick aluminium foil

(while the panel 30KFL is covered with a 0,5 mm thick sheet

of zinc-plated steel) and on the upper face with a 0,9 mm thick

plastic laminate (HPL High Pressure Laminate). The panel is

provided with a 0,45 mm thick black plastic edge material that is

self-extinguishing, non-creaking and PVC free and which is glued

along the panel sides.

30KAL and 30KFL panel physical & dimensional properties

(in compliance with European standard EN 12825)

Standard Test

40LAL and 40LFL panel physical & dimensional properties

(in compliance with European standard EN 12825)

Unit

Value

Calcium sulphate core

thickness

mm

30

Calcium sulphate core density

kg/m

Nominal panel weight

30KAL

Calcium sulphate core

electrical vertical resistance

EN 1081

ohm

Calcium sulphate core fire

reaction classification

EN 13501-1

Panel fire resistance

classification

5%

17,0

kg

30KFL

Tolerance

1500

The panel 40LAL consists of a high density particle board core

(720 kg/m3) with nominal thickness 38 mm. It is covered on the

lower face with a 0,05 mm thick aluminium foil (while the 40LFL

panel is covered with a 0,5 mm thick sheet of zinc-plated steel),

and on the upper face with a 0,9 mm thick plastic laminate (HPL

High Pressure Laminate). The panel is provided with a 0,45 mm

thick black plastic edge material that is self-extinguishing,

non-creaking and PVC free and which is glued along the panel

sides.

5%

18,1

Standard Test

Unit

Particle board core

thickness

mm

Particle board core density

kg/m

Nominal panel weight

40LAL

Value

38

720

5%

10,7

kg

40LFL

Tolerance

5%

11,8

Particle board core

electrical vertical resistance

EN 1081

ohm

Class A1

Particle board core fire

reaction classification

EN 13501-1

Class Cfl

EN 13501-2

REI 30

Panel fire resistance

classification

EN 13501-2

REI 30

Laminate covering fire

reaction classification

D.M.

26/06/84

Class 1

Laminate covering fire

reaction classification

D.M.

26/06/84

Class 1

Laminate covering electrical

vertical resistance

EN 1081

Not antistatic: 1010ohm

Static-dissipative: 106 - 108ohm

Laminate covering electrical

vertical resistance

EN 1081

Not antistatic: 1010ohm

Static-dissipative: 106 - 108ohm

Plastic edge

self-extinguishing

classification

UL94

Class V0

Plastic edge

self-extinguishing

classification

UL94

Class V0

107

30KAL and 30KFL panel physical & dimensional properties

(in compliance with European standard EN 12825)

Nominal dimension

Nominal thickness

(laminate thickness: 0,9 mm)

30KAL

30KFL

40LAL and 40LFL panel physical & dimensional properties

(in compliance with European standard EN 12825)

Unit

Value

Tolerance

mm

600x600

0,2 (class 1)

Nominal dimension

0,3 (class 1)

Nominal thickness

(laminate thickness: 0,9 mm)

31,1

mm

31,6

1010

40LAL

40LFL

Unit

Value

Tolerance

mm

600x600

0.2 (class 1)

39,1

mm

39,6

Planarity

mm

0,6

Planarity

mm

0,6

Diagonal difference

mm

0,4

Diagonal difference

mm

0,4

Inclined edge angle

degree

Inclined edge angle

degree

15

30KAL and 30KFL panel physical & dimensional properties

(in compliance with European standard EN 12825)

Type of structure: UNI8 Evolution (height: up to 600 mm)

Unit

3,1

4,0

4,6

2,8

2,9

5,1

5,2

3,9

4,2

5,2

5,5

4,4

4,6

8,5

8,6

20,0

25,0

26,0

31,0

30KAL

30KFL

30KAL

30KFL

30KAL

Concentrated load at the centre

of panel at 2.5 mm deflection

30KAL

Max allowed load at the centre

of panel (*)

30KAL

Uniformly distributed load

at 2,5 mm deflection

30KAL

Deflection class

Type of structure: UNI8 Evolution (height: up to 600 mm)

P (heavy)

Max allowed load at the centre

of side (*)

Load class

Type of stringer

2,7

30KAL

30KFL

30KFL

30KFL

30KFL

30KFL

kN

kN

kN

kN

kN/m

(*): the panel breaking load is obtained multiplying the max allowed load by 2 (safety factor).

15

40LAL and 40LFL panel physical & dimensional properties

(in compliance with European standard EN 12825)

M (medium)

Concentrated load at the centre

of side at 2.5 mm deflection

0.3 (class 1)

Unit

Concentrated load at the centre

of side at 2.5 mm deflection

40LAL

Max allowed load at the centre

of side (*)

40LAL

Concentrated load at the centre

of panel at 2.5 mm deflection

40LAL

Max allowed load at the centre

of panel (*)

40LAL

Uniformly distributed

load at 2,5 mm deflection

40LAL

Load class

Deflection class

40LFL

40LFL

40LFL

40LFL

40LFL

kN

kN

kN

kN

kN/m

Type of stringer

M (medium)

P (heavy)

2,6

3,0

3,2

3,5

3,1

3,2

4,1

4,2

3,7

4,1

4,9

5,3

6,4

6,5

6,9

7,0

18,0

22,0

25,0

30,0

40LAL

40LFL

40LAL

40LFL

(*): the panel breaking load is obtained multiplying the max allowed load by 2 (safety factor).

Uni8 Evolution Structure

Uni8 Evolution structure consists of the following elements: pedestal, connecting stringers and the

gaskets, to be put on the pedestal heads and on stringers.

Each metallic component is made from steel with an electrolytic galvanized surface treatment (minimum

thickness 3) on all surfaces.

Special versions of the pedestal are also available: with under head height regulation, with increased section

and reinforced version.

The UNI8 Evolution structure can be supplied with one of the following types of stringers:

light (L), medium (M), heavy (P), extra heavy (H version) and diagonal stringers (D and X versions).

Type of support

Components features

Nominal height

(with regulation range)

Working axial load (*)

(safety factor: 2)

UNI8 Evolution

Tube: : 20 mm / thickness: 2 mm

Threaded crossbar: M16

Base: : 90 mm / thickness: 1,5 mm

from 55 mm (10 mm)

to 620 mm (50 mm)

from 40 kN (55 mm)

to 20 kN (620 mm)

UNI8 Evolution

with under head height

regulation

Tube: : 20 mm / thickness: 2 mm

Threaded crossbar: M16

Base: : 90 mm / thickness: 1,5 mm

from 190 mm (35 mm)

to 620 mm (50 mm)

20 kN

UNI8 Evolution

with increased section

Tube: : 25 mm / thickness: 1,5 mm

Threaded crossbar: M16

Threaded bush: M16

Base: 100x100 mm / thickness: 2,5 mm

from 620 mm (50 mm)

to 980 mm (50 mm)

from 15 kN (620 mm)

to 5 kN (980 mm)

UNI8 Evolution

reinforced version

Tube: : 30 mm / thickness: 2 mm

Threaded crossbar: M20

Threaded bush: M20

Base: 100x100 mm / thickness: 2,5 mm

from 1000 mm (40 mm)

to 1500 mm (40 mm)

from 15 kN (1000 mm)

to 5 kN (1500 mm)

(*): the breaking load is obtained multiplying the working load by 2 (safety factor).

Some extra features are available:

Tubular bracing frame: made by means of tubular frames fixed to the concrete slab. The quantity and

location of the frames depend on: geometry and extension of the access floor, typology and distribution

of the static and dynamic loads applied.

Type of support

Static loads

Dynamic loads

(i.e. fork lifts, transpallet, hand-carts, cars)

UNI8 Evolution

Not necessary

Not necessary (to evaluate for higher pedestals)

UNI8 Evolution Under

head height regulation

Not necessary

Not necessary (to evaluate for higher pedestals)

UNI8 Evolution with increased section

To evaluate

Required with mechanical fixing of the pedestal base to the slab

UNI8 Evolution Reinforced version

To evaluate

Required with mechanical fixing of the pedestal base to the slab

Electrical continuity: guaranteed only by means of the stringers (every typology) fixed to the pedestal

heads by means of metric self-tapping screws.

Earthing system: feasible on structures with stringers. When the access floor area is less than 50 m2 it

is advisable to make one on each side of the floor. For access floor areas above 50 m2, it is advisable to

install one earthing system on each side of every 50 m floor area.

Alternative surface treatments: specific surface treatment such as yellow passivation and nichel

coating are available. They provide better performances against corrosion risk and the zink whiskers

phenomenon.

Brennercom Cube Reference

Brennercom manages dial-up/Internet connections in Austria and Italy and operates in co-location for several

companies.

The project concerns a 700 kW high density modular data center equipped with about 50 racks. It was

characterized by co-design activity between customer, engineer, installer and supplier of cooling solutions.

The plant design was focused on granting high system reliability and relevant energy saving benefits and

therefore the chiller units are equipped with Intelligent free-cooling and electronic expansion valve, while the

chilled water close control units are equipped with EC fans and AFPS system.

The plant operation is monitored and managed by a BMS system integrated with the cooling solution.

Server farm

Main features

Bolzano - Italy

Total cooling capacity = 700 kW

Year

Turn-key solution

2008-2009

High energy efficiency unit

Air conditioning Units

Chillers equipped with dual power supply

CW downflow close control units

Free-cooling chillers

BMS integrated system

Modular Access Floor

600x600 mm calcium sulphate panel

Lower aluminium covering

Other devices (Active floor, 588 holes steel

perforated panels, linear grills, )

Quick and easy to install and maintenance

The free placement of all the installations

(electrical, electronic, hydraulic and air conditioning

equipments) in the plenum underneath the floor

Future positioning of extra structures in order to

increase the load bearing capacity

Tight dimensional tolerances of panels

(-0,1/+0,2 mm) and fully modularity

Excellent fire and acoustic behavior

Use of eco-friendly materials

05UN0021X1A EN 11/11

adimer.net

Headquarters:

Uniflair S.p.A.

Viale della Tecnica, 2

35026 Conselve (Pd) Italy

Tel. +39 049 5388211

Fax +39 049 5388212

info@uniflair.com

uniflair.com

Owned and directed by Schneider Electric SA

EM

QU

uniflair.com

Company certified ISO9001 and ISO14001

LI

The technical data shown in this manual are not binding. The images shown in this

catalogue are for descriptive purposes only. They may therefore differ from specific

models which are selected. Schneider policy is one of continuous technological

innovation and the Company reserves the right to amend any data herein without prior

notice. All rights reserved. Reproduction in whole or in part is prohibited.

TY SY

ISO 9001 - Cert. n. 341

ISO 14001 - Cert. n. 0333A

Anda mungkin juga menyukai

- Atomic Elements TableDokumen56 halamanAtomic Elements Tableben_splBelum ada peringkat

- Edgetech Catalogue PDFDokumen17 halamanEdgetech Catalogue PDFKagitha Tirumala100% (3)

- Design Points For Negative PressureDokumen23 halamanDesign Points For Negative PressureShohei Namjoon LetoBelum ada peringkat

- EC Fan Application Note - EMERSONDokumen8 halamanEC Fan Application Note - EMERSONlouie mabiniBelum ada peringkat

- Vav - 1Dokumen10 halamanVav - 1perezismaelBelum ada peringkat

- ACH580 Drives For HVAC Catalog 3AUA0000186691 RevEDokumen36 halamanACH580 Drives For HVAC Catalog 3AUA0000186691 RevESalaar AnsarBelum ada peringkat

- SPM-D2-10 Synchronizing Unit: ManualDokumen68 halamanSPM-D2-10 Synchronizing Unit: ManualDouglas FernandoBelum ada peringkat

- Wet Steam Washing SystemDokumen7 halamanWet Steam Washing SystemPrudhvi Raj100% (1)

- Air Change Rates NewDokumen3 halamanAir Change Rates NewlakshminarayananBelum ada peringkat

- Two-Phase Flow (Gas-Flow) Line SizingDokumen24 halamanTwo-Phase Flow (Gas-Flow) Line SizingvictorvikramBelum ada peringkat

- Vol 2 Airconditioning Ventilation UserGuideDokumen44 halamanVol 2 Airconditioning Ventilation UserGuideMonica Astrid0% (1)

- Cooling Coil 03Dokumen18 halamanCooling Coil 03Sam Wang Chern Peng100% (3)

- Safety LOPADokumen28 halamanSafety LOPAnandorg1113100% (1)

- CLCP Euro - Commercial May 09: Quick Selection ProcedureDokumen2 halamanCLCP Euro - Commercial May 09: Quick Selection ProcedurehfrankieBelum ada peringkat

- Data Collection FormDokumen16 halamanData Collection FormRohit JainBelum ada peringkat

- Chilled Water Pump Head Calculation SummaryDokumen15 halamanChilled Water Pump Head Calculation SummaryZain ShariffBelum ada peringkat

- Daikin VRV III (Selection Installation Proceedure) Technical Data Book PDFDokumen56 halamanDaikin VRV III (Selection Installation Proceedure) Technical Data Book PDFHarveen Singh100% (1)

- Leaflet Climaveneta For DatacenterDokumen28 halamanLeaflet Climaveneta For Datacenterben_spl100% (1)

- Hospital Room Design RequirementsDokumen4 halamanHospital Room Design Requirementsalialavi2Belum ada peringkat

- 9.6MVA - Technical Specifications For Inverter Duty TransformerDokumen7 halaman9.6MVA - Technical Specifications For Inverter Duty Transformerarunghandwal100% (2)

- Cause Effect Analysis of Oil Loss in Edible Oil IndustryDokumen60 halamanCause Effect Analysis of Oil Loss in Edible Oil IndustrySaurabh RaiBelum ada peringkat

- 11 5 Temperature and Pressure 4th EdDokumen18 halaman11 5 Temperature and Pressure 4th Edapi-267245178Belum ada peringkat

- CH 3 Gas Refrigeration CycleDokumen20 halamanCH 3 Gas Refrigeration CycleMeleseBelum ada peringkat

- Pressure Volume Calculator 02Dokumen6 halamanPressure Volume Calculator 02Jenny Cecilia Ureña ZuriBelum ada peringkat

- Distributed Pumping ConceptDokumen52 halamanDistributed Pumping ConceptRichard Richard100% (1)

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFDokumen181 halaman320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)

- BOSS™ Pressurisation Units and Expansion Vessels PDFDokumen16 halamanBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASBelum ada peringkat

- Aspirating Smoke DetectionDokumen13 halamanAspirating Smoke Detectionpeter_joonBelum ada peringkat

- Small Absorption Chillers Process ApplicationsDokumen2 halamanSmall Absorption Chillers Process ApplicationsAdil AbdoBelum ada peringkat

- Diesel Engines for Unrestricted Continuous OperationDokumen2 halamanDiesel Engines for Unrestricted Continuous OperationJorge Bellido100% (1)

- Folio SainsDokumen15 halamanFolio SainsMohammad Afifi Rohman80% (5)

- GUNON-Janus-Novec1230 Presentation R00Dokumen48 halamanGUNON-Janus-Novec1230 Presentation R00ben_splBelum ada peringkat

- CITEC - Genesis Catalogue 2008 FinalDokumen12 halamanCITEC - Genesis Catalogue 2008 FinalDenny100% (3)

- Rahul Kumar B Electrical Dept. Abhijeet Projects LimitedDokumen23 halamanRahul Kumar B Electrical Dept. Abhijeet Projects LimitedrahulengineerBelum ada peringkat

- Aire Acondicionado INROWDokumen9 halamanAire Acondicionado INROWSander SanchezBelum ada peringkat

- Comparison of Ductwork Systems: Attributes Metal (GI) Spiralite Insulated Pre-Insulated (PI) Fabric Product AttributesDokumen5 halamanComparison of Ductwork Systems: Attributes Metal (GI) Spiralite Insulated Pre-Insulated (PI) Fabric Product Attributesthomas100% (1)

- Siemens Data Center Whitepaper Distributed Redundancy PDFDokumen8 halamanSiemens Data Center Whitepaper Distributed Redundancy PDFHo Ming ChanBelum ada peringkat

- Variable Primary Chilled Water PDFDokumen8 halamanVariable Primary Chilled Water PDFsyed mustafa aliBelum ada peringkat

- Thermomagnetic and Electronic Trip UnitsDokumen1 halamanThermomagnetic and Electronic Trip UnitsIsagani MadridBelum ada peringkat

- Fan Coil Unit Selection Program User ManualDokumen18 halamanFan Coil Unit Selection Program User ManualkirmaniBelum ada peringkat

- Genset CalculationDokumen1 halamanGenset CalculationCheah ChenBelum ada peringkat

- T053-All Tenses - English Grammar Exercises BDokumen1 halamanT053-All Tenses - English Grammar Exercises BΒασιλεία ΕυαγγέλουBelum ada peringkat

- Webinar Relief Valves 1Dokumen20 halamanWebinar Relief Valves 1einsten777Belum ada peringkat

- As 2560.2.3-2007 Sports Lighting Specific Applications - Lighting For Football (All Codes)Dokumen7 halamanAs 2560.2.3-2007 Sports Lighting Specific Applications - Lighting For Football (All Codes)SAI Global - APACBelum ada peringkat

- Daikin Packaged Unit UAYQ-C Series Engineering DataDokumen58 halamanDaikin Packaged Unit UAYQ-C Series Engineering DataMichaelBelum ada peringkat

- Return Air Square: Ceiling DiffuserDokumen1 halamanReturn Air Square: Ceiling DiffuserEnak Cenir100% (1)

- YORK PackageDokumen28 halamanYORK PackageSreekumarBelum ada peringkat

- Daikin VRV IV CatalogueDokumen46 halamanDaikin VRV IV CatalogueNathan Vo100% (5)

- Expansion tank calculationsDokumen5 halamanExpansion tank calculationspsjjoshi0% (1)

- VKM-GM Series VKM-G Series: DX-coil and Humidifier DX-coilDokumen9 halamanVKM-GM Series VKM-G Series: DX-coil and Humidifier DX-coilcodefinderBelum ada peringkat

- Advanced Air Duct Design Part 2Dokumen29 halamanAdvanced Air Duct Design Part 2Timothy Bryant100% (1)

- IntellectualDokumen24 halamanIntellectualAnonymous 6cQRWqBelum ada peringkat

- Quality NBR Insulation Thickness Guide for Condensation ControlDokumen8 halamanQuality NBR Insulation Thickness Guide for Condensation ControlSam Wing HongBelum ada peringkat

- Fire SafetyDokumen26 halamanFire SafetySharon Lambert100% (1)

- 2a. Specs For Valves - IADokumen4 halaman2a. Specs For Valves - IAPraveen KasrottaranBelum ada peringkat

- VRV SystemDokumen152 halamanVRV SystemKHA120096 StudentBelum ada peringkat

- District Cooling Guide Second Edition - Unlocked-2Dokumen2 halamanDistrict Cooling Guide Second Edition - Unlocked-2Ahmed LabibBelum ada peringkat

- Multi Split Brochure 2015Dokumen28 halamanMulti Split Brochure 2015angelseven7Belum ada peringkat

- Hunter GP100 08-2003 PDFDokumen1 halamanHunter GP100 08-2003 PDFaymanmkBelum ada peringkat

- AET-2009-AET K13-Factor 400V R1Dokumen9 halamanAET-2009-AET K13-Factor 400V R1deepuji2008Belum ada peringkat

- HVAC Design for High Ambient ConditionsDokumen15 halamanHVAC Design for High Ambient ConditionsariesBelum ada peringkat

- Ashrae 90 1 Ve-NavigatorDokumen2 halamanAshrae 90 1 Ve-NavigatorSauraj GautamBelum ada peringkat

- Honeywell Single Duct VAV - VAV Box Schema Eelctrica, Descriere, Mod de FunctionareDokumen24 halamanHoneywell Single Duct VAV - VAV Box Schema Eelctrica, Descriere, Mod de FunctionareViorel CatalinBelum ada peringkat

- Wise CatalogDokumen177 halamanWise CatalogHatim IshakBelum ada peringkat

- Product Data: Features/BenefitsDokumen60 halamanProduct Data: Features/BenefitsBJNE01Belum ada peringkat

- Thermodynamics ChapterDokumen42 halamanThermodynamics ChapterBuild AteddyBelum ada peringkat

- Sprinkler ESFRDokumen4 halamanSprinkler ESFRGustavo Torres CabañasBelum ada peringkat

- MAKRO MYANMAR ACMV PDF DWG PDFDokumen21 halamanMAKRO MYANMAR ACMV PDF DWG PDFHnin Pwint100% (1)

- Compact Fans For AC and DC 2014 enDokumen268 halamanCompact Fans For AC and DC 2014 enParasuraman SundaravelBelum ada peringkat

- Refri - Coca-Cola R290 P-T ChartDokumen4 halamanRefri - Coca-Cola R290 P-T ChartmanonpomBelum ada peringkat

- SM Dedicated Outdoor Air Unit DOASDokumen204 halamanSM Dedicated Outdoor Air Unit DOASYudha P MBelum ada peringkat

- Cibse Variable Flow DPCV CPDDokumen44 halamanCibse Variable Flow DPCV CPDoiramhoangBelum ada peringkat

- Oventrop Valve Technical SpecDokumen15 halamanOventrop Valve Technical SpecblindjaxxBelum ada peringkat

- En 12101-2 SHEV-Info EnglishDokumen21 halamanEn 12101-2 SHEV-Info EnglishStefanSevastianBelum ada peringkat

- Daikin Légkezelő KatalógusDokumen8 halamanDaikin Légkezelő KatalógusAl Dizdar NazarBelum ada peringkat

- DCW PresentationDokumen28 halamanDCW Presentationben_splBelum ada peringkat

- Voice With DPDokumen6 halamanVoice With DPben_splBelum ada peringkat

- Houston Fire Department: This Is A Fill Out On Computer & Print Form Only!Dokumen19 halamanHouston Fire Department: This Is A Fill Out On Computer & Print Form Only!ben_splBelum ada peringkat

- Meetings with community leadersDokumen1 halamanMeetings with community leadersben_splBelum ada peringkat

- Psych Process 09Dokumen9 halamanPsych Process 09mauricio duran albertosBelum ada peringkat

- DMX3Dokumen7 halamanDMX3ben_splBelum ada peringkat

- NABLUS REHABILITATION CENTER PHASE I EXCAVATIONDokumen60 halamanNABLUS REHABILITATION CENTER PHASE I EXCAVATIONben_splBelum ada peringkat

- FLEXNet CodesDokumen5 halamanFLEXNet Codesben_splBelum ada peringkat

- Pdcopro EatDokumen9 halamanPdcopro Eatben_splBelum ada peringkat

- Partial Match Lookup Ado ChesstuffDokumen403 halamanPartial Match Lookup Ado Chesstuffben_splBelum ada peringkat

- Kembtuhianan MtearaiialDokumen64 halamanKembtuhianan Mtearaiialben_splBelum ada peringkat

- Designed PresentationDokumen1 halamanDesigned Presentationben_splBelum ada peringkat

- 3M Safety Walking Slip Resistant TapeDokumen12 halaman3M Safety Walking Slip Resistant Tapeben_splBelum ada peringkat

- 3M Safety Walking Slip Resistant TapeDokumen12 halaman3M Safety Walking Slip Resistant Tapeben_splBelum ada peringkat

- 3M Safety Walk GuideDokumen2 halaman3M Safety Walk Guideben_splBelum ada peringkat

- Perhitungan Penambahan Screed Lantai Lantai 2 Project Ec Bni - Ibm SlipiDokumen2 halamanPerhitungan Penambahan Screed Lantai Lantai 2 Project Ec Bni - Ibm Slipiben_splBelum ada peringkat

- Eaton DCD Dubai 2013 Preview Press ReleaseDokumen3 halamanEaton DCD Dubai 2013 Preview Press Releaseben_splBelum ada peringkat

- Epoxy ResinDokumen7 halamanEpoxy Resinben_splBelum ada peringkat

- Hot Sync Datasheet Rev A Re WorkingDokumen2 halamanHot Sync Datasheet Rev A Re Workingben_splBelum ada peringkat

- Eaton Hotswap Epdu BrochureDokumen2 halamanEaton Hotswap Epdu Brochureben_splBelum ada peringkat

- In Centimeter (CM) : Floor Elevation DC Bni-Ibm Slipi - Jakarta by Draco InternasionalDokumen1 halamanIn Centimeter (CM) : Floor Elevation DC Bni-Ibm Slipi - Jakarta by Draco Internasionalben_splBelum ada peringkat

- In Centimeter (CM) : Floor Elevation DC Bni-Ibm Slipi - Jakarta by Draco InternasionalDokumen1 halamanIn Centimeter (CM) : Floor Elevation DC Bni-Ibm Slipi - Jakarta by Draco Internasionalben_splBelum ada peringkat

- Titik Lompat Ukur ElevasiDokumen1 halamanTitik Lompat Ukur Elevasiben_splBelum ada peringkat

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDokumen1 halamanPt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchBelum ada peringkat

- Chlorosorb Ultra Case StudiesDokumen5 halamanChlorosorb Ultra Case StudiesWitta Kartika RestuBelum ada peringkat

- Marine Chock InstallationDokumen48 halamanMarine Chock InstallationSumeet SawantBelum ada peringkat

- Medium Power Substation Instruction ManualDokumen24 halamanMedium Power Substation Instruction ManualOmar GraterolBelum ada peringkat

- Kinetic and Potential Energy PracticeDokumen1 halamanKinetic and Potential Energy Practicealchemist2000Belum ada peringkat

- Objective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaDokumen4 halamanObjective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaVidya Sagar100% (1)

- EXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSUREDokumen44 halamanEXPANSION VALVES SERIES DOCUMENT (THERMOSTATIC & CONSTANT PRESSURESite EngineeringtiaBelum ada peringkat

- 568100Dokumen2 halaman568100Talha TariqBelum ada peringkat

- WM2077CW Service ManualDokumen44 halamanWM2077CW Service ManualMichael David SharkeyBelum ada peringkat

- Graviner MK6 Oil Mist DetectorDokumen4 halamanGraviner MK6 Oil Mist DetectorDhanielBelum ada peringkat

- 39CQ Iom 06302014Dokumen20 halaman39CQ Iom 06302014Non Etabas GadnatamBelum ada peringkat

- Inspection GalleryDokumen4 halamanInspection GalleryrajmohapatraBelum ada peringkat

- Specification For Smoke Bomb Test PDFDokumen4 halamanSpecification For Smoke Bomb Test PDFARUNBelum ada peringkat

- VS1-2 Manual PDFDokumen284 halamanVS1-2 Manual PDFJorge InostrozaBelum ada peringkat

- KR AGILUS Hygienic Machine Fast Cleaning Food PharmaDokumen2 halamanKR AGILUS Hygienic Machine Fast Cleaning Food PharmaValke Athletes HandcareBelum ada peringkat

- Ufc 3 430 09Dokumen106 halamanUfc 3 430 09carlcrowBelum ada peringkat

- O359h MilDokumen90 halamanO359h MilNisar AhmedBelum ada peringkat

- Ethics IndividualDokumen3 halamanEthics IndividualJustin JJBelum ada peringkat

- Checklist Water Audit v1Dokumen19 halamanChecklist Water Audit v1hammad.phistreamBelum ada peringkat

- GS-37 LcaDokumen22 halamanGS-37 LcaGeny KucherBelum ada peringkat