Compressor FH

Diunggah oleh

omaralihasHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Compressor FH

Diunggah oleh

omaralihasHak Cipta:

Format Tersedia

IMPACT 4.00.

12

1/11/15

Chassis ID

A 760766

Path

5611/Description, Design and function//Compressor

Model

FH

Identity

130036052

Publish date

1/26/11

ID/Operation

Compressor

2COMP900

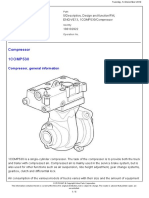

Compressor, general information

2COMP900 is a twin-cylinder compressor. The task of the compressor is to provide the vehicle with compressed air.

Compressed air is mainly used in the service brake system, but is also used for other functions such as air suspension,

ride height adjustment, gear change systems, gearbox, clutch and differential lock.

Air consumption of the various vehicle models varies with their size and the amount of equipment which uses

compressed air. When replacing a compressor with another size, the parameters must be changed. All calibration and

changes to parameter data is done via VCADS-Pro.

COPYRIGHT Volvo Group North America

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are uncontrolled.

1/5

IMPACT 4.00.12

1/11/15

The compressor for the vehicles which are covered here, has two cylinders and they are driven by a gearwheel directly

from the engine timing gears. The crankcase and the cylinder block are air-cooled, while the cylinder head is cooled by

liquid from the cooling system of the engine.

The compressor receives its lubrication via the pressure lubrication system of the engine and the main and large end

bearings are thus pressure lubricated. The small end bearing and piston are splash lubricated. The oil used by a piston

compressor to lubricate the piston and piston rings, is separated in the air drier and drains out of the air drier during the

compressor pressure relief phase (together with a considerably larger quantity of water).

Note: A certain amount of oil will show on the air drier silencer, which is normal and does not require any action.

The size of the compressor is intended to fulfil the air requirements of the vehicle rapidly and to fill the compressed air

system. Its function can be divided into two phases; charging phase and pressure relief phase.

This compressor has a Power Reduction (PR) function. The function is a relief function that closes off the compressor

air delivery to the compressed air system when the predetermined system pressure has been reached. A small amount

of the normal air volume will be allowed to flow from the air drier silencer when the compressor is relieved. The PR

signal to the compressor originates from the air drier relief function.

When the system pressure has decreased to the pre-set connecting pressure, the pressure regulator closes the

release valve of the air drier which drains the PR connection, which closes the PR valve with the aid of a return spring.

The compressor now begins to recharge the compressed air system.

The idling speed of the electrically controlled cooling fan (FAN-VISE) is lower compared with earlier fans which reduces

the cooling capacity of the cooling loop at low speed. To secure the cooling capacity of vehicles with this type of fan, an

intelligent fan control has been introduced which ensures that the fan is engaged at a higher speed when the

compressor is charging.

The fan control is only activated when the outer temperature is higher than zero degrees C, the engine speed is greater

than 700 rpm and the road speed is less than 45 km/h.

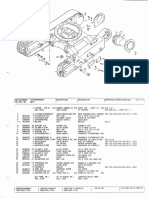

Compressor, design

Compressor 2COMP900 is used on 9, 11, 13 and 16 litre engines. Air capacity is 725 dm/min at a backpressure of

800 kPa (8 bar) and engine speed of 1525 rpm. Maximum working pressure is 1300 kPa (13 bar).

The compressor is driven by a gear wheel from the engine timing gears. The cylinder head and cylinder block with

crankshaft are separate and separable units. The crankcase and the cylinder block are air-cooled, while the cylinder

head is cooled by liquid from the engine cooling system. Each piston has three piston rings, two compression rings and

an oil scraper ring. The compressor receives its lubrication via the pressure lubrication system of the engine and the

main and large end bearings are thus pressure lubricated. The small end bearing and piston are splash lubricated.

On the cylinder head's lower part are located inlet and outlet valves. On the cylinder head's lower part are located inlet

and outlet valves. Each outlet valve is mounted on a holder on the valve plate's upper side between the cylinder block

and the cylinder head. The inlet valves are integrated in the cylinder head gasket.

The Power Reduction (PR) function's reed valves is also placed on the underside of the cylinder head, they are opened

pneumatically and closed by spring force. The PR function is controlled by two pistons. Each piston is, via a pin,

connected to a movable reed valve. The PR connection to the compressor is via the arrow A illustrated below.

COPYRIGHT Volvo Group North America

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are uncontrolled.

2/5

IMPACT 4.00.12

1/11/15

Note: Do not change these nipples for other types of standard nipples. Other types of nipples can put the PR function

at risk.

The compressor is driven by a gear wheel fixed on the tapered shaft, without a Woodruff key. The compressor flange

and rear end plate of the crankshaft is fitted with bushings. The gudgeon pin is mounted directly in the connecting rod

without bushings.

The O-ring that seals on the timing gear cover is located radially.

COPYRIGHT Volvo Group North America

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are uncontrolled.

3/5

IMPACT 4.00.12

1/11/15

Compressor, function

A vacuum is created in the cylinders as the pistons travel downwards and makes the inlet valves open. Induction air,

cleaned in the engine air filter, flows into the cylinders. When the piston travels upwards, the inlet valve closes (by the

pressure in the cylinder) and the induction air is compressed. When the pistons approach their top positions and the

pressure in the cylinders exceeds the pressure from the spring and the air above the exhaust valves, the exhaust

valves will open and the compressed air will flow into the compressed air system.

The size of the compressor is intended to fulfil the air requirements of the vehicle rapidly and to fill the compressed air

system. This function can be divided up into two phases, the charging phase and the relief phase (Power Reduction

Function). For further information about the charging phase and relief phase, refer to service information Air drier in

group 56.

Air flowing into the compressor is cleaned, dust and dirt particles being removed by the air filter of the engine. Before

the air flows into the pneumatic system, the air is dried in a separate air drier to prevent water from getting into the

system.

The air flowing from the compressor, which is frequently hotter than 150C is directed through a coil of piping of

between 3 and 5 metres in length, to be cooled to about 60C, before it enters the air drier. This is done to get the

highest possible efficiency in the air drier and to protect rubber components.

Compressor, power reduction function

COPYRIGHT Volvo Group North America

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are uncontrolled.

4/5

IMPACT 4.00.12

1/11/15

A. Open position, compressor idle.

B. Closed position, compressor pumping.

On this compressor, the energy saving function Power Reduction (PR) has two pistons. The function is a relief function

that closes off the compressor air delivery to the compressed air system when the predetermined system pressure has

been reached. The PR signal to the compressor comes from the air drier relief solenoid valve.

When the predetermined system pressure has been reached, the vehicle control unit sends a signal to the air drier

relief solenoid valve, so that it opens and releases the compressed air together with any water collected from the air

drier.

At the same time, the PR valves in the compressor cylinder head are activated by a pressure signal from the air drier

relief solenoid valve, which causes the air to be pumped back and forth between the cylinder heads instead of

delivering the air to the compressed air system. A small proportion of the normal amount of air from the compressor

now flows out through the release valve of the air drier and silencer, when the compressor runs unloaded.

When the system pressure has dropped to the predetermined engaging pressure, the air drier's relief valve is closed

and the PR line is drained from air pressure, which closes the PR valves by means of return springs. The compressor

now begins to recharge the compressed air system.

In the PR function, it is important to have the correct signal speed in order that the functions should work satisfactorily.

Signal connections which are not sealed cause the signal speed to be incorrect.

For additional information about relief, refer to service information Air drier in group 56.

COPYRIGHT Volvo Group North America

The information contained herein is current at the time of its original distribution, but is subject to change. The reader is advised that printed copies are uncontrolled.

5/5

Anda mungkin juga menyukai

- Actuator Variable Geometry Turbocharger ReplacementDokumen11 halamanActuator Variable Geometry Turbocharger ReplacementZoltán Szecsődi100% (1)

- Control Housing, Overhaul PDFDokumen23 halamanControl Housing, Overhaul PDFEsam PhlipeBelum ada peringkat

- Cathy O'Brien & Mark Philips - Trance Formation of America2Dokumen224 halamanCathy O'Brien & Mark Philips - Trance Formation of America2bld200797% (33)

- I Shift Clutc Plate Replace PDFDokumen40 halamanI Shift Clutc Plate Replace PDFRongali ganapathiBelum ada peringkat

- Volvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionDokumen3 halamanVolvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionMohammad Saleh AbbasiBelum ada peringkat

- Speed Sensor and Cable Harness, Replace PDFDokumen8 halamanSpeed Sensor and Cable Harness, Replace PDFEsam PhlipeBelum ada peringkat

- Volvo Gear Actuator: Design - Function - RepairDokumen76 halamanVolvo Gear Actuator: Design - Function - RepairNadeem Mohd100% (2)

- Volvo Control System System DescriptionDokumen11 halamanVolvo Control System System DescriptionTun Tun Win KseBelum ada peringkat

- Valves & Unit Injectors AdjustingDokumen14 halamanValves & Unit Injectors AdjustingZibao JumaBelum ada peringkat

- Aftermarket Parts CatalogDokumen390 halamanAftermarket Parts CatalogValbertg100% (1)

- Pneumatic Diagram FH, FM, CHID E730001 - English (United Kingdom) 362 KB 2007-08-21Dokumen26 halamanPneumatic Diagram FH, FM, CHID E730001 - English (United Kingdom) 362 KB 2007-08-21MTK2016Belum ada peringkat

- Cruise Control, Fault TracingDokumen12 halamanCruise Control, Fault TracingIzz BaharBelum ada peringkat

- I-Shift Calibration Operation Number 40070 Fails at Calibration of The "Stroke Length"Dokumen4 halamanI-Shift Calibration Operation Number 40070 Fails at Calibration of The "Stroke Length"Tun Tun Win KseBelum ada peringkat

- Air Supply Description and FunctionDokumen12 halamanAir Supply Description and Functionirfan100% (1)

- Electronically Controlled Suspension (ECS), System DescriptionDokumen15 halamanElectronically Controlled Suspension (ECS), System DescriptionAbo Fraj100% (3)

- B-00000 - 158513 A-0000oo-254451Dokumen132 halamanB-00000 - 158513 A-0000oo-254451Benjamin Miranda Flores100% (1)

- Adblue FH4 PDFDokumen45 halamanAdblue FH4 PDFAhmad BaharBelum ada peringkat

- Volvo Truck Fuel Bleeding GuideDokumen2 halamanVolvo Truck Fuel Bleeding GuideSherzad Chem100% (1)

- 20039-11 B11R D11C UniverseDokumen225 halaman20039-11 B11R D11C UniverseDaniel Alex SánchezBelum ada peringkat

- 431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFDokumen7 halaman431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFautoeletricamalaquiaBelum ada peringkat

- Service Bulletin Trucks: Input Shaft Sealing Ring, ReplacementDokumen13 halamanService Bulletin Trucks: Input Shaft Sealing Ring, ReplacementAndrey GaivoronskyBelum ada peringkat

- Fault Codes 11 and 12 - Accelerator Pedal Sensor and Idling Contact IssuesDokumen40 halamanFault Codes 11 and 12 - Accelerator Pedal Sensor and Idling Contact IssuesIzz BaharBelum ada peringkat

- Dokumen - Tips Volvo FH Air Suspension DiagramDokumen22 halamanDokumen - Tips Volvo FH Air Suspension DiagramHadden RatkeBelum ada peringkat

- Valve and Injector Adjustment With EPG D12, D12A, D12B, D12CDokumen9 halamanValve and Injector Adjustment With EPG D12, D12A, D12B, D12CRioga Rioga100% (1)

- Volvo Mid 136 Fault CodesDokumen72 halamanVolvo Mid 136 Fault Codesnzimageoffrey96100% (1)

- Low Compression, Fault TracingDokumen8 halamanLow Compression, Fault TracingIzz Bahar100% (2)

- Priming Fuel SystemDokumen4 halamanPriming Fuel SystemIzz BaharBelum ada peringkat

- P11X24EN Scania Opticruise and Retarder Tcm40 280864Dokumen6 halamanP11X24EN Scania Opticruise and Retarder Tcm40 280864Ionut LefterBelum ada peringkat

- Service Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Dokumen28 halamanService Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Abdelhak EzzahriouiBelum ada peringkat

- FM PDFDokumen660 halamanFM PDFEngkus KuswayaBelum ada peringkat

- Abs VolvotDokumen17 halamanAbs Volvotamri hardyBelum ada peringkat

- Clutch Compressor Service Manual For VolvoDokumen36 halamanClutch Compressor Service Manual For Volvox100% (2)

- Oil Cooler Overflow Valve ReplacementDokumen4 halamanOil Cooler Overflow Valve ReplacementIzz BaharBelum ada peringkat

- Footbrake Valve, Component DescriptionDokumen5 halamanFootbrake Valve, Component DescriptionManksBelum ada peringkat

- Veb PDFDokumen11 halamanVeb PDFIzz BaharBelum ada peringkat

- Technical Note: I - Subject: Procedure To Follow For Apm FaultDokumen11 halamanTechnical Note: I - Subject: Procedure To Follow For Apm Faultmebarki aberraouf100% (2)

- Location, EBS-3 ECU (D376)Dokumen1 halamanLocation, EBS-3 ECU (D376)Daniel PricopBelum ada peringkat

- 20005-03 B8rle Eu6 X900 D8KDokumen217 halaman20005-03 B8rle Eu6 X900 D8KGuillermo Guardia Guzman100% (1)

- PowertronicDokumen4 halamanPowertronicsherzad100% (2)

- Infoservis 2018.07.10 Premier Parts ZF For Truck and Bus WWW - Autosluzby.CzDokumen58 halamanInfoservis 2018.07.10 Premier Parts ZF For Truck and Bus WWW - Autosluzby.CzDpr OranBelum ada peringkat

- Mid 222 2Dokumen36 halamanMid 222 2danecuprija100% (1)

- Autodesk Revit Structure 2015 Certification RoadmapDokumen2 halamanAutodesk Revit Structure 2015 Certification RoadmapMohamedBelum ada peringkat

- Operation Instructions VOCOM II ToughDokumen72 halamanOperation Instructions VOCOM II ToughmusharrfBelum ada peringkat

- VW Scirocco 2008-2015 - 4-Cyl. Injection Engine (2.0l Engine, Turbocharger) VW R GMBH (CDLA CDLC CDLK)Dokumen194 halamanVW Scirocco 2008-2015 - 4-Cyl. Injection Engine (2.0l Engine, Turbocharger) VW R GMBH (CDLA CDLC CDLK)Mucowera AshaBelum ada peringkat

- Service Bulletin Trucks: Exhaust Pressure Governor, Fault TracingDokumen9 halamanService Bulletin Trucks: Exhaust Pressure Governor, Fault TracingCristhian Samuel Yacila OrdinolaBelum ada peringkat

- FOTON Section Two ENG PDFDokumen884 halamanFOTON Section Two ENG PDFRichard Zea100% (2)

- Piston Ring Liner RodDokumen4 halamanPiston Ring Liner Rodmuhammad arif100% (1)

- Mid 222Dokumen32 halamanMid 222danecuprijaBelum ada peringkat

- Caterpillar Cat 318B N Excavator (Prefix 7KZ) Service Repair Manual (7KZ00001 and Up)Dokumen27 halamanCaterpillar Cat 318B N Excavator (Prefix 7KZ) Service Repair Manual (7KZ00001 and Up)kfm8seuudu50% (2)

- ICDokumen2 halamanICsengottaiyanBelum ada peringkat

- Table of fuses and functions on electrical distribution boxDokumen274 halamanTable of fuses and functions on electrical distribution boxrashid hassanBelum ada peringkat

- MST Ks Catalogue WebDokumen180 halamanMST Ks Catalogue WebMiguel Gutierrez100% (2)

- Service Manual Trucks: Wiring Diagram FEDokumen190 halamanService Manual Trucks: Wiring Diagram FEStefan AslamBelum ada peringkat

- Engine Idle Shutdown FH4 FM4Dokumen1 halamanEngine Idle Shutdown FH4 FM4jose breno vieira silvaBelum ada peringkat

- EDC17 Maps Guide: TH THDokumen18 halamanEDC17 Maps Guide: TH THZamir Shehu100% (9)

- Volvo FH Air SuspensionDokumen24 halamanVolvo FH Air SuspensionVolvo Truck100% (2)

- Retrofitting Alarm and Theft Protection, VPS: Issue 1Dokumen36 halamanRetrofitting Alarm and Theft Protection, VPS: Issue 1ruanBelum ada peringkat

- Maintenance GensetDokumen1 halamanMaintenance GensetArif Dwi Wahyudi100% (1)

- Remove and install timing assembly in 7 stepsDokumen48 halamanRemove and install timing assembly in 7 stepsMirek100% (1)

- BIM Planning Guide For Facility Owners-Version 2.0 PDFDokumen79 halamanBIM Planning Guide For Facility Owners-Version 2.0 PDFomaralihasBelum ada peringkat

- BIM Planning Guide For Facility Owners-Version 2.0 PDFDokumen79 halamanBIM Planning Guide For Facility Owners-Version 2.0 PDFomaralihasBelum ada peringkat

- Quick software referenceDokumen34 halamanQuick software referenceYonPompeyoArbaizoTolentinoBelum ada peringkat

- Sebp4547 05 00 All PDFDokumen679 halamanSebp4547 05 00 All PDFRoberto Tenemas100% (1)

- Renault Truck C, D, K, T описаниеDokumen259 halamanRenault Truck C, D, K, T описаниеAnatoliiBelum ada peringkat

- DisplayDokumen16 halamanDisplaydesie tekaBelum ada peringkat

- EXTFILE134991159Dokumen24 halamanEXTFILE134991159Narciso JuniorBelum ada peringkat

- MS.93. MID 249. BBM. Codigo de Averias. Edicion 5Dokumen36 halamanMS.93. MID 249. BBM. Codigo de Averias. Edicion 5Benjamin Miranda Flores0% (1)

- Volvo-FH-Series Specifications Cab UKDokumen3 halamanVolvo-FH-Series Specifications Cab UKWagner Nascimento Gonçalves100% (1)

- Volvo D16 Engine Family: Volvo Trucks. Driving ProgressDokumen6 halamanVolvo D16 Engine Family: Volvo Trucks. Driving ProgressinduramBelum ada peringkat

- ERROR CODE RENAULT AND VOLVO TRUCK Mid 144 - Psid 10 - Fmi 3Dokumen10 halamanERROR CODE RENAULT AND VOLVO TRUCK Mid 144 - Psid 10 - Fmi 3lampard100% (1)

- Engine Brake Design and Function in OlvoDokumen9 halamanEngine Brake Design and Function in OlvoMohan PreethBelum ada peringkat

- Air CompressorDokumen6 halamanAir CompressorMinn Thet NaingBelum ada peringkat

- Miller Spectrum 875 XtremeDokumen4 halamanMiller Spectrum 875 XtremeomaralihasBelum ada peringkat

- Fault Tolerant TTCANDokumen8 halamanFault Tolerant TTCANPOWERBASEBelum ada peringkat

- Combine - Thesis - PDF Plasma Arc MachiningDokumen104 halamanCombine - Thesis - PDF Plasma Arc Machininggourab19Belum ada peringkat

- Understanding CNCRoutersDokumen116 halamanUnderstanding CNCRoutersHisham Tarek100% (3)

- Windows - The Official Magazine 2013-09Dokumen100 halamanWindows - The Official Magazine 2013-09omaralihasBelum ada peringkat

- CNC Plasma CutterDokumen1 halamanCNC Plasma CutteromaralihasBelum ada peringkat

- Acad Elec 2010 GetstartDokumen255 halamanAcad Elec 2010 GetstartTosu FlorinBelum ada peringkat

- Impact TriningDokumen36 halamanImpact TriningomaralihasBelum ada peringkat

- Autodesk Moldflow Expert Certification OverviewDokumen1 halamanAutodesk Moldflow Expert Certification OverviewomaralihasBelum ada peringkat

- DL650AL3Dokumen108 halamanDL650AL3Rea Cleare TampusBelum ada peringkat

- Soal Faa PowerplantDokumen136 halamanSoal Faa PowerplantDidi PurnowiantoBelum ada peringkat

- Brosur MesinDokumen1 halamanBrosur MesinMuhammad KarimBelum ada peringkat

- 2Dokumen13 halaman2msaqibraza93Belum ada peringkat

- POS 1 CO 1 ORDER ISTK 1 BENENNUNGDokumen22 halamanPOS 1 CO 1 ORDER ISTK 1 BENENNUNGНиколай НекрасовBelum ada peringkat

- Stihl Ms 440: Ersatzteilliste Spare Parts List Liste Des PiècesDokumen40 halamanStihl Ms 440: Ersatzteilliste Spare Parts List Liste Des PiècesLucas PerroneBelum ada peringkat

- 1006TAG2 ElectropaK PN1793 PDFDokumen2 halaman1006TAG2 ElectropaK PN1793 PDFAnas BasarahBelum ada peringkat

- Data Analyst Intern Case - July 2021Dokumen56 halamanData Analyst Intern Case - July 2021Mihaela GeorgianaBelum ada peringkat

- Deutz 1015 Marine Engine PDFDokumen6 halamanDeutz 1015 Marine Engine PDFGeorge Vasiliou100% (1)

- Subaru Engines Eh72 Fi OwnersDokumen80 halamanSubaru Engines Eh72 Fi OwnersjeanBelum ada peringkat

- ICE - Lecture#1 - Intro To ICEDokumen26 halamanICE - Lecture#1 - Intro To ICENik Hakim Mohammad IzaniBelum ada peringkat

- Tilt Cylinder S150 Parts List & SpecsDokumen3 halamanTilt Cylinder S150 Parts List & SpecsSIA Stats RENTBelum ada peringkat

- Parts Catalog: 2010/4 (Apr.) PublishedDokumen77 halamanParts Catalog: 2010/4 (Apr.) PublishedŠime Stipaničev100% (1)

- PowerKit 6M26 Series Diesel Engine SpecsDokumen2 halamanPowerKit 6M26 Series Diesel Engine SpecsDuc Thao VuBelum ada peringkat

- Crankshaft 3412C MarineDokumen3 halamanCrankshaft 3412C MarineSteven Y.MBelum ada peringkat

- William Controls PDFDokumen252 halamanWilliam Controls PDFWilson CendalesBelum ada peringkat

- Bobcat 442Dokumen29 halamanBobcat 442yeferson mora guerreroBelum ada peringkat

- I-Vtech Stream SeminarDokumen16 halamanI-Vtech Stream Seminarvishnu chaudharyBelum ada peringkat

- Lubrication System: To IndexDokumen13 halamanLubrication System: To IndexzeroBelum ada peringkat