APD70 24183 SC IC EMS EVA Report - Final Detailed Design 09.12.12 PDF

Diunggah oleh

Mohammad JugnuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

APD70 24183 SC IC EMS EVA Report - Final Detailed Design 09.12.12 PDF

Diunggah oleh

Mohammad JugnuHak Cipta:

Format Tersedia

Detailed Energy Value Analysis Report

For

Alfanar Labor Camp Project

Al Kharj Road Riyadh

APD70

Presented to

ALFANAR Co.

September 2012

APD70

Table of contents

INTRODUCTION.............................................................................................................15

EMS Comments and Recommendations.................................................................................. 16

1.0

Electrical Systems.................................................................................................17

1.1

Electrical Codes......................................................................................................17

1.2 Connected Load.......................................................................................................17

1.3 Labor Type 1 & 2 / Technician Type 1 & 2 Lighting .............................................18

1.4 Rest House lighting .................................................................................................20

1.5 Recreation lighting ..................................................................................................21

1.6 Restaurant/Guard House/Visitor Lounge Lighting .................................................21

1.7 Additional points on Lighting ..................................................................................22

1.8 LV Panel Construction ............................................................................................23

1.9 Capacitor Banks.......................................................................................................23

1.10

Metering & Energy Management ........................................................................24

2.0 Mechanical Systems...................................................................................................24

2.1

Mechanical Codes ..................................................................................................24

2.2 Air-Conditioning System.............................................................................................24

2.2.1 Designer Calculations...............................................................................................24

2.2.1 Suggested Cooling Load Calculations......................................................................26

2.2.1.1 Recommended Cooling Load Calculations Based on ASHRAE ..........................26

2.2.1.2 Based on Evaporative Cooling Design Guidelines Manual. .................................28

2.3 Supply Duct Sizing......................................................................................................30

2.4 Exhaust Air System. ....................................................................................................31

2.5 Steam System. .............................................................................................................31

2.5.1 Steam Boiler Sizing..................................................................................................31

2.5.2 Steam Network. ........................................................................................................31

2.6 Compressed Air System ..............................................................................................32

2.6.1 Air Compressor Sizing. ............................................................................................32

2.6.2 Compressed Air Network. ........................................................................................32

3.0 Plumbing System .......................................................................................................33

3.1 Tanks Capacity ...........................................................................................................33

3.1.1 Potable Water Storage Tank Capacity......................................................................33

3.1.2 Grey Water Collection Tank Capacity.................................................................33

3.1.2 Treated Grey Water Storage Tank Capacity ............................................................34

3.1.3 Soft Water Tank Capacity ........................................................................................35

3.1.4 Septic Tanks Capacity ..............................................................................................35

3.1.5 Fire Fighting Water and Pump. ................................................................................35

3.1.6 Electric Water Heaters..............................................................................................35

3.1.7 Solar Water Heaters..................................................................................................36

4.0 The Feasibility of Introducing Renewable Energy Solutions ...............................36

4.1 Solar Water Heating ...................................................................................................38

Energy Management Services Int.

Page 2 of 45

APD70

4.2 Solar Photovoltaic Panels ............................................................................................42

4.3 Wind Energy................................................................................................................44

Energy Management Services Int.

Page 3 of 45

APD70

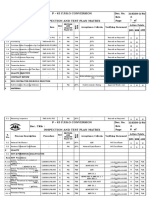

The below table show Dar Engineering comments on EMS final report and EMS clarifications and

reply to Dar Engineering comments.

Please consider this complete document as the final report of EPD 70 as it includes EMS

recommendations on preliminary design drawings; designer comments on EMS recommendations

and EMS justifications, comments and reply on the designer comments and final design drawings

and tender documents.

Point

No

1.0

1.2

1.2.1

1.2.2

Comments

ELECTRICAL SYSTEMS

The following observations

are noted in the review of

available information on

lighting layouts and power

layouts of Labor Type 1(LT1),

Technician Type1 (TT1) and

Technician Type2 (TT2)

blocks;

The lights point of 2x26W

CFL down lights has been

reduced to 18W CFL down

lights keeping the number of

light points same. This will

effectively reduce the

lighting power density.

There are 4 Nos of twin

sockets provided for each

bedroom. This results in a

socket density of 78 Watts

(VA)/m2. Considering that

the rooms are provided with

multiple beds, it is

Energy Management Services Int.

DAR Technical

Clarification

EMS

Justifications/Reply

We do not have Technician

Type1 (TT1) and Technician

Type2

(TT2) blocks. Sir, it seems

that you are commenting on

old drawings.

Noted

Earlier we proposed 2 down

lights, and made our

calculations, and then we

were asked by Al Fanar staff

to change to 4 down lights

to give better distribution.

Anyhow, Dar recalculated

the required illumination

level to reduce the power

consumption and get the

most effective, economical

and complied with code as

much as possible. See the

attached.

Earlier we produced only 3

outlets in the room, and we

were instructed to increase

additional one by Mr.

Ahmed Al

Madani. The load

calculations is as per NEC

Noted

Noted.

EMS comment is related to

the number of socket points

and not on the load

calculation.

Page 4 of 45

APD70

1.3.1

1.3.2

1.3.3

recommended to provide

one single socket per bed

with a minimum of two

sockets per bedroom. This

will reduce the socket

density by over 50%.

It is recommended to revisit

the number/type of sockets

considered in the bedrooms

in line with the design

occupancy and bedroom

layouts.

EMS recommendation was

not implemented in the

detail design.

T5 fluorescent with sensors

has been considered for

most hallways except that

the wattage shown in light

fixture schedule is 4x4 Watts

and conventional control

gear. The wattage should be

4x14W and with electronic

control gear.

Rooms

Refer to sec.1.2 above

Common Toilets

The common toilets of LT1

are provided with 2x26W

compact fluorescent down

light for the general areas

and

WC areas. The mirror lighting

is with 1x26W compact

fluorescent wall mount globe

light. Occupancy sensors

control the lighting in LT1

only.

The WC areas to have either

1x26W or 2x13W compact

fluorescent down light in

Energy Management Services Int.

code, not as per socket

density which is new word

for us, and as per the code

180 VA is considered as the

load of each receptacle (

single or double), and to

come over the total load

increment we assumed

demand factor of 0.35 for

receptacles instead of 0.4.

Pls. refer to NEC as well as

panel boards schedules

The eventual number of

sockets will depend on the

furniture layout and Clients

requirement.

Already complied.

Refer to drawing NO. E002,

Legend, General notes & List

of

abbreviations dated

September, 2012

Noted.

Refer to the same reply

above.

Already complied.

Refer to drawing NO. E002,

Legend, General notes & List

of

abbreviations dated

September, 2012

Noted

Noted in the Sep12

drawings issue.

Page 5 of 45

APD70

1.4

1.4.1

1.4.2

1.5

1.5.1

place of the current 2x26W.

The wattage of toilet lights is

not indicated on the

drawings/specifications.

Rest House lighting

Since lighting is not designed

yet for the Rest house,

the following design

considerations are

recommended for

the various areas within the

Rest house;

_ Kitchen LED/T5

fluorescent with occupancy

sensor

_ Living Dimmable LED

_ Toilet LED / compact

fluorescent with sensors

_ Bedroom Compact

fluorescent circular / LED

with

sensor

The security area and living

area lighting shown is 4x4

Watts T5. The wattage

should be 4x14W.

The bedroom lighting is of

2x38W T5. 38W T5 lamps are

not standard, instead

35Wcan be considered.

Recreation lighting

The

Gym/Tennis/Library/Prayer

Hall areas of the

Recreation building is

designed with

4x26W T5 fixtures with a

power density of 5.8W/m2,

which

seems to be optimum. The

toilets are with 2x26W

Energy Management Services Int.

Rest house lighting has

already been designed using

T5 fixtures for living room

and bedroom and CFL for

kitchen and toilets by using

occupancy sensors.

Refer Drawing No. E3RHG1

dated Sep 2012.

Noted in the Sep12

drawings issue.

Security area, living area and Noted in the Sep12

bedroom are provided with drawings issue.

2x35W T5.

Refer drawing No. E3RHG1

dated sept 2012.

Gym/Tennis/Library/Prayer

Hall areas are not designed

with 4x26W

T5 Fixture instead these are

designed with 3x35W T5 For

Gym/Tennis/Prayer Hall &

2x35W for Library.

Toilets are designed with

1x32W CFL and not with

2x26W. Refer

Noted in the Sep12

drawings issue.

Page 6 of 45

APD70

compact fluorescent down

lights

1.5.2

1.5.3

1.5.4

1.5.5

Consider sensors and/or

time schedule for all above

mentioned areas within the

recreation building including

the lockers, toilets and stairs.

The WC areas to have either

1x26W or 2x13W compact

fluorescent downlight in

place of the current 2x26W

The artificial lighting in

sports areas like the gym,

table

tennis and waiting areas

could be complemented with

day lighting elements such as

sun pipes/skylights. This will

not

only yield lighting savings

during daytime but also

improve

the indoor ambience.

The gym, prayer hall and

library area lighting is of

2x38W

T5 with 6m x 3m spacing.

The lighting power density is

8.4W/m2 which is

acceptable. However 38W T5

lamps are not standard,

instead 35W or 49W can be

considered.

Sensors have been

considered for showers and

toilets, and stairs with

pushbutton timer switches.

However the light fixture

schedule doesnt indicate the

Energy Management Services Int.

Drawing No. E002, Legend,

General notes & List of

abbreviations dated

September, 2012.

Already provided with Noted Noted in the Sep12

drawings issue.

Occupancy Sensors.

The fixtures used in the WC

area are 1x32W CFL. Refer

Drawing No

E002 & E3RECG1.

Gym, Table Tennis and

waiting areas are provided

with occupancy

sensors as per client

comments on drawing

E3RECG1 dated June

2012.

Refer Drawing No.

E3RECG1 dated sept 2012.

Acceptable. Noted in the

Sep12 drawings issue.

Sensors are considered in

the Sep12 drawings issue.

Daylight is limited to that

through windows

Noted in the Sep12

The gym, prayer hall and

drawings issue.

library area lighting are not

with 2x38W T5 instead

these areas are lit with

3x35W T5 Luminaires.

Refer Drawing No E3RECG1

dated sept 2012.

Occupancy sensor for the

toilet/ shower & timer

switches for the stair case

has already been provided.

Wattage for toilet fixtures

are

mentioned in the drawing

E002, Legend, General

notes & List of

Page 7 of 45

APD70

1.6

1.6.1

1.6.2

wattage for the specified CFL

fixtures for the showers and

toilets.

Restaurant/Guard

House/Visitor Lounge

Lighting

Since lighting is not designed

yet for the Restaurant/Guard

House/Visitor Lounge, the

following design

considerations

are recommended;

_ Dining Hall Compact

fluorescent/T5 with time

schedule

_ Toilets Compact

fluorescent/LED with sensors

_ Preparation/Dish wash T5

with time schedule

_ Laundry T5 with time

schedule

_ Kitchens/Pantry T5 with

time schedule

_ Offices T5 with

sensors/time schedule

_ Supermarket T5/LED with

time schedule

_ Security Area T5

_ Visitor Lounge T5 and

daylight system (sun

pipes/skylight)

The restaurants dining; dry

store, flour store,

preparation

and bread production areas

are designed with 4x38W T5

lights with louvers. The IP

rating should be specified for

these lights. The toilets are

with CFL and sensors. The

manager office lighting is

Energy Management Services Int.

abbreviations

Lighting layouts for the

Restaurant/Guard

House/Visitor Lounge have

already been prepared.

Refer Drawings E3RESG1,

E3RES01, E3RHG1, and

E3VLG1 dated September

2012.

These areas are designed

with T5 Fluorescent

luminaires & CFL

Down lights by using

occupancy sensors as per

client comments and

recommendations.

Noted in the Sep12

drawings issue.

Restaurants dining; dry

store, flour store,

preparation and bread

production areas are not

designed with 4x38W T5

instead these areas are

designed with 3x35W T5 &

2x 35W T5 luminaries.

Refer drawing No.

E3ResG1 & E3RES01

Noted in the Sep12

drawings issue.

Page 8 of 45

APD70

with

4x4W T5 which should be

4x14WT5.

1.6.3

1.6.4

1.7

1.8

For the rest house and guard

room, the bedroom lighting

is of 2x38W T5. 38W T5

lamps are not standard,

instead 35W can be

considered. The security area

lighting of

4x4W T5 to be respecified

as 4x14W T5.

For the visitor lounge and

supermarket, 2x38W T5 and

4x4W T5 lights are specified

respectively. 38W T5 lamps

are not standard, instead

35W can be considered. and

4x4W T5 to be respecified

as 4x14W T5.

Additional points on Lighting

Electronic ballasts are

considered in the

specification for most

lighting.

Since most common areas

are considered with sensors,

this will ensure lights will be

switched off while the areas

are unoccupied.

LV Panel Construction

All main LV Panels are

recommended to be of Form

4,

Type2 while SMDBs could be

Energy Management Services Int.

dated sept 2012.

IP Rating for all the light

fixtures are mentioned in

the drawing Eo02 dated

sept 2012.

Manager office lighting is

with 2x35W T5. Refer

drawing No. E3Res G1

dated Sep 2012.

Rest house, guard room,

security areas are provided

with 2x35W T5 fixtures.

Refer Drawing E3RHG1

dated sept 2012.

Noted in the Sep12

drawings issue.

Visitor lounge and

supermarket are lit using

2x35W T5 fixtures. Refer

Drawing No. E3VLG1.

Noted in the Sep12

drawings issue.

Already complied in the last

submittal

Noted.

It is clear in our

specifications. We are using

NFPA system for our

Panel boards and not IEC

system using Forms for

Noted.

Page 9 of 45

APD70

of Form 2 construction.

The form and type of panel

construction in not clear

from the specifications.

1.9

2.0

2.2.1

protection. Please

refer to our LV Switchgear

specifications. Form4, Type

LV panels

and Form2 are expensive

due to additional materials

required

inside the panel boards or

SMDB

Capacitor Banks

The size of the capacitor

The three transformers

bank is calculated as per the

(MDBs) are provided with

code, taking

into consideration the

450

various loads connected to

KVAR, 450 KVAR and 500

each transformer

KVAR power factor

and to achieve target power

correction capacitor banks

factor of 0.93.

respectively. Since the

demand load on

The proposed initial power

this transformers is less than factor differs according to

the load type.

1000 kW, and considering

the system load power factor The capacitor bank is steps

will be >0.85, the to achieve detuned type, and the

a target power factor of 0.93, controller will add

the Capacitor banks required the required value according

to the actual load power

is around 225 KVAR. A 330

factor.

KVAR will maintain a power

factor > 0.95. It is suggested

to Optimize the capacitor

bank size accordingly.

MECHANICAL SYSTEMS

The designer considered a

According to Alfanar

unified factor of 1000 Btu/

management requirements

m2

and site survey for the

for sizing the different

existing Labor camp the new

evaporative cooling units

HVAC design Matching with

without

the existing Camp and as per

any consideration to the

ASHRAE code the

different application as

evaporating

following:

Cooling depend on zone

Also the designer provided

area, and the application

another calculation sheet

type not effect here,

Energy Management Services Int.

Using a higher capacity

automatic correction

capacitor banks will result in

higher cost.

EMS is fully aware and

agrees that choosing the

evaporating coolers was

Alfanar management

decision; but EMS des-agree

with designer when he said

that (as per ASHRAE code

the evaporating Cooling

depend on zone area, and

the application type not

effect here) because

ASHRAE handbook 2007

Page 10 of 45

APD70

based

on ASHRAE 2007 handbook

shows that the CFM/m2 is a

bout 94 which is almost the

same result that has been

gotten form the first

assumption.

2.2.1.1 using the Hourly Analysis

Program (HAP 3.34) that was

developed by Carrier; EMS

conducted a detailed load

calculations for the Library

and the Internet hall .

2.2.1.1 From the above table; the

area of Library and Internet

hall

is 364.7 m2 and its sensible

cooling load is 68.5 kW and

coil

load is 86.9 kW,

Leaving Air Temp (LAT) = DB

((DB WB) * Efficiency)

= 115 (115 68) * 0.85 =

Energy Management Services Int.

because in desert cooler

there in no Cooling coil, but

its depend on water

vaporization to make stream

cold air.

you can Check ASHRAE

Application

mentioned under the

Evaporative Cooling section

page 51.9 that coolers

capacity might be

determined from standard

heat gain calculations.

We cant using ( HAP

Program ) to calculate the

desert cooler

Load , Because there is no

Cooling Coil , So that there is

No Latent Heat or Sensible

Heat ,

- As mentioned above

ASHRAE handbook 2007

mentioned at 51.9 that

coolers capacity might be

determined from standard

heat gain calculations.

The evaporation process

will act as the cooling coil to

remove the sensible heat

from the space.

Also your HAP Calculation

Based on incorrect area for

Library and Internet hall its

364.7m2 ,but the true are is

343.8 m2 , also your

Calculation Based on

outdoor air in Riyadh (

Tdb=44 C &Twb =25 C) but

as per ASHRAE Standard the

outdoor air in Riyadh is (

Tdb=44 C &Twb=17.8 C) .

-The designer note about the

library area is noted.

EMS Provided (HAP

Calculations) as showing ,the

Sensible and Latent Cooling

Load its strange to know

that the evaporating Cooling

cant overcome the Latent

Heat So, Please Check your

calculations mentioned

above as per new notes.

Because the parameters

EMS; in this example

followed ASHRAE

recommendations by

conducting a detailed

cooling load calculations for

the library to know:

-The actual cooling

requirements.

- The air flow which is

calculated based on sensible

load only.

-The designer note about dry

and wet bulb temp is noted

although considering the

reduced wet bulb temp will

reduce the total cooling load

to 66.7 kW instead of 86.9

kW as per EMS example.

Page 11 of 45

APD70

75.05

Air Flow= Sensible heat load

/ (1.08 * (84.5 75.05) CFM

= 22,900 CFM

The designer calculations for

the same area show that the

required air flow of the

evaporative cooling unit is

29,500 CFM..

CFM / m2 = 22,900/364.7 =

62.8

From the above; it is clear

that the CFM requirements

based on actual cooling load

calculations are 36 % less

than

that considered by the

designer

2.2.1.1 In detailed calculations of

heat load are not

economically

justified; one method of

several estimates gives

satisfactory results. In this

method, the difference

between

dry bulb design temperature

and coincident wetbulb

temperature multiplied by

10 is equal to the number of

seconds needed for each air

change.

Applying this on the same

Library and Internet hall:

2.3

the main duct sizing based

on the designer calculations

for

the library and Internet hall

(29,500 CFM) is (1900 * 750

mm) and the air velocity is

12.3 m/sec; while the main

Energy Management Services Int.

which you used incorrect.

Nobody claims that

evaporative cooling will

overcome the latent heat;

simply because its a

humidifying process needed

to overcome the gained

sensible load inside the

space.

The CFM which calculated

from your side this is the

flow rate

required for ventilation not

for air conditioning, So we

cant

compare your calculations

with our Calculations

Anybody aware of the HAP

program knows that the

output of this program will

give both the fresh

(ventilation) air and the

system air quantities.

the main duct air velocity for

the desert cooler which

located in library and

Internet hall is ( 10.4 m/s =

2000 f/m ) & friction loss

is0.73 Pa/m = 0.09w.g/100

ft) this values based on

Reducing the evaporative

coolers sizes will reduce the

air flow and hence the main

duct sizes will be reduced

and the problem resulting

from small shafts or risers

will be eliminated.

Page 12 of 45

APD70

2.5

2.5.2

(A)

2.5.2

(B)

duct

sizing based on the

suggested air flow (22,900

CFM) will be

(1500 * 750 mm) with air

velocity of 9.6 m/sec.

EMS recommends the

designer revisiting the duct

sizing

area to recalculate the duct

dimensions for each area

based on the new

evaporative coolers adjusted

air flow.

STEAM SYSTEM

EMS desagrees with pipe

sizing as it was considered

based on pressure drop of

150

Pa/m; while ASHRAE

Fundamentals handbook

recommends a pressure drop

of 450 to1100 Pa/m for such

boiler pressure, applying

this; then the main pipe

diameter from the boiler

should be

maximum 40 mm instead of

50 mm

the steam boiler which is

considered as correct action;

but the layouts didnt show

any collections for the

condensate

return line from the main

steam line or from the steam

end users to the tank, taking

into consideration that this

condensate water is 100%

pure hot water; collecting it

and returning it to the feed

Energy Management Services Int.

Ashrea

recommendation to prevent

the noise , but in Residential

buildings

( LT1,LT2) there are some

HVAC risers has high velocity

because

available Architecture shaft

in the building not sufficient

for

HVAC work, this assumption

regarding to Alfanar

management agreement.

It is clear that the designer

didnt comment on the

other 2 calculations

methods provided by EMS

that adopts almost the

same way of calculating

the evaporative coolers

capacity and resulted in

50% of air flow reduction

than designer

calculations????

Sizing is based on Maximum

allowable velocity limit of 20

m/sec for medium pressure

steam which yields 50 mm

Pipe Di The designer

equipments schedule shows

the need for installing 2 air

compressors 18ameter.

Also, Higher velocities in

pipes will give rise to high

noises. Therefore, we tried

to limit velocity

2 steam boilers and not 2 air

compressors are suggested

to be installed; but laundry

equipments list shows the

need of 564 kg of steam

which means that one boiler

only will be operational and

the second will be stand-by.

Layout shows a TCV

(Temperature control valve)

on 1 live steam line coming

from boiler for preheating

water in Feed Water Tank.

Yes there is no condensate

collection system as there

was no recoverable

condensate from laundry

equipments. Condensate to

be collected from lines will

not be sufficient enough for

EMS; des-agree with the

designer reply; as more than

60% of the steam will be

used in tumblers dryers

through heat exchangers; all

the condensate from the

tumblers and from the main

steam line can be collected

and returned back to the

steam boiler feed water tank.

Condensate water quantity

estimated to be more than

1m3/hr (water cost + water

Un Scientific and

unconvinced justification.

Page 13 of 45

APD70

2.6

2.6.1

3.0

3.1.7

water tank will reduce the

preheating costs, the water

treatment costs and the

water costs.

COMPRESSED AIR

SYSTEM

The designer equipments

schedule shows the need for

installing 2 air compressors

18 CFM each at 115 PSIG,

one

operational while the other

is standby, while his

calculations according to

laundry equipments shows

that

the compressed air

requirements is 18 CFM by

considering

5% only as safety factor and

part of that requirements is

at

115 PSIG.

PLUMBING SYSTEM

SOLAR WATER HEATERS:

Although the drawings show

the location of solar water

heaters on the roof of

different buildings; the

designer

didnt mention anything

about the surface area of

these

solar water heaters or about

its capacity, or its piping

network.

Energy Management Services Int.

economical pre heating of

water.

treatment cost+ fuel cost)

Noted (It was as per

recommendation from

equipment suppliers)

Solar water heater selection

shall be based on

manufacture/supplier

recommendation since each

manufacturer has its own

parameters and constraints.

noted

Page 14 of 45

APD70

INTRODUCTION

Energy Management Services Emirates (EMS) is pleased to submit this preliminary

Energy Value Analysis Report for the proposed APD70 (labor camp project at Al- Kharj RoadRiyadh) in KSA. This report aims to review the preliminary design drawings for the project

and subsequently provide feedback and design guidelines/changes that can be considered in

the designs where applicable.

The findings of the report are based on the data and drawings provided by DAR engineering.

All major areas in air-conditioning, lighting and power were explored in fulfillment of the

following Tasks as detailed in the scope of our services;

Task 10 Optimize Water & Waste Water Systems Designs

Task 20 Energy Value Analysis of Electrical Systems

Task 30 Energy Value Analysis of Lighting Systems

Task 40 Energy Value Analysis of Cooling Systems

Task 50 Investigate the Feasibility of Introducing Renewable Energy Techniques

Energy Management Services Int.

Page 15 of 45

APD70

EMS Comments and Recommendations

Energy Management Services Int.

Page 16 of 45

APD70

1.0

Electrical Systems

1.1

Electrical Codes

Preliminary Recommendation

The Designer has referenced electrical/lighting codes and standards, such as IESNA, NEC

and Saudi Arabian Std. Organization.

The following are some of the additional standards/codes that are recommended to be

referenced;

Saudi Energy Conservation Code

Saudi Electric Codes

ASHRAE 90.1

The major areas of the building are addressed in this section as to the specific standards

requirement, Consultants design considerations and EMS comments/recommended

technologies and control strategies;

Detail Phase Comment

The above standards are preferred to be referenced in the specification document.

1.2

Connected Load

The following observations are noted in the review of available information on lighting layouts

and power layouts of Labor Type 1(LT1), Technician Type1 (TT1) and Technician Type2 (TT2)

blocks;

1. Lighting densities

Preliminary Recommendation

Energy Management Services Int.

Page 17 of 45

APD70

The lighting points of 2x26W compact fluorescent downlights provided in rooms results

in lighting density of approx 10 watts/sqm. Each typical room is provided with 4

downlights in the bedroom.

It is recommended to reduce the number of light point in the bedroom from 4Nos. to

2Nos for LT1 and the same for TT1 & TT2 but with addition of 1No. Downlight in the

entrance area. This will reduce the number of fixtures and hence the connected load.

Detail Phase Comment

The light points of 2x26W CFL downlights has been reduced to 18W CFL downlights

keeping the number of light points same. This will effectively reduce the lighting power

density.

2. Power density

Preliminary Recommendation

There are 4 Nos of twin sockets provided for each bedroom. This results in a socket density of 78

Watts (VA)/m2. Considering that the rooms are provided with multiple beds, it is recommended

to provide one single socket per bed with a minimum of two sockets per bedroom. This will reduce

the socket density by over 50%.

It is recommended to re-visit the number/type of sockets considered in the bedrooms in line with

the design occupancy and bedroom layouts.

Detail Phase Comment

EMS recommendation was not implemented in the detail design.

1.3

Labor Type 1 & 2 / Technician Type 1 & 2 Lighting

The current lighting for the areas within the accommodation blocks is as follows;

1. Hallways

Energy Management Services Int.

Page 18 of 45

APD70

Preliminary Recommendation

The lighting provided is of 4 ft. linear fittings spaced approx 5m apart. The specifications

of the fixtures are not available. While LT1 hallway lighting is provided with occupancy

sensors, no sensors are shown in the TT1, and TT2.

The following strategies are recommended for all hallways;

Consider 2x35W T5 fluorescent

Occupancy sensors for all hallways.

Detail Phase Comment

T5 fluorescent with sensors has been considered for most hallways except that the

wattage shown in light fixture schedule is 4x4 Watts and conventional control gear. The

wattage should be 4x14W and with electronic control gear.

2. Rooms

Preliminary Recommendation

Refer to section 1.2 above

Detail Phase Comment

Refer to section 1.2 above.

3. Common Toilets

Preliminary Recommendation

The common toilets of LT1 are provided with 2x26W compact fluorescent downlight for

the general areas and WC areas. The mirror lighting is with 1x26W compact fluorescent

wall mount globe light. Occupancy sensors control the lighting in LT1 only.

The following is recommended for toilets;

The WC areas to have either 1x26W or 2x13W compact fluorescent downlight in

place of the current 2x26W.

Energy Management Services Int.

Page 19 of 45

APD70

Detail Phase Comment

The wattage of toilet lights is not indicated on the drawings/specifications.

4. Stairs

Preliminary Recommendation

The lighting in stairs is not specified yet.

The following is recommended for the stairs;

2D/circular fluorescent (max 36W) with sensors/push button timer switch or

sensor.

Detail Phase Comment

The specifications show that 43W CFL lights with push button timer switch is considered

for the stairs which is acceptable.

1.4

Rest House lighting

Preliminary Recommendation

Since lighting is not designed yet for the Rest house, the following design considerations are

recommended for the various areas within the Rest house;

Kitchen LED/T5 fluorescent with occupancy sensor

Living Dimmable LED

Toilet LED / compact fluorescent with sensors

Bedroom Compact fluorescent circular / LED with sensor

Detail Phase Comment

The security area and living area lighting shown is 4x4 Watts T5. The wattage should be

4x14W.

The bedroom lighting is of 2x38W T5. 38W T5 lamps are not standard, instead 35W can be

considered.

Energy Management Services Int.

Page 20 of 45

APD70

1.5

Recreation lighting

Preliminary Recommendation

The Gym/Tennis/Library/Prayer Hall areas of the Recreation building is designed with

4x26W T5 fixtures with a power density of 5.8W/m2, which seems to be optimum. The

toilets are with 2x26W compact fluorescent downlights.

The following are the recommendations;

Consider sensors and/or time schedule for all above mentioned areas within the

recreation building including the lockers, toilets and stairs.

The WC areas to have either 1x26W or 2x13W compact fluorescent downlight in place

of the current 2x26W

The artificial lighting in sports areas like the gym, table tennis and waiting areas could be

complemented with day lighting elements such as sun pipes/skylights. This will not only

yield lighting savings during daytime but also improve the indoor ambience.

Detail Phase Comment

The gym, prayer hall and library area lighting is of 2x38W T5 with 6m x 3m spacing. The

lighting power density is 8.4W/m2 which is acceptable. However 38W T5 lamps are not

standard, instead 35W or 49W can be considered.

Sensors have been considered for showers and toilets, and stairs with pushbutton timer

switches. However the light fixture schedule doesnt indicate the wattage for the specified

CFL fixtures for the showers and toilets.

Sensors have also been considered for most of the other areas within the building.

1.6

Restaurant/Guard House/Visitor Lounge Lighting

Preliminary Recommendation

Since lighting is not designed yet for the Restaurant/Guard House/Visitor Lounge, the

following design considerations are recommended;

Dining Hall Compact fluorescent/T5 with time schedule

Energy Management Services Int.

Page 21 of 45

APD70

Toilets - Compact fluorescent/LED with sensors

Preparation/Dish wash T5 with time schedule

Laundry T5 with time schedule

Kitchens/Pantry - T5 with time schedule

Offices T5 with sensors/time schedule

Supermarket T5/LED with time schedule

Security Area T5

Visitor Lounge T5 and daylight system (sun pipes/skylight)

Detail Phase Comment

The type of lighting considered is as per EMS recommendations. However, following are the

comments on the wattages used;

The restaurants dining; dry store, flour store, preparation and bread production areas are

designed with 4x38W T5 lights with louvers. The IP rating should be specified for these lights.

The toilets are with CFL and sensors. The manager office lighting is with 4x4W T5 which

should be 4x14WT5.

For the rest house and guard room, the bedroom lighting is of 2x38W T5. 38W T5 lamps

are not standard, instead 35W can be considered. The security area lighting of 4x4W T5 to

be re-specified as 4x14W T5.

For the visitor lounge and supermarket, 2x38W T5 and 4x4W T5 lights are specified

respectively. 38W T5 lamps are not standard, instead 35W can be considered. and 4x4W

T5 to be re-specified as 4x14W T5.

1.7

Additional points on Lighting

Preliminary Recommendation

All fluorescent fixtures to have H.F. electronic ballast.

All non-emergency interior lighting has to be automatically controlled to turn off during

non-operational hours.

Provide manual override capability for after hours use.

Energy Management Services Int.

Page 22 of 45

APD70

Detail Phase Comment

Electronic ballasts are considered in the specification for most lighting.

Since most common areas are considered with sensors, this will ensure lights will be

switched off while the areas are unoccupied.

1.8

LV Panel Construction

Preliminary Recommendation

All main LV Panels are recommended to be of Form 4, Type2 while SMDBs could be of Form

2 construction.

Detail Phase Comment.

The form and type of panel construction in not clear from the specifications.

1.9

Capacitor Banks

Preliminary Recommendation

Capacitor banks to be sized to meet the power factor requirement of the Saudi code.

However, it is recommended not to consider a low value for the initial (reference) power

factor in the capacitor bank sizing calculations to avoid oversized capacitor banks.

Detail Phase Comment

The three transformers (MDBs) are provided with 450 KVAR, 450 KVAR and 500 KVAR

power factor correction capacitor banks respectively. Since the demand load on this

transformers is less than 1000 kW, and considering the system load power factor will be

>0.85, the to achieve a target power factor of 0.93, the Capacitor banks required is around

225 KVAR. A 330 KVAR will maintain a power factor > 0.95. It is suggested to optimize the

capacitor bank size accordingly.

Energy Management Services Int.

Page 23 of 45

APD70

1.10 Metering & Energy Management

Preliminary Recommendation

It is recommended to add communicable meters at major load centers and energy

management software for energy management purposes.

Detail Phase Comment

Same as preliminary phase comments.

2.0 Mechanical Systems

2.1

Mechanical Codes

The following are some of the standards that are recommended to be referenced for the

HVAC designs;

Saudi Energy Conservation Code

Saudi Mechanical Codes

ASHRAE 62.1

ASHRAE 90.1

The above standards are preferred to be referenced in the specification document.

2.2 Air-Conditioning System

2.2.1 Designer Calculations

According to Alfanar management requirements; the designer considers evaporative cooling

system to cool down the different spaces and applications in the labor camp.

Energy Management Services Int.

Page 24 of 45

APD70

It is well known to everybody that evaporative cooling is energy efficient, environmentally

friendly and cost effective.

The designer considered a unified factor of 1000 Btu/ m2 for sizing the different evaporative

cooling units without any consideration to the different application as following:

Description

2

Area (m )

2

Heat Load (Btu/m )

Heat Load (Btu)

CFM

CFM/m2

One Room

Recreation Building

Restaurant

17

2190

2090

1,000

17,000

1,666

1,000

2,190,000

214,580

1,000

2,090,000

204,782

98

98

98

Also the designer provided another calculation sheet based on ASHRAE 2007 handbook

shows that the CFM/m2 is about 94 which is almost the same result that has been gotten

form the first assumption.

EMS disagree completely with both calculation results provided by the designer as the first

example was built on an exaggerated heat load figure (1000 Btu/m2) and the second

example which is based on ASHRAE 2007 handbook which is applicable for greenhouse

cooling load calculations where the solar radiation represents the major heat gain.

Based on the above results; the below table summarizing the evaporative cooling desert

cooling capacities as provided by the designer:

Building Type

Labor Type 1

Labor Type 2

Recreation Center

Resturant

Utility Building

Visitors Building

Energy Management Services Int.

Model

DC-1-LT1

DC-2-LT1

DC-1-LT2

DC-2-LT2

DC-1-REC

DC-1-LAU

DC-2-KIT

DC-3-LAU

DC-4-LAU

DC-5-KIT

DC-5-RES

DC-5-LAU

DC-6-KIT

DC-1-UB

DC-2-UB

DC-1-VL

DC-2-VL

CFM

30,400

19,200

32,000

33,600

29,500

9,000

13,500

16,000

21,000

29,500

29,500

29,500

32,000

8,000

1,600

10,000

6,000

QTY

1

1

1

1

5

1

1

1

1

1

6

1

1

1

1

1

1

kW

13

5.6

13

13

13

13

2.2

3.7

5.6

13

13

13

13

1.3

0.6

1.5

0.75

Page 25 of 45

APD70

2.2.1 Suggested Cooling Load Calculations

2.2.1.1 Recommended Cooling Load Calculations Based on ASHRAE

ASHRAE recommends using one of the 2 mentioned below methods to calculate the

evaporative cooling units capacities:

1- Detailed Cooling Load Calculations

Using the Hourly Analysis Program (HAP 3.34) that was developed by Carrier; EMS

conducted a detailed load calculations for the Library and the Internet hall; the following table

summarizing the results:

Energy Management Services Int.

Page 26 of 45

APD70

From the above table; the area of Library and Internet hall is 364.7 m2 and its sensible

cooling load is 68.5 kW and coil load is 86.9 kW,

Leaving Air Temp (LAT) = DB ((DB WB) * Efficiency)

= 115- (115 68) * 0.85

= 75.05

Air Flow

= Sensible heat load / (1.08 * (84.5 75.05) CFM

= 22,900 CFM

The designer calculations for the same area show that the required air flow of the

evaporative cooling unit is 29,500 CFM..

CFM / m2

= 22,900/364.7 = 62.8

From the above; it is clear that the CFM requirements based on actual cooling load

calculations are 36 % less than that considered by the designer.

The above cooling load is calculated based on the below design parameters:

Wall U value = 0.475 W/m2 oC

Roof U value = 0.425 W/ m2 oC

Windows U value = 1.72 W/ m2 oC

Windows shading Coefficient = 0.29.

Lighting load density = 16.14 W/m2

Electrical Equipments = 30 W/m2

Number of occupants = 102 person seated at rest

(67.4 & 35.2 W/person for sensible and latent heat loads per person).

Fresh air requirements 100%

Energy Management Services Int.

Page 27 of 45

APD70

2- Based on 2007 ASHRAE Handbook-HVAC Applications Assumption

It is clearly mentioned in this applications handbook that in dry climates, evaporative cooling is

effective at lower air velocities than those required in humid climates. Packaged direct

evaporative coolers are used for residential and commercial application. Coolers capacity

may be determined from standard heat gain calculations as per (ASHREA handbook

Fundamentals).

If detailed calculations of heat load are not economically justified; one method of several

estimates gives satisfactory results. In this method, the difference between dry-bulb design

temperature and coincident wet-bulb temperature multiplied by 10 is equal to the number of

seconds needed for each air change.

Applying this on the same Library and Internet hall:

Dry Bulb Temp (DB) = 45 oC

Wet Bulb Temp (WB) = 20 oC

Seconds needed for one air change = (45 20) *10 = 250 Sec.

Which means that one air change should occur at least every 4.16 minute in the space?

Number of air changes per hour = (60 * 60)/250 = 14.4

Library volume = 364.7 * 4 = 1,459 m3

Air Flow = 1,459 * 14 .4 = 21,010 m3/hr

= 12,396 CFM

Which is about 42 % of designer figure?

2.2.1.2 Based on Evaporative Cooling Design Guidelines Manual.

This manual is prepared by: Continuing Education and Development, Inc.

www.cedengineering.com

Energy Management Services Int.

Page 28 of 45

APD70

Author: J. D. Palmer, P.E., C.E.M. (NRG Engineering)

Funded By: United States Department of Energy

AND

New Mexico Energy Minerals and Natural Resources Department Energy Conservation and

Management Division

In this manual, the publisher provided a general rule of thumb to check for the evaporative air

coolers sizing based on the quantity of delivered air per unit floor area, or CFM/ft2. This value

is usually between 1.5 (on low speed) to 5 CFM/ ft2 depending on the building conditions,

internal load, insulation values, etc. For instance, an aspen pad cooler serving a poorly

insulated building with no exterior shading and many internal heat sources would typically use

4+ CFM/ ft2, while a rigid media cooler serving a well insulated building with shading on the

southwest, few internal heat sources and low occupancy would use 1.5 CFM/ ft2.

Applying these figures on the Library and Internet hall then;

Minimum air flow = 1.5 * 364.7 *10.76 = 5,886 CFM

Maximum air flow = 5 *364.7 * 10.76 = 19,621 CFM, which represents 66.5% only of the

designer consideration for the same area.

Flow per unit area = CFM/m2 = 54

EMS recommends considering sizing the evaporative cooling units based the air flow

calculated as a result of the detailed cooling load calculations (63 CFM / m2). More air

delivery means larger ducts and more fan energy and may affect the acoustics of the room. If

the airflow is insufficient, comfort cannot be maintained. A good design will include a twospeed fan so that the maximum air flow rate will only be delivered during peak load periods.

Considering this figure; then the required evaporative coolers capacities will be as

summarized in the following table:

Energy Management Services Int.

Page 29 of 45

APD70

Building Type

Labor Type 1

Labor Type 2

Recreation Center

Resturant

Utility Building

Visitors Building

Model

DC-1-LT1

DC-2-LT1

DC-1-LT2

DC-2-LT2

DC-1-REC

DC-1-LAU

DC-2-KIT

DC-3-LAU

DC-4-LAU

DC-5-KIT

DC-5-RES

DC-5-LAU

DC-6-KIT

DC-1-UB

DC-2-UB

DC-1-VL

DC-2-VL

CFM

19,600

12,400

20,600

21,600

19,000

5,800

8,700

10,300

13,500

19,000

19,000

19,000

20,600

5,200

1,100

6,500

3,900

QTY

1

1

1

1

5

1

1

1

1

1

6

1

1

1

1

1

1

2.3 Supply Duct Sizing.

The main duct sizing based on the designer calculations for the library and Internet hall

(29,500 CFM) is (1900 * 750 mm) and the air velocity is 12.3 m/sec; while the main duct

sizing based on the suggested air flow (22,900 CFM) will be (1500 * 750 mm) with air

velocity of 9.6 m/sec.

EMS recommends the designer revisiting the duct sizing area to re-calculate the duct

dimensions for each area based on the new evaporative coolers adjusted air flow.

Another point that should be raised here that the provided design drawings doesnt show the

engineering solution for exhausting the supplied air quantities from each evaporative cooler, It

is clear that exhaust from toilets will only remove very small fraction of the supply air while

the remaining air will be ex-filtrated though doors and windows.

Energy Management Services Int.

Page 30 of 45

APD70

2.4 Exhaust Air System.

The designer considered an exhaust air fan of 1200 CFM and an exhaust air duct of (500 *

250 mm) for the toilet, lockers room and changing room next to the Library and Internet Hall.

EMS checked the exhaust air quantities and found it according to ASHRAE 62.1-2007, and

agrees with the suggested fan sizing and exhaust duct dimensions.

2.5 Steam System.

2.5.1 Steam Boiler Sizing.

The designer equipments schedule shows the need for installing 2 steam boilers 626 kg

each, one operational while the other is stand-by, while his calculations according to laundry

equipments requirements shows that the steam requirements is 564 kg after considering

10% as safety factor.

EMS agrees with the designer selection.

2.5.2 Steam Network.

The steam layouts show that the main the steam from the boiler is distributed by a 2 inch

pipe diameter at 150 PSIG,

EMS dis-agrees with pipe sizing as it was considered based on pressure drop of 150 Pa/m;

while ASHRAE Fundamentals handbook recommends a pressure drop of 450 to 1100

Pa/m for such boiler pressure, applying this; then the main pipe diameter from the boiler

should be maximum 40 mm instead of 50 mm.

EMS agrees with 150 PSIG operational pressure as the required steam pressure at the

utility press is 115 PSIG.

Energy Management Services Int.

Page 31 of 45

APD70

Also steam layouts shows that the water in feed water tank is pre-heated with live steam

before introduced to the steam boiler which is considered as correct action; but the layouts

didnt show any collections for the condensate return line from the main steam line or from

the steam end users to the tank, taking into consideration that this condensate water is

100% pure hot water; collecting it and returning it to the feed water tank will reduce the preheating costs, the water treatment costs and the water costs.

EMS recommends the designer to re-visit this area to collect and direct the condensed water

from all possible points and return it back to the boiler feed water tank.

2.6 Compressed Air System

2.6.1 Air Compressor Sizing.

The designer equipments schedule shows the need for installing 2 air compressors 18 CFM

each

at 115 PSIG, one operational while the other is stand-by, while his calculations

according to laundry equipments shows that the compressed air requirements is 18 CFM by

considering 5% only as safety factor and part of that requirements is at 115 PSIG.

EMS recommends increasing the installed air-compressors capacity by at least 20% to cater

for future expansions and any compressed air leaks, also the operating pressure should be

increased to about 120 PSIG to cater for pressure drop through pipes, fittings and valves.

2.6.2 Compressed Air Network.

The compressed air layouts show that the main the compressed air from the air

compressors is distributed by a 1 inch pipe diameter at 115 PSIG,

EMS agrees with pipe size and as mentioned above; recommends increasing the operational

pressure to 120 PSIG as the required steam pressure at the utility press is 115 PSIG.

Energy Management Services Int.

Page 32 of 45

APD70

3.0 Plumbing System

3.1 Tanks Capacity

3.1.1 Potable Water Storage Tank Capacity

The designer calculations are based on water consumption of (185 liter/person/day) as

previously recommended by EMS in its preliminary report last May 2012.

The Potable storage water tank capacity is calculated as following:

Occupants requirements = 4860 person * 185 lit/p/day * 0.6 (grey water utilization)

= 540 m3/day

Water consumption for desert coolers = 97.4 m3/day

Water required for Laundry = 38 m3/day.

Total water required = 675.4 m3/day

Storage for 2 days = 1350.8 m3/day

Fire water = 228 m3/day

Total storage capacity for 2 days = 1578.8 m3

EMS agrees on the above mentioned calculations; although desert coolers consumption

should be less due to exaggerated sizing.

3.1.2 Grey Water Collection Tank Capacity

The designer calculations of the grey water collection tank capacity was based on two

sources of waste water,

Energy Management Services Int.

Page 33 of 45

APD70

The first source was based on considering 4,860 persons, 185 lit/day/person, 60%

waste water discharge factor, and 10% evaporation factor which could secure 486

m3/day.

EMS agrees with designer calculations.

The second source was based on 190 m3/day from kitchen with 80% collection

factor which could secure 152 m3/day.

Although the designer didnt provide any calculations for the water needs of the

restaurant; the considered figure is almost equivalent to the standard international

restaurants figure (35 gallons per seat per day).

Total waste water collection 638 m3/day.

EMS agrees with designer calculations.

3.1.2 Treated Grey Water Storage Tank Capacity

The designer calculation for the treated grey water storage tank capacity was based on two

main consumers:

-

Flushing system: which was calculated based on 4860 persons, 185 lit/day/person

and 40% flushing of total daily demand, which could consume (360 m3/day).

EMS agrees with designer calculations.

Irrigation system: which was calculated based on considering 10 liters per day for

each square meter of covered area and also for each palm tree, which could

consume (115.6 m3/day).

The total water treated consumption = 475.6 m3/day

Remaining treated water = 143.2 m3/day

EMS agrees with designer calculations.

Energy Management Services Int.

Page 34 of 45

APD70

3.1.3 Soft Water Tank Capacity

The designer calculations for soft water capacity were based on kitchen requirements of 190

m3/day, and drinking water of 1.8 liter/day/person which is equivalent to about 10m3/day.

The total soft water tank capacity considered by the designer is 250 m3.

EMS agrees with designer calculations.

3.1.4 Septic Tanks Capacity

The designer calculation of septic tanks capacity shows the necessity of installing 2 septic

tanks 162 m3 each, the calculations was based on considering 4,860 persons, 185

liter/day/person, 10% evaporation and 40% soil waste factor.

EMS agrees with designer calculations.

3.1.5 Fire Fighting Water and Pump.

The designer considered 228 m3 for fir fighting in his calculations; this as a result of

considering 250 gpm in residential block and 750 gpm for external network.

The calculations shows the need of a fire pump of 1000 gpm, at 250 ft total dynamic head,

and 80 HP motor.

EMS agrees with designer calculations.

3.1.6 Electric Water Heaters..

The provided designer calculations for the hot water storage tanks and electric water

heaters capacity are calculated based on the following assumptions:

Tout

= 60 oC

Tin

= 12 oC

Energy Management Services Int.

Page 35 of 45

APD70

Demand Factor = Different demand factors based on type of building

Storage Factor = Different storage factors based on type of building

Efficiency

= 0.95

And the results can be summarized in the following table:

Although; EMS agrees with designer calculations of the electric water heaters, we

recommend utilizing the steam to generate the required domestic hot water especially for

the restaurant and for any other close building.

3.1.7 Solar Water Heaters..

Although the drawings show the location of solar water heaters on the roof of different

buildings; the designer didnt mention anything about the surface area of these solar water

heaters or about its capacity, or its piping network.

EMS recommends the designer to re-visit this area to include the above mentioned data on

the drawings and to include it in the BOQ which was not provided with design package.

4.0 The Feasibility of Introducing Renewable Energy Solutions

Renewable energy systems are being used widely overall the world to help in saving the

natural resources and reduce the impact of the fossil fuel burning on the environment by

reducing the emissions or what is now called Green House Gases (GHG).

Energy Management Services Int.

Page 36 of 45

APD70

Many types and systems of renewable energy are available in the world, the applicability and

the feasibility of these systems depends on many variables that affect the installation and/or

the operation of the renewable energy systems.

In Saudi Arabia, there are some renewable energy systems that could be utilized to reduce

depending on the fossil fuel energy sources. The following systems are applicable in the:

1- Solar thermal water heating system

2- Wind energy systems

3- Solar photovoltaic systems

This report will investigate the feasibility and applicability of the above mentioned systems for

Al-Fanar Head Quarter Building.

It is well known that solar energy is the main renewable energy source especially in the

Middle East area due to high solar radiation in comparison to other areas in the world as

shown in the below figure:

World Solar Radiation

According to RETScreen software; the average daily solar radiation, wind speed and

temperature data for Riyadh region which are based on ground monthly measured data are

shown in the below table:

Energy Management Services Int.

Page 37 of 45

APD70

Table (1)

. Riyadh ground weather data

4.1 Solar Water Heating

The designer didnt provide any calculations, sizing or selection for the recommended solar

water heaters that are mentioned in the drawings on several buildings roofs

EMS calculations based on Wagner selections for the APD 32 show that:

Domestic water heating cost = 19,980 * 0.26

= 5,195 SAR/yr.

Solar Water Heaters cost

= 35,000 SAR

Pay-Back period: 6.7 yrs.

Wagner selection and other data are shown in the below figures.

Energy Management Services Int.

Page 38 of 45

APD70

Energy Management Services Int.

Page 39 of 45

APD70

Energy Management Services Int.

Page 40 of 45

APD70

Energy Management Services Int.

Page 41 of 45

APD70

4.2 Solar Photovoltaic Panels

Solar photovoltaic systems (PVs) produce power intermittently due to the lack of the

continuous sun light; therefore back up storage battery shall be used. More electricity is

produced on a clear, sunny day with more intense sunlight and direct light angle. Cloudy days

Energy Management Services Int.

Page 42 of 45

APD70

can significantly reduce the power output, and of course no power is produced at night. PV

systems work best during summer months since the day is longer and the sun intensity is

higher. Due to these variations between summer and winter, day and night, it is difficult for

PV systems to cover all the needed power, therefore it is advised to be used in conjunction

with utility-supplied electricity.

The generating capacity depends on the PV modules efficiency in converting sunlight to

electricity.

For Al-Fanar Head quarter project, electrical analysis of installing a PV system to supply part

of the buildings load was evaluated by using special PV software

It was assumed that the proposed area for installing the PV panels is on the roof empty

areas away from the equipments shading. All PV modules should be oriented to the south in

order to absorb maximum solar energy with efficient way. The available empty surface area

was not determined yet, therefore, the following estimation is referred to kWh per squared

meters. The following assumptions were considered in the study:

1) The PV panel tilted angle is 20 degree and facing to the south.

2) PV SYST version 4.0 software package was selected in this study.

3) PV module is Si- poly crystalline type with maximum efficiency of 13.4%.

4) Electric Tariff = 0.26 SAR/kWh

5) Standalone (Off-Grid) project cost = 15.0 SAR / W

Energy Management Services Int.

Page 43 of 45

APD70

PVSYST is a PC software package for the study, sizing, simulation and data analysis of

complete PV systems. It is suitable for grid-connected, stand-alone and DC-grid (public

transport) systems, and offers an extensive meteorological and PV-components database.

The total electrical generation capacity depends on the PV modules efficiency in converting

sunlight to electricity.

It was shown that for off grid project the annual energy supply is 163 kWh / m2 of module,

with electric power of 133.6 Watt /m2 for each module. In other word, the annual delivered

electrical energy from PV modules of total area 100 m2, for example, is about 16.22 MWh.

The proposed above PV arrays produce total electrical power capacity of about 19.73 kWp.

The annual saved in electrical energy = 0.26 SAR/kWh * 163 kWh = SAR 42.4 / m2

The PV cost was estimated and summarized as follows:

The above mentioned systems prices includes solar panels, batteries, inverters and charge

controller.

The capital cost of PV module = SAR 2,000 / m2.

The payback Period = 47.2 years

4.3 Wind Energy

Wind turbines are well known as an electricity generator turbines; it converts the mechanical

wind power into electrical power. Installation of wind turbines usually facing obstacles due to

many factors that affect the applicability of utilizing the wind technology. These factors could

be summarized as follows:

1) The wind potential: it depends on hourly wind speed and the speed fluctuations. Figure (2)

shows the average monthly wind speed for Riyadh, which shows that maximum wind speed is

3.7 m/sec.

2) Windmill noise: The rotation of windmill blades and the internal gears usually generates a

noise sound for the neighbors living close to the windmills.

Energy Management Services Int.

Page 44 of 45

APD70

Wind speed and wind speed fluctuations are mainly dictated by physical geography and

vegetation. The ideal site for wind energy generation should offer wind resources with the

following characteristics:

Average annual wind speed above 7 m/s

Minimal Fluctuations (Standard deviation from average wind speed)

Minimal time with wind speeds over 20-25 m/sec.

Table (1) above shows that the average winds speed for Riyadh is less than 7 m/sec.

Moreover, the minimum distance between the wind mill and the surrounding residents

building shall be not less than 10 times the height of the wind mill to avoid the windmill noises.

Since trees and surrounding building are usually considered as major wind obstacles,

therefore, height of the wind turbine should be increased in order to compensate the effect of

these obstacles. It is expected that the height of the wind mill not less than 30 meter to run

with acceptable low air resistance. Then the building should be far from the mill with at least

300 meter. Moreover, the voltage drop and cost of the electric cables will be increase the

wind turbine is installed far from the electricity local network.

Other environmental issue that limits the installation of the wind turbines is its negative

impact on the birds and other native animals on the surrounding environment which cause

the native animals and bird to leave.

Therefore, it is not recommended to install wind turbine at AlFanar Head Quarter project due

to the above obstacles.

Energy Management Services Int.

Page 45 of 45

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- WO 67 PLANDokumen1 halamanWO 67 PLANMohammad JugnuBelum ada peringkat

- Sample-B O QDokumen39 halamanSample-B O QKeyur Gajjar50% (2)

- Pump headDokumen4 halamanPump headMohammad JugnuBelum ada peringkat

- Fire-Suppression Piping System-13915 PDFDokumen21 halamanFire-Suppression Piping System-13915 PDFMohammad Jugnu100% (1)

- Balancing BasicsDokumen14 halamanBalancing BasicspbharrisBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Resistance Thermometer Measuring Transducer - MINI MCR-SL-PT100-UI - 2864435Dokumen10 halamanResistance Thermometer Measuring Transducer - MINI MCR-SL-PT100-UI - 2864435nemoneoBelum ada peringkat

- CommonIssues PDFDokumen133 halamanCommonIssues PDFJobin JoseBelum ada peringkat

- DB2 9 For Z - OS Technical OverviewDokumen624 halamanDB2 9 For Z - OS Technical Overviewtstfree2001Belum ada peringkat

- CCNA 1 Chapter 10 V4.0 AnswersDokumen9 halamanCCNA 1 Chapter 10 V4.0 AnswersAbdullah Al HawajBelum ada peringkat

- Dol PDFDokumen2 halamanDol PDFnapy400Belum ada peringkat

- Han Kit GBDokumen12 halamanHan Kit GBpnithiy_elecBelum ada peringkat

- Srs DocumentDokumen11 halamanSrs DocumentMohit DubeyBelum ada peringkat

- Astm A36Dokumen3 halamanAstm A36MarcoAntonioBelum ada peringkat

- Mru Z: The Ideal Heave, Roll and Pitch SensorDokumen2 halamanMru Z: The Ideal Heave, Roll and Pitch SensorAdi VBelum ada peringkat

- DDRS FDS V1.1Dokumen16 halamanDDRS FDS V1.1Nadir AbrarBelum ada peringkat

- En 10305-1Dokumen33 halamanEn 10305-1cataldocataldoBelum ada peringkat

- PackethDokumen4 halamanPackethAditya Kumar SinghBelum ada peringkat

- ITP For Piping WorksDokumen44 halamanITP For Piping WorksSyafril Akbar100% (3)

- Fireclass Prec En13 Logbook - 0Dokumen20 halamanFireclass Prec En13 Logbook - 0axwellBelum ada peringkat

- Module 1 - Introduction To Internet of ThingsDokumen48 halamanModule 1 - Introduction To Internet of ThingsAJ CobrirosBelum ada peringkat

- GP 10-20 26 August 2008Dokumen41 halamanGP 10-20 26 August 2008alizareiforoushBelum ada peringkat

- Link Budget 800M RLDokumen77 halamanLink Budget 800M RLDpkKSinghBelum ada peringkat

- Connecting Networks Chapter 1 v5.0 Exam Answers 2014Dokumen6 halamanConnecting Networks Chapter 1 v5.0 Exam Answers 2014adrian743842Belum ada peringkat

- Aircooler ManualDokumen6 halamanAircooler ManualToby LimBelum ada peringkat

- Ali ShanDokumen2 halamanAli Shanwajahat_abbasBelum ada peringkat

- 8071939554Dokumen1 halaman8071939554Vishnu SasindranBelum ada peringkat

- Optical Master Unit Mark II: Product Description and User's Manual Doc PN 00018UM Rev. 1.8Dokumen97 halamanOptical Master Unit Mark II: Product Description and User's Manual Doc PN 00018UM Rev. 1.8Adriane Martinez50% (2)

- SECTION 15190 Fuel Piping Rev 0Dokumen34 halamanSECTION 15190 Fuel Piping Rev 0mohamad damerlyBelum ada peringkat

- Tamiya Ms ChassisDokumen2 halamanTamiya Ms ChassisangemonaxBelum ada peringkat

- How Operating Systems Work AnswersDokumen3 halamanHow Operating Systems Work Answersapi-275907560Belum ada peringkat

- Double Headed Hydrant ValveDokumen2 halamanDouble Headed Hydrant ValveHarsh KhatriBelum ada peringkat

- Gpon Olt - Ma5600tDokumen93 halamanGpon Olt - Ma5600tfarhanwaliBelum ada peringkat

- SIM900 Hardware Design V2.00Dokumen0 halamanSIM900 Hardware Design V2.00Đặng Minh TiểnBelum ada peringkat

- BookDokumen85 halamanBookhasansmartBelum ada peringkat

- WB09 WHITE BOOK Updates 21 PDFDokumen34 halamanWB09 WHITE BOOK Updates 21 PDFGlen KarmaBelum ada peringkat