VGF24GL GLD 8068 0710

Diunggah oleh

npsJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

VGF24GL GLD 8068 0710

Diunggah oleh

npsHak Cipta:

Format Tersedia

VGF24GL/GLD

VGF Series Gas Enginator Generating System

295 - 425 kWe

Specifications

Dresser Waukesha Engine: H24GL/GLD

Cylinders: Inline 8

Piston Displacement: 1462 cu. in. (24 L)

Bore & Stroke: 5.98" x 6.5" (152 x 165 mm)

Compression Ratio: 11:1

Jacket Water System Capacity: 20 gal. (75 L)

Starting System: 24V DC electric

Lube Oil Capacity: 56 gal. (212 L)

Image may not be an accurate

representation of this model

Standard Equipment

AIR CLEANER Two stage, dry panel type with rain shield and service

indicator. Engine mounted.

BARRING DEVICE Manual.

BASE Engine, generator and radiator or heat exchanger are mounted

and aligned on a welded structural steel base, suitable for solid, or spring

isolator mounting on a proper foundation. Base is equipped with lifting

eyes.

BREATHER Closed system.

CONNECTING RODS Drop forged alloy steel, angle split, serrated joint,

oil jet piston pin lubrication.

NEMA MG1.32. Voltage: 480/277, 3 phase, 12 wire Wye, 60 Hz, and

400/230, 3 phase, 12 wire Wye, 50 Hz. Temperature rise within NEMA

105 C for continuous duty, within NEMA 130 C for standby duty.

Voltage regulation is 0.5%. All generators are rated at 0.8 power

factor, are mounted on the engine flywheel housing, and have multiple

steel disc flexible coupling drive.

GOVERNOR Woodward model EG3P electric actuator (mounted) and

magnetic pickup (mounted). NOTE: Requires separate electric governor

control Woodward model 2301D or similar (not included). See Code

6020D or 6022.

COOLING SYSTEM Choice of mounted radiator with pusher fan, core

guard and duct adaptor, heat exchanger with expansion tank (shipped

loose) or flanged connections for remote radiator cooling.

IGNITION Waukesha Custom Engine Control electronic ignition system

with coils, cables, hall effect pickup and spark plugs. Nonshielded. 24

V DC power required. Includes emergency stop/service engine protection

switch for local override of remote controls.

CRANKCASE Alloy cast iron, fully ribbed, integral with cylinder frame.

INTERCOOLER Airtowater.

CRANKSHAFT Drop forged alloy steel with thru hardened journals,

dynamically balanced and fully counterweighted. Viscous vibration

dampener.

INSTRUMENT PANEL Engine mounted, includes water temperature,

oil temperature, oil pressure, intake manifold temperature and intake

manifold pressure gauges.

CYLINDER HEADS Individual, interchangeable valveinhead type

with deep section alloy casting. Two hardfaced intake and two hard

faced exhaust valves per cylinder. Replaceable intake and exhaust valve

seats. Mechanical valve lifters with pivoted roller followers.

JUNCTION BOXES Separate AC & DC junction boxes for engine wiring

and external connections.

CYLINDERS Removable wet type liners of centrifugally cast alloy iron.

PAINT Oilfield Orange.

ENGINE PROTECTION SHUTDOWN CONTACTS High water

temperature, low oil pressure, and overspeed.

PISTONS Aluminum alloy, three ring, with patented high turbulence

combustion bowl. Oil jet cooled with full floating piston pin. 11:1

compression ratio.

EXHAUST Watercooled, cast iron exhaust manifold. Single vertical

flexible stainless steel exhaust connection with ANSI 125# 8 flange.

FUEL SYSTEM (GL) One natural gas carburetor, one Fisher Y692 gas

regulator, one 2 NPT flexible connection (shipped loose) and one 2 NPT

Magnatrol gas solenoid valve (shipped loose). Fuel pressure - 25 PSIG

minimum and 50 PSIG maximum.

FUEL SYSTEM (GLD) One natural gas carburetor, one Maxitrol RV91

gas regulator (shipped loose), one 2 NPT flexible connection (shipped

loose), and one 3 NPT Magnatrol gas solenoid valve (shipped loose).

Fuel pressure - 10 H2O minimum and 20 H2O maximum.

GENERATOR Open, dripproof, direct connected, synchronous, fan

cooled, AC revolving field type, 2/3 pitch, single bearing generator with

PMG brushless exciter for 300% short circuit sustain for 10 seconds

(250% for 50 Hz) and motor starting. TIF and Deviation Factor within

LUBRICATION SYSTEM Gear type pump, full flow spinon filters and

industrial base type oil pan. Engine mounted plate type oil cooler.

STARTING SYSTEM 24V DC starting motor. Crank termination switch,

(shipped loose).

TURBOCHARGER Drytype with wastegate.

VOLTAGE REGULATOR Automatic type (shipped loose).

WATER CIRCULATING SYSTEM, AUXILIARY CIRCUIT Gear driven

pump for intercooler and oil cooler. Inlet temperature of 130 F (54 C)

for all models.

WATER CIRCULATING SYSTEM, JACKET WATER CIRCUIT 180

190 F (82 88 C) thermostatic temperature regulation. Geardriven

pump.

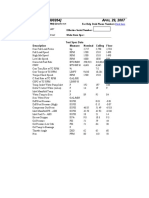

PERFORMANCE DATA: VGF24GL/GLD Gas Enginator Generating System

Heat Exchanger/Water Connection Cooling

Intercooler Water: 130F (54C)

Intake/

Exhaust

System

Heat

Balance

kW Rating

Continuous Power

1500 rpm

1800 rpm

1500 rpm

60 Hz

50 Hz

60 Hz

50 Hz

415**

340**

425

6894

4033

1043

129

256

89

1177

1238

5398

842

BSFC btu/bhp-hr (kJ/kW-hr)

Fuel Consumption Btu/hr x 1000 (kW)

Heat to Jacket Water Btu/hr x 1000 (kW)

Heat to Lube Oil Btu/hr x 1000 (kW)

Heat to Intercooler Btu/hr x 1000 (kW)

Heat to Radiation Btu/hr x 1000 (kW)

Total Exhaust Heat Btu/hr x 1000 (kW)

Induction Air Flow scfm (Nm3/hr)

Exhaust Flow lb/hr (kg/hr)

Exhaust Temperature F (C)

Standby Power

1800 rpm

(9750)

(1182)

(306)

(38)

(75)

(26)

(345)

(1903)

(2449)

(450)

6698

3282

886

93

174

83

921

1008

4393

808

(9474)

(962)

(260)

(27)

(51)

(24)

(270)

(1549)

(1992)

(431)

6846

4210

1077

131

273

88

1196

1215

5540

844

(9683)

(1234)

(316)

(38)

(80)

(26)

(351)

(1865)

(2513)

(451)

355

6656

3428

912

94

185

73

942

990

4520

810

(9417)

(1005)

(267)

(28)

(54)

(21)

(276)

(1520)

(2049)

(432)

Radiator Cooling - Mounted Intercooler Water: 130F (54C)

Intake/

Exhaust

System

Heat

Balance

kW Rating

390**

6894

4033

1043

129

256

89

1177

1238

5398

842

54091

BSFC btu/bhp-hr (kJ/kW-hr)

Fuel Consumption Btu/hr x 1000 (kW)

Heat to Jacket Water Btu/hr x 1000 (kW)

Heat to Lube Oil Btu/hr x 1000 (kW)

Heat to Intercooler Btu/hr x 1000 (kW)

Heat to Radiation Btu/hr x 1000 (kW)

Total Exhaust Heat Btu/hr x 1000 (kW)

Induction Air Flow scfm (Nm3/hr)

Exhaust Flow lb/hr (kg/hr)

Exhaust Temperature F (C)

Radiator Air Flow scfm (m3/min)

325**

(9750) 6698

(1182)

3282

(306)

886

(38)

93

(75)

174

(26)

83

(345)

921

(1903)

1008

(2449) 4393

(450)

808

(1532) 45691

405

(9474)

6846

(962)

4210

(260)

1077

(27)

131

(51)

273

(24)

88

(270)

1196

(1549)

1215

(1992) 5540

(431)

844

(1294) 54091

350

(9683) 6656

(1234)

3428

(316)

912

(38)

94

(80)

185

(26)

73

(351)

942

(1865)

990

(2513)

4520

(451)

810

(1532) 45691

(9417)

(1005)

(267)

(28)

(54)

(21)

(276)

(1520)

(2049)

(432)

(1294)

Emissions

NOx g/bhp-hr (mg/nm3 @ 5% O2)

2.00 (810)

2.50 (1011)

2.00 (810)

2.50 (1011)

CO g/bhp-hr (mg/nm3 @ 5% O2)

1.30 (542)

1.30 (217)

1.30 (542)

1.30 (217)

1.60 (652)

2.00 (806)

1.60 (652)

2.00 (806)

THC g/bhp-hr (mg/nm3 @ 5% O2)

NMHC g/bhp-hr (mg/nm3 @ 5% O2)

0.26 (105)

0.30 (121)

0.26 (105)

0.30 (121)

Typical heat data is shown, however no guarantee is expressed or implied. Consult your Dresser Waukesha Application Engineering Department for system

application assistance.

All natural gas engine ratings are based on a fuel of 900 Btu/ft3 (35.3 MJ/nm3) SLHV, with a 91 WKI. For conditions or fuels other than standard, consult the

Dresser Waukesha Application Engineering Department.

Data based on standard conditions of 77F (25C) ambient temperature, 29.53 inches Hg (100kPa) barometric pressure, 30% relative humidity (0.3 inches HG / 1

kPa water vapor pressure).

Fuel consumption based on ISO3046/1-1995 with a tolerance of +5% for commercial quality natural gas having a 900 BTU/ft3 (35.3 MJ/nm3) SLHV.

Heat data based on fuel consumption +2%.

Heat rejection based on cooling exhaust temperature to 77F (25C).

Rating Standard: The Waukesha Enginator ratings are based on ISO 3046/1-1995 with an engine mechanical efficiency of 90% and auxiliary water temperature Tcra as specified limited to 10F (5C). Ratings also valid for ISO 8528 and DIN 6271, BS 5514 standard atmospheric conditions.

Continuous Power Rating: The highest electrical power output of the Enginator available for an unlimited number of hours per year, less maintenance. It is

permissable to operate the Enginator with up to 10% overload for two hours in each 24 hour period.

Standby Power Rating: This rating applies to those systems used as a secondary source of electrical power. This rating is the electrical power output of the

Enginator (no overload) 24 hours a day, for the duration of a power source outage.

**Requires option code 1100.

Consult your local Waukesha representative for system application assistance. The manufacturer

reserves the right to change or modify without notice, the design or equipment specifications as herein

set forth without incurring any obligation either with respect to equipment previously sold or in the

process of construction except where otherwise specifically guaranteed by the manufacturer.

Dresser, Inc.

Dresser Waukesha

1101 West St. Paul Avenue

Waukesha, WI 53188-4999

T. 262 547 3311

F. 262 549 2795

Cooling

Equipment

Heat Exchanger

Water Cooler

Radiator

L in (mm)

W in (mm)

H in (mm)

Avg. Wt. lb (kg)

168 (4270)

143 (3630)

183 (4650)

54 (1370)

54 (1370)

88 (2240)

79 (2000)

79 (2000)

112 (2840)

13000 (5900)

12210 (5540)

14720 (6680)

Bulletin 8068 0710

2010 Dresser, Inc. All rights reserved. Waukesha, VGF, WKI, and Enginator are trademarks/

registered trademarks of Dresser, Inc., Dresser Waukesha

www.dresser.com/waukesha

Anda mungkin juga menyukai

- THM 700-R4 (4L60)Dokumen121 halamanTHM 700-R4 (4L60)Luis Antonio Castillo Arispe100% (12)

- Honda Gx690 Workshop ManualDokumen149 halamanHonda Gx690 Workshop ManualCosmin Ion Blaja100% (4)

- Sheppard - SteeringDokumen40 halamanSheppard - SteeringTony MelendezBelum ada peringkat

- Service Manual: One To Two Split Air ConditionerDokumen60 halamanService Manual: One To Two Split Air ConditionerCosti.HBelum ada peringkat

- Flo-Tech™ Integrated Actuator and Throttle Body: Installation and Operation ManualDokumen24 halamanFlo-Tech™ Integrated Actuator and Throttle Body: Installation and Operation ManualAbdulrehman Soomro100% (1)

- Riser Diagram 1 Single Line Diagram 2: General Notes and SpecificationDokumen11 halamanRiser Diagram 1 Single Line Diagram 2: General Notes and SpecificationCarlo DoragosBelum ada peringkat

- 2010 NComplete CatalogVol6-1Dokumen116 halaman2010 NComplete CatalogVol6-1tylerroach4771775% (4)

- Ignition SystemDokumen6 halamanIgnition SystemNopBelum ada peringkat

- 6277-5 WebDokumen356 halaman6277-5 WebTravisBelum ada peringkat

- Crankcase Component Overhaul GuideDokumen13 halamanCrankcase Component Overhaul GuideJavier LeonidasBelum ada peringkat

- John Deere 6820 ManualDokumen6 halamanJohn Deere 6820 ManualAnnabell Cady0% (9)

- Waukesha VHPDokumen2 halamanWaukesha VHPMadhana GopalBelum ada peringkat

- Af2 Adjustment PDFDokumen4 halamanAf2 Adjustment PDFFaisal NaeemBelum ada peringkat

- SERIES WIRING DIAGRAMDokumen22 halamanSERIES WIRING DIAGRAMp_janko100% (1)

- Cristian Makes and ModelsDokumen54 halamanCristian Makes and ModelsIgnacio Real BuffelliBelum ada peringkat

- 6 4019a - Print - 09 26 22Dokumen2 halaman6 4019a - Print - 09 26 22Diego MillanBelum ada peringkat

- Waukesha V HP Series 4Dokumen4 halamanWaukesha V HP Series 4rohizatBelum ada peringkat

- Altronic EPC-110/120 Air-Fuel Controller Operating ManualDokumen55 halamanAltronic EPC-110/120 Air-Fuel Controller Operating Manualfrancis_mouille_iiBelum ada peringkat

- Listado de PartesDokumen299 halamanListado de PartesAlexander RodriguezBelum ada peringkat

- WaukeshaDokumen2 halamanWaukeshacarlos angelBelum ada peringkat

- 09-2916 Regulador Series Four WaukeshaDokumen14 halaman09-2916 Regulador Series Four WaukeshaMaria Fernanda Bonilla SalasBelum ada peringkat

- 6286-2 Web - AFM PDFDokumen434 halaman6286-2 Web - AFM PDFshahzad100% (1)

- Waukeshau - Installation and Application Manual PDFDokumen272 halamanWaukeshau - Installation and Application Manual PDFRashid Mahmood100% (1)

- Gas 3400 PresentDokumen39 halamanGas 3400 PresentDjebali MouradBelum ada peringkat

- Gas Engine Emissions Technology 4th EditionDokumen16 halamanGas Engine Emissions Technology 4th EditionLenin Marcel Fajardo AlmeidaBelum ada peringkat

- Vienna Superautomatica Parts DiagramDokumen8 halamanVienna Superautomatica Parts DiagramGheorghe Mihalcovici0% (1)

- Waukesha Gas Engines VHP P9390GLDokumen2 halamanWaukesha Gas Engines VHP P9390GLrohizatBelum ada peringkat

- Ficha Técnica Engine Gas L7042GSI PDFDokumen2 halamanFicha Técnica Engine Gas L7042GSI PDFCamilo Sanchez VanegasBelum ada peringkat

- BW206AD-5 ManualDokumen274 halamanBW206AD-5 ManualYana100% (1)

- Kessler Linde Drive AxleDokumen51 halamanKessler Linde Drive Axlemliugong100% (2)

- Parts Manual PDFDokumen572 halamanParts Manual PDFjuan.vargas.calle6904100% (1)

- Gps Waukesha 7042 BrochureDokumen2 halamanGps Waukesha 7042 BrochureAlan SantosBelum ada peringkat

- 01.412833 - A9. Engine - VGF F18se-H24se 6&8 Cyl Parts CatalDokumen224 halaman01.412833 - A9. Engine - VGF F18se-H24se 6&8 Cyl Parts CatalJorge RiquelmeBelum ada peringkat

- Waukesha VGF h24gld Product Sheet 1Dokumen2 halamanWaukesha VGF h24gld Product Sheet 1nps100% (2)

- Waukesha VGF h24gld Product Sheet 1Dokumen2 halamanWaukesha VGF h24gld Product Sheet 1nps100% (2)

- Waukesha VGF36GSID GeneratorDokumen2 halamanWaukesha VGF36GSID GeneratorAnthony SolanoBelum ada peringkat

- UTB 650 Service Manual SmallDokumen201 halamanUTB 650 Service Manual Smallrom100% (3)

- 12V275GL 1Dokumen2 halaman12V275GL 1Zailand R100% (1)

- Technical Feedback on Utility Boiler Mill CommissioningDokumen37 halamanTechnical Feedback on Utility Boiler Mill Commissioningbanukiran sambojuBelum ada peringkat

- Service BUlletin 300036KDokumen4 halamanService BUlletin 300036KMuhammad ShadabBelum ada peringkat

- G3600 A4 Brochures PDFDokumen4 halamanG3600 A4 Brochures PDFVictor NunezBelum ada peringkat

- Rack and Pinion Gears InformationDokumen6 halamanRack and Pinion Gears InformationifyBelum ada peringkat

- Quick Reference Gas CatDokumen3 halamanQuick Reference Gas CatingcalderonBelum ada peringkat

- Waukesha L7042 GSI SpécificationsDokumen2 halamanWaukesha L7042 GSI SpécificationssuptedBelum ada peringkat

- Waukesha - Installation Operation Maintenance R PDFDokumen117 halamanWaukesha - Installation Operation Maintenance R PDFLEE100% (4)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDari EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesBelum ada peringkat

- Kohler Gas Generator 60rzgDokumen4 halamanKohler Gas Generator 60rzgPankaj KambleBelum ada peringkat

- (TM) Suzuki Manual de Taller Suzuki Samurai 2000Dokumen266 halaman(TM) Suzuki Manual de Taller Suzuki Samurai 2000Antonio Jose Delgado RodriguezBelum ada peringkat

- Motores Waukesha L5790gsiDokumen2 halamanMotores Waukesha L5790gsiEdgar Castro67% (3)

- AJI20024 Ajax Integral Engine Compressor DPC 2804 r0 WebDokumen2 halamanAJI20024 Ajax Integral Engine Compressor DPC 2804 r0 WebfsajnmasBelum ada peringkat

- 04-Unit - Force Feed Lubrication SystemDokumen38 halaman04-Unit - Force Feed Lubrication SystemKavi BhandariBelum ada peringkat

- Calculo Consumo Teorico WaukeshaDokumen8 halamanCalculo Consumo Teorico Waukeshahugohelo100% (1)

- Proflo Lubricator Monitor Sets Alarm for No FlowDokumen10 halamanProflo Lubricator Monitor Sets Alarm for No FlowJeff LBelum ada peringkat

- L7044gsi 7045 0710Dokumen2 halamanL7044gsi 7045 0710Martin Alejandro NievaBelum ada peringkat

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDokumen16 halaman(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- BHP - PRED Wauk v1 - 6Dokumen49 halamanBHP - PRED Wauk v1 - 6Clemente Rafael Marval EscalonaBelum ada peringkat

- Especificaciones Motor Waukesha 9390Dokumen2 halamanEspecificaciones Motor Waukesha 9390joseantoniogoncorBelum ada peringkat

- 17 2713bDokumen7 halaman17 2713bnricquartBelum ada peringkat

- SECTION 5.10: Ignition SystemDokumen36 halamanSECTION 5.10: Ignition SystemLUISA FERNANDA TORRES MANOSALVABelum ada peringkat

- TOPIC: Camshaft IDENT NO: 6-3021B SUPERSEDES: 6-3021A DATE: February 2020 SUBJECT: Updated Cam Follower Models Affected: All VHPDokumen2 halamanTOPIC: Camshaft IDENT NO: 6-3021B SUPERSEDES: 6-3021A DATE: February 2020 SUBJECT: Updated Cam Follower Models Affected: All VHPmiguel castellanosBelum ada peringkat

- Dse8600 Series Dse Configuration Suite ManualDokumen165 halamanDse8600 Series Dse Configuration Suite ManualGustavo Pereira100% (1)

- Mnit001 Meter Manual PDFDokumen9 halamanMnit001 Meter Manual PDFSergio Andres Rivera JaramilloBelum ada peringkat

- F3514 GsiDokumen2 halamanF3514 Gsikman548Belum ada peringkat

- WaukeshaDokumen68 halamanWaukeshaGilberto Prez RomeroBelum ada peringkat

- Rod ReversalDokumen21 halamanRod ReversalandresBelum ada peringkat

- 4.VGF L36GSI WKI TimingCuvre B PDFDokumen1 halaman4.VGF L36GSI WKI TimingCuvre B PDFfoobar2016Belum ada peringkat

- Grafica de Medidas para Recesion de Valvulas G3400Dokumen3 halamanGrafica de Medidas para Recesion de Valvulas G3400carlos angelBelum ada peringkat

- 6252 5edDokumen299 halaman6252 5edYaroslav RuizBelum ada peringkat

- Air Fuel Ratio Control 3516BDokumen4 halamanAir Fuel Ratio Control 3516Bwagner_guimarães_1Belum ada peringkat

- Surtidor ManualDokumen84 halamanSurtidor ManualIPJBelum ada peringkat

- MTU 20V4000 L64 Technical Data SheetDokumen2 halamanMTU 20V4000 L64 Technical Data SheetB-ENERGY INVESTMENTBelum ada peringkat

- Special Edition Tensioner JuneDokumen3 halamanSpecial Edition Tensioner JuneDjebali MouradBelum ada peringkat

- Superior 2406GDokumen79 halamanSuperior 2406GDavid Rene Martinez100% (1)

- Altronic DD20 Annunciator and TachmotersDokumen31 halamanAltronic DD20 Annunciator and TachmotersVladimirBelum ada peringkat

- Waukesha Gas Engines VGF Series Vgf36Gsid: Enginator Generating SystemDokumen2 halamanWaukesha Gas Engines VGF Series Vgf36Gsid: Enginator Generating SystemJuly E. Maldonado M.Belum ada peringkat

- Wauksha Inspeccion Multiple AdmisionDokumen2 halamanWauksha Inspeccion Multiple AdmisionLenin Marcel Fajardo AlmeidaBelum ada peringkat

- Specifications: VHP5904LTDokumen2 halamanSpecifications: VHP5904LTmuhammad wafiBelum ada peringkat

- Waukesha Engine WarrantyDokumen4 halamanWaukesha Engine WarrantyastromoBelum ada peringkat

- Upgrade your engine's performance with VGF tuningDokumen5 halamanUpgrade your engine's performance with VGF tuningnpsBelum ada peringkat

- Waukesha Powering The World BrochureDokumen12 halamanWaukesha Powering The World BrochurenpsBelum ada peringkat

- 6284 Chap4 ContentsDokumen1 halaman6284 Chap4 ContentsnpsBelum ada peringkat

- Waukesha Engine, Dresser, Inc. Express Limited Warranty For Custom Engine ControlsDokumen1 halamanWaukesha Engine, Dresser, Inc. Express Limited Warranty For Custom Engine ControlsnpsBelum ada peringkat

- Waukesha Reup BrochureDokumen6 halamanWaukesha Reup BrochurenpsBelum ada peringkat

- Waukesha Rating Charts 2016Dokumen8 halamanWaukesha Rating Charts 2016npsBelum ada peringkat

- 6284 4 30 PDFDokumen18 halaman6284 4 30 PDFnpsBelum ada peringkat

- 6284 W 2Dokumen1 halaman6284 W 2npsBelum ada peringkat

- Chapter 5 - Troubleshooting: FORM 6284 Third EditionDokumen1 halamanChapter 5 - Troubleshooting: FORM 6284 Third EditionnpsBelum ada peringkat

- LDokumen2 halamanLnpsBelum ada peringkat

- 6284 W 2Dokumen1 halaman6284 W 2npsBelum ada peringkat

- How To Use This Manual: FORM 6284 Third Edition XviiDokumen1 halamanHow To Use This Manual: FORM 6284 Third Edition XviinpsBelum ada peringkat

- 6284 1 15 PDFDokumen31 halaman6284 1 15 PDFnpsBelum ada peringkat

- 6284 Chap2 ContentsDokumen1 halaman6284 Chap2 ContentsnpsBelum ada peringkat

- 6284 4 55Dokumen4 halaman6284 4 55npsBelum ada peringkat

- Chapter 1 - Safety and General: FORM 6284 Third EditionDokumen1 halamanChapter 1 - Safety and General: FORM 6284 Third EditionnpsBelum ada peringkat

- 6284 4 65Dokumen4 halaman6284 4 65npsBelum ada peringkat

- 6284 5 00 PDFDokumen9 halaman6284 5 00 PDFnpsBelum ada peringkat

- Chapter 3 - Engine Startup and Shutdown: FORM 6284 Third EditionDokumen1 halamanChapter 3 - Engine Startup and Shutdown: FORM 6284 Third EditionnpsBelum ada peringkat

- 6284 4 60Dokumen4 halaman6284 4 60npsBelum ada peringkat

- 6284 2 30 PDFDokumen7 halaman6284 2 30 PDFnpsBelum ada peringkat

- 6284 4 50Dokumen5 halaman6284 4 50npsBelum ada peringkat

- 6284 4 40 PDFDokumen6 halaman6284 4 40 PDFnpsBelum ada peringkat

- 6284 4 10 PDFDokumen14 halaman6284 4 10 PDFnps100% (1)

- Exhaust System Maintenance GuideDokumen1 halamanExhaust System Maintenance GuidenpsBelum ada peringkat

- SECTION 4.45: Starting System MaintenanceDokumen3 halamanSECTION 4.45: Starting System MaintenancenpsBelum ada peringkat

- Hyosung RX 125 Cylinder Head and Engine Parts ListDokumen101 halamanHyosung RX 125 Cylinder Head and Engine Parts List山頭哲律Belum ada peringkat

- Bolens TractorDokumen16 halamanBolens TractorJocelyn DuteauBelum ada peringkat

- Hydronics 101: TECHNICAL FEATURE - Fundamentals at WorkDokumen9 halamanHydronics 101: TECHNICAL FEATURE - Fundamentals at WorkRaheel AhmedBelum ada peringkat

- Who Are The Leading Kirloskar, HMT, Lathe Machine Spare Parts Manufacturers in India?Dokumen15 halamanWho Are The Leading Kirloskar, HMT, Lathe Machine Spare Parts Manufacturers in India?Ramesh AmashiBelum ada peringkat

- Chassis LubricationDokumen142 halamanChassis LubricationKen ThungBelum ada peringkat

- gzn00264 P1Dokumen4 halamangzn00264 P1faraz24Belum ada peringkat

- Aftercooler CoreDokumen6 halamanAftercooler CoreRichard ChuaBelum ada peringkat

- Grundfosliterature NB NBE NK NKE 60HzDokumen20 halamanGrundfosliterature NB NBE NK NKE 60HzCarla RamosBelum ada peringkat

- Equilibrium of Machines and FlywheelDokumen9 halamanEquilibrium of Machines and FlywheelAhmee MahmoudBelum ada peringkat

- NPM pfcl25 SpecsheetDokumen1 halamanNPM pfcl25 SpecsheetElectromateBelum ada peringkat

- Pressure Relief ValvesDokumen6 halamanPressure Relief ValvesShashank Sudhakar PathakBelum ada peringkat

- DESMI Portable Centrifugal Pump: SA50-T (50-135/14) HATZ 1B20/30Dokumen14 halamanDESMI Portable Centrifugal Pump: SA50-T (50-135/14) HATZ 1B20/30Kamran AleemBelum ada peringkat

- Juki MB-372 Instruction ManualDokumen33 halamanJuki MB-372 Instruction Manualrosmel ricraBelum ada peringkat

- Electrica L Design 1: Term TestDokumen12 halamanElectrica L Design 1: Term TestReynaldo CuestaBelum ada peringkat