Diagnostic of CNC Lathe

Diunggah oleh

Rudolf-Laszlo KalmarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Diagnostic of CNC Lathe

Diunggah oleh

Rudolf-Laszlo KalmarHak Cipta:

Format Tersedia

Advances in Science and Technology

Research Journal

Volume 9, No. 28, Dec. 2015, pages 96102

Research Article

DOI: 10.12913/22998624/60793

DIAGNOSTIC OF CNC LATHE WITH QC 20 BALLBAR SYSTEM

Jerzy Jzwik1, Leszek Semotiuk1, Ivan Kuric2

1

Department of Production Engineering, Mechanical Engineering Faculty, Lublin University of Technology,

Nadbystrzycka Str. 36, 20-618 Lublin, Poland, e-mail: j.jozwik@pollub.pl

Department of Automation and Production Systems, Faculty of Mechanical Engineering, University of ilina,

Univerzitn Str. 1, 010-26 ilina, Slovakia, e-mail: ivan.kuric@fstroj.utc.sk

Received: 2015.09.21

Accepted: 2015.11.14

Published: 2015.12.04

ABSTRACT

This paper presents the evaluation of the influence of the feedmotion speed on the

value of selected geometric errors of CNC lathe CTX 310 eco by DMG, indentified by QC 20 Ballbar system. Diagnostically evaluated were: the deviation of the

axis squareness, reversal spike, and backlash. These errors determine the forming

of the dimensional and shape accuracy of a machine tool. The article discusses

the process of the CNC diagnostic test, the diagnostic evaluation and formulates

guidelines on further CNC operation. The results of measurements were presented

in tables and diagrams.

Keywords: CNC machine tool, CNC Lathe QC 20 Ballbar, diagnostics systems, accuracy, geometric errors, deviation, squareness, reversal spike, backlash.

INTRODUCTION

The diagnostics of CNC machines is the main

task during the technological machine operation.

Each machine tool during operation is prone to

wearing down over a time span. Therefore, it

should be tested periodically and its geometric condition diagnosed at a required frequency.

Both the machines already in operation as well

as the machines ordered by buyers are diagnosed.

Each such machine is tested and checked before

it arrives at the customers. Both contact and noncontact methods are used in tests [110]. Frequently, some of the measured errors need specialist testing methods, and in general, these are

non-contact interferometric methods. The fundamental limitation of the stationary interferometric methods in the machine measurements is the

considerable time amount needed to set the interferometers optics, especially for the machines

of a tooling range over a few meters. The possibility of measuring the whole tooling axis and

obtaining error information at the full range motion [15] constitutes an undisputable advantage.

The second group of diagnostic tools are the tools

96

based on contact measurements. QC 20 Ballbar or

Ballbar API Automated Precision Inc. or Ballbar

DBB 110 by DMG are the examples of contact

diagnostics and measurement systems (Fig. 1).

They enable recording the technical condition of machine tools, comparing and classifying

various machine tools according to their capacity

of providing required tooling precision. It is particularly essential in production companies with

a big machine park because it allows moving the

machining tasks of high-precision products to the

machines which enable such high dimensional

and shape accuracy [915].

RESEARCH METHODOLOGY AND

EXPERIMENTAL TESTS

Experimental tests were conducted for CNC

CTX 310 eco by DMG (Fig. 2). During the testing

the diagnostic system QC 20 Ballbar was used

norm defined as telescoping kinematic bar (Fig. 3).

Tests were conducted according to PN-ISO

230-4 standard. PN-ISO 230-4:1999 regulates

CNC diagnostics according to roundness mea-

Advances in Science and Technology Research Journal Vol. 9 (28), 2015

a)

b)

c)

Fig. 1. CNC diagnostic systems: a) QC 20 Ballbar Renishaw, b) Ballbar API Automated Precision Inc.

c) Ballbar DBB 110 by DMG [616]

Fig. 2. Test stand, CTX 310 eco lathe by DMG

Fig. 3. QC 20 Ballbar diagnostic tool (kinematic telescoping bar)

surement in numerically controlled machine tools

with the kinematic telescoping bar. The significant value was the feedmotion speed vf. The value

of the feedmotion speed was changed in the range

of 500-2000 mm/min. The measurement results

of particular errors were presented as diagrams.

Figure 4 presents QC 20 Ballbar measuring planes. These planes are universal, and after

transformation are used with reference to CNC

lathes. Figure 5 presents the experimental test on

analysed CNC and the lathe kit of QC 20 Ballbar.

Analysed errors: squareness deviation of

CNC CTX 310 eco axis, reversal spike and back-

lash. During the identification of the squareness

deviation of axis the diagnostic diagram takes

the shape of the oval or the shape of a peanut

rotated aslant at a 45 or 135 angle. The axis

of the deviation of the diagram is the same for

both directions of the circular interpolation cycle,

clockwise as well as anticlockwise. The unit of

the squareness error, mm/m, can be in the case

of Renishaw software operating QC 20 Ballbar

changed into any different unit in the test result

(such as: angle in degrees, seconds, micrometre/

foot, micrometre/millimetre) by the proper setting of software parameters. The squareness er-

97

Advances in Science and Technology Research Journal Vol. 9 (28), 2015

a)

b)

c)

Fig. 4. QC 20 Ballbar measuring planes

a)

b)

Fig. 5. CNC lathe diagnostics kit: a) tool holder and the holder spindle, b) system mounted on the lathe

ror takes positive values when the angle between

two axes in the positive direction is over 90. The

squareness error takes negative values when the

angle between two axes in their positive direction

is less than 90. The reason for the squareness error is the deviation of the direction of tested lathe

axes (e.g. X and Y) from the right angle 90 in the

area of lathes slideways, where the test is conducted. The deviation of the axis squareness can

be of local character or may be the result of the

non-misalignment of the lathes slideways over

the whole length of axis. The lathes axes can also

show distortion in the vertical plane (concave,

convex or slope), causing local misalignments.

The slideways may show excessive wear causing

an increase of excessive backlash during motion.

The effect of the lathes squareness error is the

lack of mutual squareness of the milled planes.

The repair procedure requires the repetition of the

test in positions along the slideways of the machine tool in order to determine if the squareness

error is local (occurs only in one position) or if it

occurs along the whole length of the slideways.

If the error is local, it is necessary for machining to be conducted in the area of the slideways,

where the influence of the squareness error is the

smallest. If the slideways show the squareness er-

98

ror along the whole length, the correction of the

slideways setting should be made, if possible.

When the slideways are defective, it is necessary

to replace them with new ones.

TEST RESULTS AND ANALYSIS

Analysis of squareness error measurement results with characteristics

Figure 6 presents the graph of the squareness

error of axis. The graph takes the shape of an oval

inclined at an angle of +45 or 45 in relation to

X-axis. The inclination is constant and does not

change as a result of the change of movement direction [14]. Its variability depends on the feedmotion speed. To determine this error the diagnostic device QC Ballbar with the kinematic bar

length R = 50 was used.

Figure 7 shows the dependence of changes

of the squareness deviation as a function of the

feedmotion speed vf for the kinematic bar R =

50 mm. The smallest value was observed for

the feedmotion speed vf1 = 500 mm/min and is

66.2 m/m, then for vf2 = 1000 mm/min equals

83.2 m/m, the third measurement for vf3 = 1500

mm/min is 78.4 m/m, and the highest value

Advances in Science and Technology Research Journal Vol. 9 (28), 2015

Fig. 7. Changes of squareness error (circle radius

R = 50 mm) as function of feedmotion speed vf

Fig. 6. Example of squareness error diagram [14]

for the feedmotion speed vf4 = 2000 mm/min and

equals 83.6 m/m. The graphically presented

characteristic shows that the squareness error is

of non-linear character in relation to the feedmotion speed.

Analysis of reverse spike error measurements

The reverse spike error occurs when the direction changes. The main reason for the error is

too slow a response from the servo drive to the

control system signal in the case of the direction

change. The pie chart diagram presents it as a

temporary leap of deviation, Figure 8 [14].

During the reversal spike error identification

the QC Ballbar diagnostics system with the kinematic bar R = 50 mm was used.

Figure 9 presents the process of changes of

the reversal spike as a function of variable feedmotion speed vf. The reversal spike in the Z-axis

for the requested values of the motion is equal

respectively, for vf1 = 500 mm/min is 0.2 m;

for vf2 = 1000 mm/min is 0.7 m; for vf3 = 1500

mm/min equals 2.5 m; for vf4 = 2000 mm/min

is 3.7 m. It can be stated that the decrease of

the value of the reversal spike in Z-axis is almost

directly proportional to the increase of the feedmotion speed. In X-axis the values of the reversal

spike are of sinusoidal character and are almost

equivalent, as they equal respectively: 1.8 m

(for vf1 = 500 mm/min), 2.1 m (for vf2 = 1000

mm/min), 1.9 m (for vf3 = 1500 mm/min), 2.0

m (for vf4 = 2000 mm/min).

The analysis of the backlash measurement

results

Figure 10 presents the dependence of the

backlash on the feedmotion speed. During the circular interpolation, the backlash can be observed

in the pie chart as a leap of the motion radius inside out or inside of the curve. This error is caused

by the backlash in the drive system of the lathe or

in the measuring system, or due to the insufficient

inflexibility of both. The most frequent reasons for

this error are: the backlash in the screw-cap link,

backlash in the gear train of the motor system or

the wrong strain of the toothed belt. When the direction of motion changes, one of the axes begins

the motion with delay (Fig. 10). This error is ob-

Fig. 8. Reverse spike error diagram: a) process of circle measurement of reverse spike,

b) idea of error formation [14]

99

Advances in Science and Technology Research Journal Vol. 9 (28), 2015

the QC Ballbar diagnostics system with the kinematic bar length R = 50 mm was used.

Figure 11 presents the diagram of changes of

the backlash as a function of feedmotion speed

variability. The diagram shows that the backlash

is of non-linear character. The smallest value for

the backlash in X-axis was observed for vf3 =

1500 mm/min and is 1 m, and for Z-axis for vf2

= 1000 mm/min and equals 1.9 m.

Fig. 9. Dependence of reversal spike as function of

feedmotion speed variability in XZ plane

of CNC lathe CTX 310 eco by DMG

served specifically in lathes with indirect measuring system. To delete the error it is necessary to

remove the cause, that is to delete the backlashes

in the measurement or motor system. It is also

possible to compensate for the backlash directly

in the control system of the lathe but it requires

thorough measurement of the positioning accuracy along the entire length of the axis feedmotion

[14]. During the reversal spike error identification

CONCLUSIONS

The presented test results of the geometric accuracy relate to the numerically controlled CTX

310 eco lathe. QC20-W Ballbar diagnostic kit

was the measuring and control device. The tests

aimed at defining and characterising main geometric errors of the machine tool, i.e. roundness

error, axis squareness error, reverse spike and

backlash. Numerous different errors measurements may be carried out using QC20-W Ballbar

system. However, the errors analysed here, have

the greatest impact on the dimensional and shape

accuracy of machining.

Fig. 10. Schematic example of backlash: a) error diagram, b) reason for error formation [14]

Fig. 11. Backlash as function of feedmotion speed for: measuring radius R = 50 mm,

XZ measurement plane and test angle of 360

100

Advances in Science and Technology Research Journal Vol. 9 (28), 2015

The feedmotion speed increase influences

the value of the roundness deviation variable, the

higher the feedmotion speed, the higher the value

of the deviation. In the presented example, for

three feedmotion speeds vf1 = 500 mm/min, vf2 =

1000 mm/min, vf4 = 2000 mm/min the value of

the roundness error increases slightly and equals:

11.1 m, 11.3 m and 11.6 m respectively.

However, for the adopted feedmotion speed vf3 =

1500 the local growth of deviation of up to 13.6

m takes place, disrupting the linearity of results.

This deviation tendency might be caused by local

errors of the measuring and control lathe systems.

The squareness error is the second error identified by QC20-W Ballbar system of CTX 310 eco

lathe. Figure 7 shows the summary of the results.

The presented characteristics show non-linear

character of changes of the squareness error value

as a function of the feedmotion speed vf.

During the next error identification the reversal spike it was noted that the increase of

the feedmotion speed is in line with the increasing value of the reversal spike in Z-axis. The

value of the reversal spike in X-axis remains

almost the same. In X-axis the process is of

non-linear character and in Z-axis linear (Fig. 9).

The backlash is the next presented error.

Figure 11 presents the dependence of the backlash value as a function of the feedmotion speed

variability. The given characteristics show

non-linear character of the tested function. The

diversity of the backlash test results did not show

the dependence of the feedmotion speed and the

test results.

The errors and the deviations occurring in

machine tools constitute a very important issue

because they result in the lathes tooling accuracy

and therefore, the quality and precision of machining a particular product.

It can be stated, on the basis of test results,

that the roundness deviation depends on the feedmotion speed. To minimise its negative influence

on the machine tool performance the reduction

of the remaining errors is necessary, as well as

making sure if the appropriate motor regulation

was set and if the control disruptions do not occur. The reversal spike depends also on the feedmotion speed and, as it results from the Z-axis

tests, it changes linearly. It also has a significant

influence on the value of the roundness deviation.

The reversal spike may be the result of the control system defect and a great delay in the servo

drive response. The backlash does not depend on

the feedmotion speed. It can result from an incorrect motor regulation, inter alia, wrongly selected

backlashes, as well as the backlashes resulting

from the lathes elements wear. The squareness

stems from the misalignment of the slideways

relative to each other, as well as their wear and

deformation. In order to avoid the error increase

it is necessary to control the slideways condition

and the correction of their alignment.

CTX 310 eco lathe meets expectations, however, it is hard to state it clearly for the reason that

the working area of the machine tool is limited. It

prevents more tests using various length of the kinematic bar, and therefore, the measurement had

to be made at one measurement position.

REFERENCES

1. Du Z.C., Hong C.F. Lv M.S.: Research or error

moddeling end identification of 3 axis NC machine

tools based on cross grind encored measurement.

Journal of Physics, Conf. Ser. 48, 2006, 91100.

2. Florussen G.H.J., Delbressine F.L.M.: Molengraft

M.J.G., Schellekens P.H.J. Assessing geometrical

errors of multi-axis machines by three-dimensional length measurements. Measurement, 30, 2001,

241255.

3. Honczarenko J., Kwaniewicz J.: Nowe systemy

pomiarowe do sprawdzania obrabiarek CNC. Mechanik, 12, 2008, 10121016.

4. Ibaraki S., Iritani T., Matsushita T.: Error map construction for rotary axes on five-axis machine tools

by on-the-machine measurement using a touchtrigger probe. International Journal of Machine

Tools and Manufacture, 68, 2013, 2129.

5. Ibaraki S., Irutani T., Matsushita T.: Calibration

of location errors of rotary axes on five-axis machine tools by on-the-machine measurement using

a touch-trigger probe. International Journal of Machine Tools and Manufacture, 58, 2012, 4453.

6. Jzwik J.: Ocena odchyki prostopadoci osi obrabiarki sterowanej numerycznie z wykorzystaniem

systemu diagnostycznego QC10 Ballbar. Postpy

Nauki i Techniki, 4, 2010, 91102.

7. Jzwik J., Kuric I.: Calibration of 5-axis CNC machine tool by using 3D quickSET measurement

system (In print).

8. Jzwik J., Pieko P., Krajewski G. Ocena testu

QC10 do kontroli off-line obrabiarek sterowanych

numerycznie CNC. Eksploatacja i Niezawodno,

3, 2010, 1020.

9. Majda P.: Pomiary i kompensacja bdw geometrycznych obrabiarek CNC. Inynieria Maszyn, 16

(1-2), 2011, 126134.

101

Advances in Science and Technology Research Journal Vol. 9 (28), 2015

10. Majda P.: The influence of geometric errors compensation of a CNC machine tool on the accuracy

of movement with circular interpolation. Adv. in

Manufact. Sci. and Technol., 36 (2), 2012, 5967.

11. Morek R.: Pomiary bezstykowe. Metale & Nowe

Technologie, nr 5, 2012.

12. Spaan1 H.A.M., Florussen G.H.J.: Determining

the 5-axes machine tool contouring performance

with dynamic R-Test measurements. Proceedings

102

of the 12th Euspen International Conference. IBS

Precision Engineering, Stockholm, June 2012.

13. Turek P., Kwany W., Jdrzejewski J.: Zaawansowane metody identyfikacji bdw obrabiarek. Inynieria Maszyn, 5 (1-2), 2010, 837.

14. Weikert S.: R-Test, a new device of accuracy measurements on five axis machine tools. CIRP Annales, 53 (1), 2004, 429.

15. http://www.renishaw.com.pl/pl/, access: 15.04.2015

Anda mungkin juga menyukai

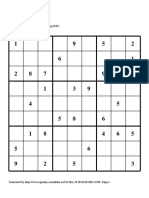

- Puzzle 1 (Medium, Difficulty Rating 0.51)Dokumen5 halamanPuzzle 1 (Medium, Difficulty Rating 0.51)Rudolf-Laszlo KalmarBelum ada peringkat

- Harmony Xb5 Xb5aw73731m5Dokumen5 halamanHarmony Xb5 Xb5aw73731m5Rudolf-Laszlo KalmarBelum ada peringkat

- Puzzle 1 (Hard, Difficulty Rating 0.71)Dokumen5 halamanPuzzle 1 (Hard, Difficulty Rating 0.71)Rudolf-Laszlo KalmarBelum ada peringkat

- Tooling Examples PDFDokumen15 halamanTooling Examples PDFRudolf-Laszlo KalmarBelum ada peringkat

- Puzzle 1 (Hard, Difficulty Rating 0.68) Puzzle 2 (Hard, Difficulty Rating 0.63)Dokumen18 halamanPuzzle 1 (Hard, Difficulty Rating 0.68) Puzzle 2 (Hard, Difficulty Rating 0.63)Rudolf-Laszlo KalmarBelum ada peringkat

- Puzzle 1 (Hard, Difficulty Rating 0.65) Puzzle 2 (Hard, Difficulty Rating 0.61)Dokumen18 halamanPuzzle 1 (Hard, Difficulty Rating 0.65) Puzzle 2 (Hard, Difficulty Rating 0.61)Rudolf-Laszlo KalmarBelum ada peringkat

- Puzzle 1 (Hard, Difficulty Rating 0.67) Puzzle 2 (Hard, Difficulty Rating 0.60)Dokumen18 halamanPuzzle 1 (Hard, Difficulty Rating 0.67) Puzzle 2 (Hard, Difficulty Rating 0.60)Rudolf-Laszlo KalmarBelum ada peringkat

- Dimensiuni rulmenti-SKFDokumen964 halamanDimensiuni rulmenti-SKFnincrisBelum ada peringkat

- Puzzle 1 (Hard, Difficulty Rating 0.70) Puzzle 2 (Hard, Difficulty Rating 0.62)Dokumen18 halamanPuzzle 1 (Hard, Difficulty Rating 0.70) Puzzle 2 (Hard, Difficulty Rating 0.62)Rudolf-Laszlo KalmarBelum ada peringkat

- Puzzle 1 (Hard, Difficulty Rating 0.63) Puzzle 2 (Hard, Difficulty Rating 0.63)Dokumen17 halamanPuzzle 1 (Hard, Difficulty Rating 0.63) Puzzle 2 (Hard, Difficulty Rating 0.63)Rudolf-Laszlo KalmarBelum ada peringkat

- Puzzle 1 (Hard, Difficulty Rating 0.61) Puzzle 2 (Hard, Difficulty Rating 0.63)Dokumen18 halamanPuzzle 1 (Hard, Difficulty Rating 0.61) Puzzle 2 (Hard, Difficulty Rating 0.63)Rudolf-Laszlo KalmarBelum ada peringkat

- Is Generated by Solidcam. For Fanuc 18Mb Is Added by YouDokumen1 halamanIs Generated by Solidcam. For Fanuc 18Mb Is Added by YouRudolf-Laszlo KalmarBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Common G Codes and M Codes For CNC Machine ControlsDokumen2 halamanCommon G Codes and M Codes For CNC Machine ControlsVidyut KumarBelum ada peringkat

- Workshop Technology (JJ104) ExerciseDokumen4 halamanWorkshop Technology (JJ104) Exerciseadib1991Belum ada peringkat

- Commutator Under CuttersDokumen17 halamanCommutator Under Cutterssalekojic5332Belum ada peringkat

- ISRO Previous Paper 2007Dokumen11 halamanISRO Previous Paper 2007Kshitija50% (2)

- ROTALIGN-Ultra Straightness ALI 209-848!08!06 1.13 GDokumen68 halamanROTALIGN-Ultra Straightness ALI 209-848!08!06 1.13 GYOJuancaBelum ada peringkat

- Lathe Operators Manual 96-8900 Rev A English January 2014Dokumen458 halamanLathe Operators Manual 96-8900 Rev A English January 2014coyoteassasin0% (1)

- KatalogDokumen6 halamanKatalogMawan BentzBelum ada peringkat

- Manufacturing - Engg Lab Vendor Details For Limited TenderingDokumen9 halamanManufacturing - Engg Lab Vendor Details For Limited TenderingÐrSúÿôg JhavarBelum ada peringkat

- Machine Tools Stock ListDokumen12 halamanMachine Tools Stock ListMuhammad NadeemBelum ada peringkat

- Machining: Workshop Practice ME-105Dokumen20 halamanMachining: Workshop Practice ME-105Mazahir habibBelum ada peringkat

- Newall C70Dokumen17 halamanNewall C70LeonardBelum ada peringkat

- Phu Tung YokeDokumen19 halamanPhu Tung YokeAnh TranBelum ada peringkat

- Thermal Spray Procedures For OHT and WTS Rear Wheel - Bearing BoresDokumen14 halamanThermal Spray Procedures For OHT and WTS Rear Wheel - Bearing Boresalan gonzalezBelum ada peringkat

- SINUMERIK 840D SL / 828D Attached Siemens Cycle Packages For SW 4.7 SP6Dokumen13 halamanSINUMERIK 840D SL / 828D Attached Siemens Cycle Packages For SW 4.7 SP6Жалолдин КимсанбоевBelum ada peringkat

- Countersink, Counterbore & SpotfaceDokumen8 halamanCountersink, Counterbore & SpotfaceŤhe Đûke100% (1)

- Chapter 13Dokumen22 halamanChapter 13RohitGupta0% (1)

- Lathe AccessoriesDokumen63 halamanLathe AccessoriesMohammed Rehan0% (1)

- "Design & Fabrication of Three Roll Bending Machine": Ir@AiktcDokumen58 halaman"Design & Fabrication of Three Roll Bending Machine": Ir@AiktcUnited DesignersBelum ada peringkat

- Machine Design Final Coaching Shuffled 1Dokumen385 halamanMachine Design Final Coaching Shuffled 1Ariel Mark Pilotin90% (10)

- Mechanical EnggDokumen81 halamanMechanical Engghaqjmi100% (2)

- Clearance and PreloadDokumen12 halamanClearance and PreloadcuccuaciaBelum ada peringkat

- Lathe DesignDokumen450 halamanLathe DesignOptimist8100% (13)

- Manufacturing ProcessesDokumen4 halamanManufacturing ProcessesVishal BangarBelum ada peringkat

- Inhouse MD 2017 4bbhDokumen100 halamanInhouse MD 2017 4bbhTempla KentBelum ada peringkat

- Programming (Beginner) #11Dokumen77 halamanProgramming (Beginner) #11MaisaGamePlays Wolff100% (1)

- Shubham SalunkheDokumen14 halamanShubham Salunkheप्रथमेश क्षीरसागरBelum ada peringkat

- Taper Turning PDFDokumen10 halamanTaper Turning PDFMaria Mehar0% (1)

- The Lathe MachineDokumen1 halamanThe Lathe MachineJamal RamseyBelum ada peringkat

- PD 250e PDFDokumen26 halamanPD 250e PDFBL LBelum ada peringkat

- D6078Dokumen9 halamanD6078rimi7alBelum ada peringkat