2863-Valve Seating Tools PDF

Diunggah oleh

syllavethyjimJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2863-Valve Seating Tools PDF

Diunggah oleh

syllavethyjimHak Cipta:

Format Tersedia

The making of tools to cut valve

seatings is described by Geometer

Valve seating

TOOLS

o BE pressure or liquid-tight,

a valve of hard or rigid

material demands an accurate seating. Of course, if a valve is

of leather, rubber, or similar

pliable material, or incorporates

such in the form of a ring or disc,

small inaccuracies in the seating

can be accommodated-though the

finish should be smooth and free

from sharp edges.

A valve, however, which is a flat

disc, a ball, cone or poppet type,

demands a geometrically accurate

seating, since only by precise matching

of valve and seating faces can leakage

be prevented.

In small and model sizes, suitable

cutters can be easily produced from

silver-steel or cast-steel rod and, after

hardening and tempering, used in a

drilling machine or by hand where

the purpose is simply to finish or

correct the seating and where, consequently, machine use would be

attended by the risk of removing too

much material.

Before hardening and tempering,

the tool is finished to shape and

dimensions, and afterwards cutting

edges are honed with hand abrasive

slips.

Colour changes

For tempering, it is polished bright

with emery cloth, then warmed and

twisted in a small spirit or blowlamp

flame well back from the cutting edge.

As heating proceeds, the surface

changes colour-light brown, brown,

blue, to dark purple. On the brown

colour reaching the cutting edge, the

tool is quenched again in water, and

after honing it is ready for use. If

the colour over-runs to purple the

tool has been made too soft.

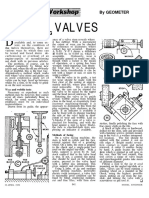

A and B illustrate a flat-seating

cutter which can be used in a hole

after a twist drill to square out the

bottom for a disc or ball valve; C

depicts a hollow cutter to remove

material from the outer edge of -a flat

seating, leaving it raised for a disc

valve; and D shows a cutter for a

small cone or poppet valve, this

having a screwed-in spigot or guide

with locknuts on the end with which

5 APRIL 1956

to regulate the cut. This guide is fitted

when the tool is finished and need

not be hardened and tempered.

Cutting edges of a flat-seating

cutter are produced by sawing and

filing, E. A central tongue is produced,

cut crosswise with a narrow saw,

then the edges are filed oppositely

with clearance or rake.

Cutting edges of a hollow cutter

are filed as F, after drilling the rod

centrally, and are opened out gradually. To save material, such a cutter

can be a shell-drilled centrally and

crosswise, countersunk, the teeth filed,

the piece cut off, heat-treated, then

riveted to a shank, G. Tempering

should be done with the tool standing

teeth upwards on flat metal. It should

be heated slowly, and finally tipped

off into water.

Making the seating

In the absence of a lathe, rod ends

can be trued in a drilled block rotating

against the face of a grinding wheel H. ,

An example of producing a seating

is that for a flat valve I. , The central

hole and a larger bore for the valve

having been drilled, a flat-seating

cutter is used to square out the bottom,

J. This is followed by a hollow

cutter, leaving the seating as at K.

Edges will remain sharp, however,

and the face of the seating may be

ringed from the flat cutter-which

would prevent complete sealing.

The edges requiring radii are finished

with coned rods as L and M, and the

face with a square-ended rod as N,

then lapped with line grinding compound. The rods can be of mildsteel, brass, aluminium, etc.

The small cone L,, can be produced

free-hand on a grinding wheel; the

larger hollow one M,

, by drilling; the

square end on the rod, N, by grinding

as H. With a smear of grinding paste

bn the faces, the rods are twisted by

fingers on the seating.

In the case of a ball valve, seating

on the raw edge of a hole, 0, is not

effective, so with a soft rod and light

hammer the ball is tapped down, the

seating being shaped to its contour, P.

A poppet-valve seating cutter is

used as Q. pressing the tool down by

hand.

q

557

0I

MODEL ENGINEER

Anda mungkin juga menyukai

- 2889-Further Drilling Methods PDFDokumen1 halaman2889-Further Drilling Methods PDFsyllavethyjimBelum ada peringkat

- 2872-Circular Clips #2 PDFDokumen1 halaman2872-Circular Clips #2 PDFsyllavethyjimBelum ada peringkat

- IMP Workshop ManualDokumen336 halamanIMP Workshop Manualsyllavethyjim67% (3)

- 2890-Nuts & Spanners PDFDokumen1 halaman2890-Nuts & Spanners PDFsyllavethyjimBelum ada peringkat

- 2878-Chains & Sprockets PDFDokumen1 halaman2878-Chains & Sprockets PDFsyllavethyjimBelum ada peringkat

- Contours 1: Hile It CannotDokumen1 halamanContours 1: Hile It CannotsyllavethyjimBelum ada peringkat

- 2886-Stud Fitting & Removal PDFDokumen1 halaman2886-Stud Fitting & Removal PDFsyllavethyjimBelum ada peringkat

- 2885-Dent & Bulge Removal PDFDokumen1 halaman2885-Dent & Bulge Removal PDFsyllavethyjimBelum ada peringkat

- 2880-Supporting & Steadying PDFDokumen1 halaman2880-Supporting & Steadying PDFsyllavethyjimBelum ada peringkat

- 2883-Metal Working PDFDokumen1 halaman2883-Metal Working PDFsyllavethyjimBelum ada peringkat

- 2888-Oblique Drilling PDFDokumen1 halaman2888-Oblique Drilling PDFsyllavethyjimBelum ada peringkat

- 2871-Circular Clips #1 PDFDokumen1 halaman2871-Circular Clips #1 PDFsyllavethyjimBelum ada peringkat

- 2881-Radii Functions and Checking PDFDokumen1 halaman2881-Radii Functions and Checking PDFsyllavethyjimBelum ada peringkat

- 2884-Panel Beating PDFDokumen1 halaman2884-Panel Beating PDFsyllavethyjim100% (1)

- 2887-Broken Drills & Taps PDFDokumen1 halaman2887-Broken Drills & Taps PDFsyllavethyjimBelum ada peringkat

- 2879-Clamping & Holding PDFDokumen1 halaman2879-Clamping & Holding PDFsyllavethyjimBelum ada peringkat

- 2874-Fitting Core Plugs PDFDokumen1 halaman2874-Fitting Core Plugs PDFsyllavethyjimBelum ada peringkat

- 2876-Belt Fasteners PDFDokumen1 halaman2876-Belt Fasteners PDFsyllavethyjimBelum ada peringkat

- Roller Chains and Sprockets GuideDokumen1 halamanRoller Chains and Sprockets GuidesyllavethyjimBelum ada peringkat

- 2870-Simple Screw Assembly PDFDokumen1 halaman2870-Simple Screw Assembly PDFsyllavethyjimBelum ada peringkat

- 2873-Cotters & Wedges PDFDokumen1 halaman2873-Cotters & Wedges PDFsyllavethyjimBelum ada peringkat

- 2875-Belt Drives PDFDokumen1 halaman2875-Belt Drives PDFsyllavethyjimBelum ada peringkat

- 2868-Glands & Pipe Fittings PDFDokumen1 halaman2868-Glands & Pipe Fittings PDFsyllavethyjimBelum ada peringkat

- 2867 Case HardeningDokumen1 halaman2867 Case HardeningEr Sukhwinder SinghBelum ada peringkat

- 2869-Fitting & Joining Pipes PDFDokumen1 halaman2869-Fitting & Joining Pipes PDFsyllavethyjimBelum ada peringkat

- 2861-Wheel & Shaft PullersDokumen1 halaman2861-Wheel & Shaft PullersSandra Barnett CrossanBelum ada peringkat

- 2865-Testing & Facing Valves PDFDokumen1 halaman2865-Testing & Facing Valves PDFsyllavethyjimBelum ada peringkat

- 2864-Poppet Valves & Seating PDFDokumen1 halaman2864-Poppet Valves & Seating PDFsyllavethyjimBelum ada peringkat

- 2866-Hardening & Tempering PDFDokumen1 halaman2866-Hardening & Tempering PDFsyllavethyjimBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- History of the QWERTY Keyboard LayoutDokumen5 halamanHistory of the QWERTY Keyboard LayoutshitfikapeBelum ada peringkat

- Your Institute Name & Logo: Abcd Abcd Abcd Abcd AbcdDokumen1 halamanYour Institute Name & Logo: Abcd Abcd Abcd Abcd AbcdNayan AgrawalBelum ada peringkat

- MD Cabinet DoorsDokumen4 halamanMD Cabinet DoorsKamel NaitBelum ada peringkat

- Attachment Report Nakayi-1Dokumen100 halamanAttachment Report Nakayi-1misodzibBelum ada peringkat

- Woodworking Safety Unit CorrectDokumen19 halamanWoodworking Safety Unit CorrectNidhinkorothBelum ada peringkat

- Components and Functions of an Air Handling UnitDokumen28 halamanComponents and Functions of an Air Handling UnitAditiBelum ada peringkat

- Kenna MetalDokumen24 halamanKenna MetalJ Ferreyra LibanoBelum ada peringkat

- ShindaiwaDokumen143 halamanShindaiwaMarcelo GiussaniBelum ada peringkat

- Sunbeam Caffe Bellissimo Em9300 Service ManualDokumen21 halamanSunbeam Caffe Bellissimo Em9300 Service ManualinfomediamarketsourceBelum ada peringkat

- DTS Nozzles R3Dokumen2 halamanDTS Nozzles R3meilia teknikBelum ada peringkat

- DIY Dremel CNC Parts ListDokumen6 halamanDIY Dremel CNC Parts Listhyungjoo yiBelum ada peringkat

- Technical Specifications ROMI C SeriesDokumen28 halamanTechnical Specifications ROMI C Seriesmetall 4uBelum ada peringkat

- Vernier Height Gauge: Parts, Diagram, Errors, PrecautionDokumen8 halamanVernier Height Gauge: Parts, Diagram, Errors, PrecautionEngineering StudentBelum ada peringkat

- Powerful Wet and Dry Vacuum Cleaner With 70 L Container Capacity and Up To Three MotorsDokumen9 halamanPowerful Wet and Dry Vacuum Cleaner With 70 L Container Capacity and Up To Three MotorsKadir ErguvenBelum ada peringkat

- Work and Simple Machines ExplainedDokumen47 halamanWork and Simple Machines ExplainedEp LohBelum ada peringkat

- Guide to Spindle BalancingDokumen2 halamanGuide to Spindle BalancingMangesh KetkarBelum ada peringkat

- Parts Catalog: H270E Harvester HeadDokumen145 halamanParts Catalog: H270E Harvester HeadjulianoBelum ada peringkat

- Taneks Brake CatalogueDokumen31 halamanTaneks Brake CatalogueeCommerce SAJID AutoBelum ada peringkat

- TurningDokumen252 halamanTurningMichael KashiotisBelum ada peringkat

- BSA Lightning Air Rifle PDFDokumen2 halamanBSA Lightning Air Rifle PDFErikBelum ada peringkat

- Spare Parts CatalogueDokumen419 halamanSpare Parts CatalogueClaudio Rafael Deola SadaBelum ada peringkat

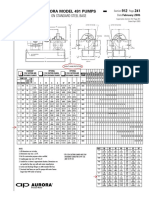

- Aurora Model 491 Pumps Technical SpecificationsDokumen1 halamanAurora Model 491 Pumps Technical SpecificationsJUAN ORTEGABelum ada peringkat

- Cleaning Care and Maintenance of Kitchen Appliances andDokumen57 halamanCleaning Care and Maintenance of Kitchen Appliances andMary Jane Blanco Fio50% (2)

- NRC Generic Fundamentals Examination Question Bank - PWR February 2016Dokumen65 halamanNRC Generic Fundamentals Examination Question Bank - PWR February 2016Iqbal HayatkhanBelum ada peringkat

- Screw Technical Data SheetDokumen32 halamanScrew Technical Data SheetRenju ReghuBelum ada peringkat

- Cold Room & Freezer RoomDokumen38 halamanCold Room & Freezer RoomSamuel AtBelum ada peringkat

- Colt M16A1 Assault RifleDokumen4 halamanColt M16A1 Assault Riflesaledin1100% (3)

- Vihtavuori Reloading Guide 2021 ENGDokumen59 halamanVihtavuori Reloading Guide 2021 ENGFabien BonatoBelum ada peringkat

- Machine Control Gage Selection GuideDokumen15 halamanMachine Control Gage Selection GuideVikas ChoudharyBelum ada peringkat

- Torque Converter Clutch Case: Automatic TransmissionDokumen4 halamanTorque Converter Clutch Case: Automatic TransmissionAnton FortovBelum ada peringkat