.750" To 16.250" (19.1 To 412.8 MM) O.D.: Flange Facing

Diunggah oleh

TulioLopezJJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

.750" To 16.250" (19.1 To 412.8 MM) O.D.: Flange Facing

Diunggah oleh

TulioLopezJHak Cipta:

Format Tersedia

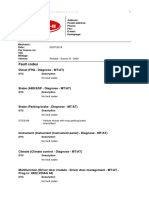

Flange Facing

.750" to 16.250" (19.1 to 412.8 mm) O.D.

Simple, Safe, Accurate

Flange Facing

H&S Tool offers four models of

reliable pipe machine tools with

premium flange facing conversion

accessories. Each is powered

by reliable pneumatic or electric

motors to accurately meet your

job site or shop requirements.

The tools are portable, making

them ideal for use in the field.

Setup and operation is easily

handled by a single worker.

Kits include everything necessary

to convert your Model B, MS,

MT or MFT beveling tool with

illustrated instructions.

Standard wedge plates can

be used for internal locking or

precision elbow mandrels are

available. The mandrels are

designed to mount in short-radius

elbows. The minimum straight

depth to mount the model MSF

is .500" [12.7 mm], model MTF

is 1.000" [25.4 mm] and model

MFTF is 1.250" [31.8 mm]).

Centering and squaring devices

make accurate machining of

gasket surfaces and/or bolt

patterns simple and safe.

Single Person Setup

And Operation

Field Conversion

Between Beveling

Machine And

Flange Facer Is

Quick And Easy

Adjust Between A

Wide Range Of Face

Surfaces

Internal Locking

Increases Safety

and Accuracy

Flange Facing Tools and Accessories

Model BF Model MSF

Model MTF

Model MFTF

Working Range* .750" I.D. to 4.120" O.D. 1.250" I.D. to 6.190" O.D. 3.250" I.D. to 10.630" O.D. 4.250" I.D. to 16.250" O.D.

(19.1 to 104.6 mm) (31.8 to 157.2 mm)

(82.6 to 270.0 mm)

(108.0 to 412.8 mm)

Surface Finish

63 to 250 RMS 63 to 500 RMS

Approx. Finish/Pin

1 = 63 RMS, 2= 125RMS 1 = 63 RMS, 3 = 125 RMS, 6 = 500 RMS

4 = 250 RMS

Tool Feed Rate

.005" (0.13 mm) per pin. Pins must be engaged at opposing positions for even resurfacing.

Max. Tool Travel*

1.500" (38.1 mm) 2.000" (50.8 mm)

Axial Feed Rate

Per Full Turn

.062" (1.6 mm)

Adjustments

1/4 turn

1/2 turn

3/4 turn

.015" (0.38mm) .015" (0.38 mm)

.031" (0.79 mm) .031" (0.79 mm)

.046" (1.2 mm) .046" (1.2 mm)

Internal Locking/

Locating

.062" (1.6 mm)

3.000" (76.2 mm)

3.000" (76.2 mm)

.083" (2.1 mm)

.083" (2.1 mm)

.021" (0.53 mm)

.042" (1.1 mm)

.063" (1.6 mm)

.021" (0.53 mm)

.042" (1.1 mm)

.063" (1.6 mm)

Collet Internal Precision elbow mandrels with "Z" axis adjustment.

Locking

Alignment

Centering/squaring machined aluminum plate, spoked adapter

and dial indicator attachment for use with elbow mandrels.

Minimum

Mounting Depth

.750" (191. mm) .500" (12.7 mm)

1.000" (25.4 mm)

1.250" (31.8 mm)

Tooling

Weight

Power Unit

Mandrel

Single point replaceable carbide insert in steel tool holder,

two machining points per insert.

19.0 lbs. (8.6 kgs.) 27.0 lbs. (12.2 kgs.)

N/A 4.0 lbs. (1.8 kgs.)

55.0 lbs. (24.9 kgs.)

10.0 lbs. (4.5 kgs.)

70.0 lbs. (31.8 kgs.)

13.0 lbs. (5.9 kgs.)

Dimensions

Mandrel Length 12.500" (317.5 mm) 14.000" (355.6 mm)

Radial Clearance* 4.000" (101.6 mm)* 6.000" (152.4 mm)

15.000" (381.0 mm)

9.000" (228.6 mm)

18.000" (457.2 mm)

11.000" (279.4 mm)

Motor, Pneumatic

.9 HP (0.66 kW) 1.625 HP (1.2 kW)

Air Volume

38 CFM (1.1 M3/Min.) 38 CFM (1.1 M3/Min.)

Pressure

90.0 psi (6.1 bar) 90.0 psi (6.1 bar)

Speed, Adjustable

90 RPM, Max. 50 RPM, Max.

3.0 HP (2.2 kW)

65 CFM (1.9 M3/Min.)

90.0 psi (6.1 bar)

22 RPM, Max.

3.0 HP (2.2 kW)

65 CFM (1.9 M3/Min.)

90.0 psi (6.1 bar)

18 RPM, Max

*Model BF has a tight clearance option available. This option reduces the maximum working range to 2.500" (63.5 mm). Tool travel

is limited to 1.000" (25.4 mm). Radial clearance is reduced to 2.750" (69.9 mm).

BF

MSF

MTF

MFTF

Model MSF Elbow Mandrel

Size

A

B

C

D

E

F

Pin

I.D. Range

Length

Inches

MM

0.594

1.750 2.000

44.5 50.8

0.719

2.000 2.250

50.8 57.2

0.844

2.250 2.500

57.2 63.5

0.969

2.500 2.750

63.5 69.9

1.094

2.750 3.000

69.9 76.2

1.219

3.000 3.250

76.2 82.6

Size

G

H

I

J

K

Pin

I.D. Range

Length

Inches

MM

1.344

3.250 3.500 82.6 88.9

1.469

3.500 3.750 88.9 95.3

1.594

3.750 4.000 95.3 101.6

1.719

4.000 4.250 101.6 108.0

1.844

4.250 4.500 108.0 114.3

Model MTF Elbow Mandrel

Size

MT1

MT2

MT3

MT4

Pin

I.D. Range

Length

Inches

MM

1.250

3.250 4.000

82.6 101.6

1.625

4.000 4.750

101.6 120.7

2.000

4.750 5.500

120.7 139.7

2.375

5.500 6.250

139.7 158.8

Size

MT5

MT6

MT7

Pin I.D. Range

Length

Inches

MM

2.750

6.250 7.000 158.8 177.8

3.125

7.000 7.750 177.8 196.9

3.500

7.750 8.500 196.9 215.9

Model MFTF Elbow Mandrel

Size

FT1

FT2

Pin

I.D. Range

Length

Inches

MM

1.750 4.250 5.000 108.0 127.0

2.125 5.000 5.750 127.0 146.1

FT3

FT4

2.500

2.875

5.750 6.500 146.1 165.1

6.500 7.250 165.1 184.2

FT5

FT6

3.250 7.250 8.000 184.2 203.2

3.625 8.000 8.750 203.2 222.3

Specifications are subject to change without notice.

Locator Pins For Extended Head

Size

Pin I.D. Range

Length

Inches

MM

FT7

2.375

8.750 9.500 222.3 241.3

FT8

2.750 9.500 10.250 241.3 260.4

FT9

3.125 10.250 11.000 260.4 279.4

FT10

3.500 11.000 11.750 279.4 298.5

FT11

3.875 11.750 12.500 298.5 317.5

FT12

4.250 12.500 13.250 317.5 336.6

FT13

4.625 13.250 14.000 336.6 355.6

FT14

5.000 14.000 14.750 355.6 374.7

FT15

5.375 14.750 15.500 374.7 393.7

O.D. Mount Flange Facing

Our versatile line of split-frame machines use

a counterbore head to quickly and accurately

resurface flanges from 4.000" to 86.000" O.D.

(101.6 mm to 2184.4 mm).

By altering the number of tripper pins, surface

finishes can be machined from 63 to 500 RMS.

Contact your H&S representative or our

headquarters at the information listed below.

Distributed locally by:

2010. All rights reserved.

Form No. FF-06

Printed in U.S.A.

Anda mungkin juga menyukai

- Climaxportable Lathe Pl3000-EDokumen6 halamanClimaxportable Lathe Pl3000-EjpolancosBelum ada peringkat

- Midas Rex Legend Tool CatalogDokumen28 halamanMidas Rex Legend Tool CatalogCharlene Ting100% (1)

- Kindrick Torque WrenchDokumen4 halamanKindrick Torque WrenchGibbs PerBelum ada peringkat

- BB3000 Line Boring MachineDokumen8 halamanBB3000 Line Boring MachineadnyaBelum ada peringkat

- MS CitizenDokumen22 halamanMS CitizenFavoreel PatrickBelum ada peringkat

- Ac650 Mandrinadora Vertical P Cilindros y Bloques PDFDokumen8 halamanAc650 Mandrinadora Vertical P Cilindros y Bloques PDFJoseDavidSanchezYepesBelum ada peringkat

- Multi-Master Indexable - Low ResDokumen28 halamanMulti-Master Indexable - Low ResrianrureBelum ada peringkat

- Ricci ClamshellDokumen12 halamanRicci ClamshellEmily MartiniBelum ada peringkat

- Economically Cuts All Desired ShapesDokumen4 halamanEconomically Cuts All Desired ShapesJose BustosBelum ada peringkat

- Longitudinal Seam Welders BrochureDokumen8 halamanLongitudinal Seam Welders Brochuregrincheu70Belum ada peringkat

- 93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTDokumen72 halaman93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTdgc513Belum ada peringkat

- Service SpecificationDokumen95 halamanService SpecificationLoc TruongBelum ada peringkat

- Bolt EqualentsDokumen1 halamanBolt EqualentsvkturkiBelum ada peringkat

- Mould Components. Componentes para Moldes Fertrading Group VenezuelaDokumen5 halamanMould Components. Componentes para Moldes Fertrading Group VenezuelaRenso PiovesanBelum ada peringkat

- Catalog Strunguri Pentru Lemn - August 2013Dokumen11 halamanCatalog Strunguri Pentru Lemn - August 2013Expert Masini UnelteBelum ada peringkat

- Threadmilling Brochure SecoDokumen16 halamanThreadmilling Brochure SecoIvica LabudovicBelum ada peringkat

- Bridgeport Series Milling Machine - BrochureDokumen2 halamanBridgeport Series Milling Machine - Brochurehbpr9999100% (1)

- SpannersDokumen48 halamanSpannersvineeshBelum ada peringkat

- FL6003 PDFDokumen4 halamanFL6003 PDFMauricio Barrios CastellanosBelum ada peringkat

- Fletcher 2100 ManualDokumen27 halamanFletcher 2100 ManualLaura Stolfi67% (3)

- Presentation On Internship AT "D U Industries PVT - LTD": Prepared By: Guided byDokumen37 halamanPresentation On Internship AT "D U Industries PVT - LTD": Prepared By: Guided byNIRAJ PATELBelum ada peringkat

- Armstrong ArmaCoil Brass InsertsDokumen12 halamanArmstrong ArmaCoil Brass InsertsAce Industrial SuppliesBelum ada peringkat

- Lintech CatalogDokumen75 halamanLintech CatalogElectromateBelum ada peringkat

- Service - Specifications Toyota ProboxDokumen85 halamanService - Specifications Toyota Proboxcpgmotors83% (6)

- Trimmer PartsDokumen29 halamanTrimmer PartsHAVENSALBelum ada peringkat

- Catalogo Trens (Tos) TornosDokumen4 halamanCatalogo Trens (Tos) Tornosrodrigo_aguilar_4100% (1)

- 14 Bernardo Soustruhy deDokumen40 halaman14 Bernardo Soustruhy deTanase Constantin0% (1)

- Precision and Laboratory EquipmentsDokumen33 halamanPrecision and Laboratory EquipmentsTone RatanalertBelum ada peringkat

- Kw15-907 Precision Gear Head Lathe MachDokumen1 halamanKw15-907 Precision Gear Head Lathe MachettypasewangBelum ada peringkat

- Well HandyDokumen6 halamanWell HandymtonellyBelum ada peringkat

- Gaging InspectionDokumen22 halamanGaging Inspectiongeav25653855Belum ada peringkat

- 13.-En NT Bolts UtilcellDokumen3 halaman13.-En NT Bolts Utilcellnu.arabiaBelum ada peringkat

- Meraj Engineering - CatalogueDokumen29 halamanMeraj Engineering - CatalogueMohammad Iqbal KhanBelum ada peringkat

- Operating Manual: ZAY7032G ZAY7040G ZAY7045G ZAY7032G/1 ZAY7040G/1 ZAY7045G/1Dokumen22 halamanOperating Manual: ZAY7032G ZAY7040G ZAY7045G ZAY7032G/1 ZAY7040G/1 ZAY7045G/1Anonymous Cx74V6ntI80% (1)

- ExtractPage17 18B PDFDokumen4 halamanExtractPage17 18B PDFDries VandezandeBelum ada peringkat

- Metal Core Drilling MachineDokumen13 halamanMetal Core Drilling MachineamekhzoumiBelum ada peringkat

- Hand ToolsDokumen273 halamanHand ToolsTone Ratanalert100% (1)

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyDokumen4 halamanTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69Belum ada peringkat

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDokumen5 halamanEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- Bore Hole MachineDokumen8 halamanBore Hole Machineomni_partsBelum ada peringkat

- C4.4 Medida Cigüeñal PermitidasDokumen3 halamanC4.4 Medida Cigüeñal PermitidasLuis GutiérrezBelum ada peringkat

- Modul Mesin BubutDokumen1 halamanModul Mesin BubutNata Nawar VanditaBelum ada peringkat

- Catalogo de CouplingsDokumen32 halamanCatalogo de CouplingsjoravicaBelum ada peringkat

- Esp. VirabrequimDokumen4 halamanEsp. VirabrequimflavioBelum ada peringkat

- Ebore Twin Cutter EnglishDokumen7 halamanEbore Twin Cutter EnglishLeandro LechechenBelum ada peringkat

- Taladro Magnetico Rotabest Mini 36-50 Manual OperacionDokumen12 halamanTaladro Magnetico Rotabest Mini 36-50 Manual OperacionAtahualpa Bulganin Infante YañezBelum ada peringkat

- Parting and Grooving - User S GuideDokumen84 halamanParting and Grooving - User S GuideKhai HuynhBelum ada peringkat

- Bolt StandardDokumen42 halamanBolt StandardSHIVASHANKARBelum ada peringkat

- Compound & Slide Compound Miter SawsDokumen3 halamanCompound & Slide Compound Miter SawsUnodostres Cinco Ocho TreceBelum ada peringkat

- ION 6200 RMD Retrofit Instructions: Location & MountingDokumen3 halamanION 6200 RMD Retrofit Instructions: Location & MountingAzar TajBelum ada peringkat

- Technical Characteristics: Upon RequestDokumen7 halamanTechnical Characteristics: Upon RequestMoin AftabBelum ada peringkat

- Aircraft and Turbine Engine Maintenance ToolsDokumen12 halamanAircraft and Turbine Engine Maintenance ToolsFloyd PriceBelum ada peringkat

- Lathe Machine CZ1440G-1 ManualDokumen32 halamanLathe Machine CZ1440G-1 Manualsecondharbour China100% (1)

- 16 2013 Taps and Dies EbookDokumen46 halaman16 2013 Taps and Dies Ebookwhitelizard2001Belum ada peringkat

- Axial Lock Nuts PDFDokumen3 halamanAxial Lock Nuts PDFcharlnnmdBelum ada peringkat

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDari EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MorePenilaian: 4.5 dari 5 bintang4.5/5 (11)

- Weld Like a Pro: Beginning to Advanced TechniquesDari EverandWeld Like a Pro: Beginning to Advanced TechniquesPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDari EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LathePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Heavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualDokumen36 halamanHeavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualTulioLopezJBelum ada peringkat

- SDB 206 2 Small Diameter Beveler DatasheetDokumen2 halamanSDB 206 2 Small Diameter Beveler DatasheetTulioLopezJBelum ada peringkat

- SP STP Fault TreeDokumen14 halamanSP STP Fault TreeTulioLopezJBelum ada peringkat

- MT FF Operating Parts PDFDokumen6 halamanMT FF Operating Parts PDFTulioLopezJBelum ada peringkat

- 212spflyer PDFDokumen2 halaman212spflyer PDFTulioLopezJBelum ada peringkat

- HCM-3E4 Hydraulic Power Unit Owner ManualDokumen20 halamanHCM-3E4 Hydraulic Power Unit Owner ManualTulioLopezJ100% (1)

- Heavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualDokumen36 halamanHeavy Duty Split Frame Single Point Cantilevered Tool Slide: User's ManualTulioLopezJBelum ada peringkat

- Hex Nut Bolt Sizes E411 GBDokumen1 halamanHex Nut Bolt Sizes E411 GBShahen ShahBelum ada peringkat

- Iso 2768-1: 1989Dokumen7 halamanIso 2768-1: 1989jferreiraBelum ada peringkat

- Hytorc Bolt Loads Ref ChartDokumen1 halamanHytorc Bolt Loads Ref ChartTulioLopezJBelum ada peringkat

- Wrench CmhartsDokumen1 halamanWrench Cmhartsmsaqibraza93Belum ada peringkat

- Flange Torque Recommendations GF PDFDokumen2 halamanFlange Torque Recommendations GF PDFTulioLopezJBelum ada peringkat

- 140109-Rt Ccee Leaflet FilmstripDokumen4 halaman140109-Rt Ccee Leaflet FilmstripTulioLopezJBelum ada peringkat

- hf10b EngDokumen6 halamanhf10b EngTulioLopezJBelum ada peringkat

- Assembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners From SteelDokumen1 halamanAssembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners From SteelDani Quirante Flaaut EtcBelum ada peringkat

- Torque Values (FT/LBS.) 100% of Yield: Bolt Diam Nut Size Moly Lube Nickel Lube Copper Lube OIL DRYDokumen6 halamanTorque Values (FT/LBS.) 100% of Yield: Bolt Diam Nut Size Moly Lube Nickel Lube Copper Lube OIL DRYTulioLopezJBelum ada peringkat

- Bearing Self Study PDFDokumen73 halamanBearing Self Study PDFcakendriBelum ada peringkat

- Wrench CmhartsDokumen1 halamanWrench Cmhartsmsaqibraza93Belum ada peringkat

- FASTORQ Standard Stud Heavy Hex Nut SpecsDokumen1 halamanFASTORQ Standard Stud Heavy Hex Nut SpecsTulioLopezJBelum ada peringkat

- FLIP p5Dokumen1 halamanFLIP p5TulioLopezJBelum ada peringkat

- Bolt Depot - US To Metric Conversion TableDokumen2 halamanBolt Depot - US To Metric Conversion TableTulioLopezJBelum ada peringkat

- Bolt and Nut Standard Size CatalogDokumen154 halamanBolt and Nut Standard Size Catalogiskandarmeran100% (1)

- Tabla Conversion ShimDokumen1 halamanTabla Conversion ShimTulioLopezJBelum ada peringkat

- 212b Flange Facer Doc 92-0291 Rev 921230Dokumen22 halaman212b Flange Facer Doc 92-0291 Rev 921230TulioLopezJBelum ada peringkat

- 212 SP FlyerDokumen2 halaman212 SP FlyerTulioLopezJBelum ada peringkat

- RT03 Torque ChartDokumen2 halamanRT03 Torque ChartTulioLopezJBelum ada peringkat

- RT03 Torque ChartDokumen2 halamanRT03 Torque ChartTulioLopezJBelum ada peringkat

- RT03 Torque ChartDokumen2 halamanRT03 Torque ChartTulioLopezJBelum ada peringkat

- 212b FF Tech SpecDokumen3 halaman212b FF Tech SpecTulioLopezJBelum ada peringkat

- 212b Elbow Mandrel Doc 92-0262 Rev 970321Dokumen16 halaman212b Elbow Mandrel Doc 92-0262 Rev 970321TulioLopezJBelum ada peringkat

- Michael JordanDokumen10 halamanMichael Jordanapi-534780597Belum ada peringkat

- Form SIKA Baru Rev04 - 2019 - CETAKDokumen1 halamanForm SIKA Baru Rev04 - 2019 - CETAKBambang HariantoBelum ada peringkat

- The Avengers Workout: Build A Superhero Physique in Six WeeksDokumen1 halamanThe Avengers Workout: Build A Superhero Physique in Six WeeksefidjozaBelum ada peringkat

- 22 Clockwork Wonders - The Crawling ShieldDokumen1 halaman22 Clockwork Wonders - The Crawling ShieldDavid L. Sant'AnaBelum ada peringkat

- 1Dokumen17 halaman1RVRM1995Belum ada peringkat

- Bangladesh Government National Pay ScalesDokumen2 halamanBangladesh Government National Pay Scalesrashu198284% (79)

- Alfa Alfasud 1.3 PDFDokumen50 halamanAlfa Alfasud 1.3 PDFnubercard6111100% (1)

- 2004 Polaris Parts ManualDokumen67 halaman2004 Polaris Parts ManualAngela TullochBelum ada peringkat

- Combilift Sideloader CatalogueDokumen2 halamanCombilift Sideloader CatalogueAulia TiaraBelum ada peringkat

- ZF 5HP19HL PDFDokumen4 halamanZF 5HP19HL PDFwilderBelum ada peringkat

- Pre Intermediate Student's Book Answer KeyDokumen53 halamanPre Intermediate Student's Book Answer KeyAna Pociello SamperizBelum ada peringkat

- Tennis Industry MagazineDokumen64 halamanTennis Industry MagazineLiya DavidovBelum ada peringkat

- Forensic 6 Module - JjbaDokumen71 halamanForensic 6 Module - Jjbabicams02Belum ada peringkat

- Kenway TXCR325 PDFDokumen24 halamanKenway TXCR325 PDFadan felipe romanBelum ada peringkat

- Free Daily Planner MondayDokumen9 halamanFree Daily Planner MondayEdgarBelum ada peringkat

- Dam Fighting Guide in Thadou-KukiDokumen43 halamanDam Fighting Guide in Thadou-Kukilulun120027598100% (1)

- 010 - CAT-6015 - RH40E - Swing SystemDokumen24 halaman010 - CAT-6015 - RH40E - Swing SystemJHONNYS ALFONSO MANJARREZ GUTIERREZBelum ada peringkat

- I410 Ecn 0199 2022 001 000168432Dokumen13 halamanI410 Ecn 0199 2022 001 000168432kwym31Belum ada peringkat

- Рессоры - Dosemenler (ALL)Dokumen114 halamanРессоры - Dosemenler (ALL)Сергей МартинюкBelum ada peringkat

- Fiat Tractors 411r Service ManualDokumen9 halamanFiat Tractors 411r Service Manualteri100% (25)

- Forensic Ballistics WK 3Dokumen18 halamanForensic Ballistics WK 3Jennielyn VillanuevaBelum ada peringkat

- Woodelf 2Dokumen22 halamanWoodelf 2Antonio Hernández PeñaBelum ada peringkat

- Optimization of Intake and Exhaust System For FSAE Car Based On Orthogonal Array Testing PDFDokumen5 halamanOptimization of Intake and Exhaust System For FSAE Car Based On Orthogonal Array Testing PDFDanielBelum ada peringkat

- 3.road MarkingDokumen9 halaman3.road MarkingMalith De SilvaBelum ada peringkat

- CQM1 OC222 Operation ManualDokumen1 halamanCQM1 OC222 Operation ManualRoberto Carlos GalavisBelum ada peringkat

- L70ae DeycDokumen11 halamanL70ae DeycAndré LuisBelum ada peringkat

- Foo Fighters - ArlandriaDokumen7 halamanFoo Fighters - ArlandriaGabriel Gonçalves AssunçãoBelum ada peringkat

- Sample Training Program: Presented by Functional Bodybuilding and Revival StrengthDokumen5 halamanSample Training Program: Presented by Functional Bodybuilding and Revival StrengthFabrizio Bosch67% (3)

- LithiumDokumen3 halamanLithiumTommaso ParmigianiBelum ada peringkat

- Log 2Dokumen2 halamanLog 2Emanuela MarinescuBelum ada peringkat