NCR Control Procedure

Diunggah oleh

Romi Abdul RahmanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

NCR Control Procedure

Diunggah oleh

Romi Abdul RahmanHak Cipta:

Format Tersedia

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

PT UNITED SINDO PERKASA

Document Number

Document Title

NON CONFORMANCE CONTROL

PROCEDURE

USP-NC-NCP-004

Page

1 of 6

Rev

Date

19 MAR 2010

NON CONFORMANCE CONTROL PROCEDURE

Project

KINOA 4307

Company

NAVTECH KELOA/KINOA INVESTMENT S.A

Contractor

PT. UNITED SINDO PERKASA

Document no

USP-NC-NCP-004

Document revision

status

Rev

For Submission

Date

Description

QA

Project

Manager

ABS

Client

Prepared

Reviewed

Reviewed

Approved

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

PT UNITED SINDO PERKASA

Document Number

Document Title

NON CONFORMANCE CONTROL

PROCEDURE

USP-NC-NCP-004

TABLE OF CONTENTS

1.

Scope

2.

Purpose

3.

Reference Document

4.

Definition

5.

Responsibilities

5.1. QA/QC Department

5.2

6.

Production Department

Procedure

6.1. General

6.2. Mechanism of Non Conformance Report

Attachments

Flow Chart control of Non Conformance Report

Page

2 of 6

Rev

Date

19 MAR 2010

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

PT UNITED SINDO PERKASA

Document Number

USP-NC-NCP-004

Document Title

NON CONFORMANCE CONTROL

PROCEDURE

Page

3 of 6

Rev

Date

19 MAR 2010

1. Scope

This procedure applied in when Non Conformance Report are issue and up to completion of

contract.

At Completion of project all NCR must closed.

2. Purpose

To ensure non-conforming products are identified, duly segregated and appropriate actions taken to

rectify the non-conformance.

3. Reference Documents

a. Client/Owner Specification

b. Class Rule (ABS)

c. Approved Drawings

d. Inspection & Test Plan

e. Test Procedures

f. Statutory regulations

4. Definition

1. Non conformance items are material or workmanship that does not comply with

requirements.

2. NCR are Non Conformance Report of material / item / product that found and need to be

followed up.

5. Responsibilities

5.1.

QA/QC Department

a. Perform inspection according to inspection request from production department.

b. Identify the non-conformance material and product.

c. Issue NCR and perform verification.

PT UNITED SINDO PERKASA

Document Number

USP-NC-NCP-004

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Title

NON CONFORMANCE CONTROL

PROCEDURE

Page

4 of 6

Rev

Date

19 MAR 2010

d. Perform evaluation and propose method of repair (if necessary) on the NCR sheet.

e. Coordination with related department, if necessary, for observation & evaluation of NCR.

f. Prepare NCR log and file.

5.2. Production Department.

a. Segregate the non-conformance material or product and then place on separated area if

possible.

b. Prepare solution by repair, reject, or re-build.

c. Perform follow up according to conclusion of evaluation.

d. Inform NCR that have been followed up to QA/QC Inspector accordingly.

6. Procedure

6.1. General

a. NCR shall be issued by QA/QC Department on their observations and on the advice of owner

representative during inspection at site.

b. NCR sheet shall be issued for correction of defect and preventing same defect in the future.

c. Non Conformance material and product should be marked & recorded and then issued NCR.

d. Non Conformance material and product should be placed separately if possible.

e. Non Conformance material and product must be observed & evaluated to find solution and the

conclusion should be relayed to appropriate party.

f. The person performing evaluation must be qualified in that field.

g. The material and product that has been repaired must be re-inspected.

h. All activity of non conformance items control must be filed, reported and recorded on NCR log.

PT UNITED SINDO PERKASA

Document Number

USP-NC-NCP-004

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

Document Title

NON CONFORMANCE CONTROL

PROCEDURE

Page

5 of 6

Rev

Date

19 MAR 2010

i. Production process maybe not continued while the NCR is not verified, Project Manager to

decide. Any affect on production process must be immediately intimated to the owner.

j. Emergency/special condition shall be recommended by Project Manager and when Non

Conformance item was finished and then re-inspection should be performed by QA/QC

Inspector.

6.2.

Mechanism of Non Conformance Report

a. QA/QC Department performs inspection subject to inspection & test request schedule.

b. QA inspector issues NCR as soon as possible to Production Department with copy to Project

Manager if the non conformance item found.

c. Production Department shall follow up the NCR as soon as possible.

d. The follow up of the NCR shall be informed to QA/QC Inspector for verification.

e. QA/QC Department performs re-inspection and decides NCR status.

f. QA/QC Department submits NCR status to responsible parties and keeps the NCR file.

g. Enclosed the flow chart of Non Conformance Assessment

Attachment see next page

KINOA 4307 ACCOMMODATION

PLATFORM SERVICE

PT UNITED SINDO PERKASA

Document Number

Document Title

NON CONFORMANCE CONTROL

PROCEDURE

USP-NC-NCP-004

Page

6 of 6

Rev

Date

19 MAR 2010

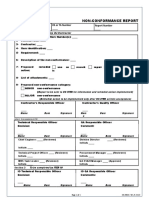

Attachment . Flow Chart Control of Non Conformance Assessment

ACTION

WHAT?

WHO?

Declare the Non

conformance

Discoverer

Analyse

Task manager

Is the product

defective

No

No

Yes

Can it be

reworked

Yes

Record:

- Decision

- Performance

- Checking

- Closure

Reworking

No

Decision maker

QA / QC

No

Can it be

repaired

Yes

Repair proposal

No

Can it be

accepted

as

delivered

No

Acceptance by

waiver

Yes

Residual

anomaly

Minor

Waiver

Major

Critical

anomaly

Discard

Not applicable

Record

- Decision

- checking

- closure

Decision

maker

QA / QC

Anda mungkin juga menyukai

- NCR ProcedureDokumen10 halamanNCR ProcedureLilian RobertsonBelum ada peringkat

- QAP-07 Material Control Procedure PDFDokumen22 halamanQAP-07 Material Control Procedure PDFnaseema1100% (9)

- Control of Non-Conforming Products ProcedureDokumen4 halamanControl of Non-Conforming Products ProcedureAlmario Sagun100% (1)

- DWST-MTHL-QP009 Non-Conforming Item Control ProcedureDokumen15 halamanDWST-MTHL-QP009 Non-Conforming Item Control ProcedureDeepak UpadhayayBelum ada peringkat

- ISO - Control of Non-Conforming ProductsDokumen5 halamanISO - Control of Non-Conforming ProductsAlmario SagunBelum ada peringkat

- PR 1718 999 QM 0017 2 Non Conformity ProcedureDokumen13 halamanPR 1718 999 QM 0017 2 Non Conformity ProcedureYousefi760% (1)

- Procedure For Control of RecordsDokumen3 halamanProcedure For Control of Recordsmatrixmaze50% (2)

- Flow Chart - QCDokumen2 halamanFlow Chart - QCKarthikeyan Shanmugavel100% (1)

- ISO-Control of Non Conforming ProductsDokumen3 halamanISO-Control of Non Conforming Productsnoufal27100% (2)

- Quality Record Procedure Rev-JDokumen4 halamanQuality Record Procedure Rev-JherminBelum ada peringkat

- Non Conformance ManagementDokumen22 halamanNon Conformance Managementssoni_famycare100% (1)

- Inspection Procedure MaterialDokumen1 halamanInspection Procedure MaterialZharel AhmadBelum ada peringkat

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Dokumen9 halamanMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanBelum ada peringkat

- NCR ReportDokumen9 halamanNCR ReportshaikhbwcBelum ada peringkat

- QA Non Conformance Report Word TemplateDokumen2 halamanQA Non Conformance Report Word TemplateTomi Kazuo100% (1)

- Typical Project Quality Plan & ITP CPCDokumen15 halamanTypical Project Quality Plan & ITP CPCnice guy100% (1)

- NCR 1871 33Dokumen2 halamanNCR 1871 33Arafat Baunto100% (1)

- 1.validation of Processes For Production Service Provision ProcedureDokumen4 halaman1.validation of Processes For Production Service Provision ProcedureLora Jackson100% (1)

- QSV 2 Product Release Procedure EN 01Dokumen6 halamanQSV 2 Product Release Procedure EN 01prashanthBelum ada peringkat

- NCR ProcedureDokumen5 halamanNCR ProcedureCarlos Mohan75% (4)

- Monitoring and Measurement of QmsDokumen3 halamanMonitoring and Measurement of QmsamoBelum ada peringkat

- Identification and TraceabilityDokumen3 halamanIdentification and TraceabilityRainer-Slawetzki100% (1)

- PR020 Control of Non Conformances ProcedureDokumen6 halamanPR020 Control of Non Conformances ProcedureSandraBelum ada peringkat

- Receiving Inspection ProcedureDokumen2 halamanReceiving Inspection ProcedureErwin SantosoBelum ada peringkat

- Non Conformance Control ProcedureDokumen12 halamanNon Conformance Control ProcedurePanneer Bala100% (9)

- Quality Requirements For Subcontractor: Project ProcedureDokumen15 halamanQuality Requirements For Subcontractor: Project ProcedureDindo QuintanBelum ada peringkat

- Document Control Procedure ExampleDokumen3 halamanDocument Control Procedure ExampleErich Kadow33% (3)

- VQA - PR.06 Customer Satisfaction ProcedureDokumen2 halamanVQA - PR.06 Customer Satisfaction ProcedureNyadroh Clement Mchammonds100% (1)

- Concession RequestDokumen2 halamanConcession RequestBrandon Hale100% (4)

- IMSP 01 Control of DocumentsDokumen8 halamanIMSP 01 Control of Documentsemeka20120% (1)

- Corrective ActionsDokumen3 halamanCorrective Actionsasderbva100% (1)

- Control of Documents (IMS)Dokumen11 halamanControl of Documents (IMS)Rambir Kaushik0% (1)

- QSP 621 01customer Satisfaction ProcedureDokumen6 halamanQSP 621 01customer Satisfaction ProcedureMacel100% (1)

- QP Nonconforming Product Sample 2014Dokumen2 halamanQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Control of Monitoring and Measuring EquipmentDokumen3 halamanControl of Monitoring and Measuring EquipmentLinda Setya WatiBelum ada peringkat

- Procedure For Control of Non-Conforming ProductsDokumen4 halamanProcedure For Control of Non-Conforming Productsmatrixmaze100% (3)

- QIR 114 Material RequisitionDokumen1 halamanQIR 114 Material RequisitionSamer BayatiBelum ada peringkat

- ESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsDokumen6 halamanESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsadiqualityconsultBelum ada peringkat

- Request For InspectionDokumen1 halamanRequest For Inspection알안젤로Belum ada peringkat

- Manufacturing ProcedureDokumen3 halamanManufacturing ProcedureAkhilesh KumarBelum ada peringkat

- Procedure - Control of RecordsDokumen4 halamanProcedure - Control of RecordsMarjorie Dulay DumolBelum ada peringkat

- Control of Production and Service OperationsDokumen3 halamanControl of Production and Service Operationskashifbutty2kBelum ada peringkat

- Control of Non-ConformanceDokumen6 halamanControl of Non-ConformanceLawzy Elsadig Seddig100% (1)

- Project-Specific Quality PlanDokumen9 halamanProject-Specific Quality PlanAlmario Sagun100% (2)

- Non Conformance ProcedureDokumen1 halamanNon Conformance ProcedureZharel AhmadBelum ada peringkat

- A#9 - Non Conformity Report Form Rev 2.Dokumen2 halamanA#9 - Non Conformity Report Form Rev 2.Mohammed AzizBelum ada peringkat

- External Origin Documents ListDokumen2 halamanExternal Origin Documents ListSyed Mujtaba Ali Bukhari100% (1)

- ISO 9001:2008 Standard Operating Procedures Manual: A P & C, IDokumen88 halamanISO 9001:2008 Standard Operating Procedures Manual: A P & C, IBuenoflor GrandeaBelum ada peringkat

- Quality Management System Master18 February 2014Dokumen27 halamanQuality Management System Master18 February 2014shani5573Belum ada peringkat

- QM501FA - Nonconformance ReportDokumen1 halamanQM501FA - Nonconformance ReportRio Handoko100% (1)

- ESCL-QSP-004, Procedrue For Control of Nonconforming ProductDokumen6 halamanESCL-QSP-004, Procedrue For Control of Nonconforming Productadiqualityconsult100% (1)

- Project Materials Handling and Preservation ProcedureDokumen2 halamanProject Materials Handling and Preservation ProcedureGbenga Mobolade100% (3)

- 11.01.00 Calibration of Inspection Measuring and Test EquipmentDokumen11 halaman11.01.00 Calibration of Inspection Measuring and Test EquipmentSanjeev Reddy Kasula100% (1)

- 70.control of NCR Issued To Subcon (Flow Chart)Dokumen1 halaman70.control of NCR Issued To Subcon (Flow Chart)Syerifaizal Hj. Mustapha100% (1)

- Control of Monitoring & Measuring DevicesDokumen10 halamanControl of Monitoring & Measuring DevicesRamesh mudunuriBelum ada peringkat

- Material Receiving Inspection ProcedureDokumen11 halamanMaterial Receiving Inspection ProcedureMaheshwar polepallyBelum ada peringkat

- Qhi Classroom Training List PDFDokumen2 halamanQhi Classroom Training List PDFPrakash kumarTripathiBelum ada peringkat

- NCR Form ExampleDokumen1 halamanNCR Form ExampleFrank BarnesBelum ada peringkat

- MST Compressed Air PipingDokumen62 halamanMST Compressed Air PipingAhmed GamalBelum ada peringkat

- QP9 Inspection & TestingDokumen4 halamanQP9 Inspection & TestingMuhammad Shiraz KhalidBelum ada peringkat

- WPS KinoaDokumen31 halamanWPS KinoaRomi Abdul RahmanBelum ada peringkat

- Welding Control ProcedureDokumen9 halamanWelding Control ProcedureRomi Abdul RahmanBelum ada peringkat

- Sequence of InspectionDokumen7 halamanSequence of InspectionRomi Abdul RahmanBelum ada peringkat

- Welding Control ProcedureDokumen9 halamanWelding Control ProcedureRomi Abdul RahmanBelum ada peringkat

- Material Receiving ProcedureDokumen7 halamanMaterial Receiving ProcedureRomi Abdul Rahman100% (3)

- Standard PracticeDokumen14 halamanStandard PracticeRomi Abdul RahmanBelum ada peringkat

- Precaution Before WeldingDokumen10 halamanPrecaution Before WeldingRomi Abdul RahmanBelum ada peringkat

- Flame Straightening ProcedureDokumen7 halamanFlame Straightening ProcedureRomi Abdul RahmanBelum ada peringkat

- ARAMCO ExaminationDokumen5 halamanARAMCO ExaminationAsad Bin Ala Qatari100% (6)

- Comparison of PWHT Requirements of Asme Codes: GeneralDokumen3 halamanComparison of PWHT Requirements of Asme Codes: Generalcisar0007Belum ada peringkat

- Carbon Steel GradesDokumen4 halamanCarbon Steel GradesKiky IchanafiBelum ada peringkat

- Coating StandardDokumen40 halamanCoating Standardkendo_qn100% (8)

- Welders Hand BookDokumen23 halamanWelders Hand Booksamyqatar100% (2)

- Restaurant Training Manuals: Bus ManualDokumen15 halamanRestaurant Training Manuals: Bus ManualKehinde Ajijedidun100% (1)

- Chapter 4 Lesson 1 Global CulturesDokumen22 halamanChapter 4 Lesson 1 Global CulturesChristian PeltierBelum ada peringkat

- CBSE Class 11 Business Studies Important Questions Internal TradeDokumen4 halamanCBSE Class 11 Business Studies Important Questions Internal TradeAryan Dev SinghBelum ada peringkat

- The Purple JarDokumen4 halamanThe Purple JarAndrada Matei0% (1)

- Identity Mapping ExerciseDokumen2 halamanIdentity Mapping ExerciseAnastasia WeningtiasBelum ada peringkat

- 10 Biggest LiesDokumen12 halaman10 Biggest LiesJose RenteriaBelum ada peringkat

- The Defense of The Faith Cornelius Van TilDokumen8 halamanThe Defense of The Faith Cornelius Van TilEmanuel Gutiérrez100% (1)

- Laffitte 2nd Retrial Motion DeniedDokumen6 halamanLaffitte 2nd Retrial Motion DeniedJoseph Erickson100% (1)

- 4 Socioeconomic Impact AnalysisDokumen13 halaman4 Socioeconomic Impact AnalysisAnabel Marinda TulihBelum ada peringkat

- BARCLAYS BANK INVOICE TRANSFER - PulihkanDokumen3 halamanBARCLAYS BANK INVOICE TRANSFER - PulihkanIndo Tracking67% (3)

- Zambia National Holdings Limtied and United National Independence Party (Unip) v. The Attorney-General (1994) S.J. 22 (S.C.) SupreDokumen12 halamanZambia National Holdings Limtied and United National Independence Party (Unip) v. The Attorney-General (1994) S.J. 22 (S.C.) SupreNkumbu kaluweBelum ada peringkat

- 40 Days of ProsperityDokumen97 halaman40 Days of ProsperityGodson100% (3)

- CRPC MergedDokumen121 halamanCRPC MergedNishal KiniBelum ada peringkat

- The Construction of Nationality in Galician Rus enDokumen61 halamanThe Construction of Nationality in Galician Rus enpsgdyrwnomail.infoBelum ada peringkat

- The Macabre Motifs in MacbethDokumen4 halamanThe Macabre Motifs in MacbethJIA QIAOBelum ada peringkat

- 6500-1 Unique.Dokumen21 halaman6500-1 Unique.Karampuri BabuBelum ada peringkat

- Introduction To The Philosophy of The Human Person Lesson 3 - The Human PersonDokumen5 halamanIntroduction To The Philosophy of The Human Person Lesson 3 - The Human PersonPaolo AtienzaBelum ada peringkat

- Sales Agency and Credit Transactions 1Dokumen144 halamanSales Agency and Credit Transactions 1Shaneen AdorableBelum ada peringkat

- Why Study Business?: What Are The Advantages of A Business Diploma?Dokumen5 halamanWhy Study Business?: What Are The Advantages of A Business Diploma?rodinibBelum ada peringkat

- IP Pump DataSheet CNLDokumen2 halamanIP Pump DataSheet CNLAmit ChourasiaBelum ada peringkat

- Epekto NG Kantutan Sa Mga KabataanDokumen27 halamanEpekto NG Kantutan Sa Mga KabataanAngelo0% (1)

- AMGPricelistEN 09122022Dokumen1 halamanAMGPricelistEN 09122022nikdianaBelum ada peringkat

- Determinants of Formal and Informal Sector Employment in The Urban Areas of Turkey (#276083) - 257277Dokumen15 halamanDeterminants of Formal and Informal Sector Employment in The Urban Areas of Turkey (#276083) - 257277Irfan KurniawanBelum ada peringkat

- Sub Contract Agreement TabukDokumen7 halamanSub Contract Agreement TabukHanabishi RekkaBelum ada peringkat

- District MeetDokumen2 halamanDistrict MeetAllan Ragen WadiongBelum ada peringkat

- Cheat Sheet - Logistics Term & Salary DetailsDokumen4 halamanCheat Sheet - Logistics Term & Salary Detailstaseenzaheer33Belum ada peringkat

- Drdtah: Eticket Itinerary / ReceiptDokumen8 halamanDrdtah: Eticket Itinerary / ReceiptDoni HidayatBelum ada peringkat

- Theories of MotivationDokumen8 halamanTheories of Motivationankushsingh007100% (12)

- Our Official Guidelines For The Online Quiz Bee Is HereDokumen3 halamanOur Official Guidelines For The Online Quiz Bee Is HereAguinaldo Geroy JohnBelum ada peringkat

- Boundary Wall DrawingDokumen1 halamanBoundary Wall Drawingsandip wankhadeBelum ada peringkat