HeavyWeight 3.5 25.58lbs NC-38

Diunggah oleh

Инженер Луис А. ГарсиаHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

HeavyWeight 3.5 25.58lbs NC-38

Diunggah oleh

Инженер Луис А. ГарсиаHak Cipta:

Format Tersedia

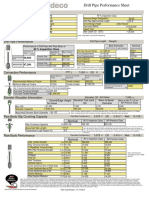

Heavy Weight Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

HWDP Configuration

Note: Unbalanced Connection, Box weak (Connection OD should be larger or ID larger).

Pipe Body OD

(in)

Pipe Body ID

(in)

Heavy Weight Type

Pipe Body Grade

Connection

Connection OD

Connection ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

Friction Factor

3.500

2.062

Standard

Standard 1340

NC38

4.750

2.250 Chamfered

27

21

1.0

(in)

Wall Thickness

Approximate Length

Pipe Body SMYS

SmoothEdge Height

Tool Joint SMYS

Max Upset OD (DTE)

Number of Wearpads

(ft)

(psi)

(in)

(psi)

(in)

Wearpad Length (per Wearpad)

(in)

0.719

31.0

55,000

3/32 Raised

120,000

3.875

3

8.7

Note: Tong space may include hardfacing.

HWDP Length 31.0

HWDP Performance

Best Estimates

Performance of HWDP Assembly

Applied Make-up Operational Torque

Torque

(ft-lbs)

(ft-lbs)

Maximum MUT

Minimum MUT

11,500

9,600

Drill Pipe Adjusted Weight

Max Tension

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

(lbs)

0

11,500

345,400

279,500

0

9,600

345,400

301,000

(lbs/ft)

(gal/ft)

(Bbls/ft)

(gal/ft)

(Bbls/ft)

(in)

25.58

0.39

0.0093

0.17

0.0041

1.812

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

NC38

Connection Performance

4.750

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

Maximum Make-up Torque

Minimum Make-up Torque

11,500

9,600

(in)

OD X

2.250 (in)

Tension at Connection

Yield

(lbs)

(lbs)

Tensile Limited

730,700

820,900

852,700

ID

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for

Counterbore

(in)

5.017

Not Applicable

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 11,200 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

(ft-lbs)

(lbs)

19,200

852,700

Elevator Shoulder Information

SmoothEdge Height

Box OD

Elevator Capacity

Assumed Elevator Bore

(in)

(lbs)

3/32 Raised

4.938

746,000

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

4.750

589,000

4.938

(in)

4.578

450,200

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

3.969

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

3.5 (in)

OD

2.062

ID

(in)

55,000 (psi)

Nominal

Slip Crushing Capacity

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

269,300

16.5

4.2

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

Pipe Body Configuration

3.5 (in)

OD

2.062

(in)

ID

55,000 (psi)

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

(lbs)

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

Cross Sectional Area of Pipe Body

(in^2)

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in^2)

(in^2)

(in^3)

(in^3)

345,400

19,600

0.98

15,700

19,766

17,950

3.500

0.719

2.062

6.280

9.621

3.341

3.702

7.403

Note: Nominal Burst calculated at 87.5% RBW per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. HWDP assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. It is the responsibility of the customer and the end user to determine the

appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box

IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 10-16-2014

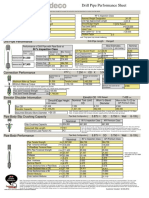

Operational Limits of HWDP

Connection

Pipe Body

NC38

Connection OD

Pipe Body OD

(in)

Pipe Body ID

3.5

(in)

(in)

4.750

2.062

Connection ID (in) 2.250

Chamfered

Pipe Body SMYS

Combined Loading for HWDP at

Maximum Make-up Torque = 11,500

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

600

1,200

1,800

2,400

3,000

3,600

4,200

4,800

5,400

6,100

6,700

7,300

7,900

8,500

9,100

9,700

10,300

10,900

11,500

(lbs)

345,400

345,200

344,800

343,900

342,800

341,300

339,500

337,400

334,900

332,000

328,200

324,500

320,500

316,000

311,200

305,800

300,000

293,700

286,900

279,500

55,000

Combined Loading for HWDP at

Minimum Make-up Torque = 9,600

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

(psi)

Tool Joint Specified

120,000

Minimum Yield Strength (psi)

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

(lbs)

345,400

345,400

730,700

345,400

820,900

345,200

820,900

500

345,300

345,300

730,700

820,900

1,000

344,900

344,900

730,700

730,700

344,800

343,900

820,900

1,500

344,400

344,400

342,800

820,900

2,000

343,600

343,600

730,700

341,300

820,900

2,500

342,600

342,600

730,700

339,500

820,900

3,000

341,300

341,300

730,700

820,900

3,500

339,800

339,800

730,700

820,900

4,000

338,100

338,100

730,700

820,900

4,500

336,200

336,200

730,700

730,700

337,400

334,900

332,000

328,200

820,900

5,100

333,500

333,500

324,500

820,900

5,600

331,000

331,000

730,700

320,500

820,900

6,100

328,200

328,200

730,700

316,000

820,900

6,600

325,200

325,200

730,700

820,900

7,100

321,900

321,900

730,700

820,900

7,600

318,300

318,300

730,700

314,500

314,500

730,700

730,700

311,200

305,800

300,000

8,100

820,900

293,700

820,900

8,600

310,300

310,300

286,900

820,900

9,100

305,800

305,800

730,700

279,500

820,900

9,600

301,000

301,000

730,700

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Rec MUT

9,600

9,800

10,000

10,200

10,400

10,700

10,900

11,100

11,300

11,500

Connection Max

Tension

(lbs)

730,700

745,900

761,100

776,300

791,600

814,400

829,600

844,800

842,300

820,900

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. HWDP assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. It is the responsibility of the customer and the end user to determine the

appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box

IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

10-16-2014

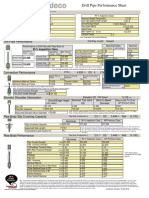

Connection Wear Table

Connection

NC38

Connection OD

Connection

Wear

Tool

Joint OD

New OD

(in)

4.750

Connection ID (in) 2.250

Chamfered

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

19,200

17,600

16,000

14,400

12,900

11,400

9,900

8,500

7,100

5,600

4,300

2,900

11,500

10,500

9,600

8,700

7,700

6,800

6,000

5,100

4,200

3,400

2,600

1,800

4.75

4.695

4.639

4.584

4.528

4.473

4.418

4.362

4.307

4.251

4.196

4.141

Worn OD

(in)

(ft-lbs)

Tool Joint Specified

120,000

Minimum Yield Strength (psi)

Min MUT

(lbs)

820,900

842,600

817,900

791,700

755,500

686,800

630,800

567,200

504,300

456,000

409,100

364,900

Connection Max

Tension

(lbs)

(ft-lbs)

9,600

730,700

8,800

706,200

8,000

681,600

7,200

655,200

6,400

627,900

5,700

575,700

5,000

525,700

4,200

467,100

3,500

420,300

2,800

375,500

2,100

330,400

1,500

304,100

Note for API Connections: Tension at shoulder separation and Tension at connection failure may fluctuate as OD

decreases due to Recommended make-up toqure exceeding T4.

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

Pipe Body Torque

(in)

Pipe Body ID

3.5

(in)

2.062

Pipe Body SMYS

(psi)

55,000

1,800

3,600

5,300

7,100

8,900

10,700

12,500

14,200

16,000

17,800

19,500

343,900

339,500

332,500

321,900

307,700

289,300

265,800

237,800

199,100

143,800

31,000

(ft-lbs)

Pipe Body Max

345,400

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. HWDP assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. It is the responsibility of the customer and the end user to determine the

appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box

IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

10-16-2014

Anda mungkin juga menyukai

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Drill Pipe Performance and SpecificationsDokumen3 halamanDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаBelum ada peringkat

- Drill CollarDokumen1 halamanDrill CollarGuillermo Rangel AvalosBelum ada peringkat

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Dokumen3 halamanDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaBelum ada peringkat

- Down HoleDokumen14 halamanDown HoleGhinet Teodor-ioanBelum ada peringkat

- Shock Sub Tool: Impact and Vibration Reduction ToolDokumen4 halamanShock Sub Tool: Impact and Vibration Reduction ToolLeonardo Barrios0% (1)

- TM 120 Daily and Weekly Inspection and Maintenance TasksDokumen23 halamanTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoBelum ada peringkat

- Cameron Type U BOPDokumen3 halamanCameron Type U BOPPablo David SaabBelum ada peringkat

- D392005428-MKT-001 6012 Bop PDFDokumen2 halamanD392005428-MKT-001 6012 Bop PDFMitul PatelBelum ada peringkat

- HY10 1630US 5 2012-Bladder AccumulatorsDokumen14 halamanHY10 1630US 5 2012-Bladder AccumulatorsAlejandro GilBelum ada peringkat

- C200-019-23 TM-210.1 2.875 Motorhead AssemblyDokumen13 halamanC200-019-23 TM-210.1 2.875 Motorhead AssemblysamanBelum ada peringkat

- Dampener Hydrill Dimenciones PDFDokumen2 halamanDampener Hydrill Dimenciones PDFCESAR SEGURABelum ada peringkat

- Study of Dies and InsertsDokumen14 halamanStudy of Dies and InsertstraidenBelum ada peringkat

- Sara Sae - Manual TongDokumen5 halamanSara Sae - Manual Tonganon_374733272Belum ada peringkat

- Plaster & Wald Consulting Corp.: Fill in Shaded AreasDokumen2 halamanPlaster & Wald Consulting Corp.: Fill in Shaded AreasmarvinBelum ada peringkat

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Dokumen28 halaman21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniBelum ada peringkat

- Cameron Hydraulic Gate Valves Type F & FCDokumen3 halamanCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosBelum ada peringkat

- Fishing Jars Brochure PDFDokumen5 halamanFishing Jars Brochure PDFLincoln ZhaoXi100% (1)

- Mud King Swivel Cartridge GuideDokumen16 halamanMud King Swivel Cartridge GuideVishal RamsookBelum ada peringkat

- Logan Taper Taps Catch Stuck ToolsDokumen2 halamanLogan Taper Taps Catch Stuck ToolsrezaBelum ada peringkat

- Drill Pipe Performance DataDokumen35 halamanDrill Pipe Performance DatasnatajBelum ada peringkat

- Logan Lubricated Bumper Sub (English)Dokumen20 halamanLogan Lubricated Bumper Sub (English)Gianfranco Exequiel Sebastian GarciaBelum ada peringkat

- Drilling Spool SpecsDokumen2 halamanDrilling Spool SpecsCarlos Sarmiento CalderónBelum ada peringkat

- CDS 5.500 20.00lb L80+13Cr VAM+TOP+®+Casing SD+4.700 87.5Dokumen1 halamanCDS 5.500 20.00lb L80+13Cr VAM+TOP+®+Casing SD+4.700 87.5ZAMFERLENOBelum ada peringkat

- Circulating SwagesDokumen1 halamanCirculating Swageskaveh-bahiraeeBelum ada peringkat

- Tubulars and Tubular Services Catalog: DrilcoDokumen29 halamanTubulars and Tubular Services Catalog: DrilcoDoni KurniawanBelum ada peringkat

- Scrugrab 05-03-10 PDFDokumen2 halamanScrugrab 05-03-10 PDFfabisysBelum ada peringkat

- Mill Washover ShoesDokumen2 halamanMill Washover ShoesEdwin MP100% (1)

- Technical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Dokumen16 halamanTechnical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Riski KurniawanBelum ada peringkat

- Operating manual for Wenzel double acting hydraulic drilling jarDokumen10 halamanOperating manual for Wenzel double acting hydraulic drilling jarDanciulescu Mircea GabrielBelum ada peringkat

- Lot 8 Dafora Appendix B Standards and Specifications DaforaDokumen81 halamanLot 8 Dafora Appendix B Standards and Specifications DaforaZamfirMarianBelum ada peringkat

- Oilfield Union Color Code GuideDokumen5 halamanOilfield Union Color Code Guidelalberto96Belum ada peringkat

- HMH KFDJ Diverters r1Dokumen9 halamanHMH KFDJ Diverters r1budygmoodBelum ada peringkat

- Venturetech XK 90 Power Swivel Spec SheetDokumen1 halamanVenturetech XK 90 Power Swivel Spec Sheetwilliam pinzonBelum ada peringkat

- ABOP ElementsDokumen1 halamanABOP ElementsArdalan FezziBelum ada peringkat

- Ds Shearing Blind Ram Tc1399Dokumen2 halamanDs Shearing Blind Ram Tc1399Gregory StewartBelum ada peringkat

- 1976-77 Koomey General CatalogDokumen152 halaman1976-77 Koomey General CatalogNicasio AlonzoBelum ada peringkat

- Low Force Shear Ram Test Results SummaryDokumen2 halamanLow Force Shear Ram Test Results SummaryBala KrishnanBelum ada peringkat

- 1PackerSystem PackerAccessories&tools PDFDokumen21 halaman1PackerSystem PackerAccessories&tools PDFAnand aashishBelum ada peringkat

- 13.625 10K Double Cameron U BOP PDFDokumen2 halaman13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- Shock Tool Manual PDFDokumen23 halamanShock Tool Manual PDFAbboud KingBelum ada peringkat

- RDT Heavy Weight Drill Pipe PDFDokumen2 halamanRDT Heavy Weight Drill Pipe PDFLizandro Quispe GomezBelum ada peringkat

- Nov Bushings Slips ClampsDokumen8 halamanNov Bushings Slips ClampsRICHARDBelum ada peringkat

- Fishing Bumper Subs: Instruction Manual 4460Dokumen15 halamanFishing Bumper Subs: Instruction Manual 4460Foros IscBelum ada peringkat

- Cameron EB 538 D Rev D2 - Shear Rams - Op & MaintDokumen7 halamanCameron EB 538 D Rev D2 - Shear Rams - Op & MaintCanrig RamdeBelum ada peringkat

- ReLineMNS Omega PDFDokumen3 halamanReLineMNS Omega PDFJuan Manuel Rojas AcuñaBelum ada peringkat

- Drilltech Services (USA) Inc: Spiro-TorqDokumen10 halamanDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanBelum ada peringkat

- Stripper TOT 2.50 10M DS34 TechMan1146Dokumen13 halamanStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaBelum ada peringkat

- Drilling FormulasDokumen5 halamanDrilling FormulasJoshua RosensteinBelum ada peringkat

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDokumen19 halamanSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13Belum ada peringkat

- Releasing & Circulating OvershotDokumen16 halamanReleasing & Circulating OvershotPrime Energy Warehouse-YemenBelum ada peringkat

- Rotating Control Device: SperrydrillingservicesDokumen4 halamanRotating Control Device: SperrydrillingservicesSlim.B100% (1)

- Drill Pipe Performance Sheet 5.875 XT57 G105Dokumen3 halamanDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoBelum ada peringkat

- Drill Pipe Performance SheetDokumen3 halamanDrill Pipe Performance SheetGarcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokumen3 halamanDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoBelum ada peringkat

- Drill Pipe Performance Data SheetDokumen3 halamanDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Drill pipe performance and operational limitsDokumen3 halamanDrill pipe performance and operational limitsGarcia C L AlbertoBelum ada peringkat

- Drill Pipe Performance SheetDokumen3 halamanDrill Pipe Performance SheetGarcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokumen3 halamanDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaBelum ada peringkat

- How To Form "Be Going To" Sentences: Subject Statement NegativeDokumen2 halamanHow To Form "Be Going To" Sentences: Subject Statement NegativeИнженер Луис А. ГарсиаBelum ada peringkat

- Drilling An Oil Well From Surface Drilling To CompletionDokumen9 halamanDrilling An Oil Well From Surface Drilling To CompletionИнженер Луис А. ГарсиаBelum ada peringkat

- Directional Drilling NoDokumen4 halamanDirectional Drilling NoИнженер Луис А. ГарсиаBelum ada peringkat

- B Borehole Drilling-GEOT026 4Dokumen1 halamanB Borehole Drilling-GEOT026 4Инженер Луис А. ГарсиаBelum ada peringkat

- Player Prefs 1Dokumen6 halamanPlayer Prefs 1Prabhat VishwasBelum ada peringkat

- What Will You Do About Your Homework?Dokumen3 halamanWhat Will You Do About Your Homework?Инженер Луис А. ГарсиаBelum ada peringkat

- Second Conditional Quiz.Dokumen2 halamanSecond Conditional Quiz.Инженер Луис А. ГарсиаBelum ada peringkat

- Top Drive Solutions d392001277 MKT 001Dokumen12 halamanTop Drive Solutions d392001277 MKT 001JINDAL100% (2)

- Possessive CaseDokumen1 halamanPossessive CaseИнженер Луис А. ГарсиаBelum ada peringkat

- Universidad Politecnica Del Golfo de Mexico Evidencia de Conocimiento 1 Aplicación de Evaluacion Fecha 26 de Noviembre de 2008Dokumen3 halamanUniversidad Politecnica Del Golfo de Mexico Evidencia de Conocimiento 1 Aplicación de Evaluacion Fecha 26 de Noviembre de 2008Инженер Луис А. ГарсиаBelum ada peringkat

- 15 Fun Activities To Practice Will For PredictionsDokumen3 halaman15 Fun Activities To Practice Will For PredictionsSonsaku HakufuBelum ada peringkat

- Future: Will Verb (Base Form)Dokumen4 halamanFuture: Will Verb (Base Form)Инженер Луис А. ГарсиаBelum ada peringkat

- Regular Comparatives and SuperlativesDokumen2 halamanRegular Comparatives and SuperlativesValter Pinheiro LimaBelum ada peringkat

- Regular Comparatives and SuperlativesDokumen2 halamanRegular Comparatives and SuperlativesValter Pinheiro LimaBelum ada peringkat

- Comparison (3) - As... As/than: David EricDokumen1 halamanComparison (3) - As... As/than: David EricИнженер Луис А. ГарсиаBelum ada peringkat

- Funny StoriesDokumen8 halamanFunny StoriesИнженер Луис А. ГарсиаBelum ada peringkat

- Time ContrastDokumen2 halamanTime ContrastИнженер Луис А. ГарсиаBelum ada peringkat

- Expressing Yourself 3Dokumen1 halamanExpressing Yourself 3Onufriiciuc Raluca100% (1)

- Subject + Will + 1: 1 2 3 Go Went Gone Affirmative Negative InterrogativeDokumen6 halamanSubject + Will + 1: 1 2 3 Go Went Gone Affirmative Negative InterrogativeИнженер Луис А. ГарсиаBelum ada peringkat

- 15 Fun Activities To Practice Will For PredictionsDokumen3 halaman15 Fun Activities To Practice Will For PredictionsSonsaku HakufuBelum ada peringkat

- List of Comparatives and SuperlativeDokumen7 halamanList of Comparatives and SuperlativeInga JurjuBelum ada peringkat

- African Lion (Reading)Dokumen2 halamanAfrican Lion (Reading)Инженер Луис А. ГарсиаBelum ada peringkat

- Likes and Dislikes worksheetDokumen1 halamanLikes and Dislikes worksheetИнженер Луис А. Гарсиа100% (1)

- Food DislikesDokumen1 halamanFood DislikesИнженер Луис А. ГарсиаBelum ada peringkat

- Expressing Likes and DislikesDokumen2 halamanExpressing Likes and DislikesИнженер Луис А. ГарсиаBelum ada peringkat

- Personal Information PDFDokumen1 halamanPersonal Information PDFИнженер Луис А. ГарсиаBelum ada peringkat

- Datum I VremeDokumen1 halamanDatum I VremeEli PanovaBelum ada peringkat

- Community Landmarks: Directions: Try To Write at Least Two Activities of Each Community LandmarkDokumen2 halamanCommunity Landmarks: Directions: Try To Write at Least Two Activities of Each Community LandmarkLaura CosteiuBelum ada peringkat

- Past Continuous ExerciseDokumen2 halamanPast Continuous ExerciseИнженер Луис А. ГарсиаBelum ada peringkat

- Would, Would Like, Would Love Completion ActivityDokumen1 halamanWould, Would Like, Would Love Completion ActivitySonja KostoskaBelum ada peringkat

- Tilt Up Pre Cast Cop 2003Dokumen44 halamanTilt Up Pre Cast Cop 2003akashbhedekarBelum ada peringkat

- Wong 2000Dokumen18 halamanWong 2000reddyBelum ada peringkat

- Piling GuideDokumen3 halamanPiling GuidesandycastleBelum ada peringkat

- An Overview and Validation of The Fitness-For-Service Assessment Procedures For Local Thin AreasDokumen280 halamanAn Overview and Validation of The Fitness-For-Service Assessment Procedures For Local Thin AreasCARLOS M.Belum ada peringkat

- Mechanical Engineering MaterialsDokumen57 halamanMechanical Engineering MaterialsZeeshan HameedBelum ada peringkat

- Otc 21575Dokumen7 halamanOtc 21575Mintu ChoudhuryBelum ada peringkat

- 50998335YG1M - Design of Machine Elements - II - Solution ManualDokumen80 halaman50998335YG1M - Design of Machine Elements - II - Solution ManualKetan V. JoshiBelum ada peringkat

- DRAG Chain Conveyor Design AnalysisDokumen35 halamanDRAG Chain Conveyor Design AnalysisMichael McClain80% (5)

- Snow Load SlovakiaDokumen6 halamanSnow Load Slovakiacarlosgmon2Belum ada peringkat

- Hilti HIT System - Rebar Hand OutDokumen34 halamanHilti HIT System - Rebar Hand Outmcwong_98Belum ada peringkat

- E-50 - Aeroengine Gearbox Design - BAPT 09 - P 595Dokumen6 halamanE-50 - Aeroengine Gearbox Design - BAPT 09 - P 595Nikos VaxevanidisBelum ada peringkat

- Catalogo Rod&CasingDokumen70 halamanCatalogo Rod&Casingtomas caputoBelum ada peringkat

- Maurer Seismic Protection IIDokumen23 halamanMaurer Seismic Protection IIKaren BZBelum ada peringkat

- Bs5400 DesignDokumen10 halamanBs5400 DesignMahesh Pokhrel67% (3)

- IS 2911-Part 1-Sec 3Dokumen28 halamanIS 2911-Part 1-Sec 3chandra chanduBelum ada peringkat

- Shallow Foundation CalculationDokumen5 halamanShallow Foundation CalculationSanjay BossBelum ada peringkat

- Nauticus Hull - Steel Plates UnstiffenedDokumen90 halamanNauticus Hull - Steel Plates Unstiffenedbosskoj100% (1)

- Satellite Design Course Spacecraft Configuration Structural Design Preliminary Design MethodsDokumen85 halamanSatellite Design Course Spacecraft Configuration Structural Design Preliminary Design Methodsmegustalazorra100% (1)

- Deflection of BeamsDokumen5 halamanDeflection of BeamswzpttsslBelum ada peringkat

- Introduction To Ceramic Engineering DesignDokumen457 halamanIntroduction To Ceramic Engineering DesignRaghavendra nathBelum ada peringkat

- Design Manual OverviewDokumen184 halamanDesign Manual OverviewZdravko IvancicBelum ada peringkat

- Is 2911 Part 4 2013Dokumen17 halamanIs 2911 Part 4 2013Manvendra Nigam60% (15)

- Group 10 Final ReportDokumen61 halamanGroup 10 Final ReportMohd TahaBelum ada peringkat

- OTC 17236 The New API RP 2A, 22 Edition Tubular Joint Design PracticeDokumen0 halamanOTC 17236 The New API RP 2A, 22 Edition Tubular Joint Design PracticeKrutarth Purohit0% (1)

- Chapter 1 IntroductionDokumen47 halamanChapter 1 IntroductionAli RaxaBelum ada peringkat

- 15 Yrs of Geotechnical Limit State Design in AustraliaDokumen6 halaman15 Yrs of Geotechnical Limit State Design in AustraliaJackBelum ada peringkat

- EDU COURSE SSShhhiiippp SSStttrrruuuccctttuuurrreeesss IIIIDokumen174 halamanEDU COURSE SSShhhiiippp SSStttrrruuuccctttuuurrreeesss IIIIreda redaBelum ada peringkat

- HeavyWeight 3.5 25.58lbs NC-38Dokumen3 halamanHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаBelum ada peringkat

- Stud Welding Stud and Ferrule CatalogDokumen107 halamanStud Welding Stud and Ferrule Catalogkoulis13Belum ada peringkat

- Torques FagDokumen52 halamanTorques FagAlain Gonzalo Larama CastroBelum ada peringkat