Cost Reduction Techniques in Press Part Production

Diunggah oleh

ramanamurtytv7176Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cost Reduction Techniques in Press Part Production

Diunggah oleh

ramanamurtytv7176Hak Cipta:

Format Tersedia

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

Study and Analysis of Cost Reduction Techniques

in Press Part Production: A Case Study of Stamping

Unit

Anuroop Athalye1, Pankaj Gera2, Dr. A.R. Madan3

1

Department of Mechanical Engineering. MITS, Ujjain (M.P.), India

Associate Professor, Mechanical Engineering, MITS, Ujjain (M.P.), India

Workshop Superintendent, Ujjain Engineering College, Ujjain (M.P.), India

Abstract: In this paper, industrial engineering and management tools like TQM, TPM, JIT, Value Analysis & Value Engineering,

Lean manufacturing, Kaizen etc. have been studied and analyzed for cost reduction in a specific production process of an auto ancillary

industrial firm. For this a case study was performed on sheet metal stamping process of LCV/HCV body parts at XYZ Company at

Pithampur (Indore)M.P.. A survey in interview form was conducted among managerial and engineering professionals from various

similar type industries. The survey is based on cost reduction techniques, related challenges, market role etc. Attempts have been made

to investigate the role of vendors in cost reduction and the problems faced from their side. Application of job plan in investigating the

problems in productivity improvement has also been studied. The outcomes have been analyzed and discussed in details.

Keywords: Cost reduction, productivity improvement, lean manufacturing, Kaizen etc.

1. Introduction

An industrial organization needs sustainable design analysis

and process optimization in manufacturing and service for

controlling production cost. There is always demand for

quality improvement with product price drop from end

users. Share and stock holders also anticipate excellent rate

of returns against investments. Thus, cost has become a

residual. The challenge is to manufacture or provide service

within the stipulated cost frame work. Thus, cost

management has to be an ongoing continuous improvement

programme. Today the market leaders are even pursuing

cost reduction as strategic imperative. They want to stay

ahead of the market by continuously widening the gap

between their cost and that of their competitors and redeploy the recourses for profitable growth. The project will

focus on impact of cost control and cost reduction

techniques in present scenario.

A business enterprise must survive, grow and prosper only if

the unwanted cost must control and reduced necessarily.

There is now a cut throat competition from various concerns

of the world.

As a result there is now a raise to secure a place for survival.

This has increased the importance of cost control and cost

reduction. Hence it is required to study the different tools

and techniques used for the same. We can classify the cost

according to their nature, behavior then we can easily know

the cost which can be controlled or reduced. Here more

emphasis is on the controllable and non- controllable cost,

because this classification of the costs helps us

understanding what and how we can control. If the cost can

be controlled then what steps should be taken for controlling

purpose; if cannot be controlled, what should be done. It

totally depends up on the managerial decisions and it is the

activity of management accounting. The study identifies the

Paper ID: SUB15187

scope in manufacturing industry by means of conventional

methods/techniques like TQM, TPM, Kaizen, Lean

manufacturing, Value analysis &Value engineering, JIT etc.

in different areas.

The interview sessions are conducted to get the opinion

about modern methods for reducing cost in their

organizations.

2. Literature Review

There are some techniques/concepts is being studied to

benefitting different areas of the organizations, also Identify

the process which can reduce their cost and improve

working environment.

2.1 What is Cost and Cost Reduction

An amount, that has to be paid or given up in order to get

something. In business, cost is usually a monetary valuation

of effort, material, resources, time and utilities consumed,

risk incurred, and opportunities for gone in production and

delivery of a goods or service.[1]

Cost Reduction is to be understood as the achievement of

real and permanent reduction in the unit cost of goods

manufacture or services rendered without impairing their

suitability for the use intended. [1]

2.2 What is TPM

In 1971, Nippon Denso Co., Ltd. first introduced and

successfully implemented TPM in Japan. They won the

Japan Institute of Plant Maintenance (JIPM) PM Excellent

Plant Award for their activities. This was the beginning of

TPM in Japan. Since then, TPM has spread progressively

throughout the world and established itself as a renowned

Volume 4 Issue 1, January 2015

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

487

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

cultural improvement programme. First example of TPM

used in Europe to deliver world class performance was by

Volvo in Ghent, Belgium, who won the PM prize for their

work in the paint shop. This was quickly followed in the

early 1990s by other European automotive companies trying

to close the productivity and quality gap to their Japanese

competitors.[7]

Unilever, Wrigley, Tetra Pak, Heineken and Arcelor Mittal.

The Japan Institute of Plant Maintenance (JIPM) approach

to TPM

The JIPM definition of TPM is:

T = Total. Must involve all employees at all levels of the

organization.

P = Productive. Effective utilization of all resources.

M = Maintenance. Keeping the Man-Machine-Material

system in optimum condition.

JIPM developed an eight pillar approach to TPM focused on

achieving:

Zero Accidents

Zero Break-downs

Zero Defects

was a way to do it. Miles often found that many of the

substitutes used were providing equal or better performance

at less cost. The function approach proved to be effective.

[4]

With active support of his superiors Miles developed and

refined the technique that he called as Value Analysis

(VA). Based upon the success experienced by General

Electric, the concept soon spread throughout private industry

because of its ability to yield a large return for a relatively

modest investment.[4]

2.5 Lean Manufacturing

The fundamental philosophy behind Lean Manufacturing is

to provide superior quality products for more Customers at a

significantly lower price and to contribute to a more

prosperous society. [5]

It is important to build a Company production system based

on this philosophy. Lean Manufacturing has Endeavour to

rationalize production by:

To completely eliminating waste in the production

process

To build quality into the process

To reduce costs - productivity improvements

To develop its own unique approach toward corporate

management

To create and develop integrated techniques that will

contribute to corporate operation.

2.6 Kaizen

Figure 2.1: Pillars of TPM

2.3 Total Quality Management

Total quality management is a general philosophy of

gradually improving the operations of a business. This is

done through the application of rigorous process analysis by

every involved employee and business partner. TQM is

usually applied at the tactical, front-line level, where

production, clerical, and low-level managers are deeply

involved. There are a number of tools available to assist in a

TQM effort, such as: [3]

Benchmarking

Failure analysis

Plan-do-check-act (PCDA) cycle

Process management

Product design control

Statistical process control

2.4 Value Engineering & Value Analysis

The Value Engineering (VE) technique emerged during the

years of World War II at General Electric Company, USA.

Mr. Lawrence D. Miles of General Electric Company was

assigned the task of "finding, negotiating for and getting a

number of vital materials that were in short supply.

Invariably suppliers declined to supply. In this desperate

situation, Miles was forced to basics. Whenever he was

faced with serious shortages, he aimed at getting the product

functions met by some alternate means. Repeatedly there

Paper ID: SUB15187

"Kai" means change, and "Zen" means good ( for the better

). Basically kaizen is for small improvements, but carried

out on a continual basis and involve all people in the

organization. Kaizen is opposite to big spectacular

innovations. Kaizen requires no or little investment. The

principle behind is that "a very large number of small

improvements are move effective in an organizational

environment than a few improvements of large value. This

pillar is aimed at reducing losses in the workplace that affect

our efficiencies [7].

2.7 Just-in-Time Inventory System

When considering the costs of housing inventory, it is

important to distinguish between value added activities and

non-value added activities.[21]

Value added activities add value to a product or service at

a given stage in the production cycle or supply chain;

customers are willing to pay for value added activities

because they make the product or service better.

Non-value added activities increase the final cost of the

product or service, but do not increase the value to the

customer.

The cost of warehousing inventory is a non-value added

activity. Upon receiving merchandise, your customers only

concern is, Does it work and is it going to perform the

function for which it was purchased? Just-in-time (JIT)

purchasing and just-in-time production help combat these

undesirable, non-value added inventory costs. These

demand-pull inventory systems are applied by requiring that

Volume 4 Issue 1, January 2015

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

488

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

raw materials arrive in your warehouse exactly as they are

needed for production or distribution. The goal of JIT

systems is to eliminate all non-value added activities.[20]

3. Research Methodology

As we know, any product is made of different parts used to

perform the desired function. The cost of that product

includes cost of all parts used inside it. Many times we are

observing that, large scale manufacturing industries

purchases some parts (used in the product) by the vendors or

suppliers. Such parts are known as bought out parts (BOP).

As we have discussed earlier that the profit maximization is

depends on cost reduction and there are many ways to

reduce unwanted cost of product or process. [24]

The price of bought out parts are depends on their cost of

manufacturing. If we analyze the scope of cost reduction in

bought out parts, then it can improve the overall profit of

that product.

The above thought was encouraged me to conduct a study in

supplier industry to find out the scope in cost reduction

comparing with the cost reduction techniques used in

present large scale Original Equipment Manufacturing

(OEM) Industries.

To understand the working of such manufacturers and their

focus towards the cost reduction for betterment, The

Interview sessions are conducted with different area of

personnel to discuss their experiences on cost reduction

techniques used in their respective organizations.

3.1 The Interview Sessions

Following are the general information of the personnel.

10

TATA Tech.

D. Tare

Remarks

Gender

35

Age

Organization

R&D

Work Experience

(Years)

Mr.

Designation /Area

of work

S.N.

Table 3.1

Design and

Service

Industry

Tyre

Industry

Prod.

30

Bridgestone

Mr. Swapnil

Saxena

Prod.

29

TATA Motors Automobile

Industry

Mr. Pulin

Sharma

Mr. Paresh

Sharma

Maint.

30

Opt.

31

Bosch India Automobile

Industry

J.P. Cement

Cement

Industry

(General Information about Personnel for Interview)

Paper ID: SUB15187

Following Questions were asked to above personnel of

different organisations to know their experiences about

present cost reduction techniques.

1. What type of cost reduction technique is being used in

your organization?

2. How this technique is being used in organization?

(brief description)

3. For how long you are using this technique?

4. How your organization gets benefited by this cost

reduction technique?

5. What types of challenges you are facing, while

implementing of this technique?

6. Is there any scope after achieving at certain level by this

technique?

7. Would you like to continue this cost reduction

technique, while introducing new product/ process line?

8. Is your current cost reduction technique gives

satisfactory solution to achieve your organization goal.

9. How the market affects the cost reduction technique?

10. How much business relation affects by cost reduction

technique?

3.2 Outcome of Interview sessions

As per the discussion with above personnel followings

points are noted:

1. There are many activities but Lean Manufacturing, and

Kaizen are using frequently

2. Every organization is using technique according their

management objective

3. Cost reduction techniques are using more from last 10

years

4. Every organization is getting benefit.

5. There are some common challenges like resource,

manpower resistance etc.

6. Scope of cost reduction is there by changing techniques.

7. Sometime techniques need to change.

8. Depends up on focus and seniority of management.

9. Depends on market conditions, if sales is down then

profit does not affect.

10. Improve business relations.

3.3 Company Profile

Mr. R. Plotra

Maint.

3.1 Questionnaire

An auto ancillary is being selected for conducting study.

This company is middle scale organization manufacturing

press parts for OEMs.

3.4 Job Plan

The methodology (referred to as the job plan) can be

applied to any subject or problem. It is a vehicle to carry the

project from inception to conclusion. By adhering to certain

formalities. So the ultimate goal of Kaizen strategy and

activities aim at improving Quality, Cost, and Delivery

(QCD), thus QCD target has become a top priority for

survival in business. On the instruction given by

management for cost reduction activity by 600 Tonne press

machine productivity improvement. The Kaizen is being

planned to achieve the goal. For that following methodology

is adopted.

Volume 4 Issue 1, January 2015

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

489

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

P- Plan: Define the problem and prepare for study is to be

conducting. How it is done: -Two teams are forming for

indentify the scope in productivity improvement in 6ooT

mechanical press. The targets for improvement and

evaluation factors while building cohesion among team

members. Collection of Bill of material (BOM) from PPC

department and operation standards (ISO 9001:2000 & TS

16494) of above press parts from production department. All

the relative information were mentioned in BOM and

operation standard.

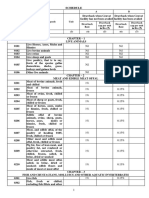

Table 4.1: Operation Standard

Op. std no. OPE/64/101

Part no: IA207437

Customer Name: EML

Press speed

(spm)

112

3.5-5.5

17-Dec

600T

3.5-5.5

15-25

600T

3.5-5.5

15-25

400T

3.5-5.5

15-25

kg/cm

1.5-3.0

600T

Cushion press

kg/cm

4-Apr

4-Feb

Cushion stroke

(mm)

After seen all the operation standards the part which selected

is R/F Cab stays blank of size 1.2x270x405 mm3 needs four

operations one by one at 600 T m/c at least as per standards.

The weight and dimension of dies are suitable to hold in

600T press machine. The operation 3/ 4 die is having less

height than operation 2/4. So the idea is generated to hold

the die the packing plate with the help of long bolts during

trial.

4-Mar

Punching Trimming

The press machine is in genral each stroke doing a single

operation of particular part, so if combinning two single

action dies in single stroke by loading in press machine

simultaneously under safe working, will increase

productivity by saving production time and operation cost.

Cam

piercing

4-Jan

Balancer press

Part name: Reinforcement cab

stay lcv

No. of cushion

pins

3.5 Problem Identification:

After applying the job plan for productivity improvement of

600 T mechanical press the R/F Cab stay LCV dies 2/4 and

3/4, the calculations are done on the basis of observations

during trial.

Press tonnage

A Act: Standardize the process

How it is done: - Document the results and prepare the

presentation for management approval.

4. Results & Analysis

Drawing Operation

C- Check: Monitor the results

How it is done: - Check the 5 sample parts after each

operation and compare with standard part and operation

standard. The machine parameters are observed during the

trial time.

The results are calculated on the basis of different criteria.

Figure 3.1: Double Die Hold on 600T press during trial.

Operation no.

D DO: Apply the technique by filtering ideas coming out

in brain storming sessions, and finalizing the work schedule.

How it is done: - For 600T machine the improvement of

productivity is depends on reducing number of dies change,

improve production strokes per minute SPM and improve

overall equipment efficiency (OEE) for which the press part

reinforcement cab stay is production process is examine

under the scheduled tool trial. The results of tool trial and

quality check are noted. Calculation of total cost saving

during productivity improvement.

4.1 Trial inspection report: In this report the data is noted

during tool trial.

Table 4.1: Production Parameter

The scheduled is planed by the production planning team.

By this technique we will save the production time and

production cost of one operation. The annual requirement

for the vehicle part is multiplied by this above savings. After

tool trials of a single lot 1000 parts 8 parts were rejected due

to misfeed. The production rate, safety, quality and machine

capabilities were checked during trial. Further the trial report

is send to management for approval from costumer end. As

per definition, the value of the product is increased.

Paper ID: SUB15187

Volume 4 Issue 1, January 2015

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

490

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

Note: Per Stroke Cost denoted here as X is calculated as

per annual budget 2,61,27,360/- (Rs/Annum) } allotted for

press shop, which contains all expenditures like Utility

(crane, fork lifter, cooling tower, transportation, DG,

compressors, Lights/lamps etc.), Salaries/ Wages (operators,

helpers, fork lifter driver, line leaders, engineers, press shop

In charge, Production managers etc.), Power consumption

charges, Machine cost, General Maintenance, tool

maintenance

(tools,

nut

bolts,),

Housekeeping,

miscellaneous charges like lockers, safety shoes, safety

goggles, hand gloves, aprons, uniforms, ear plug, stationary

etc.)

Description of figure 4.3

Y red bars shows time taken during die change & blue bars

shows no. of die change.

X axis shows no. of days

Minimum die change on 10th day due to Kaizen for

productivity improvement.

Target die change time is 10 min

4.1.3 Calculations

Machine specifications

Type: Pneumatic Press

Bolster size 1450 x 2210 mm2

Tonnage= 600T

Efficiency = 80%

Stroke length =2260mm

Shut height = 450mm

Die Specifications as per operation standard

Operation 2/4 (Trimming)

Die size =530 x 840 mm2

Height of die = 630mm

Manpower required = 04

Weight of Upper half of die =110.5 kgf

Approved Cost for operation at 600T = Rs 8/stroke

Figure 4.1: SPM trend refers to the number strokes per

minute by any press machine in total available time

Description of figure 4.1

Y axis shows strokes per minute of 600 T mechanical press

X axis shows no. of days

Target SPM 6.3

The maximum SPM at 10th day due to kaizen for

productivity improvement

As per the daily production report the production trend for

the day for all press machines in press shop for the day.

The following observations of 600T mechanical press are:

i) Number strokes for two shifts are 4992

ii) Number of die set up 04

iii) Strokes per minute is 5.74

iv) O.E.E is 90.21

Operation 3/4 (punching)

Die size =560 x 810 mm2

Height of die = 610mm

No of packing plates required of thickness 5mm = 04

Weight of upper half of die after packing plates = 110.5kg

Manpower required = 04

Approved Cost for operation at 600T = Rs 8/stroke

Procedure

Operation cost is indicated here as number as production

strokes of the press machine

(A) Operation cost = approved per stroke cost x annual

requirement of parts = 8 x 22000 = 1, 76,000/Standard die change time is the time taken during

removing of previous operation die and uploading next

operation die on bolster.

Standard die changing time = 10 mins

Annual saving in standard die change time(SDCT)

=(annualproduction/lotsize)xSDCT

=(22000/1000)x10min =220minsStandard SPM of

600T Machine = 6.3 strokes/min

Annual increment in production strokes as per standard

SPM of 600T Machine = Annual savings in SDCT x

Standard SPM of 600T Machine =220x6.3 = 1386

production strokes

(B) Annual improvement in production cost= productions

strokes x standard costing of M/c =1386x8 = 11088/Total savings in VAVE = (A) + (B) =176000+11088 =

187088/-

5. Conclusion & Discussion

5.1 Conclusions of the Work

Figure 4.2: Die changing time refers to the average time

taken for total die change in a day on a press machine.

Paper ID: SUB15187

This paper is based on analysis and finding various

opportunities, where any organization can reduce the

unwanted cost. Following are the conclusions:

Volume 4 Issue 1, January 2015

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

491

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

1) The paper is based on cost reduction techniques at

supplier end for reduce overall cost of the final product

& also contributes to improve in value of the product.

The study is conducted in press shop of an automotive

stamping part supplier unit, to check the scope in

productivity improvement, scrap utilization on the

concept of lean manufacturing & Kaizen, studied

during this project. During the study, there are 300 types

of press parts manufacturing in press shop as per bill of

material (BOM).

2) There are following parameters of productivity

improvement in 600T Mechanical Press

SN

1

Table 5.1: Data Findings

Factors

Findings

Previous

Strokes per

minute SPM

Over all

equipment

efficiency

OEE

No. of strokes

Cost reduce

per annum

5.74

5.67

90.21%

89.65%

Average of

month

4927 (Targeted

for two working

shifts)

4992

187088/-

Dimensions, weight of die and tonnage requirement are

selected from operation standard for productivity

improvement. The part Reinforcement Cab stay LH/RH is

having die is selecting for tool trial. After finding the ok part

the die Operation no. 3/4 upper half is require to increase its

height by 20mm. The O.E.E. for the day FTD is 90.21%,

which is more than month till date MTD 89.65%. The

improved SPM (strokes per minute) of the 600 T press

machine for the day is 5.74 which is maximum SPM from

last 09 days production. The die change is minimum for the

day FTD is 04 and the no. of strokes for the day for two

shifts are 4992, which are higher than the target strokes per

two shifts 4927.

5.2 Limitation of Study

The study is based on standard value which are set by

company on their past experience and analysis. There are

many factors like, working environment, operator skill,

manpower efficiency, machine performance and other

miscellaneous factors are not considered. Cost reduction

technique may vary for purpose of study, product, process,

geometry, weight and material grade and fitment in vehicle.

This study excludes production losses because of low

production dies, which have complex geometries and also

cause accidents of operator during work.

The concept is checked during tool trials and final part is

compared by the standard part, so if all parameters are ok

during trial then only consider. This method is based on

ideas comes in the mind during work in production. There

Paper ID: SUB15187

are some thumb rules, which can affect the results on the

others parts.

5.3 Scope for Future Work

This study is a specific study restricted to the case

organization .A number of such studies can be done in

variety of industries to reach at common conclusions,

which can be generalist in nature.

The interview sessions are conducted with different

personnels to find out the cost reduction techniques which

are used at their organizations. There are some more

techniques, which can be used in the case organization

like technical surveys, weighted score method, decision

matrix etc.

This study is conducted at the scale of middle level

organization. It can be scale down at small scale industries

and scale up for large scale industries.

In this work, five interview sessions are conducted. The

sample size can be increased up to 10, 15, 20, 30, 40 up to

50 for taking different opinions about cost reduction

techniques.

References

[1] Impact of Cost Control and Cost Reduction Techniques

on Manufacturing sector, ISRJ Vol. 3

[2] Buffa Elwood, Operations Management Johnwiley N.Y.

(1976)

[3] S.M. Sumdaraju, Total quality management, Tata

McGraw Hill, New Delhi (1995)

[4] Witschey, W. & Wulff, R. 2002. How to ensure quality

and cut costs with cultural institution value

methodology. A case study of value engineering on an

history renovation project.

[5] Womack,J. & Jones,D.,The machine that changed the

world :The story of lean production 1991 , New York

:Harper Collins.

[6] Bowles,J.& Hammond, J., Beyond quality how 50

wining companies use continuous improvement

,1991,NewYork: Putnam

[7] Barnes,T.,Kaizen

strategies

for

successful

leadership,1996, Pitman Publishing London

[8] Capital Works Investment: Value Management Manual:

New South Wales Government.

[9] Creswell, J.W. 2003 Research Design, Qualitative,

quantity and mixed methods approaches. (2.ed)

Thousang Oak : sage publication.

[10] 10.Cheser,R., Kaizen is more than continuous

improvement ,Quality progress ,April 1994, pp. 23-26

[11] Davies, K. E. L. 2004. Finding value in value

engineering. Cost Engineering, 46(12):

[12] Dell'Isola, A. J. 1988. Value engineering in the

construction industry. Washington D. C. Smith

Hinchman & Grylls.

[13] Drury, C. 2000. Management & Cost Accounting (Fifth

ed.). London: Business Press Thomson Learning.

[14] Flyvbjerg, B. 2006. Five misunderstandings about casestudy research. Qualitative Inquiry, 12(2): 219-245.

[15] Fong, P. S. W. 1998 a. Value engineering in Hong

Kong - A powerful tool for a changing society.

Computers Industrial Engineers, 35(3/4): 627-630

Volume 4 Issue 1, January 2015

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

492

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

[16] Guidebook for VE activities - A basic manual: Society

of Japanese Value Engineering. 1- 32

[17] Garvin , D., Competing on the eight dimensions of

quality

,1987,

Harvard

Business

improvement,1993,.NewYork:Sterling Publishing.

[18] I.L.O. Introduction to wok study. ILO, Geneva(1979)

[19] Imai, M., Kaizen :The key to Japans competitive

success , 1986, McGraw Hill,

[20] Kobayashi,I., 20keys to workplace improvement

,1990,Cambridge :productivity press

[21] Kerzner Harold, A Systems Approach to planning

scheduling and controlling Von Nostr and

Reinholtcony. (1979)

[22] Knouse, S. B. , The reward and recognition process in

total quality management , 1996, . Milwaukee, WI:

ASQC, Quality Press

[23] Management Accounting Concepts: International

Federation of Accountants.

[24] Martand Telsang, Industrial Engineering and Production

Management, S. Chand & Co., New Delhi. Page 532534

[25] Miles, L. D. 1963. Definitions: Lawrence D. Miles

value Engineering Reference Center: Wendt Library.

[26] Miller, R. & Floricel, S. 2004. Value Creation and

games

of

innovation

Research

Technology

Management: 25-37.

[27] Mitsufuji, T. 2003. How an innovation is formed: A

case study of Japan word processors. Technological

Forecasting & Social Change, 70: 671-685.

[28] P.P. Pandey and C.K. Singh production engineering

sciences by standard publishers distributors nai sarak,

delhi 110006 fifth edition 1984 page 500-550

[29] Sperling, R. B. 2001. Understanding value engineering.

IIE Solutions, 33(8): 45-51.

[30] Buffa, E.S. and W.H. Taubert, Production Inventory

System Planning and Control, Irwin Homewood

Illinois.

[31] Samuel Eilon, Elements of production planning and

control Universal Publication, Mumbai (1994)

[32] Tek, O. H. & Yeomans, P. R. 2002. Value

Management: Enhancing project cost performance.

[33] The Society of Japanese Value Engineering (SJVE)

(1981, pg.3)

[34] Textbook, Kaizen, teian 1 ,1992, JHRA, Productivity

Press, Portland OR. pp 16

[35] Value Methodology Standard: SAVE International "The

value society" 1-16

Website Reviewed

1. www.kaizen- institute.com, viewed on 23 /03/ 2014

2. www.peterkeen.com, viewed on28 /03/ 2014

3. www.gembakaizen.com,viewed on 04 /04/ 2014

Paper ID: SUB15187

Volume 4 Issue 1, January 2015

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

493

Anda mungkin juga menyukai

- Closing Case Chapter 13Dokumen4 halamanClosing Case Chapter 13kelvin orongeBelum ada peringkat

- Rebranding Cadbury BytesDokumen10 halamanRebranding Cadbury BytesPrerona Dey100% (1)

- IBDP Economic HL Chapter 7 NotesDokumen8 halamanIBDP Economic HL Chapter 7 NotesAditya Rathi100% (1)

- BCS L3 Digital Marketer IfATE V1.1 KM2 Marketing Principles Sample Paper B Answer Sheet V1.2Dokumen8 halamanBCS L3 Digital Marketer IfATE V1.1 KM2 Marketing Principles Sample Paper B Answer Sheet V1.2IT AssessorBelum ada peringkat

- Pepsi Targets Diet Drinks to Teens and MillennialsDokumen2 halamanPepsi Targets Diet Drinks to Teens and MillennialsFahad Malik100% (1)

- Improving Manufacturing Productivity Through Lean TechniquesDokumen4 halamanImproving Manufacturing Productivity Through Lean TechniquesVikas SuryavanshiBelum ada peringkat

- Ford Production SystemDokumen4 halamanFord Production Systempravit08Belum ada peringkat

- Seminar Report On Lean ManufacturingDokumen26 halamanSeminar Report On Lean ManufacturingAbhishek BhardwajBelum ada peringkat

- Toyota Success RecipeDokumen7 halamanToyota Success Recipeapi-3740973Belum ada peringkat

- Lean ManufacturingDokumen17 halamanLean ManufacturingAmbarish100% (6)

- Reducing The Throughput Time by Value Stream Mapping in A Tyre Manufacturing Industry IJERTV3IS110267Dokumen5 halamanReducing The Throughput Time by Value Stream Mapping in A Tyre Manufacturing Industry IJERTV3IS110267akshaykumarBelum ada peringkat

- Impact of Lean Production in Different SectorsDokumen9 halamanImpact of Lean Production in Different SectorsramyathecuteBelum ada peringkat

- VALUE STREAM MAPPING TECHNIQUEDokumen3 halamanVALUE STREAM MAPPING TECHNIQUEhendryaristyo100% (1)

- Chapter 1. Introduction: 1.1. BackgroundDokumen92 halamanChapter 1. Introduction: 1.1. BackgroundSanjay KmrBelum ada peringkat

- LEANDokumen29 halamanLEANkmsteamBelum ada peringkat

- Lean Plastics Manufacturing PrinciplesDokumen7 halamanLean Plastics Manufacturing Principles2b-or-not2bBelum ada peringkat

- Lean Manufacturing-Case Study at MACPLDokumen53 halamanLean Manufacturing-Case Study at MACPLpraful100% (1)

- Toyota Production SystemDokumen33 halamanToyota Production SystemMohit SharmaBelum ada peringkat

- Binning StrategyDokumen80 halamanBinning StrategyJonah100% (1)

- Unit 2 Concepts of Total Quality Management: StructureDokumen26 halamanUnit 2 Concepts of Total Quality Management: StructureM MehraBelum ada peringkat

- Productivity Improvement Using Lean Manufacturing '" A Case Study at Muththamizh IndustriesDokumen9 halamanProductivity Improvement Using Lean Manufacturing '" A Case Study at Muththamizh IndustriesEditor IJTSRDBelum ada peringkat

- Kaizen Case StudyDokumen44 halamanKaizen Case StudyTanmoy ChakrabortyBelum ada peringkat

- The DefinitionDokumen9 halamanThe DefinitionRitesh ChoudharyBelum ada peringkat

- Kaizen Event 2Dokumen20 halamanKaizen Event 2Elena CavedagnaBelum ada peringkat

- Value Stream MappingDokumen40 halamanValue Stream Mappingjinyue7302Belum ada peringkat

- Spaghetti Diagram PDFDokumen4 halamanSpaghetti Diagram PDFLaila M. ElmougyBelum ada peringkat

- Value Stream MappingDokumen21 halamanValue Stream MappingDch Narrasimhan100% (1)

- MUDA (7 Waste)Dokumen3 halamanMUDA (7 Waste)Shamshair Ali100% (1)

- Operations ManagementDokumen50 halamanOperations ManagementyknidBelum ada peringkat

- Lean Manufacturing - An IntroductionDokumen44 halamanLean Manufacturing - An IntroductionSiva Rama Krishna Patimalla100% (1)

- Traditipn Production Planning and ControlDokumen16 halamanTraditipn Production Planning and ControlpaulineBelum ada peringkat

- The 7 WastesDokumen7 halamanThe 7 WastesAditya PrasharBelum ada peringkat

- Just in Time System: Anuradha Kushwaha Harshpreet Kaur Vrinda GuptaDokumen19 halamanJust in Time System: Anuradha Kushwaha Harshpreet Kaur Vrinda GuptaVrinda GuptaBelum ada peringkat

- World Class Manufacturing, 16Dokumen14 halamanWorld Class Manufacturing, 16Santhilal S Pillai100% (1)

- Lean Manufacturing REPORTDokumen15 halamanLean Manufacturing REPORTSandeep GrBelum ada peringkat

- Lean ManufacturingDokumen47 halamanLean ManufacturingSaumya SaumyaBelum ada peringkat

- Just in Time Toyota Vs NissanDokumen27 halamanJust in Time Toyota Vs NissanCristina Peñalver GilBelum ada peringkat

- Lean Manufacturing 4 - KaizenDokumen49 halamanLean Manufacturing 4 - KaizenAbhiBelum ada peringkat

- Value Stream Mapping Process - Supply Chain ManagementDokumen21 halamanValue Stream Mapping Process - Supply Chain ManagementMANTECH Publications100% (1)

- Toyota Production System and the Origins of Lean ManufacturingDokumen14 halamanToyota Production System and the Origins of Lean ManufacturingVan Michael100% (2)

- Best in Class Vs World ClassDokumen3 halamanBest in Class Vs World ClassJohn OoBelum ada peringkat

- Assignment Lean ManufacturingDokumen26 halamanAssignment Lean ManufacturingNisarg Shukla100% (1)

- Managing OEE To Optimize Factory Performance PDFDokumen20 halamanManaging OEE To Optimize Factory Performance PDFEstevao SalvadorBelum ada peringkat

- Value Stream Mapping Guide for Garment ManufacturingDokumen9 halamanValue Stream Mapping Guide for Garment ManufacturingAanchal ChawlaBelum ada peringkat

- Pharmaceutical Manufacturers Embracing Lean Six SigmaDokumen6 halamanPharmaceutical Manufacturers Embracing Lean Six SigmahaiderfatmiBelum ada peringkat

- Just in TimeDokumen20 halamanJust in TimeRatan GohelBelum ada peringkat

- KaizenDokumen21 halamanKaizenluv18100% (2)

- Lean Manufacturing, Lean Enterprise, or Lean Production, Often Simply, "Lean", Is ADokumen10 halamanLean Manufacturing, Lean Enterprise, or Lean Production, Often Simply, "Lean", Is AvanausabBelum ada peringkat

- Key Concepts of Supply Chain ManagementDokumen28 halamanKey Concepts of Supply Chain ManagementMASROOR ALI SOOMROBelum ada peringkat

- Lean Case StudiesDokumen8 halamanLean Case StudiesTengku SmyBelum ada peringkat

- 1 Lean GlossaryDokumen7 halaman1 Lean GlossaryHilalAldemirBelum ada peringkat

- Using Lean Techniques to Improve Ready Wear EfficiencyDokumen7 halamanUsing Lean Techniques to Improve Ready Wear Efficiencyhemlata2014Belum ada peringkat

- Eliminate Waste With Lean ManagementDokumen33 halamanEliminate Waste With Lean ManagementAkshay RaturiBelum ada peringkat

- Just in Time - TechniqueDokumen21 halamanJust in Time - Techniquemuneerpp100% (3)

- HeijunkaDokumen6 halamanHeijunkajosegarreraBelum ada peringkat

- Lean Supply ChainDokumen45 halamanLean Supply ChainHenra HalimBelum ada peringkat

- 7 Slides Cell DesignDokumen30 halaman7 Slides Cell DesignLuis Alberto Lamas LavinBelum ada peringkat

- The Two Key Principles of Toyota Production System Were Just in Time and JidokaDokumen2 halamanThe Two Key Principles of Toyota Production System Were Just in Time and JidokaF13 NIECBelum ada peringkat

- Single Minute Exchange of Dies College ProjectDokumen99 halamanSingle Minute Exchange of Dies College ProjectAkshay Shah50% (2)

- Know The Meaning of Various Color Coding Used in Floor Marking!Dokumen12 halamanKnow The Meaning of Various Color Coding Used in Floor Marking!Aditya vatsyayanBelum ada peringkat

- SMED single minute exchange of die A Complete Guide - 2019 EditionDari EverandSMED single minute exchange of die A Complete Guide - 2019 EditionBelum ada peringkat

- Grommets Sorted by BoreDokumen5 halamanGrommets Sorted by Boreramanamurtytv7176Belum ada peringkat

- Revised Duty Drawback Rates Schedule 2016 17 Wef 15 Nov 2016Dokumen185 halamanRevised Duty Drawback Rates Schedule 2016 17 Wef 15 Nov 2016Emmanuel OpeyBelum ada peringkat

- Takt Time CalculatorDokumen6 halamanTakt Time CalculatorRohmat SesBelum ada peringkat

- APP Carbon Grade Chart v6Dokumen1 halamanAPP Carbon Grade Chart v6Tashrif YusufBelum ada peringkat

- Bright Steel Bars PDFDokumen14 halamanBright Steel Bars PDFramanamurtytv7176Belum ada peringkat

- Internal Audit Checklist: System & Process Compliance AuditingDokumen7 halamanInternal Audit Checklist: System & Process Compliance AuditingEl BieBelum ada peringkat

- Auto Mobile CLusterDokumen22 halamanAuto Mobile CLusterAkshay RanaBelum ada peringkat

- MildSteel AISI 1018Dokumen2 halamanMildSteel AISI 1018ramanamurtytv7176Belum ada peringkat

- High Tensile Steel 4140Dokumen2 halamanHigh Tensile Steel 4140Sadullah TaşkınBelum ada peringkat

- Assertiveness Skills BasicsDokumen84 halamanAssertiveness Skills BasicsCorina NeaguBelum ada peringkat

- High Tensile Alloy 4140Dokumen1 halamanHigh Tensile Alloy 4140browniezboyBelum ada peringkat

- Hollow Bar ChartDokumen1 halamanHollow Bar Chartramanamurtytv7176Belum ada peringkat

- 292 - Chapter n.2 Modern Machines in Agriculture - SpainDokumen8 halaman292 - Chapter n.2 Modern Machines in Agriculture - SpainSarath KumarBelum ada peringkat

- About En19Dokumen1 halamanAbout En19ramanamurtytv7176Belum ada peringkat

- Supply Chain SolutionsDokumen12 halamanSupply Chain Solutionsramanamurtytv7176Belum ada peringkat

- Tillage PartsDokumen33 halamanTillage Partsramanamurtytv7176Belum ada peringkat

- Alloy Steel Properties and UseDokumen270 halamanAlloy Steel Properties and UseKritika TayaBelum ada peringkat

- SAPH 440 MaterialDokumen16 halamanSAPH 440 MaterialDinesh SharmaBelum ada peringkat

- Special Steels 3Dokumen100 halamanSpecial Steels 3ramanamurtytv7176Belum ada peringkat

- Intro 2 EngDokumen33 halamanIntro 2 EngNguyen Huu HieuBelum ada peringkat

- GL Huyett EngineeringHandbookDokumen95 halamanGL Huyett EngineeringHandbookSwetha PattelaBelum ada peringkat

- SAPH 440 MaterialDokumen16 halamanSAPH 440 MaterialDinesh SharmaBelum ada peringkat

- New Special Steels BookletDokumen22 halamanNew Special Steels Bookletramanamurtytv7176Belum ada peringkat

- Design and Manufacturing of Sheet Metal Parts - Using Features ToDokumen34 halamanDesign and Manufacturing of Sheet Metal Parts - Using Features ToElaine JohnsonBelum ada peringkat

- New Special Steels BookletDokumen22 halamanNew Special Steels Bookletramanamurtytv7176Belum ada peringkat

- Achieving Lean Manufacturing Through Lean Design PDFDokumen3 halamanAchieving Lean Manufacturing Through Lean Design PDFJulián EduardoBelum ada peringkat

- GL Huyett EngineeringHandbookDokumen95 halamanGL Huyett EngineeringHandbookSwetha PattelaBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen21 halamanDisclosure To Promote The Right To InformationBrijeshBelum ada peringkat

- Auto Expo 2010 Product DetailsDokumen60 halamanAuto Expo 2010 Product DetailsAbhijeet Kulshreshtha100% (2)

- Examne Final Inglrs 3Dokumen6 halamanExamne Final Inglrs 3anonimoBelum ada peringkat

- Design Thinking InnovationDokumen90 halamanDesign Thinking Innovationsupermarco744735100% (1)

- Mba GuideDokumen43 halamanMba GuideArif JalilBelum ada peringkat

- Satisfaction of DealersDokumen59 halamanSatisfaction of DealersMaza Street100% (5)

- Final Coca-Cola Plans BookDokumen36 halamanFinal Coca-Cola Plans BookSportzchick2287100% (6)

- E Commerce ReportDokumen21 halamanE Commerce ReportMidul Khan100% (2)

- Demantra SOP EBS Integration Process v1.0Dokumen20 halamanDemantra SOP EBS Integration Process v1.0kmurali321100% (1)

- Apple PESTLE ReportDokumen4 halamanApple PESTLE ReportAngeline SahagunBelum ada peringkat

- Spring 2023 - MGT501 - 1Dokumen3 halamanSpring 2023 - MGT501 - 1Usman AliBelum ada peringkat

- Esso Standard Eastern, Inc. Vs CA and United Cigarette CorporationDokumen4 halamanEsso Standard Eastern, Inc. Vs CA and United Cigarette CorporationSarah De Guzman0% (1)

- Conferenceobject 84116Dokumen13 halamanConferenceobject 84116blueBelum ada peringkat

- Walt Disney Corporation Culture ChangeDokumen19 halamanWalt Disney Corporation Culture Changeyadav_sheetalBelum ada peringkat

- CH 01Dokumen10 halamanCH 01haixazzBelum ada peringkat

- Cadbury, the confectionery giant and the world's second largest confectionery brandDokumen13 halamanCadbury, the confectionery giant and the world's second largest confectionery brandPoonam Dimple RuchwaniBelum ada peringkat

- E Commerce Jury NIFTDokumen21 halamanE Commerce Jury NIFTAkanksha SharmaBelum ada peringkat

- Marketing Strategy of BajajDokumen76 halamanMarketing Strategy of Bajajraunak singh100% (2)

- Yale University Press Fall/Winter 2010 Seasonal CatalogDokumen180 halamanYale University Press Fall/Winter 2010 Seasonal CatalogYale University PressBelum ada peringkat

- Business Studies: IgcseDokumen29 halamanBusiness Studies: IgcsePoonam AroraBelum ada peringkat

- Viviana Ferrrer ResumeDokumen2 halamanViviana Ferrrer ResumevivianarfBelum ada peringkat

- Shell Brunei - Certification TestDokumen4 halamanShell Brunei - Certification TestTom Robin PiolBelum ada peringkat

- Managerial Application of AnalyticsDokumen4 halamanManagerial Application of AnalyticsshailajaBelum ada peringkat

- Acknowledgement: Analysis The Indian Airline Industry Management ResearchDokumen103 halamanAcknowledgement: Analysis The Indian Airline Industry Management ResearchSanguta PrasadBelum ada peringkat

- BK Amharic Business InfoDokumen2 halamanBK Amharic Business InfoMusab BaigBelum ada peringkat

- Corporate Strategy - Supply Chain Management - Dell Case StudyDokumen22 halamanCorporate Strategy - Supply Chain Management - Dell Case StudyDr Rushen Singh100% (1)

- Essay Question1Dokumen14 halamanEssay Question1Aldrich AmoguisBelum ada peringkat