2870-Simple Screw Assembly PDF

Diunggah oleh

syllavethyjim0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

31 tayangan1 halamanJudul Asli

2870-Simple Screw Assembly.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

31 tayangan1 halaman2870-Simple Screw Assembly PDF

Diunggah oleh

syllavethyjimHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

By Geometer

SIMPLE SCREW

ASSEMBLY

I

1

/

t

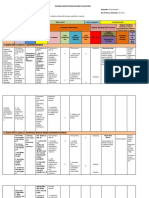

in assembly

work, only familiarity with

some dodge or other

enables a screw, bolt, or nut to be

fitted without a great deal of

frustration and loss of time. Much

the same is true if a screw or small

component is dropped in an inaccessible position.

CCASIONALLY

Small screws and components can

be handled effectively with tweezers,

and medium-sized ones with long

thin-jawed pliers; and there are

various means of maintaining screws

on screwdrivers.

If the screw slot and screwdriver

blade are both good, and the screw is

to be pushed into a horizontal or

overhead hole, it can be done by

simply placing the screw on the blade.

If the hole is substantially downwards,

however, the screw will fall off unless

held in some manner. To do this, the

screwdriver blade can be magnetised

for a steel screw, or alternatively a

small blob of thick grease or Plasticine

used-as for a brass screw. Some

screwdrivers have a type of sliding

jaw which can be pushed down the

blade to hold the screw.

With a good screw slot, an ordinary

thin rubber band can be looped one

end through the other round the

blade, twisted tight, then the free

end passed over the screw shank A.

Where the difficulty is mainly in

fitting a screw in a hole, or maintaining it in alignment for screwdriver

to be used, it can be done as B,

employing a wire loop, and pulling

it off when the screw has started.

Another idea, where the hole is

downwards, is to slot a piece of thin

steel, C, for the screw to lie in. This

method is also effective for driving in

tacks and small nails without damage

to fingers.

Other methods

Bolts and nuts can often be fitted

by placing them in tubular box

spanners, or in socket spanners with

long shanks. A bolt or setscrew which

is one of a number with the head

drilled for a common locking wire,

can be manipulated and fitted with a

type of wire tweezers, D, bent from thin

rod or wire. A slotted holder, a

development of that at C, is as E ,

where a short strip of sheet steel is

riveted on to hold the bolt in the

slot. The hexagon can then be turned

with an open spanner.

Occasionally, it is required to fit a

screw in from the back of some panel

or sheet metal work and a nut and

washer outside. The wire loop method

B may be practicable.

But if the

position is really inaccessible, a wire

can. be pushed through the hole from

t h e front, out to where the screw can

be fitted, this soldered on the end

and pulled into place, F. The wire can

be broken off and the thread cleaned

up with the screw shank gripped by

thin-jawed pliers.

On an inaccessible stud, a nut can

sometimes be fitted by sliding down

24 MAY 1956

853

a wire, then flicking round with a

screwdriver to start it until a cranked

spanner can be used, G.

A screw fitted to the rear of a

panel can be prevented from turning

by soldering or brazing on a plate H

to abut against an edge. Where there

is no access at all to the rear of a

panel, a hole can be drilled offposition to pass the screw head, then

a slot filed to bring the screw into

position I. The hole being made large

enough (or wide and the metal

kinked), the screw can be fitted with

a plate H to cover the slot and prevent

turning.

Rotation can also be prevented in

initial fitting, which may be all that

is necessary, by using a long screw,

gripping the shank with pliers for the

nut to be tightened, then snipping

off and filing smooth, J. A tapped

plate, K, enables screws to be fitted

from outside. If not soldered, it

can- be guided into position with a

wire.

For badly-placed screws,

various types of round the corner

screwdriver can be bought or made

from strip steel, case hardened,

L, M, N.

MODEL ENGINEER

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- 2886-Stud Fitting & Removal PDFDokumen1 halaman2886-Stud Fitting & Removal PDFsyllavethyjimBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- IMP Workshop ManualDokumen336 halamanIMP Workshop Manualsyllavethyjim67% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- 2888-Oblique Drilling PDFDokumen1 halaman2888-Oblique Drilling PDFsyllavethyjimBelum ada peringkat

- 2873-Cotters & Wedges PDFDokumen1 halaman2873-Cotters & Wedges PDFsyllavethyjimBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Contours 1: Hile It CannotDokumen1 halamanContours 1: Hile It CannotsyllavethyjimBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- 2884-Panel Beating PDFDokumen1 halaman2884-Panel Beating PDFsyllavethyjim100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- 2878-Chains & Sprockets PDFDokumen1 halaman2878-Chains & Sprockets PDFsyllavethyjimBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- 2853-Simple Drilling JigsDokumen1 halaman2853-Simple Drilling JigssyllavethyjimBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- 2877-Roller Chain & Sprockets PDFDokumen1 halaman2877-Roller Chain & Sprockets PDFsyllavethyjimBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- 2864-Poppet Valves & Seating PDFDokumen1 halaman2864-Poppet Valves & Seating PDFsyllavethyjimBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- 2858-How To Use Scrapers PDFDokumen1 halaman2858-How To Use Scrapers PDFsyllavethyjimBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- 2852-Polishing Metal SurfacesDokumen1 halaman2852-Polishing Metal SurfacessyllavethyjimBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- 2847-Keys & Driving PinsDokumen1 halaman2847-Keys & Driving PinssyllavethyjimBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Continue: Rudolf Bultmann Theology of The New Testament PDFDokumen3 halamanContinue: Rudolf Bultmann Theology of The New Testament PDFpishoi gerges0% (1)

- Saet Work AnsDokumen5 halamanSaet Work AnsSeanLejeeBajan89% (27)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- IdM11gR2 Sizing WP LatestDokumen31 halamanIdM11gR2 Sizing WP Latesttranhieu5959Belum ada peringkat

- Engineering Management (Final Exam)Dokumen2 halamanEngineering Management (Final Exam)Efryl Ann de GuzmanBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Wiley Chapter 11 Depreciation Impairments and DepletionDokumen43 halamanWiley Chapter 11 Depreciation Impairments and Depletion靳雪娇Belum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Escario Vs NLRCDokumen10 halamanEscario Vs NLRCnat_wmsu2010Belum ada peringkat

- Audit On ERP Implementation UN PWCDokumen28 halamanAudit On ERP Implementation UN PWCSamina InkandellaBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDokumen27 halamanSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunBelum ada peringkat

- Vangood Quotation - Refrigerator Part - 2023.3.2Dokumen5 halamanVangood Quotation - Refrigerator Part - 2023.3.2Enmanuel Jossue Artigas VillaBelum ada peringkat

- Shahroz Khan CVDokumen5 halamanShahroz Khan CVsid202pkBelum ada peringkat

- JAZEL Resume-2-1-2-1-3-1Dokumen2 halamanJAZEL Resume-2-1-2-1-3-1GirlieJoyGayoBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- 2.1 Components and General Features of Financial Statements (3114AFE)Dokumen19 halaman2.1 Components and General Features of Financial Statements (3114AFE)WilsonBelum ada peringkat

- Working Capital ManagementDokumen39 halamanWorking Capital ManagementRebelliousRascalBelum ada peringkat

- CSEC Jan 2011 Paper 1Dokumen8 halamanCSEC Jan 2011 Paper 1R.D. KhanBelum ada peringkat

- Ucm6510 Usermanual PDFDokumen393 halamanUcm6510 Usermanual PDFCristhian ArecoBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- General Field Definitions PlusDokumen9 halamanGeneral Field Definitions PlusOscar Alberto ZambranoBelum ada peringkat

- Maths PDFDokumen3 halamanMaths PDFChristina HemsworthBelum ada peringkat

- Catalog Celule Siemens 8DJHDokumen80 halamanCatalog Celule Siemens 8DJHAlexandru HalauBelum ada peringkat

- Employees' Pension Scheme, 1995: Form No. 10 C (E.P.S)Dokumen4 halamanEmployees' Pension Scheme, 1995: Form No. 10 C (E.P.S)nasir ahmedBelum ada peringkat

- Subqueries-and-JOINs-ExercisesDokumen7 halamanSubqueries-and-JOINs-ExerciseserlanBelum ada peringkat

- Photon Trading - Market Structure BasicsDokumen11 halamanPhoton Trading - Market Structure Basicstula amar100% (2)

- Rofi Operation and Maintenance ManualDokumen3 halamanRofi Operation and Maintenance ManualSteve NewmanBelum ada peringkat

- Basics: Define The Task of Having Braking System in A VehicleDokumen27 halamanBasics: Define The Task of Having Braking System in A VehiclearupBelum ada peringkat

- Fidp ResearchDokumen3 halamanFidp ResearchIn SanityBelum ada peringkat

- On CatiaDokumen42 halamanOn Catiahimanshuvermac3053100% (1)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Banjara EmbroideryDokumen34 halamanBanjara EmbroideryKriti Rama ManiBelum ada peringkat

- Are Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceDokumen6 halamanAre Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceNely Noer SofwatiBelum ada peringkat

- Phase 1: API Lifecycle (2 Days)Dokumen3 halamanPhase 1: API Lifecycle (2 Days)DevendraBelum ada peringkat

- Historical Development of AccountingDokumen25 halamanHistorical Development of AccountingstrifehartBelum ada peringkat

- 6 V 6 PlexiDokumen8 halaman6 V 6 PlexiFlyinGaitBelum ada peringkat

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingDari EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingPenilaian: 4.5 dari 5 bintang4.5/5 (847)