Assembly Sceme

Diunggah oleh

Anonymous sfkedkymHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Assembly Sceme

Diunggah oleh

Anonymous sfkedkymHak Cipta:

Format Tersedia

Doc. No. HMM/16/EDFC/SEUS/002 dt.

20-07-2016

STRUCTURE / EQUIPMENT ASSEMBLY SCHEME

BRIEF DETAILS OF PROJECT: BHAUPUR-KHURJA SECTION OF EASTERN

DEDICATED FREIGHT CORRIDOR-LOT - 101.

CLIENT NAME

DFCCIL

PMC

SAI-TYPSA (JV)

CONTRACTOR NAME

TATA ALDESA (JV)

SUPPLIER

HMM Infra Ltd.

This Assembly scheme is applicable to Assembly of Superstructure/ Steel

girders at various sites of EDFC project.

1. Name of the Equipment / Major Structure

: Girder Assembly

2. Weight of material to be lifted

: Ranging between

08 MT to 22 MT

Page 1 of 6

Doc. No. HMM/16/EDFC/SEUS/002 dt. 20-07-2016

HMM INFRA LTD.

TATA-ALDESA (JV)

PMC

DFCCIL

Brief description of Assembly plan :

1. Land preparation for Assembly of structures should be leveled with

compacting of GSB layer.

2. Girder Shifting Work will be done by Crane and trailer which is used at

site.

3. Trailer position as per the availability of assembling area which is used

for assembly.

4. Positioning of crane with respect to the loaded trailer of girder and

girder Unloading activity will be done under the supervision of trained

fore-man/signal man along with the trained riggers on assembling area.

5. Unloading of girder can be done manually or with cranes. Lifting nylon

or cloth belts with suitable SWL(Safe Working Load) shall be used for

unloading the materials to ensure the safe unloading. Be sure to connect

wire rope slings to component with the right no. of points and position

so that the load/dimensions of component itself do not hit/infringe the

lifting and unloading arrangements.

6. Always attach a tag line to the lifting component.

7. Girder properly mounted on MS Cribs. There are 09 Nos.MS cribs will be

used to consisting of all segments.

Page 2 of 6

Doc. No. HMM/16/EDFC/SEUS/002 dt. 20-07-2016

8. In Assembly of girders first we will start connection of segment B1G1 to

B1G2 and similarly B1G2 to B1G3 and B1G3 to B1G4 and B1G4 to B1G5.

9. Similarly we will start connection of segment B2G1 to B2G2 and

similarly B2G2 to B2G3 and B2G3 to B2G3 to B2G4 and B2G4 to B2G5.

10. After Connection of Both Assembled girders lines we will start cambering

and bolting in both girder lines as per the DRG.

11. After bolt fixing and cambering in both assembled girder line we will start

the torque tightening as per the RDSO specification.

12. Completion of Alignment and torque tightening of both girder line we will

arise inspection call to RDSO for Girder Assembly inspection.

13. All the tools and tackles shall be checked by SHE(Safety, Health and

Environmental) department before the assembly activity start. Safe

execution of the assembly activity shall be carried out in presence of

Structural Engineer of HMM/TATA-ALDESA (JV).

14. All materials receipt at site shall be visually inspected by site supervisor

for any damage. Remedial works to the damage shall be taken immediately, if

possible, to avoid any delay to erection.

Page 3 of 6

Doc. No. HMM/16/EDFC/SEUS/002 dt. 20-07-2016

HMM INFRA LTD.

TATA-ALDESA (JV)

PMC

DFCCIL

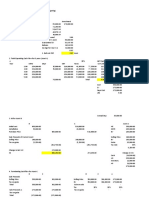

1. Crane capacity / Radius / Boom length: Load Chart for various types of

2.

3.

4.

5.

cranes (Enclosed) .

Lifting Tools and Tackles to be used.

Slings/Wire ropes 25mm dia X 06 mtrs Long 4 nos.

D-Shackles (10 ton - 04 Nos.)

Tag line: As per component dimensions shall be decided by Foreman/HMM

& Structural Engineer of TATA ALDESA ( JV ) .

6. Compare with test certificate to verify the specified limit of crane,

Slings/wire ropes.

7. Name of the persons are to be written with whom Assembly plan was

discussed and safety precautions identified- SHE In charge & Structural

Engineer/Foreman - M/s TATA ALDESA ( JV) & M/s HMM Infra Ltd.

Page 4 of 6

Doc. No. HMM/16/EDFC/SEUS/002 dt. 20-07-2016

Assembly Manager (TATA-Aldesa JV) : Mr._KK SINGH CPM LOT 101 AND

HIS NOMINATED REPRESENTATIVE._______________________

Employers Engineer Representative: Nominated officials of DFCC & PMC

(SAI TYPSA JV)

Riggers

: M/s. HMM Infra Limited

Crane /Hydra Operator

: Licensed operator from Crane supplier.

Safety Engineer Of Contractor

: Mr. Bikesh Vairagi M/s HMM Infra

Ltd.

HMM INFRA LTD.

TATA-ALDESA (JV)

Assembly plan understood by all concerned

PMC

DFCCIL

: Yes

surrounding area Proper level : Yes

Additional precautions (if any)

Crane operator and rigger shall be trained to carry out assembly operations.

Nobody should stand below the suspended load.

Guide ropes shall be used to control swing of lifted material. Use of cranes at

night shall be done with adequate illumination and communication equipment.

Page 5 of 6

Doc. No. HMM/16/EDFC/SEUS/002 dt. 20-07-2016

HMM INFRA LTD.

TATA-ALDESA (JV)

Page 6 of 6

PMC

DFCCIL

Anda mungkin juga menyukai

- Manufacturers Data Report SummaryDokumen13 halamanManufacturers Data Report SummarySaut Maruli Tua Samosir100% (4)

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualDari EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualBelum ada peringkat

- MV Cable Pulling and Installation Method StatementDokumen9 halamanMV Cable Pulling and Installation Method StatementMark Tristan Vallesteros100% (6)

- DESIGN CALCULATION OF SPILLWAY GATEDokumen11 halamanDESIGN CALCULATION OF SPILLWAY GATEramkumar121100% (5)

- Connection 1Dokumen22 halamanConnection 1Anonymous sfkedkymBelum ada peringkat

- Chassis ModificationDokumen46 halamanChassis ModificationJawahar Raj0% (1)

- 013-MS For Mass Concrete Works PDFDokumen26 halaman013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- Citizenship-Immigration Status 2016Dokumen1 halamanCitizenship-Immigration Status 2016rendaoBelum ada peringkat

- Plate GirderDokumen7 halamanPlate GirderAnonymous sfkedkymBelum ada peringkat

- Drawing Submittal FormDokumen3.989 halamanDrawing Submittal FormAhamed MinverBelum ada peringkat

- 001-MS For Structural Steel Assembly and Erection PDFDokumen28 halaman001-MS For Structural Steel Assembly and Erection PDFKöksal Patan100% (1)

- Teodoro M. Hernandez V The Honorable Commission On Audit FactsDokumen2 halamanTeodoro M. Hernandez V The Honorable Commission On Audit FactsAngela Louise SabaoanBelum ada peringkat

- IOCL Panipat CCRU Heater Revamp Toolbox Meeting RecordsDokumen30 halamanIOCL Panipat CCRU Heater Revamp Toolbox Meeting RecordsMukesh KatarnavareBelum ada peringkat

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDokumen16 halaman012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- Installation of Cranes in PS-17Dokumen18 halamanInstallation of Cranes in PS-17Ijaz Mh100% (7)

- Weekly Report on Installation of Cartridge FilterDokumen21 halamanWeekly Report on Installation of Cartridge FilterThirukkumaranBalasubramanian100% (1)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDokumen23 halaman014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanBelum ada peringkat

- BSNL FTTH Wallet GuideDokumen43 halamanBSNL FTTH Wallet GuideNarottam Narayan100% (2)

- Ownership Dispute Over Corporation's RecordsDokumen2 halamanOwnership Dispute Over Corporation's RecordsFrancisco Ashley AcedilloBelum ada peringkat

- 017-CIVIL-MS For Installation of Fence & Gate PDFDokumen18 halaman017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- NRL2TRK2102Dokumen123 halamanNRL2TRK2102Kevin Jee100% (2)

- RDSO composite girder Web and flange splice designDokumen8 halamanRDSO composite girder Web and flange splice designAnonymous sfkedkymBelum ada peringkat

- Delhi Metro Rail Launching Girder Method StatementDokumen143 halamanDelhi Metro Rail Launching Girder Method StatementRavi GuptaBelum ada peringkat

- DepEd Form 137-ADokumen2 halamanDepEd Form 137-Akianmiguel84% (116)

- Compression Design Section1Dokumen10 halamanCompression Design Section1Anonymous sfkedkymBelum ada peringkat

- Compression Design Section2Dokumen10 halamanCompression Design Section2Anonymous sfkedkymBelum ada peringkat

- 40t Rope Drum Hoist220512Dokumen37 halaman40t Rope Drum Hoist220512Anonymous sfkedkymBelum ada peringkat

- Industrial Piping and Equipment Estimating ManualDari EverandIndustrial Piping and Equipment Estimating ManualPenilaian: 5 dari 5 bintang5/5 (7)

- Technical Vol-II of II-High RiseDokumen103 halamanTechnical Vol-II of II-High Riseupesddn2010Belum ada peringkat

- Beam Cantiliever CalculationDokumen16 halamanBeam Cantiliever CalculationAnonymous sfkedkymBelum ada peringkat

- 009-Method Statement - Main Erection Sequence For Acc PDFDokumen68 halaman009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- Talampas Vs Moldex Realty Inc. DigestDokumen2 halamanTalampas Vs Moldex Realty Inc. DigestNOLLIE CALISING100% (2)

- Ameerpet Roof Document Rev A PDFDokumen360 halamanAmeerpet Roof Document Rev A PDFrajusk24Belum ada peringkat

- Mos DrainageDokumen3 halamanMos DrainageaniesbaekBelum ada peringkat

- Manila Banking Co. vs. University of BaguioDokumen2 halamanManila Banking Co. vs. University of BaguioMarianne Andres100% (2)

- Key provisions of the Philippine Civil Code on laws and jurisprudenceDokumen7 halamanKey provisions of the Philippine Civil Code on laws and jurisprudenceIzay NunagBelum ada peringkat

- 20.312 D02 Rev 01 Design BriefDokumen17 halaman20.312 D02 Rev 01 Design BriefSarah PerezBelum ada peringkat

- 004-MS For Earthing System PDFDokumen10 halaman004-MS For Earthing System PDFKöksal PatanBelum ada peringkat

- LTE CS Fallback (CSFB) Call Flow Procedure - 3GLTEInfoDokumen10 halamanLTE CS Fallback (CSFB) Call Flow Procedure - 3GLTEInfoClive MangwiroBelum ada peringkat

- T11M408 I1 Takraf 03910 Vdcme02 P1me01 004Dokumen42 halamanT11M408 I1 Takraf 03910 Vdcme02 P1me01 004manuelarranoBelum ada peringkat

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDokumen18 halaman012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanBelum ada peringkat

- Specification Gp-217 271104Dokumen113 halamanSpecification Gp-217 271104Sunil JadhavBelum ada peringkat

- Submission of Method Statement For Prestressing Works For T-Girder (Rev-01) From Dynamic Prestress Projects & Services Pvt. LTDDokumen50 halamanSubmission of Method Statement For Prestressing Works For T-Girder (Rev-01) From Dynamic Prestress Projects & Services Pvt. LTDDinesh ChoudharyBelum ada peringkat

- Strict Shunting Rules DriveDokumen2 halamanStrict Shunting Rules DriveB.m. SanthoshBelum ada peringkat

- 2018.05.29 - 04-05-31et 0017Dokumen81 halaman2018.05.29 - 04-05-31et 0017mankari.kamal.18022963Belum ada peringkat

- Draft P.O - TCC After Modify - 01Dokumen5 halamanDraft P.O - TCC After Modify - 01Ehab ShataBelum ada peringkat

- Fiberstrong Wavistrong Flange GuideDokumen52 halamanFiberstrong Wavistrong Flange Guidemuhammedemraan100% (1)

- Technical Agenda - Bim - 2019 PDFDokumen13 halamanTechnical Agenda - Bim - 2019 PDFa k singhBelum ada peringkat

- CT PT Marshalling BoxesDokumen19 halamanCT PT Marshalling BoxesBoddu ThirupathiBelum ada peringkat

- Rashtriya Ispat Nigam Limited (A Government of India Enterprise)Dokumen11 halamanRashtriya Ispat Nigam Limited (A Government of India Enterprise)Devi ChaitanyaBelum ada peringkat

- Raju Jayshankar 5Dokumen9 halamanRaju Jayshankar 5sujaraghupsBelum ada peringkat

- SOP Trial StretchDokumen4 halamanSOP Trial StretchashutoshpathakcivilBelum ada peringkat

- Field Attachment Report: HELD ON 04.06.18 TO 07.06.18 Team Name: MeghnaDokumen42 halamanField Attachment Report: HELD ON 04.06.18 TO 07.06.18 Team Name: MeghnaZahidul Islam AumiBelum ada peringkat

- CP Post RelocationDokumen2 halamanCP Post RelocationamitlalyanBelum ada peringkat

- Rail, sleeper and fastenings document summaryDokumen48 halamanRail, sleeper and fastenings document summaryShipra MishraBelum ada peringkat

- 03Dokumen4 halaman03SURJIT SINGHBelum ada peringkat

- DSL Car InspectionDokumen78 halamanDSL Car InspectionJanardan RamekarBelum ada peringkat

- Letter No1103Dokumen3 halamanLetter No1103Raju GambhirBelum ada peringkat

- KKJ-HRI Inspection NoteDokumen4 halamanKKJ-HRI Inspection NoteVijay GargBelum ada peringkat

- 2014 C3.1 ECC3 Employers Works InformationDokumen11 halaman2014 C3.1 ECC3 Employers Works InformationGunadevan ChandrasekaranBelum ada peringkat

- Scope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDokumen9 halamanScope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDevang PatelBelum ada peringkat

- Mom 1Dokumen1 halamanMom 1Sagar TaleBelum ada peringkat

- Use of Alternative Materials and Technology For Roads PDFDokumen10 halamanUse of Alternative Materials and Technology For Roads PDFDwijendra ChanumoluBelum ada peringkat

- SOW Medium-Voltage Equipment 2024.01.02Dokumen7 halamanSOW Medium-Voltage Equipment 2024.01.02Christian BernalBelum ada peringkat

- Rate Contract for Mechanical and Electrical Works for CNG Stations in Multiple StatesDokumen417 halamanRate Contract for Mechanical and Electrical Works for CNG Stations in Multiple StatesTenders TGSPLBelum ada peringkat

- TEFDDokumen25 halamanTEFDRahadian Dwi PutraBelum ada peringkat

- Guidance on Installation of Barriers at Emergency and Contingency CrossingsDokumen11 halamanGuidance on Installation of Barriers at Emergency and Contingency CrossingsDanny LamBelum ada peringkat

- LCC Basement Formwork SystemDokumen59 halamanLCC Basement Formwork SystemgabuchiaBelum ada peringkat

- Safe WorkingDokumen22 halamanSafe Workingromvos8469Belum ada peringkat

- Gepco Inspection Certificate STG18-35Dokumen3 halamanGepco Inspection Certificate STG18-35Farhan IlyasBelum ada peringkat

- SA PaintingDokumen11 halamanSA PaintingParameswararao BillaBelum ada peringkat

- Vol III of III BGL Kakinada 1Dokumen69 halamanVol III of III BGL Kakinada 1dileepciplBelum ada peringkat

- SSR 2013-2014Dokumen361 halamanSSR 2013-2014vanamgoutham100% (1)

- Longwall Mining at Shallow Depth of Cover in IndiaDari EverandLongwall Mining at Shallow Depth of Cover in IndiaBelum ada peringkat

- Steel Structures Design Based on Eurocode 3Dari EverandSteel Structures Design Based on Eurocode 3Penilaian: 3 dari 5 bintang3/5 (1)

- Regards, Puneet Sharda Manager (Design) 9729036767 HMM INFRA LTD (Ambala)Dokumen1 halamanRegards, Puneet Sharda Manager (Design) 9729036767 HMM INFRA LTD (Ambala)Anonymous sfkedkymBelum ada peringkat

- Design of Optimum Cross Section For EOT Crane GirderDokumen5 halamanDesign of Optimum Cross Section For EOT Crane GirderAshok SharmaBelum ada peringkat

- FootingDokumen10 halamanFootingAnonymous sfkedkymBelum ada peringkat

- SXDCFDokumen104 halamanSXDCFAnonymous sfkedkymBelum ada peringkat

- 12345Dokumen7 halaman12345Anonymous sfkedkymBelum ada peringkat

- Design v. PasteDokumen4 halamanDesign v. PasteAnonymous sfkedkymBelum ada peringkat

- Tsati Penstock DesignDokumen48 halamanTsati Penstock DesignAnonymous sfkedkymBelum ada peringkat

- Calories Protine Break Fast 4 Eggs 68 14.4 Milk 150 9.75 Rusk 135Dokumen1 halamanCalories Protine Break Fast 4 Eggs 68 14.4 Milk 150 9.75 Rusk 135Anonymous sfkedkymBelum ada peringkat

- Compression Design Section 3Dokumen8 halamanCompression Design Section 3Anonymous sfkedkymBelum ada peringkat

- BEAMDokumen7 halamanBEAMAnonymous sfkedkym100% (1)

- Compression Design Section1Dokumen10 halamanCompression Design Section1Anonymous sfkedkymBelum ada peringkat

- Design of tension member axial load analysisDokumen8 halamanDesign of tension member axial load analysisAnonymous sfkedkymBelum ada peringkat

- Calculations of Moment of Inertia Comp. Width Depth X-Datum Y-DatumDokumen7 halamanCalculations of Moment of Inertia Comp. Width Depth X-Datum Y-DatumAnonymous sfkedkymBelum ada peringkat

- Plate GirderDokumen12 halamanPlate GirderAnonymous sfkedkymBelum ada peringkat

- Compression Design Section1Dokumen10 halamanCompression Design Section1Anonymous sfkedkymBelum ada peringkat

- Tension Designwith Bat Section1Dokumen11 halamanTension Designwith Bat Section1Anonymous sfkedkymBelum ada peringkat

- Forces in CGDokumen2 halamanForces in CGAnonymous sfkedkymBelum ada peringkat

- Plate GirderDokumen12 halamanPlate GirderAnonymous sfkedkymBelum ada peringkat

- Compression Design Section 3Dokumen8 halamanCompression Design Section 3Anonymous sfkedkymBelum ada peringkat

- Design of tension member axial load analysisDokumen8 halamanDesign of tension member axial load analysisAnonymous sfkedkymBelum ada peringkat

- Stageing Design - TowerDokumen25 halamanStageing Design - TowerAnonymous sfkedkymBelum ada peringkat

- Chapter 6Dokumen46 halamanChapter 6Anonymous sfkedkymBelum ada peringkat

- (RBI) OdtDokumen2 halaman(RBI) OdtSheethal HGBelum ada peringkat

- Tohfa e Ithna Ashariyya - 2 (Urdu) by Sheikh Shah Abdul Aziz Dehlvi (R.a)Dokumen418 halamanTohfa e Ithna Ashariyya - 2 (Urdu) by Sheikh Shah Abdul Aziz Dehlvi (R.a)Musalman Bhai100% (1)

- PNB V CADokumen7 halamanPNB V CAAriana Cristelle L. PagdangananBelum ada peringkat

- Introduction to Investment and SecuritiesDokumen27 halamanIntroduction to Investment and Securitiesanandhi_jagan0% (1)

- Materi 5: Business Ethics and The Legal Environment of BusinessDokumen30 halamanMateri 5: Business Ethics and The Legal Environment of BusinessChikita DindaBelum ada peringkat

- Lecture Powerpoints: Physics For Scientists and Engineers, With Modern Physics, 4 EditionDokumen29 halamanLecture Powerpoints: Physics For Scientists and Engineers, With Modern Physics, 4 EditionKhawla MustafaBelum ada peringkat

- BC t?ng tr??ng User Internet Banking có g?n TK TGTT- Xu?t chi ti?tDokumen12 halamanBC t?ng tr??ng User Internet Banking có g?n TK TGTT- Xu?t chi ti?tMy TruongBelum ada peringkat

- Daan vs. SandiganbayanDokumen7 halamanDaan vs. SandiganbayanDeric MacalinaoBelum ada peringkat

- Tutang Sinampay:: Jerzon Senador Probably Wants To Be Famous and Show The World How Naughty He Is by Hanging HisDokumen2 halamanTutang Sinampay:: Jerzon Senador Probably Wants To Be Famous and Show The World How Naughty He Is by Hanging HisClaire Anne BernardoBelum ada peringkat

- Grace Christian High School's Right to Board Seat UpheldDokumen7 halamanGrace Christian High School's Right to Board Seat UpheldPaul Joshua SubaBelum ada peringkat

- Criminal Revision 11 of 2019Dokumen2 halamanCriminal Revision 11 of 2019wanyamaBelum ada peringkat

- Diplomacy settings and interactionsDokumen31 halamanDiplomacy settings and interactionscaerani429Belum ada peringkat

- Esguerra ReviewerDokumen130 halamanEsguerra Reviewerdiane1984100% (1)

- Daniel Nyandika Kimori v V A O minor suit negligence caseDokumen2 halamanDaniel Nyandika Kimori v V A O minor suit negligence casevusBelum ada peringkat

- Meredith WhitneyDokumen13 halamanMeredith WhitneyFortuneBelum ada peringkat

- FNDWRRDokumen2 halamanFNDWRRCameron WrightBelum ada peringkat

- Immanuel Sangcate ResumeDokumen2 halamanImmanuel Sangcate ResumeNonjTreborTendenillaToltolBelum ada peringkat

- ABL Internship ReportDokumen36 halamanABL Internship ReportMubasher Ciit100% (2)

- United States v. Walter Swiderski and Maritza de Los Santos, 548 F.2d 445, 2d Cir. (1977)Dokumen9 halamanUnited States v. Walter Swiderski and Maritza de Los Santos, 548 F.2d 445, 2d Cir. (1977)Scribd Government DocsBelum ada peringkat

- AE 315 FM Sum2021 Week 3 Capital Budgeting Quiz Anserki B FOR DISTRIBDokumen7 halamanAE 315 FM Sum2021 Week 3 Capital Budgeting Quiz Anserki B FOR DISTRIBArly Kurt TorresBelum ada peringkat

- Constraint Manager User's Manual: Release PADS VX.2.7Dokumen228 halamanConstraint Manager User's Manual: Release PADS VX.2.7Mokorily PalmerstonBelum ada peringkat