CivaCon - API Bottom Loading Adaptor - Instruction & Maintenance Manual

Diunggah oleh

esham2Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CivaCon - API Bottom Loading Adaptor - Instruction & Maintenance Manual

Diunggah oleh

esham2Hak Cipta:

Format Tersedia

API Assembly

1. Insert handle shaft through hole in body and place large e-clip on shaft.

2. Apply fluorosilicon grease (Dow Corning 3452 or equivalent) to quad ring, washer, handle shaft

and inside the hole in which these components are inserted. Press quad ring, washer and bearing over shaft and into the hole in body until flange on bearing is flush with surface on body.

891 Series Flat Bottom Loading Adaptor

Instruction & Maintenance Manual

3. Place o-ring, washer, spring, hub and nylon washer over shaft. Position handle so the hole in

the shaft aligns with the hole in the handle and the slot in the hub. Insert the fulcrum pin into the

hole and secure it with the bowtie clip.

4. Insert poppet bearing into the hole in the body, then insert the poppet assembly through the

spring and through the bearing.

P/N: 12000PA

Rev. B, Jul. 2010

5. Insert pin through poppet shaft.

6. Insert link 2 through poppet shaft and secure with pins.

7. Insert link 1 into hole in handle shaft and put small e-clip on link 1 to secure it to the handle

shaft.

8. Place o-ring into slot on the body.

9. Coat screws with NEVER SEEZE and attach nose piece to body with screws and lock washers.

10. Verify proper operation as described in semi annual inspection.

11. Place float ball over one of the holes on the side of the body. Place the sight glass o-ring inside

the groove of the sight glass and place the sight glass over the four holes on the body. Secure

the sight glass with screws and washers.

Warranty

All parts and products are thoroughly inspected and tested from the time raw material is received at

our plant, until the product is completed. We guarantee that all products are free from defects in

materials and workmanship for a period of one year from the date of shipment. Any product that

may prove defective within said one year period will, at our discretion, be promptly repaired, replaced or credit given for future orders. This warranty shall not apply to any products which has

been altered in any way, which has been repaired by any parts other that an authorized service

representative, or when such a failure is due to misuse or condition of use. We shall have no liability for labor costs, freight costs or any other costs or charges in excess of the amount of invoice for

the products.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED AND

SPECIFICALLY THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

WARNING!!

Product Description

CIVACON products should be used in compliance with the applicable federal, state and local laws

and regulations. Product selection should be based on physical specifications and limitations, compatibility with the environment, and the material being handled.

CIVACON MAKES NO WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE.

Civacons 891 flat bottom API adaptor design reduces product retention and increases flow while

unloading. The ergonomic handle smoothly opens the poppet during manual operation and the

hardened nose is rotatable for longer service life. The poppet seal is easily serviced without removing the API from the truck. The 891 adaptor conforms to API 1004 and EN13083 regulations.

Civacons 891 is a direct replacement for the 861, 897 and all competitors bottom loading adaptors.

TECHNICAL ASSISTANCE

Manual

If at any time during the installation a question arises that is not covered in this manual or with any

other applicable documents feel free to call the Customer Service Department or visit our website at

www.civacon.com.

In the U.S., call 1-888-526-5657

In all other countries, call your local agent.

This manual contains the inspection, maintenance schedule and instructions for repairing and replacing parts for all the 891 API adaptors. The following schedule, based on the environmental

conditions in the northern United States, is only a recommendation: Inspection and maintenance

intervals must be adjusted according to use and operating conditions. If any parts are damaged,

refer to the Annual Inspection and Maintenance section.

PHONE: (816) 741-6600 (888) 526-5657 Fax: (816) 741-1061

4304 Mattox Road Kansas City, MO 64150 www.civacon.com

PHONE: (816) 741-6600 (888) 526-5657 Fax: (816) 741-1061

4304 Mattox Road Kansas City, MO 64150 www.civacon.com

Semi-Annual Inspection

Annual Inspection

Visually inspect and test the valve for proper operation. This inspection can be done without removing the API from the trailer. Before the inspection, ensure that all lines are empty. Follow all safety

procedures. If any of the following parts need to be repaired or replaced, refer to the Annual Inspection & Maintenance section.

1. Remove API from the trailer, and inspect it at the workbench.

2. Keep the API in the closed position.

3. Remove the six screws and lock washers from the nose. When the nose is removed the poppet

assembly will extend less that 1/4.

4. Remove o-ring from the body.

Visual Inspection

1. Inspect the nose external sealing surface for dents or gouges

which could interfere with interfacing equipment or cause leaks.

See Figure 2.

FIGURE 2:

API Nose Surface

External Sealing Surface

5. Remove the small e-clip and slide link our of the handle shaft.

6. Disassemble poppet assembly. Remove the clevis pins located at the end of the poppet assembly by depressing the spring loaded wedge. Slide link out of the poppet shaft. Remove

poppet assembly and spring.

2. Inspect the backside of the nose (as shown in Figure 3) for excessive wear from the loading coupler. Its hard coated surface

should be free of gouges and grooves which could cause leaks. If

gouges and grooves exist, the adaptor end should be rotated or

replaced. Inspect the inside sealing surface (as shown in figure 3)

for wear.

7. Inspect and replace poppet o-ring as needed. Do not damage the poppet o-ring groove when

removing the o-ring. Do not twist O-Ring when installing.

3. Inspect stop pin for excessive wear or damage. The handle

should remain in the open position when placed on top of the stop

pin. If the valve does not remain open because the stop pin is

worn, replace the pin. The gap between the stop pin and handle

should be at least 3/16 as shown in Figure 4.

10. Inspect inside of the poppet bearing for wear or foreign material. Wipe off any contamination

and replace bearing if necessary.

8. Inspect the sealing surface of the nose for wear as shown in Figure 3, page 2.

9. Inspect the poppet shaft for scoring or contamination. Wipe off any contamination, if shaft is

scored a 600 grit or finer polishing cloth may be used.

11. Remove large e-clip.

12. Remove handle assembly from body.

13. Remove bowtie clip and pin to disengage handle.

FIGURE 3: Backside of Adaptor End

Inside

Sealing

Surface

FIGURE 4:

API Handle Gap

14. Inspect quad ring and washer for wear and contamination and replace if needed.

15. Inspect surface of handle shaft and inside surface of the hub and bearing for wear. Hub should

move freely over the shaft. Wipe off any contamination, polish with 600 grit or finer polishing

cloth or replace as needed.

16. Inspect nylon washers, o-ring, spring, and fulcrum pin for wear and replace as needed.

Coupler

Surface

17. For adaptors that have sight glasses remove the screws and washers and inspect the sight

glass for wear or cracks. Inspect the o-ring and float ball for wear or cracks and replace as

needed.

Installation Procedure

1. Remove nuts, bolts and washers from existing API adaptor.

3/16

minimum

2. Remove API adaptor and gasket. Thoroughly clean mounting flange.

3. Install new gasket (P/N 9095).

4. Position new API adaptor with notch in mounting flange oriented to the top position.

Physical Inspection

5. Install nuts, bolts and washers.

1. Use the handle to open and close the API several times. The handle should move smoothly.

2. Open the API with the handle as if unloading. Release the handle from the latched position allowing the poppet to slam shut. The poppet should close and center itself.

3. Open the valve by pushing on the poppet with a soft nonmetallic tool as far off center as possible

and allow the poppet to slowly close. Repeat several times, the poppet should center and reseat

every time.

CAUTION: OVERSIZED MOUNTING HARDWARE COULD

CASUE DAMAGE TO THIS VALVE DURING ASSEMBLY.

MOUNTING HARDWARE TO BE NO LONGER THAN 1 1/2 IN.

SEE MANUAL FOR ADDITIONAL DETAILS

Anda mungkin juga menyukai

- 2007 HD Difftrans 2006Dokumen334 halaman2007 HD Difftrans 2006David RosadoBelum ada peringkat

- 7785 A5Dokumen13 halaman7785 A5hmltdt9221100% (1)

- Engine Misfire, Runs Rough or Is UnstableDokumen4 halamanEngine Misfire, Runs Rough or Is UnstableAdolfo Dario Saavedra0% (1)

- NGP029 Exhaust Products CatalogDokumen108 halamanNGP029 Exhaust Products CatalogAndres PachecoBelum ada peringkat

- Graco Part ManualDokumen22 halamanGraco Part ManualandraBelum ada peringkat

- 2015 Civacon Mechanical List PricingDokumen8 halaman2015 Civacon Mechanical List PricingmartinBelum ada peringkat

- Ecf9 Nh3 ManualDokumen20 halamanEcf9 Nh3 Manualgonza100% (1)

- Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Dokumen1 halamanStem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Mohamed El-Sawah0% (1)

- Motor Bomba Alemite 3234404 - 7786-A5Dokumen12 halamanMotor Bomba Alemite 3234404 - 7786-A5Gezzy Boys 28Belum ada peringkat

- 2013 Us Shop Tech BrochureDokumen16 halaman2013 Us Shop Tech Brochurefollowjesus100% (1)

- Axsm 0041Dokumen98 halamanAxsm 0041Walter ╰⏝╯ MaonesBelum ada peringkat

- Carpeta Tecnica Equipamiento Flush byDokumen655 halamanCarpeta Tecnica Equipamiento Flush byFederico MoranBelum ada peringkat

- Installation: 1Gr-Fe Engine Mechanical - Drive BeltDokumen1 halamanInstallation: 1Gr-Fe Engine Mechanical - Drive BeltPedro Javier Castro SanchezBelum ada peringkat

- Maestro Codificado Listado de InventariosDokumen422 halamanMaestro Codificado Listado de Inventariosfiltros y lubricantes la nacionalBelum ada peringkat

- Franks Cabot - Q02 - 13 de 17 - STEERING PDFDokumen7 halamanFranks Cabot - Q02 - 13 de 17 - STEERING PDFcarlospais2Belum ada peringkat

- Maintenance Interval Schedule c15 MCW PDFDokumen3 halamanMaintenance Interval Schedule c15 MCW PDFVictor NunezBelum ada peringkat

- Ram Type Blowout Preventer MODEL100Dokumen12 halamanRam Type Blowout Preventer MODEL100Boedi SyafiqBelum ada peringkat

- Test Report 12CA23872-002 Carrier 38KCD109313GDokumen14 halamanTest Report 12CA23872-002 Carrier 38KCD109313GJuan Carlos Mendez100% (1)

- Winpower Wisc v-465d EngineDokumen5 halamanWinpower Wisc v-465d Engine80sDweebBelum ada peringkat

- Installation and Maintenance Instructions Standard Ventilated Clutch Model SVDokumen4 halamanInstallation and Maintenance Instructions Standard Ventilated Clutch Model SVWilson CendalesBelum ada peringkat

- Magnum Manual Mtt20 PartsDokumen40 halamanMagnum Manual Mtt20 Partsbalajiboss005Belum ada peringkat

- Transtec Servicio Pesado 2018Dokumen5 halamanTranstec Servicio Pesado 2018Ana Karina González Moreno100% (1)

- D25980-B3 Manual de Partes 1Dokumen6 halamanD25980-B3 Manual de Partes 1Duala Maquinaria100% (1)

- H 276Dokumen46 halamanH 276gustavofx21Belum ada peringkat

- Fruitland PDFDokumen21 halamanFruitland PDFALEXBelum ada peringkat

- Caja de Cambio Caracteristicas T318 PDFDokumen2 halamanCaja de Cambio Caracteristicas T318 PDFLenny Virgo100% (1)

- Vortec 1.6L I-4 IndustrialDokumen3 halamanVortec 1.6L I-4 IndustrialSantiago UrgilesBelum ada peringkat

- Brake Shoe IdDokumen3 halamanBrake Shoe Idalxsscabal100% (1)

- A Pilotair ValvesDokumen33 halamanA Pilotair ValvesZMCONTROL100% (1)

- MC 10129631 9999 PDFDokumen3 halamanMC 10129631 9999 PDFCompras CrdieselBelum ada peringkat

- Air Intake System Exhaust System Exhaust GasDokumen2 halamanAir Intake System Exhaust System Exhaust Gassinger50Belum ada peringkat

- Workshop Service Management Slide Chapter 3Dokumen13 halamanWorkshop Service Management Slide Chapter 3Ilham ArChBelum ada peringkat

- Maintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinDokumen2 halamanMaintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinedilsonBelum ada peringkat

- U341E Automatic Transmission / Transaxle: Valve Body Assembly: Removal (2010 Corolla)Dokumen4 halamanU341E Automatic Transmission / Transaxle: Valve Body Assembly: Removal (2010 Corolla)Afghan SportBelum ada peringkat

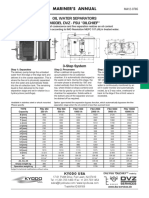

- Oil Water Separators Model DVZ - Fsu "Oilchief": 3-Step SystemDokumen1 halamanOil Water Separators Model DVZ - Fsu "Oilchief": 3-Step SystemRajishkumar RadhakrishnanBelum ada peringkat

- Barksdale General Installation InstructionsDokumen2 halamanBarksdale General Installation InstructionsLina Delgado OsorioBelum ada peringkat

- Manual Wheel Bearing Adj Procedures Sell SheetDokumen2 halamanManual Wheel Bearing Adj Procedures Sell SheetKhanh Pham DangBelum ada peringkat

- Filtros Mack Gu813 - Motor MP8 PDFDokumen1 halamanFiltros Mack Gu813 - Motor MP8 PDFNicolas Prieto MolinaBelum ada peringkat

- 1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualDokumen2 halaman1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualvictoverBelum ada peringkat

- Drivemaster 2speed Installation InstructionsDokumen17 halamanDrivemaster 2speed Installation InstructionsAngel DlsgBelum ada peringkat

- MODEL: T100-V: Installation and Operating .. ManualDokumen38 halamanMODEL: T100-V: Installation and Operating .. ManualLeonid KolesnikovBelum ada peringkat

- 4216 Mud Balance ManualDokumen2 halaman4216 Mud Balance ManualAli AliievBelum ada peringkat

- 3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingDokumen4 halaman3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingPhamLeDanBelum ada peringkat

- Sd-Egrd-6.7c-07 (6.7l 07-09' Cummins Egr Delete)Dokumen12 halamanSd-Egrd-6.7c-07 (6.7l 07-09' Cummins Egr Delete)Angel FraustoBelum ada peringkat

- Catalogo Lovejoy Serie JawDokumen26 halamanCatalogo Lovejoy Serie JawJuan Pablo CirizaBelum ada peringkat

- Freightliner AllianceDokumen20 halamanFreightliner AllianceDIEGO FRAUSTOBelum ada peringkat

- 65590-gd Cutsheet Template gd-600 2015 LRDokumen2 halaman65590-gd Cutsheet Template gd-600 2015 LRjys_yanqui100% (1)

- Kenworth T800 Brochure.Dokumen28 halamanKenworth T800 Brochure.scribdadiddlyBelum ada peringkat

- 30-100 High-Torque Casing Tong: ApplicationsDokumen1 halaman30-100 High-Torque Casing Tong: ApplicationsLuis Arreaza BelisarioBelum ada peringkat

- Lincoln p203 PumpDokumen4 halamanLincoln p203 PumphalimBelum ada peringkat

- AXSM0034-In Axle Speed SensorDokumen34 halamanAXSM0034-In Axle Speed Sensorwadalla100100% (1)

- Illustrated Parts List: RTO-14908LL November 2008Dokumen34 halamanIllustrated Parts List: RTO-14908LL November 2008Agustin FigueroaBelum ada peringkat

- Procedimiento Parker para Prueba de CilindrosDokumen7 halamanProcedimiento Parker para Prueba de Cilindrosspider3486Belum ada peringkat

- GA15 Engine DisassemblyDokumen79 halamanGA15 Engine DisassemblyJohn CoxxBelum ada peringkat

- BHDC - 37 WQDokumen12 halamanBHDC - 37 WQAli HusseinBelum ada peringkat

- Dragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198Dokumen16 halamanDragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198jesus alfonso fragozo calderonBelum ada peringkat

- Arrow CDokumen118 halamanArrow CjulioramcaBelum ada peringkat

- 4.XJ250 Convenio Tecnico de FlushbyDokumen11 halaman4.XJ250 Convenio Tecnico de FlushbyGabriel Alejandro JoaquinBelum ada peringkat

- 200TG Installation and Maintenance InstructionsDokumen2 halaman200TG Installation and Maintenance InstructionsMiguel MedinaBelum ada peringkat

- g312 ManualDokumen14 halamang312 Manualflasher_for_nokiaBelum ada peringkat

- Lincoln - Lubrication Equipment PDFDokumen92 halamanLincoln - Lubrication Equipment PDFesham2Belum ada peringkat

- Tiger & FrogDokumen1 halamanTiger & Frogesham2Belum ada peringkat

- Rovsco - Xtreme LubricatorDokumen1 halamanRovsco - Xtreme Lubricatoresham2Belum ada peringkat

- 3 MechanismsDokumen35 halaman3 Mechanismsesham2100% (1)

- CivaCon - Cane Probe Installation ManualDokumen6 halamanCivaCon - Cane Probe Installation Manualesham2Belum ada peringkat

- CivaCon - Cane ProbeDokumen1 halamanCivaCon - Cane Probeesham2Belum ada peringkat

- CivaCon - API Tank Truck AdaptorDokumen2 halamanCivaCon - API Tank Truck Adaptoresham2Belum ada peringkat

- CivaCon - Air Interlock ValvesDokumen2 halamanCivaCon - Air Interlock Valvesesham2Belum ada peringkat

- Coastal F: Ansi B16.5 Class 150 Welding Neck FlangesDokumen1 halamanCoastal F: Ansi B16.5 Class 150 Welding Neck FlangesHendri SinagaBelum ada peringkat

- CivaCon - API Tank Truck AdaptorDokumen2 halamanCivaCon - API Tank Truck Adaptoresham2Belum ada peringkat

- CivaCon - Aluminium Manhole Covers PDFDokumen1 halamanCivaCon - Aluminium Manhole Covers PDFesham2Belum ada peringkat

- CivaCon - API Dust CapDokumen2 halamanCivaCon - API Dust Capesham2Belum ada peringkat

- CivaCon - API Lock AssemblyDokumen2 halamanCivaCon - API Lock Assemblyesham2Belum ada peringkat

- CivaCon - Cane Probe Installation ManualDokumen6 halamanCivaCon - Cane Probe Installation Manualesham2Belum ada peringkat

- CivaCon - Aluminium Manhole Covers PDFDokumen1 halamanCivaCon - Aluminium Manhole Covers PDFesham2Belum ada peringkat

- CivaCon - Petroleum Manhole CoversDokumen1 halamanCivaCon - Petroleum Manhole Coversesham2Belum ada peringkat

- CivaCon - API Bottom Loading AdaptorDokumen6 halamanCivaCon - API Bottom Loading Adaptoresham2Belum ada peringkat

- Jerusalem in The Qur'anDokumen142 halamanJerusalem in The Qur'anshakebfaruqui78% (9)

- Creating Motion in SolidWorks-Motion DriversDokumen58 halamanCreating Motion in SolidWorks-Motion Driversesham2Belum ada peringkat

- Jerusalem in The Qur'anDokumen142 halamanJerusalem in The Qur'anshakebfaruqui78% (9)

- The Welding of Aluminium and Its AlloysDokumen3 halamanThe Welding of Aluminium and Its Alloysesham2Belum ada peringkat

- Stream RSZDokumen8 halamanStream RSZsbahrimBelum ada peringkat

- Dajjal Book EngDokumen146 halamanDajjal Book EngMuhibBelum ada peringkat

- DTB ManualDokumen190 halamanDTB ManualElvis VásquezBelum ada peringkat

- LPG VaporizersDokumen8 halamanLPG Vaporizerssizweh100% (1)

- Maintenance Instructions SystemDokumen29 halamanMaintenance Instructions SystemSandra Yanira Vivas DiázBelum ada peringkat

- Gas Density MeasurementDokumen31 halamanGas Density MeasurementJamesh BabuBelum ada peringkat

- Instructions For Use Installation and Servicing: Hideaway 50Dokumen24 halamanInstructions For Use Installation and Servicing: Hideaway 50tedboaterBelum ada peringkat

- Float Level Isolation Valve: DN200 & DN300Dokumen2 halamanFloat Level Isolation Valve: DN200 & DN300Fer VFBelum ada peringkat

- HCi Product Listing 2022Dokumen38 halamanHCi Product Listing 2022Karl MarxitoBelum ada peringkat

- Rafal Living by Kempinski Tower - ATC1Dokumen31 halamanRafal Living by Kempinski Tower - ATC1Marina StankovićBelum ada peringkat

- 04 SAMSS 001 Gate ValveDokumen10 halaman04 SAMSS 001 Gate Valveshganesh81gmailcom100% (1)

- 7-1. Maintenance StandardDokumen36 halaman7-1. Maintenance StandardYamilaBelum ada peringkat

- KCG 2006 - 7Dokumen48 halamanKCG 2006 - 7bkchoi5690Belum ada peringkat

- 3 Port Solenoid Valve: Series S070Dokumen24 halaman3 Port Solenoid Valve: Series S070kemboenoerBelum ada peringkat

- SSP 379 d2 PDFDokumen19 halamanSSP 379 d2 PDFAlfredo RodriguezBelum ada peringkat

- CHA 550, 660, 1100 WITHOUT CABIN Operation: B 05310 - 1 GB 0897 / MAH 1Dokumen11 halamanCHA 550, 660, 1100 WITHOUT CABIN Operation: B 05310 - 1 GB 0897 / MAH 1João GuardadoBelum ada peringkat

- Copland Outdoor UnitsDokumen18 halamanCopland Outdoor UnitsatiqBelum ada peringkat

- OPW NozzlesDokumen3 halamanOPW NozzlesjayendrapatilBelum ada peringkat

- Janus Probe st-500 ManualDokumen30 halamanJanus Probe st-500 ManualSiddharthTrivediBelum ada peringkat

- Mechanical PlugsDokumen6 halamanMechanical Plugskategord0% (1)

- SECTION 23 52 39 Fire Tube BoilersDokumen38 halamanSECTION 23 52 39 Fire Tube BoilersresalBelum ada peringkat

- IDS1 ServiceMAn DeutagDokumen432 halamanIDS1 ServiceMAn DeutagMohamed BadranBelum ada peringkat

- Universal, Independent Dual System Hydraulic Test Stand: 920 SeriesDokumen8 halamanUniversal, Independent Dual System Hydraulic Test Stand: 920 SeriesSajad KarimiBelum ada peringkat

- How To Select Valve MaterialsDokumen12 halamanHow To Select Valve MaterialsrizalatanBelum ada peringkat

- T83890en HOJA TÉCNICA EXPERT PLUS 3731-3Dokumen8 halamanT83890en HOJA TÉCNICA EXPERT PLUS 3731-3Fredi F FBelum ada peringkat

- Catalog Engineering - Liquidflo PDFDokumen58 halamanCatalog Engineering - Liquidflo PDFTARCÍSIO FERNANDES GOMESBelum ada peringkat

- Test Pack SampleDokumen12 halamanTest Pack SampleGomathyselviBelum ada peringkat

- MB Lal CommitteeDokumen23 halamanMB Lal CommitteechemsaneBelum ada peringkat

- Exrun: Valve Actuators With Continuous ControlDokumen4 halamanExrun: Valve Actuators With Continuous ControlAqeelah RashidiBelum ada peringkat

- Manual Dustless Blasting - Db800-Instruction-manualDokumen32 halamanManual Dustless Blasting - Db800-Instruction-manualJose Lin MontenegroBelum ada peringkat

- NGS Ipg 5000Dokumen2 halamanNGS Ipg 5000Hamatouty TottiBelum ada peringkat

- CC12-4.90/1.5/0.5 12MW Double-Extraction Condensing Turbine Regulating System Instruction ManualDokumen14 halamanCC12-4.90/1.5/0.5 12MW Double-Extraction Condensing Turbine Regulating System Instruction ManualMUBASHIR ASLAMBelum ada peringkat