Faecal Sludge Characterization Final Report 250215 PDF

Diunggah oleh

irpansejatiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Faecal Sludge Characterization Final Report 250215 PDF

Diunggah oleh

irpansejatiHak Cipta:

Format Tersedia

FAECAL SLUDGE CHARACTERIZATION IN INDONESIA

TA-7739 INO: SUPPORTING WATER OPERATORS' PARTNERSHIPS

FINAL REPORT

February 2014

Prepared by:

Freya Mills

With Acknowledgements to

Ministry of Public Works, Government of Indonesia

Wastewater Authorities in Bogor, Jakarta, Makassar and Surakarta.

Javier Coloma Brotons, Urban Development Specialist (Water Supply and Sanitation) ADB

Leo Silvando, Sanitation Consultant ADB

Budi Darmawan, Faecal Sludge Management Consultant IUWASH/WSP

Emasesa (EmpresaMetropolitana de Abastecimiento y Saneamiento de Aguas de Sevilla, Spain)

IUWASH (Indonesia Urban Water, Sanitation and Hygiene Project)

WSP (Water and Sanitation Program) World Bank, Indonesia

Faecal Sludge Characterization Indonesia

EXECUTIVE SUMMARY

As part of ADBs Supporting Water Operators Partnership in Asia this input develops a dataset and

approach to analyzing faecal sludge to improve management of waste from on-site sanitation

systems. The majority of Indonesian households use on on-site systems for wastewater disposal,

however the safe management of faecal sludge is limited with low rates of pit emptying and poor

operation of sludge treatment plants. Adding to the knowledge of faecal sludge characteristics will

lead to better design and operation of treatment plants and opportunities for sludge reuse.

In the same four cities partnering with Spanish Water Authority Emasesa, 19 samples were taken

from sludge truck discharge to understand inflow for design of sludge treatment plants. In Jakarta

and Bogor the sludge treatment plants were operating sufficiently to also sample the treatment

processes and dried sludge, however in Makassar and Solo the treatment is used but not operating

as designed so not suitable to analyze. Samples were analyzed by local laboratories and compared

with analysis by the health and environment laboratories of the University Indonesia in Jakarta.

Possibly due to limited experience in wastewater analysis and almost no experience with sludge, the

results from the laboratories were extremely varied with the difference between duplicates outside

an acceptable range. Whilst faecal sludge characteristics are varied, there was no clear trend if one

laboratory was more accurate. However the results typically fell within the range of previous

International studies and are a guide to typical characteristics in Indonesia, although improved

laboratory techniques and equipment could lead to a more accurate and narrower range.

The survey of households emptied found on-site systems were typically single leach pits,

approximately 2.5m3 and on average operated for 6 years before emptying. The results shown in

Table 1 show most parameters are on the low end of International findings and can be classified as

low strength septage (Heinss 1998). In comparison with current design guidelines for Indonesian

Sludge Treatment Plants, these values are 2-6 times smaller, which along with assumption of much

higher emptying rate than occurs, could be the reason for oversized treatment plants. Despite the 6

years storage, due to the poor pre-treatment occurring in single leach pits, sludge is not fully

stabilized, therefore anaerobic treatment or digesters is suitable prior to dewatering.

TABLE 1 SUMMARY OF FAECAL SLUDGE PARAMETERS

Parameter

Total Solids (TS) mg/L

Total Suspended Solids (TSS) mg/L

Volatile Solids (VS) %TS

COD mg/L

BOD5 mg/L

pH

NH3-N mg/L

Helminth egg total No./L

Existing International

Data

5,000-71,000

5,000-52,000

45-83%

1,200-83,000

600-2,600

6-7.7

150-1230

16-91/gTS, 16-50/gFS

N

17

15

9

24

23

29

16

6

Survey

Accepted Range

3,820-43,894

274-11,383

56-84%

549-17,875

215-3,500

6.3-8.0

96-398

0-200

Mean

15,052

2,664

73%

3,284

1,009

7.4

200

37/gFS

The results from the Jakarta and Bogor treatment plants found both had effective removal

compared with influent sludge quality however the discharge quality did not meet standards and

operation could be improved. The dried sludge in Jakarta met International reuse standards however

the Bogor sample was highly contaminated.

Whilst these results provide a useful indication of sludge characteristics in Indonesia, the analysis

highlighted the need for provision of training and more automated equipment for the laboratories.

ii

Faecal Sludge Characterization Indonesia

Contents

Executive summary ................................................................................................................................. ii

1 Introduction .................................................................................................................................... 1

1.1

Purpose of Research ............................................................................................................... 1

1.2

Scope of Work ......................................................................................................................... 1

1.3

Background Faecal Sludge Characteristics ........................................................................... 2

1.4

Faecal Sludge Physical and Chemical Characteristics ............................................................. 3

1.4.1

Solids ............................................................................................................................... 3

1.4.2

Biochemical and Chemical Oxygen Demand................................................................... 4

1.4.3

Nutrients & Ph................................................................................................................. 4

1.4.4

Pathogens........................................................................................................................ 4

2 Method ........................................................................................................................................... 5

2.1

Analysis framework ................................................................................................................. 5

2.2

Method of Sampling and Analysis........................................................................................... 5

2.2.1

Pre-sampling preparation ............................................................................................... 5

2.2.2

Sampling .......................................................................................................................... 5

2.2.3

Transport ......................................................................................................................... 6

2.2.4

Analysis ........................................................................................................................... 6

3 City Sampling................................................................................................................................... 7

3.1

Bogor ....................................................................................................................................... 7

3.1.1

Sludge Emptying Analysis................................................................................................ 7

3.1.2

Analysis of Sludge Treatment Plant and Dried Sludge .................................................... 8

3.2

Jakarta ..................................................................................................................................... 9

3.2.1

Sludge Emptying Analysis................................................................................................ 9

3.2.2

Analysis of Sludge Treatment Plant and Dried Sludge .................................................. 10

3.3

Solo........................................................................................................................................ 11

3.3.1

Sludge Emptying Analysis.............................................................................................. 11

3.3.2

Analysis of Sludge Treatment Plant and Dried Sludge .................................................. 12

3.4

Makassar ............................................................................................................................... 13

3.4.1

Sludge Emptying Analysis.............................................................................................. 13

3.4.2

Analysis of Sludge Treatment Plant and Dried Sludge .................................................. 14

4 Results ........................................................................................................................................... 14

4.1

Quality Assurance ................................................................................................................. 14

4.2

Faecal sludge characterization .............................................................................................. 15

4.2.1

Solids Parameters: TS, TSS, VS, SVI ............................................................................... 16

4.2.2

Biological Parameters: BOD, COD ................................................................................. 17

4.2.3

Nutrient & Pathogen Parameters ................................................................................. 18

4.2.4

Summary - Strength ...................................................................................................... 18

4.3

Treatment & Dry Sludge ....................................................................................................... 19

5 Conclusion ..................................................................................................................................... 22

6 Reference ...................................................................................................................................... 23

Appendix A Guidelines: Fecal Sludge Characterization Indonesia ........ Error! Bookmark not defined.

Steps ........................................................................................................ Error! Bookmark not defined.

Steps ........................................................................................................ Error! Bookmark not defined.

Pit Emptying Survey Form / Survei di Tangki Septik dan Sedot ............... Error! Bookmark not defined.

Appendix B Results............................................................................................................................. 24

Appendix C Summary of Sludge Treatment Plant Operations ........................................................... 31

C.1 Bogor ........................................................................................................................................... 31

C.2 Jakarta ......................................................................................................................................... 33

C.3 Surakarta ..................................................................................................................................... 34

C.4 Makassar ..................................................................................................................................... 36

iii

Faecal Sludge Characterization Indonesia

TABLE OF TABLES

Table 1 Summary of Faecal Sludge Parameters ................................................................................... ii

Table 2 Typical Urban Sanitation Characteristics Indonesia ................................................................ 3

Table 3 Analysis of Duplicate Samples Accuracy ................................................................................ 14

Table 4 - Comparison with international data ...................................................................................... 16

Table 5 Solid Parameters Analysis Results ......................................................................................... 17

Table 6 Biological Parameter Results ................................................................................................. 18

Table 7 Nutrient and Pathogen Parameters Results .......................................................................... 18

Table 8 Comparison of Sludge Strength............................................................................................. 19

Table 9 Comparison With Influent Standard Guidelie ....................................................................... 19

Table 10 Efficiency of Sludge Treatment Plants................................................................................. 19

Table 11 Effluent Discharge Standards .............................................................................................. 20

Table 12 Dried Sludge Parameters ..................................................................................................... 22

Table 13 Summary of Faecal Sludge Parameters ............................................................................... 22

Table 14 Survey Results Bogor and Jakarta ....................................................................................... 29

Table 15 Survey Results Makassar and Surakarta.............................................................................. 30

Table 16 Summary of Design and Operation Issues IPLT Bogor ........................................................ 32

Table 17 Pulo Gebang New Treatment Plant ..................................................................................... 33

Table 18 Pulo Gebang Old Treatment Plant....................................................................................... 34

Table 19 Design and Operation Issues Makassar............................................................................... 36

TABLE OF FIGURES

Figure 1 Faecal Sludge Service Chain ................................................................................................... 1

Figure 2 Map of Cities Sampled ........................................................................................................... 2

Figure 3 - Summary of operation issues & sample locations (B1-B10) .................................................. 9

Figure 4 - Inflow to Jakarta Sludge Treatment Plants ......................................................................... 10

Figure 5 IPLT East New System layout and Sample Locations ........................................................... 11

Figure 6 IPLT East New System layout and Sample Locations ........................................................... 12

Figure 7 IPLT Putri Cempo Surakarta ................................................................................................. 13

Figure 8 Treatment Performance of Bogor and Jakarta IPLT ............................................................. 21

Figure 9 - Design Drawings of IPLT Tegal Gundil ................................................................................... 31

Figure 10 - IPLT Pulo Gebang Old System Layout ................................................................................. 34

Figure 11 IPLT Putri Cempo Surakarta ............................................................................................... 35

Figure 12 Putri Cempo: Inlet chamber, Sludge Drying Beds and Anaerobic Pond 2.......................... 36

Figure 13 Makassar Sludge Treatment Plant Design Drawing ........................................................... 38

ABBREVIATIONS

ADB

Asian Development Bank

FSM Faecal Sludge Management

IPAL Instalasi Pengolahan Air Limbah (Wastewater treatment plant)

IPLT

Instalasi Pengolahan Lumpur Tinja (Sludge treatment plant)

IUWASH Indonesian Urban Water, Sanitation, Hygiene (USAID)

PDAM Perusahaan Daerah Air Minum (Regional Drinking Water Enterprise)

PD-PAL Perusahaan Daerah Pengelolaan Air Limbah (City wastewater management company)

PU

Pekerjaan Umum (Public Works)

UPTD Unit Pengelola Teknis Daerah (technical services unit within a local government department)

WSP Water and Sanitation Program (World Bank)

iv

Faecal Sludge Characterization Indonesia

1 INTRODUCTION

1.1 PURPOSE OF RESEARCH

As part of ADBs technical assistance Supporting Water Operators Partnership in Asia (WOPs

program) this input aims to develop a dataset and approach to analyzing faecal sludge (FS) to

improve management of waste from on-site sanitation systems. Indonesia has one of the lowest

rates of urban sewerage coverage in Asia, with only 2% of the urban population connected to a

networked sewerage system and 83% of urban residents using on-site sanitation systems.1 As part of

the Acceleration of Sanitation Development in Human Settlements (PPSP) Program, the widespread

use of on-site sanitation systems in urban areas will continue. Foreseeing this demand, the Ministry

of Public Works has reviewed the performance of 150 existing sludge treatment plants (IPLT) and

found that less than 10% are operating. In 2013 approximately $20 million will be invested for their

upgrade and repair. Many septage treatment plants appear to be underutilized or oversized for local

conditions, often due to limited data on which to base designs and a low inflow due to on-demand

emptying. This work hopes to improve the knowledge of faecal sludge characteristics by developing

a data-set from four Indonesian cities and a methodology that can be adopted in other cities.

1.2 SCOPE OF WORK

Faecal sludge management is not limited to just sludge treatment but involves the entire service

chain from accumulation in on-site systems to reuse. The data required to design and manage each

part of this service chain varies due to the different objectives and requirements. This analysis

focuses on the treatment and reuse/disposal components which is a key focus of the Wastewater

Operators participating in the twinning program. Local data already exists for the containment and

demand for emptying2 and the transport in three of the four assessed cities is undertaken by private

operators who lack emptying records to analyse.

FIGURE 1 FAECAL SLUDGE SERVICE CHAIN3

The scope of works includes:

Develop a sampling plan and analysis framework that can be adopted by relevant agencies in

other cities and for ongoing monitoring;

Faecal sludge characterization of influence to improve treatment design and operation.

Analysis of various stages in existing treatment to understand treatment performance.

FS characterization of dried sludge to assess its potential reuse benefit and health risks;

The sampling will occur in four cities already participating in ADB SWOP twinning program: Bogor,

Jakarta, Makassar and Surakarta.

BPS (2013) Indonesia Demographic and Health Survey 2012. BPS: Jakarta.

WSP (2013) Sludge Accumulation and Pit Emptying Study. WSP: Jakarta.

3

WSP (2014) The Missing Link in Sanitation Service Delivery: A review of Fecal Sludge Management in 12

Cities. WSP: Washington DC.

2

Faecal Sludge Characterization Indonesia

MAKASSAR

BOGOR

SURAKARTA

FIGURE 2 MAP OF CITIES SAMPLED

1.3 BACKGROUND FAECAL SLUDGE CHARACTERISTICS

Although there is a much data on wastewater characteristics, the organic matter, total solids,

ammonium and helminth egg concentrations in faecal sludge are typically higher by a factor of10100 compared to wastewater sludge.4 The availability of faecal sludge analysis data is limited and

what exists internationally highlights the variability between and within countries.

To design sludge treatment plants, including selection of treatment method and sizing, requires

accurate data on faecal sludge characteristics. Systems in Indonesia are sometimes operating well

below the design load and due to the characteristics of the sludge, such as high solids content or

stabilization; the treatment technology may not be the most suited. Without understanding the

characteristics specific to each local conditions, treatment plants can be significantly over or undersized. An example of this is a sludge treatment plant built in Burkina Faso for 125m 3/d and TS load of

21,000mg/L, with recent analysis of sludge finding TS strength is half that, therefore the plant is

double the necessary size.5

Some data has been collected in Indonesia which this study will compile and build on to determine a

typical set of characteristics relevant to the local conditions. Previous international studies have

found the characteristics are influenced by local variables such as type of on-site system, toilet use

behaviour, and groundwater and soil conditions. Some typical characteristics of on-site systems in as

assessed in other recent studies in Indonesia6:

Montangero, A. and Strauss, M. (2002). Faecal Sludge Treatment. Lecture Notes, IHE Delft, February.

SANDEC.http://www.sandec.ch/files/IHE_Lecture_notes_FS.pdf

5

Bassan, M., Mbgur, M., Tchonda, T., Zabsonre, F., Strande, L. (2013b). Integrated faecal sludge

management scheme

for the cities of Burkina Faso. Journal of Water, Sanitation and Hygiene for Development 3(2), p.216221.

6

Mills (2013), Sludge Accumulation and Pity Emptying in Indonesia, WEDC 37 Conference, Hanoi 2014.

Faecal Sludge Characterization Indonesia

TABLE 2 TYPICAL URBAN SANITATION CHARACTERISTICS INDONESIA

Type of toilet

Squat toilet, goose neck/water sealed, manually flushed with bucket

Solids added

No, water cleansing is typically practiced and rubbish not commonly added.

Greywater

Typically not added to on-site system and discharges directly to drain

Type of On-site

system

Most are a single pit with sealed walls and leaking base. Some twin septic tanks,

typically with second chamber unsealed and about 20% of systems have

overflow to drain/river.

Sludge

Accumulation

Average sludge accumulation 25L/p/year, higher in first years after emptying

and lower for well sealed systems or ones with overflow to drain.

Emptying

Low frequency of emptying, most systems never emptied and an average of 16

years before first requiring emptying. Emptying by government or private

vacuum truck, occasionally need to add water and mix contents.

Other influencing Groundwater level is often high and can infiltrate tanks. Sandy soil with high

factors

permeability.

1.4 FAECAL SLUDGE PHYSICAL AND CHEMICAL CHARACTERISTICS

The following section summarizes the main parameters used in designing faecal sludge treatment

and assessing quality of sludge and effluent produced. A main source of information from Eawag

Faecal Sludge Management Book, 2014.

1.4.1 SOLIDS

Measuring the solids concentration is used to understand the strength of sludge and useful in

determining the loading on the sludge treatment plant, type and size of treatment required and

efficiency of treatment.

The Total Solids (TS) are the sum of suspended (TSS) and dissolved solids (TDS) and include

organic and inorganic matter. They are determined by the material remaining after 24 hours

drying in an oven at 103-105C, Indonesian standard SNI 06-6989.26-2005.

Total Suspended Solids (TSS) are the solids not able to pass through a filter, typically 0.45 m

filter is used wastewater analysis. The solids that pass through are called dissolved solids. If the

sludge is too dense, total solids is more commonly reported. Indonesian standard SNI 06-6989.32004

Total Volatile Solids (TVS or VS) are the fraction that are ignited and burned off at 500C. The

ratio of VS to TS indicates the relative amount of organic material and biochemical stability and

used to assess the need for digestion. Indonesian standard SNI 06-6989.26-2005.

Sludge volume index (SVI in mL/g) is an empirical method to determine the settling ability of

sludge based on the volume of settled sludge in an Imhoff cone after 30-60mins (mL/L) divided

by the total suspended solids of the sample (g/L). Based on experiences in the design of settlingthickening tanks for wastewater treatment plants, wastewater sludge with a SVI of less than 100

(mL/g SS) achieves good solids-liquid separation in settling-thickening tanks (lower value better

sedimentation/thickening behaviour).7

Eawag 2014, Faecal Sludge Management Book, Chapter 6.

Faecal Sludge Characterization Indonesia

1.4.2 BIOCHEMICAL AND CHEMICAL OXYGEN DEMAND

As well as Volatile Solids indicating stabilisation, the oxygen demand of faecal sludge is an indicator

for the amount of degradable organic matter and an important parameter to assess operation and

discharge quality.

BOD measures the strength of wastewater by measuring the oxygen consumption of

microorganisms to digest organic matter under controlled time (5 days) and temperature (20C).

BOD5 is typically much higher in faecal sludge than wastewater. Oxygen demand is affected by

nitrifying organisms, which can increase the reported BOD and is also affected by delays in

analysing the sample after collection. Winkler methods used since no DO probe following SNI6989.72-2009.

COD is a measure of the oxygen consumption by both organic and inorganic matter, and

represents the organic matter that can be oxidised using a strong chemical agent (potassium

dichromate). Since the test if much quicker often the results are considered more accurate than

BOD and the ratio of COD:BOD is often used to assess accuracy of the two measurements, with

COD always greater than BOD. COD is measured in Indonesia using the reflux method as per

APHA 5220.C-2005.

1.4.3 NUTRIENTS & PH

High nutrient concentrations of faecal sludge can be both a benefit when reused in agriculture as an

alternative to fertilizers but also pose a contamination risk to receiving waterway and soils.

Total nitrogen concentrations in faecal sludge are much higher than in wastewater (10-100

times) and typically exists as Ammonia/Ammonium (NH3/NH4), nitrate/nitrite (NO3-N/NO2-N)

and organic nitrogen. Ammonia (NH3) and ammonium (NH4) exist in equilibrium depending on

pH and mostly comes from urine. Ammonia is tested based on SNI 06-6989.30-2005, using HACH

electrode method or colorimetric. The laboratories were unable to test Total Nitrogen for liquid

samples.

Phosphorus concentration in faecal sludge is also much higher than wastewater (2-50 times) and

is present as phosphate, orthophosphate or organically bound phosphate. Phosphate is

determined colorimetrically as reactive phosphorus or if hydrolysis/digestion performed total

phosphorus can be measured. University Indonesia was only able to test for PO4 SNI 06-6989.312005.

pH is influenced by the contents of on-site systems with chemicals, industrial or commercial

inflows possibly causing it to vary outside the standard range of 6-9 which could upset biological

processes.

1.4.4 PATHOGENS

Faecal sludge contains large amounts of pathogenic microorganisms which pose a danger to

operators working with sludge and potential reuse. Commonly measured pathogens to assess health

risk are:

Total Coliforms are a group of bacteria used to indicate the faecal contamination of water and

give indication of pathogen reduction in the treatment process. Tested in Indonesia using the

Multiple Tubes Fermentation Method following International standard APHA 9221-2005.

Helminth eggs are used as an indicator of treatment effectiveness due to their prevalence in

low-middle income countries, resist inactivation and a health risk to those exposed. Types

4

Faecal Sludge Characterization Indonesia

monitored in Indonesia include Ascaris lumbricoides eggs (roundworm) which make up the

majority of Helminth eggs in developing countries, Hookworm larvae/egg, Trichuris trichura eggs

(whipworm). The Department of Parasitology University Indonesia is the only known laboratory

with experience testing for Helminth eggs, using method of direct examination of the egg/larvae

recovered in a sucrose floatation from 5 gram sludge sample.

2 METHOD

2.1 ANALYSIS FRAMEWORK

The sampling framework focuses on the three main uses for faecal sludge data:

Design treatment plant: based on the characteristics of influent sludge from vacuum trucks.

Propose 5 samples based on the limited number of trucks discharging per day in most cities

(often 1-3). Requires co-ordination with authority responsible for emptying to ensure trucks are

discharging on the day and time required for sampling and may need delaying some orders or

early delivery depending on laboratory opening hours.

Operation of treatment and quality of discharge: Sampling various stages of treatment to

understand the performance of each system. Only suitable if the treatment is in a sufficient

operational state, since bypassing phases of treatment or clogging with vegetation resulting in

substantially different operation to design.

Reuse of Sludge: The nutrient quality of faecal sludge make it a potentially valuable natural

fertilizer, however the remaining health risk needs to be considered. Most sludge treatment

facilities are not operating sufficiently to produce regular well treated sludge and currently use

of sludge is not common. In systems where dry sludge is produced can be tested, however it is

difficult to assess how long sludge is stored to dry without regular operation standards.

2.2 METHOD OF SAMPLING AND ANALYSIS

2.2.1 PRE-SAMPLING PREPARATION

Preliminary site visit to assess treatment and determine the number of samples required;

Visit local laboratory to confirm opening hours/day, parameters that can be assessed, sample

size required and collect sample bottles for faecal coliform;

Prepare bottles for analysis: Sample size varied from 10 grams for helminth eggs, 0.5L (University

Indonesia) to 1.5L at some local laboratories. Clean bottles with pure water (not chlorinated)

and allow to dry, bottles with large opening are best since samples contain solids. Label each

bottle with sticker and waterproof pen (ie. J01, J02 for Jakarta), using the same label for

duplicate bottles;

Prepare safety equipment glasses, face mask, gloves, large bucket for collecting sample, bucket

on string or bottle attached to pole for deep tanks, water for cleaning;

Prepare cold storage for transporting (ie. cooler bag and ice packs);

Brief sludge truck operators on survey questions, request that only one pit is collected per truck

and co-ordinate time of emptying.

2.2.2 SAMPLING

Samples were collected from the mid-stream of truck discharge. Compared with sampling directly

from the on-site system this provides a more accurate analysis of what is actually entering the

sludge treatment plant, with a mix of solids, liquids and any added water or collected sand during

5

Faecal Sludge Characterization Indonesia

emptying. The sample is well mixed on the drive to the treatment plant, which typically takes 20-40

minutes, however some trucks discharged sludge collected the previous evening (this was not

sampled). For comparative analysis, only household discharge was sampled since this is the

predominate discharge to the treatment plants assessed, therefore sludge from commercial facilities

and public toilets were avoided, as were samples from multiple households which could not be

compared with survey. Sampling the mid-stream of the discharge was difficult due to the pressure of

flow and required safety equipment to protect against splashing and a large bucket. However often

the truck emptiers collected the sample and refused safety equipment since they typically do not

ware any protection during removal or disposal (bare face, hand, and feet).

Samples from various stages of the treatment were sampled with care given to take a submerged

sample (not top floating layer), from a flowing (not stagnant) point in the treatment and trying not

to create turbulence or scrape any solids from bottom or sides. Single grab samples were collected

from each operating system. In Jakarta the dry sludge sample was collected at the end of the drying

but not from the stored sludge are since no indication of how long they had been stored or whether

from the old treatment plant. In Bogor the sludge was estimated to be 6 months since emptying

from the sludge drying bed and a mixed sampled from lower and upper layers taken.

2.2.3 TRANSPORT

Samples were stored in a cooler container with ice packs during sampling (up to one hour) and

transport to the laboratories. Transport to the local laboratory was less than 30 minutes and to

Jakarta up to 4 hours (including flights). Samples should be kept below 4C to reduce microbial

activity and stop the sample degrading, however with ambient temperatures at over 30C, it is

unlikely that they cooled to this temperature.

2.2.4 ANALYSIS

Duplicate samples were tested at local laboratory and the University Indonesia laboratories in

Jakarta. Sampling typically occurred over two days and depending on the number of trucks

discharging, 2-3 samples were taken to the local laboratory on the first day. The second day 2-3

trucks sampled and the treatment system and dry sludge, with all samples having duplicate tests at

the local laboratory and University Indonesia.

Local Laboratory Each city health or environmental department has the ability to measure a

range of basic parameters and has the benefit of reduced transportation time. However,

experience with wastewater analysis is often minimal and typically no previous sludge analysis

and evidence of unrealistic results (Surakarta BOD>COD). Local laboratories used included

Seameo Biotrop Services Laboratory Bogor, Makassar Ministry of Health Laboratory, University

NS Faculty of Mathematics and Natural Science Laboratory Solo and the University Gajah Mada

Centre for Environmental Health Engineering and Communicable Disease Control Laboratory

(BTKL) at for Solo duplicate testing.

University Indonesia Environmental Engineering Department in Depok near Jakarta had

previous experience testing sludge samples and is able to most required parameters including

Volatile Solids and Sludge Volume Index. However limited in Total Nitrogen and Phosphorus

analysis.

Faecal Sludge Characterization Indonesia

University Indonesia Medicine Faculty, Parasitological Department in Jakarta is the only known

laboratory with experience testing helminth eggs.

Limitation of sampling includes:

Single grab sample of treatment only portraying the condition at the time of sampling;

Effect of any operational changes such as inflow of river water into the Bogor treatment plant to

increase flow in the day prior to sampling.

Uncertain duration of Dry sample mixed but from the driest bed only.

Limited experience of local laboratories in wastewater analysis and no experience in sludge

analysis.

Limited equipment at local laboratories therefore relying on less accurate manual techniques for

analysis. (ie. The PDAM wastewater laboratory in Solo uses manual methods for BOD and COD

analysis and were limited to concentrations <400 and <1500mg/L respectively)

3 CITY SAMPLING

3.1 BOGOR

Bogor is located in West Java, 60km south of Jakarta with a population of 1.1 million, it is an inland

hilly area with high average annual rainfall of 1700mm. The Unit Pelaksana Teknis Dinas (UPTD) is

responsible for the management of the wastewater treatment plant, sewer, sludge treatment plant

(IPLT in Indonesian) and sludge emptying. There is a current proposal to change some of these

responsibilities to the local water authority but not yet confirmed. Both private and government

sludge emptying trucks exist, however only the government trucks discharge at the IPLT Tegal

Gundil. IUWASH is currently working with UPT-Bogor to develop a regular desludging trial in one

housing estate. The Seameo Biotrop8 laboratory was recommended by UPTD and used for their

wastewater analysis, however the IPLT had never been analysed.

3.1.1 SLUDGE EMPTYING ANALYSIS

UPTD have four 4m3 trucks and 2 small (0.45m3) motanks which are not commonly used since there

is no demand from dense slum areas. Service is provided on-call basis, with customers telephoning

the UPTD office to book emptying. Approximately 4 private operators also exist, discussions in 2013

indicated demand is lower than UPT with only 2-4 houses/week and typically disposed to river or to

neighbouring city Depoks treatment plant9.

Previous studies by WSP and IUWASH10 found the majority of households in Bogor had never

emptied their on-site systems (84% IUWASH). UPT estimates that approximately 3 households are

emptied per day with government trucks, with large fluctuations, as shown in their monthly income

varying from estimated 206 households emptied in March 2014 to 75 households in July 2014.

Seameo Biotrop, the Southeast Asian Regional Centre for Tropical Biology, services.lab@biotrop.org, (62)

2518357175. Able to analyze all parameters except VS, SVI, Helminth but not the dried sludge sample.

9

WSP 2013 Sludge Accumulation and Pit Empting in Indonesia

10

IUWASH 2014 Results Survey Sludge Emptying Bogor

Faecal Sludge Characterization Indonesia

Income/month (Rp ,000)

Monthly Sludge Emptying Income

16,000

14,000

12,000

10,000

8,000

6,000

4,000

2,000

-

2012

2013

2014

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

FIG 5. MONTHLY INCOME FROM SLUDGE EMPTYING

The two days of sampling (30-31 October 2014) had low demand for emptying and orders were

requested for emptying in the evening or weekend which didnt align with delivering samples to the

laboratories. UPTD was supportive of the analysis and re-scheduled emptying and also emptied from

an employees house (pit was almost full). Three samples (B1-3) were taken to the local laboratory

on the 30 October and two samples (B4-5) were analyzed at both the local laboratory and University

Indonesia, taking approximately 3 hours to be delivered.

3.1.2 ANALYSIS OF SLUDGE TREATMENT PLANT AND DRIED SLUDGE

The Bogor sludge treatment plant located in Tegal Gundil, the same site as the wastewater

treatment plant, was rebuilt by National Ministry Public Works in 2010 and operational since 2013.

There are many operational issues predominately due to the plant sized much larger than current

inflow, as detailed in Appendix C. Designed for 30m3/d approximately 7-10 trucks/day, it is currently

receiving an average of 3 trucks/day with long retention time causing dried sludge to block the

biodigester, baffle reactor and channels. Five samples (B6-B10) were taken at the locations shown in

Figure 3 and tested at both the local laboratory and University Indonesia.

There is no current reuse of sludge from the sludge drying beds, which is restricted by the lack of

operation plan limiting safe sludge drying (see Appendix C). The operator expected there would be

interest in sludge reuse but the quality would need to be approved.

Influences of current operation on sampling included:

The day prior to sampling a pipe diverting water from the river into the treatment plant was the

operators solution to reduce blockages.;

The pipe from 2nd chamber in baffle reactor always opened, sludge only stored in one chamber

before discharge to SDB, other chambers empty.

Sludge drying beds (SDB) not filled/emptied based on a schedule, uncertain length of time the

dried sludge has been stored. There is no current emptying or reuse of sludge from drying beds.

No clear inflow from SDB to gravel filter, SDB possibly leaking or diverted directly to ponds.

Faecal Sludge Characterization Indonesia

B8 Inflow to

SDB B7 Inflow to

Baffle Reactor

Discharge to

ponds then

sample B9 at

Outlet to River

B6 Digester Outlet

(shallow tank)

B10 Dry sludge

Est. 6 months old

B1-B5 Truck

Discharge

FIGURE 3 - SUMMARY OF OPERATION ISSUES & SAMPLE LOCATIONS (B1-B10)

3.2 JAKARTA

DKI Jakarta, Special Capital Region of Jakarta, is the capital of Indonesia and also the largest and

most dense province with a population of 9.76 million (2012) and density of 14,464/km 2. Jakarta is a

flat coastal city with fast draining sandy soil and high groundwater with flooding also a common

problem. Groundwater depth varies from 0-40m below surface and survey in 2012 found 68% of

shallow wells are polluted with faecal contamination11, despite this wells are still commonly used,

however the majority receive piped water supply (66%) and use bottled water for drinking (63%).

3.2.1 SLUDGE EMPTYING ANALYSIS

Data from WSP 2014 study in low income areas in Jakarta found a typical on-site system was a single

leach pits although some households had a two chamber septic tank, often with the second for

infiltration. 58% of households had never emptied their pits after an average 12years.

At the time of the study the City Waste Department (Dinas Kebersihan) was responsible for the

sludge treatment plant and pit emptying and operating an on-call emptying service from a fleet of

approximately 70-100 trucks operating from five city offices (North, Central, South, East, West).

Management of sludge emptying and treatment will be handed over to PD-PDAL Jaya in January

2015 in addition to their current responsibility for sewerage and wastewater treatment. IUWASH are

working with PD-PAL to develop a regular emptying program, commencing with government

buildings and then to trial in east Jakarta, with regulations already in place. PD-PDAL have 4 trucks

which are predominately used for sewerage and commercial customers.

11

JICA WW Masterplan Review Surveys in Jakarta from 2007-2009 found 75-77% shallow wells (generally

<20m) contaminated with coliform bacteria due to poor wastewater management.

Faecal Sludge Characterization Indonesia

There are two sludge treatment plants in Jakarta, one in the west at Duri Kosambi and in east at Pulo

Gebang. The Pulo Gebang is new and has higher rates of emptying so was recommended by PDPAL

for analysis, the is the same site assessed by Emasesa for the WOP. Figure 4 shows the data available

from 2009-2014 with detailed data from 2012 indicating a much higher inflow. The data from 2009

and 2010 is not disaggregated between private and government and daily rate was estimated from

annual volume (and known truck volume from 2012 detailed data). Data from 2012 indicated that

approximately 83 trucks discharged to Pulo Gebang and 57 trucks to Duri Kosambi12. During the

survey the operator of IPLT Pulo Gebang estimated an average 40 trucks per day, with 80% private,

however daily records from the IPLT for October 2014 had an average 33/day with 53% private. It

why this is lower than 2012, whether there is an actual reduction in discharge or changes in accuracy

of recording. However with over 40 trucks per day, there were sufficient trucks to collect 5 samples

in one day, with all samples analyzed in University Indonesia taking approximately 1.5hrs to be

delivered.

Daily Discharge to Jakarta Sludge Treatment

Trucks/day (based on volume data)

160

140

Duri Kosambi - Private

Duri Kosambi - Govt.

Pulo Gebang - Private

Pulo Gebang - Govt.

120

100

80

60

40

20

-

2009

2010

2012

2014

FIGURE 4 - INFLOW TO JAKARTA SLUDGE TREATMENT PLANTS

3.2.2 ANALYSIS OF SLUDGE TREATMENT PLANT AND DRIED SLUDGE

Two parallel treatment plants exist at Pulo Gebang, a new system at the back of the site and old

system at the front. The rear IPLT has improved treatment and safety features but is used less since

it is located at the back of the property and trucks typically only discharge to it when the front

system is occupied (operator estimated 70% to the front/old system and 30% to the back/new).

Another reason for preference to discharge into the old system is due to need to pump discharge

into the inlet/screen in the new system vs. gravity discharge to the old.

No design drawings were provided for either the old or new systems which made sampling difficult

because the operators were not able to describe exactly the configuration and flow of each plant.

The systems appear predominately separate however there are some overflow connections in the

final ponds which appear to be in use and no clear discharge point could be found with the high level

overflow to drain indicated as the outflow with levels well below overflow so no discharge.

Since the new treatment plant was expected to be more closely following design operation, samples

were taken from each of the systems and freshly dewatered sludge. Other than the uncertainty of

discharge meaning the final measurement was from the final pond rather than stream inflow, the

12

Report provided by PDPAL Aktivitas Pembuangan Limbah Tangki Septik di IPLS yang berasal dari Armada

Swasta

10

Faecal Sludge Characterization Indonesia

operational issues presented in Appendix C are not expected to have affected the analysis. The onsite laboratory test Pulo Gebang and Duri Kosambi treatment train for TSS, pH and COD.

FIGURE 5 IPLT EAST NEW SYSTEM LAYOUT AND SAMPLE LOCATIONS

The agriculture university has twice used the dried sludge for fertilizer for pilot projects. In 2012 for

plantation and 2013 for flowers, the sludge quality wasnt tested but said it had good results.

3.3 SOLO

Surakarta, or Solo as it is commonly known, is located in central Java with a population of 520,061

and a gently sloping inland city surrounded by volcanoes Mt Merapi and Lawu and intersected by

four main rivers. PDAM manages water, wastewater and faecal sludge, with approximately 57%

households receiving piped water sourced from spring and deep wells.

3.3.1 SLUDGE EMPTYING ANALYSIS

Although PDAM have one sludge emptying truck, the private operators are the main sludge

emptying service provider in Solo with up to 7 companies. IUWASH is working with PDAM to develop

a regular emptying trial program in cooperation with private trucks, regulations already exists and

despite delays it is hoped to commence mid 2015.

Data from WSP 2014 study in low income areas in Solo found most toilets discharged to either a

multi chamber septic tank or twin pits. 74% of systems had never been emptied despite an average

age of 12 years. 26% of systems had an overflow to the drain or river, which is higher than other

cities and could lead to the low emptying rate.

The operator of IPLT estimated an average 1-4 trucks per day, predominately private operators. The

log book for November 2014 indicated a total 46 trucks for the month (ave 1.8/day if closed Sunday)

and estimated discharge of 130m3 (ave. 2.8m3/truck). Figure 6 below shows the data from PDAM for

2014 converted from volume by the average 2.8m3/truck recorded in November. While the January

to April data appears incomplete, the average monthly trucks from May-October is 58 trucks per

month or 2.3/day.

11

Faecal Sludge Characterization Indonesia

ITruck/month

80

Solo IPLT Inflow 2014

70

PDAM

60

Total Private

50

40

30

20

10

0

Jan Feb Mar Apr May Jun

Jul Aug Sep Oct

FIGURE 6 IPLT EAST NEW SYSTEM LAYOUT AND SAMPLE LOCATIONS

The treatment plant is located at the back of the city landfill site and reports of inaccessibility or

difficult access refer to the road previously being in poor condition. This was fixed/paved early 2014

and could be one reason for the low discharge values in Figure 6, however there is still an issue with

access daily due to piles of rubbish or bulldozers often blocking the only entry. Although not officially

reported, comments that trucks often discharge to rivers or land when they cannot access the

treatment.

Two tucks were sampled on the first day but the results from the PDAM wastewater laboratory were

not accurate and they are unable to measure BOD >400mg/L, COD>1500mg/. Despite having two

ovens for volatile solids analysis (provided by previous ADB Twinning project), one is in the PDAM

office and the laboratory staff did not remember how to use the other located at the wastewater

treatment plant laboratory. This laboratory has receive various training support from ADB including

training in Korea, multiple visits by twinning authority Emasesa, however with lack of practice were

unable to complete any sludge analysis. The subsequent day sampling was not possible due to

delays and no trucks therefore PDAM staff sampled independently on Thursday 4th October and

delivered samples to the local University (UNS) Faculty of Mathematics and Natural Science (MIPA)

Laboratory Solo and in a cooler box to the laboratory at the university of Centre For Environmental

Health Engineering and Communicable Disease Control (BTKL) at Universitas Gajah Mada

Yogyakarta, approximately 2 hours delivery time.

3.3.2 ANALYSIS OF SLUDGE TREATMENT PLANT AND DRIED SLUDGE

The treatment plant at Putri Cempo was handed over from previous government agency to PDAM

ten years ago, which the operator comments was not in good conditions and has not operated

properly since. Although sludge is still emptied (when accessible, see issues above) it goes directly

into one pond which flows to a overgrown second pond before discharge to the river. There are no

design drawings but an estimated layout is shown below and reported to be 26m3/d capacity

(approximately 9 trucks).

12

Faecal Sludge Characterization Indonesia

Inlet

Sludge

Drying Beds

Anaerobic

Pond 2

Facultative

Pond

Maturation

Pond

Anaerobic

Pond 1

River

FIGURE 7 IPLT PUTRI CEMPO SURAKARTA

Sludge is discharged directly into the Anaerobic pond 2 since the inlet chamber is blocked. This

discharges to an overgrown Facultative pond and maturation pond, which appear to be leaking. The

final discharge into the river was not accessible. Due to thick vegetation and clear solids build up in

both ponds, they do not function as designed with many stagnant areas and therefore not

considered worthwhile assessing. There is no dry sludge for reuse analysis. See Appendix C for

further details of operation issues.

3.4 MAKASSAR

Makassar is the capital of South Sulawesi province with a population of 1.27million. It is a flat coastal

city experiencing issues of tide induced flooding near the coast but rising to hilly areas in the east

with deep groundwater. PDAM supplies piped water to 65% of households, sourced predominately

from two rivers running through the city and well water use is common for the un-served

households. UPTD was set up in January 2013 to manage septic tank emptying, sludge treatment

operation, support to community treatment systems and sewerage when the proposed treatment

and sewer is built in the coming years.

3.4.1 SLUDGE EMPTYING ANALYSIS

UPT Makassar have 8 sludge emptying trucks and typically operate 2-3 each day with an on-call

operation where customers come or call the office to place orders, and once three orders exist one

truck is sent. Although the trucks are 2.5-3m3 and survey of on-site systems found pits on average

2.5m3, it is UPT policy for trucks to empty multiple pits before discharging to the treatment to save

on petrol costs since the IPLT is 20km from the city.

Two private companies empty sludge into IPLT, one has 4 trucks the other only one. There is maybe

one other operator but not discharging to the IPLT. The two companies are charged

Rp25,000/discharge and pay monthly based on the IPLT log book.

Although incomplete the log book at the treatment plant had up 1-2 private sludge trucks

discharging per day and 1-3 UPT trucks. Previous studies found more than half the on-site systems

13

Faecal Sludge Characterization Indonesia

are never emptied13. During the visit UPT estimated that an average 6 households were emptied

with 2 trucks and up to 12 households in wet season.

The UPTD arranged for early empting and allowed trucks to empty only one house per trip for the

benefit of the survey. Due to low emptying rates only 2 samples were possible on the first day

before the local laboratory closed and only two samples arrived the morning of the second day, with

long travel time needed to deliver the samples back to Jakarta before 4pm.

3.4.2 ANALYSIS OF SLUDGE TREATMENT PLANT AND DRIED SLUDGE

The treatment plant in Nipa-Nipa plant was originally built in 1991 and rehabilitated from April 2013

by National Public Works with expected capacity of 100 m3/day. A second rehabilitation contract

from May 2014 to build an additional inlet/grit chamber was underway at the time of visit. There are

many design and operational issues, with the new imhoff tank becoming blocked within weeks of

operation and sludge trucks discharge directly to the anaerobic pond. Additionally the final

maturation pond was not finished so discharge from the facultative pond to the river. There are also

design issues with the new inlet chamber and likely to also clog with sludge. Details of design and

operation issues are in Appendix C, and with no pre-treatment and overgrown and sludge filled

ponds the system was not sufficiently operating to effectively monitor. Additionally sludge in the

new drying beds was wet and overgrown with vegetation therefore also not sampled.

4 RESULTS

4.1 QUALITY ASSURANCE

Knowing that most laboratories in Indonesia had little experience with faecal sludge analysis,

duplicate samples were tested at both a local laboratory and the University of Indonesia (UI)

laboratory, as well as two sets of duplicate tested at UI.

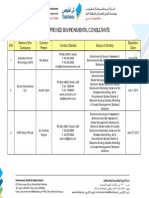

TABLE 3 ANALYSIS OF DUPLICATE SAMPLES ACCURACY

Parameter

Local Lab

BOD

993

1,109

1,035

630

7-194%

COD

2,514

2,984

4,362

5,930

21-183%

TS

17,598

15,233

12,790

13,963

11-173%

TSS

4,284

4,639

812

718

6-190%

VS

NA

NA

73%

9%

NA

Ave

Stdev

National Lab

Ave

Stdev

Difference %

(N=11 Range (abs)

(UI* Local)/ave. pairs)

Average abs.

88%

89%

92%

93%

NA

difference

Difference %

(N=2

Average abs.

39%

42%

12%

96%

12%

(UI UI)/ave.

pairs)

difference

Previous UI duplicate data Average abs.

24%

13%

9%

70%

Difference % (N=3 pairs)

difference

UI* - also includes the comparison of Local laboratory at Solo UNS and duplicate at Yogyakarta BTKL

13

WSP 2013 Sludge Accumulation and Pit Emptying Study

14

Faecal Sludge Characterization Indonesia

Seen in Table 3 there is a significant difference (acceptable is <10%) between all duplicate samples

ranging from 6-200% difference, both between testing at the University Indonesia and Local

Laboratory and even within University Indonesia. The characteristics of faecal sludge are known to

show a broad range of possible values along with the uncertainty of these non-comparable results

limits ability to present definite values for sludge characteristics in Indonesia. Possible reasons for

the discrepancies include:

Sample changing Whilst the local laboratory was within 30minutes to 1 hours of sampling, the

transport of samples took up to 4 hours to reach the University Indonesia laboratory (including

flights). Although the samples were kept in a cooler bag surrounded by ice, due to ambient

temperatures over 30C and the sample also commencing at this temperature, it is unlikely they

were at the recommended 4C for transport. However this typically reduces the BOD value

whereas the UI BOD is much higher.

Total Solids are however should not have been effected by the transport and the 170%

difference between local and UI laboratories indicates that other reasons are likely. The

duplicate samples tested at UI had least difference of all analysis and indicate a consistent

analysis method.

Technique and equipment is a likely factor to cause variation. Although they all referred to

standard techniques, most of the local laboratories have limited technology and rely more on

manual testing the equipment (ie. BOD/COD by titration & conversion from table rather than a

DO probe). Also most local laboratories has little or no experience in wastewater analysis and no

experience in faecal sludge analysis. This may be reason why the TSS results are so varied, with

different techniques needed for thick FS TSS analysis.

There was also a discrepancy with the reporting of parameters, with inconsistency in reporting

atom or molecule weight. Where possible this was confirmed with the laboratory and converted

(ie. NH3 to NH3-N /1.21589; NH4 to NH4-N / 1.8786). However it is uncertain whether the

laboratories were clear on what they are measuring/reporting. Additionally some of the liquid

sludge samples were reported based on weight rather than volume, making them incomparable

with international values or discharge standards.

In light of these discrepancies, as detailed below the majority of results are within the expected

range of faecal sludge parameters and therefore still a useful dataset to improve understanding of

Indonesian faecal sludge characteristics. Although with the uncertainty in data there are no definite

values, the range of likely values should be considered for design rather than the average. And

importantly, an improvement in wastewater analysis skills and equipment in Indonesia could lead to

an more accurate understanding of faecal sludge characteristics.

4.2 FAECAL SLUDGE CHARACTERIZATION

As detailed in the method above, samples were taken from the discharge of 15 trucks in the four

cities. The trucks had typically emptied one household (2 had emptied multiple households) and

driven straight to the treatment plant taking approximately 20-40minutes. Below is a table

summarizing the results in comparison with International and Previous Indonesia findings, with each

parameter explain the following section.

15

Faecal Sludge Characterization Indonesia

TABLE 4 - COMPARISON WITH INTERNATIONAL DATA

Parameter

Total Solids (TS)

mg/L

Total Suspended

Solids (TSS) mg/L

Volatile mg/L

Solids

% TS

(VS)

Sludge Volume

Index (SVI) mL/g

CODmg/L

BOD5 mg/L

COD: BOD Ratio

pH

NH3-N or NH4-N

mg/L

Phosphate (PO4)

mg/L

Total Coliform

MPN/100mL

Helminth egg

total

No./L

4.2.1

Existing

International

Data14

5,000-71,000

5,000-52,000

Existing

Indonesian

Data15

1,332554,400

76-208,113

Mean

Stdev

427-43,894

Survey

Accepted

N

Range

3,820-43,894 17

15,052

14,322

66-11,383

274-11,383

15

2,664

3,767

2,200-33,096

56-84%

9

9

9,869

73%

12,176

8.6%

Actual Range

3,000-47,000

45-83%

68-88%

298-257,503

17-2254%

24-80

NA

47-3,367

47-58

52

1,200-83,000

600-2,600

6-9

6-7.7

150-1230

160-11,878

65-630

1.9-15

6.8-10

64-722

53-18,501

24-16,934

0.8-4.4

6.3-8.0

2-39816

549-17,875

215-3,500

1.3-2.9

Same

96-398

24

23

23

29

16

3,284

1,009

2.0

7.4

200

4,434

934

0.53

0.38

93

69-186*

(sewage)

0.6-9 million

74-386

1-277

37-277

14

153

83

110-350

400039million

17

8mil

15mill

16-91/gTS

16-50/gFS

4000/L

0-30/g FS

40002.4billion

0-200/gFS

37/gFS

800

SOLIDS PARAMETERS: TS, TSS, VS, SVI

The total solids values were typically within the range but on the low side of international values and

similar to previous analysis from Indonesia. However most of the results for total suspended solids

were well below international levels, which are most likely due to the difficult of testing more dense

faecal sludge with typical liquid filter methods. It is recommended that Total Solids are calculated

separately rather than summing the results of TDS and TSS due to the difficulty measuring TSS in

thick sludge.

The percentage of volatile solids to total solids were within international range (except for Solo

analysis at BTKL Yogyakarta) and indicate that some stabilization has occurred although there was no

clear correlation between percentage volatile solids and years stored in tank. Since full stabilization

14

International Results from: Bassan et al 2013 (Burkina Faso), Kone and Strauss 2004 (Ghana, Burkina Faso,

Thailand), Strade et al 2014 (various countries), Schoebitz et al 2014 (Vietnam), Gallizzi 2004 (Ghana), JimenezCisneros 2007 (Mexico) Spit et al 2014 (Malawi), Awuah and Abrokwa, 2008 (Ghana), Lekeufack 2012

(Cameroon).

15

Indonesia Results, all data, not all realistic values. From: WSP 2014 (Balikpapan 4 samples), WSP 2013

(various cities 6 samples), IUWASH 2014 ( Surakarta 1 sample), Yulfaizi 2003 (Bandung).

16

UI results reported in NH3, converted to N-NH3 diving by 1.21589

16

Faecal Sludge Characterization Indonesia

has not yet occurred the use of anaerobic treatment or digesters is suitable, compared with highly

stabilized sludge which could be directly dewatered.17

The sludge volume index values in all results except two samples from the UNS Local Laboratory Solo

are too high to be realistic, which is most likely due to the low suspended solids values. For the

results from Solo the SVI of 47-58 mL/g indicate good settling/separation. For the remainder, the

settled sludge volume was back calculated (mL settled sludge in 1L) and more than half the samples

had achieved good settling, <400mL/L within the 60 minutes.18 However the results from one sample

from Makassar showed almost no solid liquid separation with 940/960 mL/L with this sample also

having the highest TS and two samples from Jakarta were average settling at 500 & 526mL/L.

TABLE 5 SOLID PARAMETERS ANALYSIS RESULTS

Parameter

TS mg/L

TSS mg/L

VS mg/L

VS % TS

SVI mL/g

V60# ml/L

Typical

International

N

Data

5,000-71,000 17

(>3800)

5,000-52,000 15

(250 sewage) (>250)

3,000-47,000 9

45-83%

9

24-80

2

NA

Acceptable Data

Range

Mean* Stdev*

All Data

Range

3,820-43,894

15,052

14,322

27

427-43,894

Mean

All

10,045

274-11,383

2,664

3,767

27

66-11,383

1,546

2,200-33,096

56-84%

47-58

NA

9,869

73%

52

12,176

8.6%

8

12

298-257,503

17-2254%

47-3,367

94-960

28,912

246%

1,242

417

9

9

*Mean and Standard Deviation exclude the outliers that are considered incorrect.

#

V60 calculated from SVI x TSS

4.2.2 BIOLOGICAL PARAMETERS: BOD, COD

The low COD values indicate that some stabilization has occurred and reduced the organic content

of sludge. This accord with the lower values of the volatile solids and as expected for on-site systems

which had not been emptied from 3 months to 14 years.

The low values could be due to the degradation of the sample between sampling and analysis which

was up to 4 hours delivered to the lab and possibly starting the next day. Although the samples were

stored in a cooler with ice, since sample & surrounding temperatures were around 30C, it is unlikely

the samples were at 4 degrees, which is not realistic unless frozen. Other explanations for low BOD

results are when samples are incubated in presence of light, causing photosynthesis which satisfies

oxygen demand or insufficient stirring of the sample. High Ammonia levels which also consume

oxygen can present false high BOD results, however the two high BOD results did not have high

Ammonia levels there was no clear trend in BOD vs N-NH3. Another reason could be the method of

analysis in local laboratories using Winkler titration and comparing with a table when the BOD values

in sludge are typically much higher than in wastewater. This limited the analysis in the wastewater

laboratory at PDAM Solo since the limit in their conversion tables for BOD <400mg/L and COD

<1500mg/L.

The very low COD:BOD ratio which is more typical of sewerage than faecal sludge, could be due to

the low BOD results, since a low COD:BOD ratio indicates very high/easy biodegradability, where as

17

18

Montangero and Strauss, Eawag 2002.IHE Delft Faecal Sludge Treatment Lecture Notes

As above

17

Faecal Sludge Characterization Indonesia

the VS% and low COD indicate average biodegradability. Although the BOD and COD were reported

to have been independently tested in Makassar, it is surprising that all samples had identical

COD:BOD ratio of 2.50.

TABLE 6 BIOLOGICAL PARAMETER RESULTS

Parameter

COD

BOD5

COD:BOD

Typical

International

N

Data

1,200-83,000 24

600-2,600

23

6-9

23

Acceptable Data

Range

Mean* Stdev*

549-17,875

215-3,500

1.3-2.9

3,284

1,009

2.0

4,434

934

0.53

N

27

27

27

All Data

Range

53-18,501

24-16,934

0.8-4.4

Mean

All

3,618

2,081

2.1

4.2.3 NUTRIENT & PATHOGEN PARAMETERS

The pH is within the neutral range as expected for household septage. Ammonia levels are within

international range and indicate a low strength septage as per the other parameters. Not possible to

test Total Nitrogen or Total Phosphorus of liquid sludge samples in either the local or national

laboratories. The data on Phosphate for faecal sludge is limited and the above range is from

sewerage influent to a wetland treatment system in Cameroon, with the concentration of total

phosphorus of faecal sludge 2-50 times the concentration of domestic wastewater.19

Total coliform data showed varied results and for tropical countries not always accurate due to the

high temperatures influencing the analysis. Helminth eggs provide a more useful indication of

pathogen reduction in treatment and is discussed further in the analysis of treatment performance

and dried sludge quality. Comparison with international data is difficult due to different units and

the limitation that the helminth eggs are analyzed in a different laboratory to TS so reporting in that

unit is difficult.

TABLE 7 NUTRIENT AND PATHOGEN PARAMETERS RESULTS

Parameter

pH

N-NH4

PO4

Total

Coliform

Typical

International

Data

6-7.7

150-1230

69-186*

0.6-9million

N

29

16

14

17

Helminth 16-91/gTS, 16- 6

Egg

50/gFS, 4000/L

* Only data on PO4 from sewage

Acceptable Data

Range

Mean* Stdev*

Same

96-398

37-277

400039million

7.4

200

153

8mil

0.38

93

83

15mill

37/gFS

800

N

29

22

21

19

All Data

Range

6.3-8.0

2-39820

0.3-277

40002.4billion

Mean

All

7.4

148

108

145

million

0-200/gFS

4.2.4 SUMMARY - STRENGTH

Despite the limited quality assurance of the analysis with large difference in duplicate sample

results, overall the results align with international data. Seen in Table 8 below, many of the

parameters indicate that the sludge from on-site systems in Indonesia is Low Strength having

undergone some digestion over the average 6 years accumulation.

19

20

Eawag 2014 Faecal Sludge Management Book Chapter 2

UI results reported in NH3, converted to N-NH3 diving by 1.21589

18

Faecal Sludge Characterization Indonesia

TABLE 8 COMPARISON OF SLUDGE STRENGTH

Parameter

Storage

COD mg/L

COD:BOD

NH4-N mg/L

TS mg/L

Helminth Egg no./L

High Strength

(Public toilet)

Days-weeks

20,000-50,000

2:1-5:1

2,000-5,000

>35,000

20,000-60,000

Low Strength

(Septic tank)

Month-years

<10,000

5:1-9:1

<1000

<30,000

<4,000

Tropical

Sewerage

No storage

500-2,500

2:1

30-70

<10,000

300-2,000

Findings Indonesia

Mean (Range)

Ave 6 years storage

3,284 (549-17,875)

2.0 (1.3-2.9)

200 (96-398)

15,052 (3,820-43,894)

37 (0-200 Ascaris Egg)

Current influent design guidelines for sludge treatment plants in Indonesia21 recommend assuming

the influent concentrations seen in table xx below.

TABLE 9 COMPARISON WITH INFLUENT STANDARD GUIDELIE

Std

TS

TSS

TVS

BOD5

40,000

15,000

25,000

5,000

Indonesia Findings

Mean

Range

15,052

3,820-43,894

2,664

274-11,383

9,869

2,220-33,096

1,009

215-3,500

Potential Oversize

(Standard/mean)

2.5x

6x

2.5x

5x

4.3 TREATMENT & DRY SLUDGE

Of the four cities assessed, only the sludge treatment facilities in Jakarta and Bogor were operating

sufficiently to assess their function. Although sludge was still being emptied into the systems in

Makassar and Solo, they were typically missing the initial treatment step(s), not flowing to other

ponds as per designed (assumed) and with no clear discharge due to overgrowth/leaking. Design and

operation issues and suggestions are included in Appendix C.

Another challenge is the lack of design drawings available, since the utility is not typically involved in

the construction and on occasions could not provide design basis or clearly explain the intended

operation. The table and figures below show the two systems and sampling points with the following

graphs showing key analysis results.

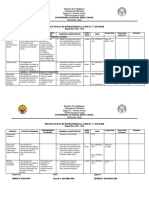

TABLE 10 EFFICIENCY OF SLUDGE TREATMENT PLANTS

City

Treatment Plant Details

Sample Points

Sample

Reduction from ave.

inflow to Outlet

Reduction from sample

in first pond to Outlet

Bogor

IPLT Tegal Gunil, built 2010, designed for

30m3/d receives approximately <9m3/d.

1 Outlet Biodigester

2- Inlet Baffle Reactor

3- Inlet Sludge Drying Bed

4 Outlet to River

TS

TSS

COD

BOD

96-99% 99% 98-97%

96-98%

99-98%

98%

99%

99-98%

Jakarta

IPLT Pulo Gebang, new

system.

1 SST1 First Aeration Pond

2- Second Aeration Pond

3 Chlorination pond

4 SST2 Outlet pond

TS

TSS

COD BOD

77% 64% 93% 75%

-4%

35%

27%

-10%

21

Petunjukteknis Tata Cara Perencanaan IPLT Sistem Kolam Ministry of Public Works. (Technical Guidelines

for Planning Procedures IPLT Pond System) from IUWASH Solo IPLT Design.

19

Faecal Sludge Characterization Indonesia

The Local analysis treatment data for Bogor typically found an increase from the influent, to the

discharge of Biodigester to inlet to baffle reactor (drawn from the base of the biodigester outlet

tank). But then reduced after the baffle reactor to the outlet. Surprisingly the volatile solids were not

reduced from the influent values to the digester discharge however reduced after the baffle reactor.

Also surprising is the increase in Total Coli forms through the treatment. Ph is particularly low in the

digester, baffle reactor and inflow to sludge drying bed which could impact the performance.

For the treatment in Jakarta there is an overall reduction in all parameters across the treatment,

which are typically much lower than the Bogor treatment values. The new system in Jakarta has well

operating initial and second aeration ponds, however the subsequent ponds appeared stagnant and

flow diversions or leaking might cause low levels and the worsening quality.

As can be seen in the table and graphs the treatment performance in Jakarta IPLT is worse in the

final ponds, as can be seen in the appendix C, these are both green and have low water levels

despite the high volume of inflow. It is possible that the sludge discharges to the old system after the

aeration but the operators were uncertain of the design.

Although Table 10 showed good treatment efficiency, the comparison of effluent quality with

Indonesian domestic discharge standards in Table 11 shows that for the analysis from University

Indonesia, neither plant meets discharge requirements. Additionally in comparison with existing

data for Jakarta, previous tests also indicate the insufficient treatment.

According to the UI results, and also previous analysis by BPLHD, the discharge does not meet the

Indonesian standards for either plant, however the Jakarta system was not actual discharge and

instead the final pond since the discharge channel was dry (unlikely since very high inflow)/could not

indicate where the discharge was.

TABLE 11 EFFLUENT DISCHARGE STANDARDS

Parameter

TS (mg/L)

TSS

BOD

COD

pH

N-NH3

Bogor Outlet

Local

UI

458

3

20

43

7.36

0

224

4

154

251

9

UI

278

216

222

345

7.12

82

Jakarta Outlet

On-site

BPLHD24

laboratory23

61

167

7.5

280

1050

4170

8.9

218

Indonesian Standard22

100

100

(250 recommended)

6-9

22

Ministry of Environment Decree No.112/2003 on Domestic Wastewater Quality Standard.

Jakarta IPLT On-site laboratory weekly analysis results Average July-Nov 2014

24

BPLHD Analysis of IPLT on 19/09/14

23

20

Faecal Sludge Characterization Indonesia

FIGURE 8 TREATMENT PERFORMANCE OF BOGOR AND JAKARTA IPLT

TS

80000

Bogor (Local)

Bogor (UI)

Jakarta (UI)

Int. Min

Int. Max

60000

TSS

1000

Bogor (Local)

Bogor (UI)

800

Jakarta (UI)