Scheme Design For Formwork

Diunggah oleh

Billy CastilloJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Scheme Design For Formwork

Diunggah oleh

Billy CastilloHak Cipta:

Format Tersedia

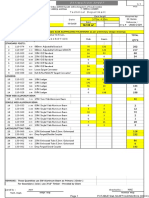

Application Risk Assessment UIX20100

Formwork

Section 1 Risk Associated with Scheme Design

Ref.

1.1

1.2

Hazard

Risk

Actions to Mitigate Risk

Incorrect provision of design input information

regarding, loading, construction sequence,

location and geometry.

Unfit design for the intended purpose.

Possible problems due to non-fit,

overloading, local failure or collapse

Issue comprehensive Design Brief and/or Project

Documentation to RMD

Other

Discuss requirements with customer and complete

detailed Customer Enquiry Form and RMD Design

Brief

RMD

Incorrect determination of applied loads,

structural analysis, design, stability check,

provision of lateral restraint or other calculated

criteria required as a part of the design of the

RMD equipment.

Overloading or failure of components or

assemblies possibly leading to collapse

Insufficient provision for access platforms or

guard-rails

Falls from the structure

1.4

Lifting of made up formwork panels

1.5

Permanent works or temporary foundations

unable to accept reactions from formwork

system

Check Box Key

Issue D

09/06/14

Designs to be carried out by appropriately

experienced staff in accordance with technical

standards applicable to the country in which the

equipment will be used.

RMD

Check design in accordance with RMD Technical

Office Procedures

Placing of parts inadequately defined

1.3

Check

Box

Consider access for all necessary work operations

as part of the design process. RMD access

designed and detailed where appropriate

RMD

Overloading of lifting accessories, failure of

form connections, fall of the load

Consider handling of the formwork during the

design and communicate suitable measures

RMD

Excessive

settlement,

overstress

supporting structure or strata, collapse

Show maximum reactions from formwork system

on RMD Drawing

RMD

Ensure adequacy of foundations and/or permanent

works

Other

RMD - Mitigating measures by RMD Kwikform

of

Other - Mitigating measures required by others

Further info: +44 (0) 1922 743743

RMD = RMD Kwikform

Sheet 1 of 4

The information contained within this document remains the property of RMD Kwikform and is not to be altered or reproduced in any other form without permission. RMDK reserve the right to change any specification without giving prior notice.

Residual Risk information is detailed on the RMDK scheme drawings. It is the customers responsibility to identify all other hazards and take appropriate action to mitigate the risk associated with these as well as with the hazards checked Other above

Application Risk Assessment UIX20100

Formwork

Section 2 Risk Associated with Material Supply and Return

Ref.

2.1

Risk

Actions to Mitigate Risk

Check

Box

Parts omitted, inadequate or unsuitable for

load applied leading to possible failure

Inspect materials to a pre-defined standard

established in RMD QA Operating Procedure.

Reject non-conforming materials

RMD

Identify items by data sheets / brochures and

reference by code numbers

RMD

Implement product training for relevant RMD

staff

RMD

Hazard

Damaged or deteriorated material sent to site

2.2

Incorrect components sent to site

2.3

Part

identification is not clear

understood by relevant RMD staff

2.4

Unsafe bundling, stillaging, stacking, loading or

lashing by RMD staff. Inadequate provision of

access for lifting accessories to permit

offloading on site

Unintentional shift or fall of load during any

stage of transit, unloading, distribution or

unpacking. Illegal load

Pack and secure materials in accordance with

RMD Product Handling Manual/HIM sheets

Cutting of steel or plastic banding

Eye injury, lacerations due to spring action.

Collapse of the bundle once bands have been

released, crushing injuries

Identify and employ operating methods to

avoid injury. Keep banded bundles in post

pallets to avoid collapse

Other

Unintentional shift or fall of load during any

stage of transit, unloading or unpacking. Illegal

load

Pack and secure materials in accordance with

RMD Product Handling Manual/HIM Sheets

Other

Provide RMD Product Handling Manual/HIM

sheets on request

RMD

2.5

2.6

or

not

Unsafe bundling, stillaging, stacking, loading,

overloading or lashing by customers staff.

Inadequate provision of access for lifting

accessories to permit offloading at RMD

branch

Check Box Key

Issue D

09/06/14

RMD - Mitigating measures by RMD Kwikform

Other - Mitigating measures required by others

Further info: +44 (0) 1922 743743

RMD

RMD = RMD Kwikform

Sheet 2 of 4

The information contained within this document remains the property of RMD Kwikform and is not to be altered or reproduced in any other form without permission. RMDK reserve the right to change any specification without giving prior notice.

Residual Risk information is detailed on the RMDK scheme drawings. It is the customers responsibility to identify all other hazards and take appropriate action to mitigate the risk associated with these as well as with the hazards checked Other above

Application Risk Assessment UIX20100

Formwork

Section 3 Risk Associated with Assembly/Erection/Dismantling

Ref.

Hazard

Risk

Actions to Mitigate Risk

Check

Box

3.1

Components with mass exceeding 25kg

Manual handling injury

Plan lifts to comply with applicable manual

handling regulations

Other

3.2

Incorrect attachment of lifting equipment to

formwork components

Local failure, falls of load, crushing injuries

Use RMD accessories correctly to attach the

load to the lifting equipment

Other

3.3

Improper erection or dismantling sequence

Local instability ,partial or global failure

Prepare method statement for all phases

Other

Provide best practice guidance

RMD

Operate control and checking procedures in

accordance with country-of-use industry best

practice standards. Inform RMD Technical

Office of any intended departures from the

drawings.

Other

3.4

3.5

3.6

Setting out incorrect, omission or use of wrong

parts, incorrect waler plates used for tie load,

misplacing of form ties, incorrect spacing of

beams, connections not secured or tightened.

Unplanned modifications to layouts

Overloading

of

components,

deflection, instability, failure

Incorrect placement of alignment rails, clamps

and fasteners at the joints between formwork

panels. Lifting of forms made of assembled

panels with an orientation not covered by the

design (lifting assembled panel forms up by the

edges)

Failure of the made up form at the joints during

lifting. Falling of forms, crushing injuries

Material obtained from different suppliers or

contractors own stocks

Differing quality of components

Check Box Key

Issue D

09/06/14

RMD - Mitigating measures by RMD Kwikform

excessive

Communicate restrictions to lifting practice to

users

Other

Communicate restrictions to lifting practice to

customer

RMD

Ensure that non-RMD materials conform with

the standards required by the design and are

compatible with RMD materials

Other

Other - Mitigating measures required by others

Further info: +44 (0) 1922 743743

RMD = RMD Kwikform

Sheet 3 of 4

The information contained within this document remains the property of RMD Kwikform and is not to be altered or reproduced in any other form without permission. RMDK reserve the right to change any specification without giving prior notice.

Residual Risk information is detailed on the RMDK scheme drawings. It is the customers responsibility to identify all other hazards and take appropriate action to mitigate the risk associated with these as well as with the hazards checked Other above

Application Risk Assessment UIX20100

Formwork

Section 4 Risk Associated with Equipment Use

Ref.

4.1

4.2

Hazard

Risk

Unconsidered loads placed on formwork such

as concrete pressure higher than allowed for in

design, excessive live/access loads, rough or

incorrect handling

Local failure or collapse

Improper sequence of operation

Local instability causing injury to operatives.

Partial failure of structure

Check

Box

Actions to Mitigate Risk

Supervise operations to ensure they remain

within the constraints of the RMD documents

Other

Prepare method statement for all work phases,

establish/use appropriate control procedures

Other

Provide best practice guidance

RMD

4.3

Working at height

Falls of men or materials from height

Ensure all necessary edge

provided

4.4

Lifting of forms made of assembled panels with

an orientation not covered by the design (lifting

assembled panel forms up by the edges)

Failure of the made up form at the joints during

lifting. Falling of forms, crushing injuries

Communicate restrictions to lifting practice to

users

Other

Communicate restrictions to lifting practice to

customer

RMD

protection is

Other

4.5

The placing of operatives within the confines of

the formwork

Falls, abrasion on rebar, difficulty in extraction

in an emergency.

Formulate and ensure safe working practice.

4.6

Wind - Storm conditions exceeding the design

considerations

Failure of structure

Inspect structure after any significant wind or

storm conditions

Other

4.7

Snow or ice formation. Accumulation of mud on

working platforms

Overloading or impediment to working.

Slips trips and falls.

Clear working platforms or await better

conditions before operating. Use boot wash

before accessing platforms

Other

Check Box Key

Issue D

09/06/14

RMD - Mitigating measures by RMD Kwikform

Other - Mitigating measures required by others

Further info: +44 (0) 1922 743743

Other

RMD = RMD Kwikform

Sheet 4 of 4

The information contained within this document remains the property of RMD Kwikform and is not to be altered or reproduced in any other form without permission. RMDK reserve the right to change any specification without giving prior notice.

Residual Risk information is detailed on the RMDK scheme drawings. It is the customers responsibility to identify all other hazards and take appropriate action to mitigate the risk associated with these as well as with the hazards checked Other above

Anda mungkin juga menyukai

- Safe Work Method Statement Slab Concreting PurposeDokumen4 halamanSafe Work Method Statement Slab Concreting Purposeyogesh shindeBelum ada peringkat

- Ojt SafetyDokumen122 halamanOjt SafetyChristopher Oares100% (1)

- 2010 10 OnlineDokumen72 halaman2010 10 OnlineSanja RadovicBelum ada peringkat

- RMD Shoring PDFDokumen2 halamanRMD Shoring PDFBalaji SubramanianBelum ada peringkat

- Peri Formwork Scaffolding Engineering CompressDokumen20 halamanPeri Formwork Scaffolding Engineering CompressChandra Purnomo Adjie100% (1)

- Method Statement 09062023Dokumen13 halamanMethod Statement 09062023JAMES neelBelum ada peringkat

- Formwork and Falsework (Safe Work Austrelia)Dokumen43 halamanFormwork and Falsework (Safe Work Austrelia)Anupam GhoshBelum ada peringkat

- Scaffolding SafetyDokumen51 halamanScaffolding SafetySatya NaiduBelum ada peringkat

- 3.WA Timber Formwork TablesDokumen3 halaman3.WA Timber Formwork Tablestuong buiBelum ada peringkat

- Method Statement: Emergency Contact DetailsDokumen9 halamanMethod Statement: Emergency Contact DetailsShazwaniBelum ada peringkat

- A Guide To Commissioning Scaffold Design: 1 of 6 June 2020Dokumen6 halamanA Guide To Commissioning Scaffold Design: 1 of 6 June 2020Matthew PowellBelum ada peringkat

- Kwikstage Propping RMD Kwikform UAE 8705 Low 5Dokumen10 halamanKwikstage Propping RMD Kwikform UAE 8705 Low 5vINODBelum ada peringkat

- Demolition 4 PDFDokumen19 halamanDemolition 4 PDFazrulBelum ada peringkat

- Sample Fall ProtectionDokumen5 halamanSample Fall ProtectionLiz CBelum ada peringkat

- Method Statement For Interlocking PavingDokumen5 halamanMethod Statement For Interlocking Pavingdinidu3priyankara3saBelum ada peringkat

- Demolition and Alterations: Construction Technology IvDokumen75 halamanDemolition and Alterations: Construction Technology IvLaici Kang0% (1)

- RAPIDSHOREDokumen44 halamanRAPIDSHOREwaquarshai100% (1)

- Method Statement For DemolitionDokumen7 halamanMethod Statement For DemolitionNikita KasyanovBelum ada peringkat

- Calculation Sheet of Slab Scaffolding: Middle East Scaffolding TR. L.L.CDokumen8 halamanCalculation Sheet of Slab Scaffolding: Middle East Scaffolding TR. L.L.CissaBelum ada peringkat

- Formwork Handbook DLF Capital GreensDokumen48 halamanFormwork Handbook DLF Capital GreensAnupam GhoshBelum ada peringkat

- Vario GT 24 Girder Wall Formwork Instructions For Assembly and UseDokumen96 halamanVario GT 24 Girder Wall Formwork Instructions For Assembly and UsePaul LadjarBelum ada peringkat

- SfgfdsDokumen10 halamanSfgfdsMartyn M. EleBelum ada peringkat

- Method Statement To Seal The OpeningDokumen3 halamanMethod Statement To Seal The OpeningprabhuBelum ada peringkat

- Concrete Formwork Suspended SlabDokumen5 halamanConcrete Formwork Suspended SlabKate HopleyBelum ada peringkat

- Base Connection DesignDokumen7 halamanBase Connection Designmsiddiq1Belum ada peringkat

- Method Statement - Site ClearanceDokumen6 halamanMethod Statement - Site Clearanceqoci5ko100% (1)

- Acrow Vari Form SystemDokumen20 halamanAcrow Vari Form SystemYasserMohsenBelum ada peringkat

- Sistema MODEX HunnebeckDokumen7 halamanSistema MODEX HunnebeckDavid Carballo RetanaBelum ada peringkat

- RMD Trench Boxes - Issue CDokumen26 halamanRMD Trench Boxes - Issue CMohammed HafizBelum ada peringkat

- Scaffolding PropDokumen6 halamanScaffolding Propwaquarshai100% (1)

- Peri Formwork or False Systems For Pier ConstructionDokumen142 halamanPeri Formwork or False Systems For Pier ConstructionKhaja MohiddinBelum ada peringkat

- Doka Top50Dokumen148 halamanDoka Top50Mohammed Adnan100% (2)

- Access Scaffolding - Leader FortDokumen8 halamanAccess Scaffolding - Leader FortMuhammad ZuhayrBelum ada peringkat

- 001 SWMS - Piling WorkDokumen20 halaman001 SWMS - Piling Worksasi kumar0% (1)

- Method Statement For R.C.C PDFDokumen2 halamanMethod Statement For R.C.C PDFVVRAO100% (1)

- MegaShor Technical DataDokumen83 halamanMegaShor Technical Datadcp40322Belum ada peringkat

- GL 17 ScaffoldingDokumen18 halamanGL 17 Scaffoldingtp101267Belum ada peringkat

- WHS 2016 Demolition SWMS-1Dokumen12 halamanWHS 2016 Demolition SWMS-1Cherylea haassBelum ada peringkat

- 35 - Method Statements For Erection of Steel PDFDokumen1 halaman35 - Method Statements For Erection of Steel PDFAbdul RahmanBelum ada peringkat

- Tower Mobile Scaffolds Information SheetDokumen2 halamanTower Mobile Scaffolds Information SheetthecrowdedhouseBelum ada peringkat

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Dokumen1 halamanPOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelBelum ada peringkat

- Dokascaff: One Scaffold, Multiple ApplicationsDokumen36 halamanDokascaff: One Scaffold, Multiple Applicationscuong voBelum ada peringkat

- Doka Formwork Manual 999776002 - 2015 - 04 - OnlineDokumen48 halamanDoka Formwork Manual 999776002 - 2015 - 04 - OnlineEyo Etim50% (2)

- Scaffolding SafetyDokumen4 halamanScaffolding Safetyrguy3223Belum ada peringkat

- Basics of A ScaffoldDokumen47 halamanBasics of A ScaffoldAhmed IsahBelum ada peringkat

- Example Site Specific Erection PlanDokumen3 halamanExample Site Specific Erection PlanQi ZengBelum ada peringkat

- Design Repropping Beam 24FDokumen11 halamanDesign Repropping Beam 24FNelson WongBelum ada peringkat

- 5.backfilling and CompactionDokumen4 halaman5.backfilling and CompactionZeeshan Abbasi100% (1)

- Scaffold Safe Work Method Statement: Project TitleDokumen11 halamanScaffold Safe Work Method Statement: Project TitleGirish R RaoBelum ada peringkat

- Circular Formwork H20: User InformationDokumen36 halamanCircular Formwork H20: User InformationMMMSLOUHBelum ada peringkat

- Acrow SpanDokumen2 halamanAcrow SpangattaiahBelum ada peringkat

- Rapidshor RMD Kwikform United Kingdom 382 Low PDFDokumen11 halamanRapidshor RMD Kwikform United Kingdom 382 Low PDFAhmed Yousry AbbasyBelum ada peringkat

- Falsework CheckingDokumen8 halamanFalsework Checkingdineshsirasat100% (1)

- Work Method Statement For Sub Structure Works: (Pile Cap)Dokumen9 halamanWork Method Statement For Sub Structure Works: (Pile Cap)AlbawaviBelum ada peringkat

- Doka Framed Formwork DokaXlightDokumen92 halamanDoka Framed Formwork DokaXlightCông - 62XD6 Đỗ VănBelum ada peringkat

- Safety With Doka 2010-06 enDokumen44 halamanSafety With Doka 2010-06 enAnupam GhoshBelum ada peringkat

- Seismic Analysis of The MinaretDokumen17 halamanSeismic Analysis of The MinaretalditikosBelum ada peringkat

- Stage 1 Demolition Method StatementDokumen27 halamanStage 1 Demolition Method StatementPaul OchiengBelum ada peringkat

- Method Statement For Construction - Method Statement - Non Suspended SlabDokumen3 halamanMethod Statement For Construction - Method Statement - Non Suspended SlabKellyBelum ada peringkat

- White Paper Standardization Electrical Equipment MachinesDokumen17 halamanWhite Paper Standardization Electrical Equipment MachinesDejanStarčevićBelum ada peringkat

- Semester Subject Name Subject Code Exam Date Session: 19-09-13 Branch Name: B.Tech-Information TechDokumen12 halamanSemester Subject Name Subject Code Exam Date Session: 19-09-13 Branch Name: B.Tech-Information TechMuzzamil MusthafaBelum ada peringkat

- Arch 331Dokumen2 halamanArch 331Neven Ahmed HassanBelum ada peringkat

- EC2 - Lecture - Mpa - Concrete Centre PDFDokumen38 halamanEC2 - Lecture - Mpa - Concrete Centre PDFShishir Kumar NayakBelum ada peringkat

- Simsolid DatasheetDokumen2 halamanSimsolid DatasheetADVOKASI PPI MALAYSIABelum ada peringkat

- ProceedingDokumen609 halamanProceedingGeneration GenerationBelum ada peringkat

- University of Alberta - Ansys Tutorials PDFDokumen639 halamanUniversity of Alberta - Ansys Tutorials PDFchandrucuteboyBelum ada peringkat

- Construction Stage Analysis For ILMDokumen69 halamanConstruction Stage Analysis For ILMIonut FalcescuBelum ada peringkat

- 9 - Drawing Influence LinesDokumen5 halaman9 - Drawing Influence LinesFrancis Ko Badongen-Cawi Tabaniag Jr.Belum ada peringkat

- PIT For Finals (CE311)Dokumen2 halamanPIT For Finals (CE311)Prances CloribelBelum ada peringkat

- Graitec Advance Design Brochure EN 2014 PDFDokumen6 halamanGraitec Advance Design Brochure EN 2014 PDFPaco RaoulBelum ada peringkat

- Course Guide - Ceng121Dokumen7 halamanCourse Guide - Ceng121Jay Dela CruzBelum ada peringkat

- Verification Manual Russian Code SNiP 52-01-2003Dokumen24 halamanVerification Manual Russian Code SNiP 52-01-2003LýThườngKiệtBelum ada peringkat

- Module 1.1 Civil Engg, Bridges PDFDokumen63 halamanModule 1.1 Civil Engg, Bridges PDFShiva CharanBelum ada peringkat

- Civil Engineeri-WPS OfficeDokumen2 halamanCivil Engineeri-WPS OfficeJD FBBelum ada peringkat

- Finite Element Analysis of Wood Materials MADERA FEM MET GRADIENTE PDFDokumen13 halamanFinite Element Analysis of Wood Materials MADERA FEM MET GRADIENTE PDFJuan Carlos Moreno OrtizBelum ada peringkat

- Direct Displacement MethodDokumen5 halamanDirect Displacement MethodTewodros AbateBelum ada peringkat

- Internal Loadings Developed in Structural MembersDokumen31 halamanInternal Loadings Developed in Structural MembersJOSE MANUEL TORIZ RUELASBelum ada peringkat

- Structural Analysis and Design Report of Car Wash Center: September, 2017Dokumen30 halamanStructural Analysis and Design Report of Car Wash Center: September, 2017Samikshya ShahBelum ada peringkat

- Sce5321 Theory of Structure 2Dokumen9 halamanSce5321 Theory of Structure 2DAWIT DEJENEBelum ada peringkat

- ACI 352-13 Guide To The Code For Evaluation, Repair, and RehabilitationDokumen110 halamanACI 352-13 Guide To The Code For Evaluation, Repair, and RehabilitationMëGø SãYëd100% (1)

- Sa 2 Chap 11Dokumen18 halamanSa 2 Chap 11VK BarackBelum ada peringkat

- Ce 316 Structural Theory Module 1Dokumen29 halamanCe 316 Structural Theory Module 1Espe SaquinBelum ada peringkat

- Iss35 Art1 - Comparison of Structural Elements Response in PLAXIS 3D & SAP2000Dokumen6 halamanIss35 Art1 - Comparison of Structural Elements Response in PLAXIS 3D & SAP2000Albano ViveirosBelum ada peringkat

- Technical (Structural) & Financial Proposal of Proposed Hotel Building at Cox's BazarDokumen9 halamanTechnical (Structural) & Financial Proposal of Proposed Hotel Building at Cox's BazarABDUL JABBERBelum ada peringkat

- ANSYS Mechanical APDL Technology Showcase Example ProblemsDokumen1.020 halamanANSYS Mechanical APDL Technology Showcase Example Problemsradu marinescuBelum ada peringkat

- Truss Analysis Using Matrix MethodDokumen20 halamanTruss Analysis Using Matrix MethodMirza Sajjad HussainBelum ada peringkat

- Structural Analysis Software Downloads - CESDbDokumen2 halamanStructural Analysis Software Downloads - CESDbalfreliaBelum ada peringkat

- Given: A Continuous Beam Over Three Spans With Integral Column Supports As ShownDokumen6 halamanGiven: A Continuous Beam Over Three Spans With Integral Column Supports As ShowngertjaniBelum ada peringkat

- Structure Analysis I Structure Analysis IDokumen72 halamanStructure Analysis I Structure Analysis Ishaheen juttBelum ada peringkat

- ANSYS, Inc. Release Notes - 000410Dokumen180 halamanANSYS, Inc. Release Notes - 000410Ian AsBelum ada peringkat