Plastic Design Guide - Part Design, Material Selection, Processing Conditions

Diunggah oleh

Adithya SjJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Plastic Design Guide - Part Design, Material Selection, Processing Conditions

Diunggah oleh

Adithya SjHak Cipta:

Format Tersedia

6/22/2016

PlasticDesignGuide:PartDesign,MaterialSelection,ProcessingConditions

ISO9001:2008(PDF) /

/ callus:5163337577

Home Services Resources AboutUs ContactUs RequestAQuote

Resources

BasicResinGuide

PlasticDesignGuide

FAQs

AdditionalResources

PLASTICDESIGNGUIDE

APIengineersanddesignerscanworkwithyoutodevelopanddesignyourplasticinjectionmoldedcomponent.To

ensureaqualitypart,therearethreemajorareasoffocusthroughoutthedesignstage:

1.Properplasticpartdesign

2.Propermaterialselectionplasticpartdesign

3.Processingconditionsforplasticinjectionmolding

ThedesignersandengineersatAPIhaveover250combinedyearsofexperienceindesigningpartsforplasticinjection

molding,selectingmaterials,andprocessingresins(specializinginengineeringandhighperformanceresins).Thisguide

wasdesignedtodemonstratethebasicelementsofproperplasticpartdesign.

DESIGNINGPARTSFORUP&DOWNMOLDINGHELPSCONTROLCOST

Designingapartthatcanbemoldedwitha"straightpull"or"up&down"motionisagreatwaytokeepthecostofthe

molddown.Astraightpullmoldisdesignedsothatwhenthetwohalves(AsideandBside)ofthemoldseparatefrom

eachother,thereisnoplasticblockingthepathofthemetalinthedirectionofthepull.Undercutsonthepartcausethis

blockageofpathandrequireanactioninthemold(cams,corepulls,etc.).Actioninthemoldcanhaveamajorimpact

onthecost(andoverallsize)ofamold.

ReadCaseStudies

UNIFORMWALLTHICKNESSHELPSTOPREVENTDEFECTS

Properwallthicknessisoneofthemostfundamentalrequirementsindesigningapartforplasticinjectionmolding.

Plasticshrinksasitcoolswhichcanleadtodefectssuchassinkmarks,voids,stresses,andwarping.Plasticresin

solidifiesinthemoldnearertotheoutsideofthepart(closesttothemoldsurface).Thicksectionsofaparttendtopull

inward,creatingstresses,sinkmarks,orvoids.Sincethinnersectionscoolquicker,stresscanbuildinthepartbetween

thinnerandthickersections,resultinginpartwarpage.

DRAFTALLOWSFORPARTSTORELEASEFROMTHEMOLD

Draftisrequiredonallpartsinthedirectionofmoldmovementinordertoallowpartstoreleaseorejectfromthemold

properly.Draftistheangleinwhichthepartistaperedtoallowittorelease.Asthepartcools,ittendstowanttoshrink

tothecoresideofthemold.Addingdrafthelpstheparttorelease.Mostpartsorapplicationsrequireaminimumof1/2

to1degree,however11/2to2degreesiswidelyacceptedasthenorm.

HOLESENHANCEPARTFUNCTIONALITYANDREDUCEWEIGHT

Holescanbeaddedtoapartforfunctionalityortoreduceoverallpartweight(coring).Corepinsaretypicallyusedto

formahole,preventingthemoltenplasticfromfillinginthatspace.Throughholesgoallthewaythroughapart.Blind

http://www.apisolution.com/plasticdesignguide.php

1/5

6/22/2016

PlasticDesignGuide:PartDesign,MaterialSelection,ProcessingConditions

holesdonotcompletelygothroughapart.Corepinsforablindholeareonlysupportedbyoneend,sothereisagreater

degreeofdifficultyinformingthemwithoutdefect.Formingholescanleadtodefectsorhaveanegativeimpacton

aesthetics.Sincethemoltenplasticflowsaroundthecorepin,itcanleaveaweldline(whichmaybevisibleand/orbe

weakerthantheremainderofthepart).

1.Thedepthofablindholeshouldbeabouttwotimesthediameterofthecorepinforsmallpins(lessthan3/16")

andfourtimesthediameterofthecorepinforpinsgreaterthan3/16".

2.Distancefromtheedgeofaholetoaverticalsurface(edgeorpartorrib)oranotherholeshouldbeatleasttwo

timesthethicknessofthepartoratleastthediameterofthecorepin(hole).

3.Holescreatedinthedirectionoftheopening/closingofthemoldorparalleltothepartinglinearerelativelyeasyto

produce.Holesatdifferentanglescanbecreated,butmayrequirespecialactioninthemoldutilizingcorepullsor

camswhichcanhavesignificantcostimpacts.

BOSSESAIDINASSEMBLYANDMOUNTING

Bossescanbeaddedtothepartdesignforassembly,locating,ormountingofapart.Improperplacementofaboss

leadstounevenwallthicknessandcanhaveanegativeimpactontheaesthetics,shrinking,orstrengthofapart.

1.Wallthicknessaroundabossfeatureshouldbe55%65%ofthenominalwallthicknessforthinwalls(lessthan

1/8")oraround40%ofthenominalwallthicknessifgreaterthan1/8"

2.Bossheightshouldbenomorethan21/2timesthediameterofaholeintheboss

RIBSENHANCEPARTSTRENGTHANDSTABILITY

Ribscanbeaddedtopartstoaddrigidityorstiffness.Addingribsallowsforaparttoincreasestrengthandbearahigher

load.Ribstoohaverecommendedguidelinestomaximizefunctionalityandminimizedefects.

1.Ribthicknessshouldbelessthanthewallthickness.Recommendedthicknessis60%to80%ofthenominal

wall.

2.Addingmoreribsaddsmorestrengthorstiffnesstoapart.Itisbettertoaddmoreribsthanmakelargerorthicker

ribs.

3.Ribsshouldbespacedatleasttwotimesthenominalwallthicknessfromoneanother.

4.Ribheightshouldbelessthanthreetimesthenominalwallthicknessofthepart.

5.Ifathickribisrequired,thecenteroftheribshouldbecored(cutout)toallowforuniformwallthickness.

ADDINGARADIUSREDUCESSTRESSONCORNERS

Radiishouldbeaddedtoanglestopreventsharpcorners.Cornerscanleadtostresses,limitmaterialflow,andoften

reducepartstrength.

1.Insideradiusofacornershouldbeatleasthalfofthewallthickness

2.Outsideradiusofacornershouldbeequaltothepartthicknessplustheinsideradius

3.Aradiusbeingaddedtoabossorribshouldbe1/4ofthepartthickness,nosmallerthan.015

Materialselectionandprocessingconditionsareequallyimportantfactorsintheproperdesignforaplasticinjection

moldedcomponentorpart.

http://www.apisolution.com/plasticdesignguide.php

2/5

6/22/2016

PlasticDesignGuide:PartDesign,MaterialSelection,ProcessingConditions

Weunderstandthatinitially,materialselectionmayseemoverwhelmingsincetherearesomanymaterialstochoose

from.YoucanresteasyknowingthatAPIhaspartneredwithresinsuppliersforover60yearsandhasamultitudeof

experienceinmanufacturingplasticpartswitheventhemostdifficulttoprocessresins.Pleaseseeourbasicresinguide

forafewexamplesofcommodityandengineeringresinsthatAPIhasbecomeanexpertinmolding.

Giveusacalltoday(516)3337577todiscussyourplasticdesignorrequestaquotetoday.

20082016AutronicPlasticsInc.Allrightsreserved.SitebyInnovativeImages.

Buildingcustommoldsandmanufacturing

plasticcomponentssince1953

Ihaveapartnooneelsecando

AutronicPlastics,Inc.succeedswheremanyothermoldershavefailed.APIspecializesinworkingwithdifficulttoprocess,engineeringresinsandhigh

percentageglassfilledmaterials.

APIpartnerswithmultipleresinsupplierstodeterminethebestsuitablematerialforcustomerneeds

RigorousR&Dandtestingcompletedonmaterialstoimproveplasticprocessingandqualityandreducecostofmanufacturing

API'sfullservicemoldshopreducessupplychainleadtimesandimprovesspeedtomarket

Onsitemolddesignersandengineerswith250combinedyearsofexperienceinplasticinjectionmoldingallowustoresolveissuesandpresentsolutions

quickly

KeyIndustries:

Security,Lighting,Military,Medical/Dental,LifeSafety,Aerospace,Healthcare,Automotive,Displays,andmore

AdditionalCapabilities:

PlasticMoldMaking,Engineering,ContractManufacturing,AutomatedandManualAssembly,CellularManufacturing,RapidPrototyping,R&D,

Joining,Decorating,Packaging,andBonding

CallUs:5163337577

EmailUs

RequestAQuote

Ihaveanidea

AutronicPlastics,Inc.canhelpyoubringyourideafromconcepttocompletion.APIisafullservicecustomplasticinjectionmolderthatworkswithcustomersto

designanddevelopnewproducts,engineersprototypes,buildsmolds,andmanufacturesplasticpartsallunderthesameroofinLongIsland,NY.

APImakesandtestsprototypestoensureproductdesignwillmeeteverystandardimaginable.

Fullspectrumplasticproductdesignandengineeringfromideationtocompletedassembly

Designersandengineersworkwithcustomerstocreate2Dprintsand3Dmodelsifneeded

75+clientpatentintheU.S.andInternationalMarkets

RapidprototypingwithinhouseFDMMachine(FusedDepositionModeling)allowourcustomerstohaveaphysicalplasticparttoevaluatepriortomold

construction

API'sprototypeevaluationforfunctionalandperformanceanalysisaswellasmanufacturabilityensuresyourproductisdesigned"RighttheFirstTime"

http://www.apisolution.com/plasticdesignguide.php

3/5

6/22/2016

PlasticDesignGuide:PartDesign,MaterialSelection,ProcessingConditions

CallUs:5163337577

EmailUs

RequestAQuote

IhaveaDesign

ExperiencedAPIdesignersandengineersworkwithyoudirectlytobringyourdesignconcepttoreality.TheAutronicPlasticsteamworkstoimproveclient

productideasandhelpstodesignplasticproductsformanufacturabilityandcostefficiency.

APIDesignersandEngineerscanworkwithcustomerstocreateorimprove2Dprintsand3Dmodels.

PlasticprototypesarecreatedwithinhouseFDMMachine(FusedDepositionModeling)toreduceoveralldevelopmenttimelineandhelpstobringyour

producttomarketquicker

Customizedrigorousprototypevalidationandtestinghelpstoensurefunctionality,manufacturabilityandcostefficiencyofyourplasticinjectionmolded

part

RighttheFirstTimeDesignNoOverDesignorUnderDesignhelpstobringyourproducttomarketquicklyandefficientlywhileavoidingcostly

aftermarketsolutions

CallUs:5163337577

EmailUs

RequestAQuote

IhaveapartIwanttoreplicate

AutronicPlastics,Inc.canreverseengineermetal,composite,orplasticinjectionmoldedpartsandcanworkwithyoutoredesign,reengineer,orreproduce

thosecomponents.

APIisexperiencedinmoldingallthermoplastics,specializinginengineering,highperformance,andglassreinforcedresins.

Optimizationandredesignservicesforexistingpartstoresolvedesignormanufacturingproblemsandtohelpreduceoverallcost

Highqualityandprecisionapplications

Everydayplasticproductsdesignedenvironmentallyfriendly

MetalReplacementforreducedweight,vibrationandnoisedampening,andlowcorrosion

Rubberreplacementforcut&abrasionresistanceandcostreduction

Nanocompositesforunique,"unplastic"typeperformance

PPAPandaftermarketreplacementforimprovedperformanceandlowercost

CallUs:5163337577

EmailUs

RequestAQuote

INeedhelpwithmyexistingpart

AutronicPlastics,Inc.hasexperiencetransferringexistingplasticinjectionmolds,canreverseengineerexistingparts,andcantroubleshootproblematic

componentstoachievesuperiorperformanceandfunctionality.

TheAPIengineersanddesignershaveover250yearsofcombinedexperienceandstrivetoexceedourcustomer'sexpectations.Ourengineersbecomea

valuableextensionofyourproductdevelopmentteam.

http://www.apisolution.com/plasticdesignguide.php

4/5

6/22/2016

PlasticDesignGuide:PartDesign,MaterialSelection,ProcessingConditions

Modifications/repairsmadetoplasticinjectionmoldsinouronsitetoolroom

Aftermarketsolutionsforexistingproducts

Everydayplasticproductsdesignedenvironmentallyfriendly

Partnershipwithmultipleresinsuppliersforexpertiseinresinselectionandprocessing

Moldflowanalysistoensurehighestlevelofqualityandbestoverallcost

CallUs:5163337577

EmailUs

RequestAQuote

http://www.apisolution.com/plasticdesignguide.php

5/5

Anda mungkin juga menyukai

- Proto Labs Whitepaper PDFDokumen15 halamanProto Labs Whitepaper PDFSugarboy3 SurBelum ada peringkat

- MIT15 769F10 Lec01 Operations StrategyDokumen16 halamanMIT15 769F10 Lec01 Operations StrategyrakeshblrBelum ada peringkat

- MK Factory EquipmentDokumen152 halamanMK Factory EquipmentironalejanBelum ada peringkat

- Turning and Drilling PPT MFG Chapter23 FinalDokumen78 halamanTurning and Drilling PPT MFG Chapter23 FinalRavichandran GBelum ada peringkat

- Module 3 PDFDokumen55 halamanModule 3 PDFSandeep VermaBelum ada peringkat

- HOW To DO Capsmill Cycle Time Reduction CadcamDokumen23 halamanHOW To DO Capsmill Cycle Time Reduction CadcamrajualagBelum ada peringkat

- Mould BaseDokumen8 halamanMould BaseMould Base ManufacturerBelum ada peringkat

- AMI Co-Injection Molding: Autodesk® Moldflow® Insight 2012Dokumen18 halamanAMI Co-Injection Molding: Autodesk® Moldflow® Insight 2012ansari_poly5264Belum ada peringkat

- Different Types of Manufacturing Processes, Their Advantages, Disadvantages and Ideal Applications Blog - MechGuruDokumen4 halamanDifferent Types of Manufacturing Processes, Their Advantages, Disadvantages and Ideal Applications Blog - MechGuruvsdeepakchandra0% (1)

- Design and Fabrication of Pneumatic Sheet Metal CuDokumen3 halamanDesign and Fabrication of Pneumatic Sheet Metal CuMohammed Abdul KaleemBelum ada peringkat

- CH 5 Plastic ProcessingDokumen23 halamanCH 5 Plastic ProcessingSahibsartaj Dhaliwal83% (6)

- Ecor WoodDokumen27 halamanEcor Woodxavier668Belum ada peringkat

- The Importance of Engineering Drawing in The Industrial Engineering ResearchDokumen6 halamanThe Importance of Engineering Drawing in The Industrial Engineering ResearchWiwit MartaBelum ada peringkat

- Rolling (Metalworking) : From Wikipedia, The Free EncyclopediaDokumen12 halamanRolling (Metalworking) : From Wikipedia, The Free Encyclopediarhajtv100% (1)

- Acronyms - Six Sigma - LeanDokumen3 halamanAcronyms - Six Sigma - LeanRone Da-anoyBelum ada peringkat

- 2.design For SustainabilityDokumen3 halaman2.design For SustainabilitySenthil KumarBelum ada peringkat

- Applications of GearsDokumen5 halamanApplications of Gearsmechanical-engg100% (3)

- Prashik Project ReportDokumen43 halamanPrashik Project ReportOm Kishor RathodBelum ada peringkat

- MAPAL Competence ISO enDokumen206 halamanMAPAL Competence ISO enMarcio ParrachoBelum ada peringkat

- Windsor Machines LTDDokumen92 halamanWindsor Machines LTDChirag kadam100% (1)

- Punch Price BookDokumen28 halamanPunch Price Book4U6ogj8b9snylkslkn3nBelum ada peringkat

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionDari EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionBelum ada peringkat

- Selective Laser SinteringDokumen5 halamanSelective Laser Sinteringmanoharanpark_433315Belum ada peringkat

- Industrial TrainingDokumen60 halamanIndustrial TrainingAnshul JangaleBelum ada peringkat

- Analysis To Optimizing Inventory Management in Dies-Mold Making Factory by Partial Least Square (PLS) Case Study: ABC CompanyDokumen3 halamanAnalysis To Optimizing Inventory Management in Dies-Mold Making Factory by Partial Least Square (PLS) Case Study: ABC CompanyInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Steps Follwed of Procedure of Making DieDokumen38 halamanSteps Follwed of Procedure of Making DieteekamBelum ada peringkat

- Broach and Form ToolDokumen20 halamanBroach and Form Toolsonu kumarBelum ada peringkat

- Environmentally Conscious, &: DesignDokumen26 halamanEnvironmentally Conscious, &: Designleila hanjani hanantoBelum ada peringkat

- Chap01-01b Preamble - Introduction To CAD CAM PDFDokumen15 halamanChap01-01b Preamble - Introduction To CAD CAM PDFRam Babu ShripatBelum ada peringkat

- Pro Sheetmetal LESSONDokumen125 halamanPro Sheetmetal LESSONramamoorthy100% (13)

- Optimization of Kerf Quality During Pulsed Laser Cutting of Aluminium Alloy SheetDokumen7 halamanOptimization of Kerf Quality During Pulsed Laser Cutting of Aluminium Alloy SheetSyafril AbdillahBelum ada peringkat

- Cold Shut DefectsDokumen3 halamanCold Shut Defectsvivek1312Belum ada peringkat

- CNC Machining Designing For SpeedDokumen9 halamanCNC Machining Designing For SpeedjaimeBelum ada peringkat

- Product Design and Value EngineeringDokumen5 halamanProduct Design and Value EngineeringParth PatelBelum ada peringkat

- 08.804 Product Design and DevelopmentDokumen4 halaman08.804 Product Design and DevelopmentManjunath NadarajanBelum ada peringkat

- Metal Injection MouldingDokumen1 halamanMetal Injection Mouldingkranthi1992Belum ada peringkat

- FRP Pultrusion CatalogDokumen6 halamanFRP Pultrusion CatalogMani MaranBelum ada peringkat

- Water LevelDokumen25 halamanWater LevelPradeep Kumar RoutrayBelum ada peringkat

- How Voids Can Occur in Plastic Injection Molded PartsDokumen4 halamanHow Voids Can Occur in Plastic Injection Molded PartsRavindra ErabattiBelum ada peringkat

- Compression Molding: Presented By: S.Muthu Raj Polymer TechnologyDokumen14 halamanCompression Molding: Presented By: S.Muthu Raj Polymer Technologymuthuu09Belum ada peringkat

- ECN Balzers 20april10 AC Falen PresterenDokumen76 halamanECN Balzers 20april10 AC Falen PresterenMiguelBelum ada peringkat

- Productivity and Reliability-Based Maintenance Management, Second EditionDari EverandProductivity and Reliability-Based Maintenance Management, Second EditionBelum ada peringkat

- QFD For Gas OvenDokumen1 halamanQFD For Gas OvenEngr Jehangir Khan100% (1)

- Solid Freeform FabricationDokumen24 halamanSolid Freeform FabricationpsenthilpkumarBelum ada peringkat

- Manufacturing Operation InstructionDokumen74 halamanManufacturing Operation InstructionEastWest Industries100% (1)

- Designing and Manufacturing of Alloy Wheel Using 3d Printing TechnologyDokumen6 halamanDesigning and Manufacturing of Alloy Wheel Using 3d Printing TechnologyEditor IJTSRDBelum ada peringkat

- Traditipn Production Planning and ControlDokumen16 halamanTraditipn Production Planning and ControlpaulineBelum ada peringkat

- The Word Manufacture First Appeared in English in 1567 and Is Derived From The Latin Manu FactusDokumen8 halamanThe Word Manufacture First Appeared in English in 1567 and Is Derived From The Latin Manu Factushassan9705Belum ada peringkat

- Get A Free Injection Molded Part Quote From Proto Labs - ProtoQuote DemoDokumen4 halamanGet A Free Injection Molded Part Quote From Proto Labs - ProtoQuote DemoДушан ТомићBelum ada peringkat

- Hybrid Additive ManufacturingDokumen9 halamanHybrid Additive ManufacturingAbhishek KaleBelum ada peringkat

- General Introduction: ISYE6061-Manufacturing Engineering Technology in SI Units, 6 EditionDokumen49 halamanGeneral Introduction: ISYE6061-Manufacturing Engineering Technology in SI Units, 6 EditionSinta AmiraBelum ada peringkat

- AB Steel For Moulds EngDokumen28 halamanAB Steel For Moulds EngsansagithBelum ada peringkat

- Metalworking Processes LVDDokumen12 halamanMetalworking Processes LVDSang Ka KalaBelum ada peringkat

- Shubham Singh Project ReportDokumen123 halamanShubham Singh Project ReportShivani SahuBelum ada peringkat

- Alfa Week 1Dokumen13 halamanAlfa Week 1Cikgu kannaBelum ada peringkat

- CURRICULUM PharmasubDokumen10 halamanCURRICULUM PharmasubZE Mart DanmarkBelum ada peringkat

- Immunity Question Paper For A Level BiologyDokumen2 halamanImmunity Question Paper For A Level BiologyJansi Angel100% (1)

- Angle Modulation: Hệ thống viễn thông (Communication Systems)Dokumen41 halamanAngle Modulation: Hệ thống viễn thông (Communication Systems)Thành VỹBelum ada peringkat

- Nizkor Project Fallacies - LabossierDokumen77 halamanNizkor Project Fallacies - Labossierapi-3766098100% (1)

- Evidence Prove DiscriminationDokumen5 halamanEvidence Prove DiscriminationRenzo JimenezBelum ada peringkat

- Federalist Papers 10 51 ExcerptsDokumen2 halamanFederalist Papers 10 51 Excerptsapi-292351355Belum ada peringkat

- CATaclysm Preview ReleaseDokumen52 halamanCATaclysm Preview ReleaseGhaderalBelum ada peringkat

- Simran's ResumeDokumen1 halamanSimran's ResumesimranBelum ada peringkat

- Analysis of Rates (Nh-15 Barmer - Sanchor)Dokumen118 halamanAnalysis of Rates (Nh-15 Barmer - Sanchor)rahulchauhan7869Belum ada peringkat

- SG110CX: Multi-MPPT String Inverter For SystemDokumen2 halamanSG110CX: Multi-MPPT String Inverter For SystemKatherine SmithBelum ada peringkat

- DirectionDokumen1 halamanDirectionJessica BacaniBelum ada peringkat

- Smartfind E5 g5 User ManualDokumen49 halamanSmartfind E5 g5 User ManualdrewlioBelum ada peringkat

- Applying For A Job: Pre-ReadingDokumen5 halamanApplying For A Job: Pre-ReadingDianitta MaciasBelum ada peringkat

- 3D Printing & Embedded ElectronicsDokumen7 halaman3D Printing & Embedded ElectronicsSantiago PatitucciBelum ada peringkat

- 19 Dark PPT TemplateDokumen15 halaman19 Dark PPT TemplateKurt W. DelleraBelum ada peringkat

- 02 Object Modeling TechniqueDokumen50 halaman02 Object Modeling TechniqueMuhammad Romadhon Batukarang EsdBelum ada peringkat

- Existentialism in CinemaDokumen25 halamanExistentialism in CinemanormatthewBelum ada peringkat

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFDokumen18 halamanIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamBelum ada peringkat

- IM1 Calculus 2 Revised 2024 PUPSMBDokumen14 halamanIM1 Calculus 2 Revised 2024 PUPSMBEunice AlonzoBelum ada peringkat

- Project Quality Plan (JFJS-788)Dokumen18 halamanProject Quality Plan (JFJS-788)mominBelum ada peringkat

- CHARACTER FORMATION 1 PrelimDokumen15 halamanCHARACTER FORMATION 1 PrelimAiza Minalabag100% (1)

- Safety Bulletin 09 - Emergency Escape Breathing Device - Product RecallDokumen2 halamanSafety Bulletin 09 - Emergency Escape Breathing Device - Product RecallMuhammadBelum ada peringkat

- PostScript Quick ReferenceDokumen2 halamanPostScript Quick ReferenceSneetsher CrispyBelum ada peringkat

- Research FinalDokumen55 halamanResearch Finalkieferdem071908Belum ada peringkat

- Zomato Restaurant Clustering & Sentiment Analysis - Ipynb - ColaboratoryDokumen27 halamanZomato Restaurant Clustering & Sentiment Analysis - Ipynb - Colaboratorybilal nagoriBelum ada peringkat

- Virtual WorkDokumen12 halamanVirtual Workdkgupta28Belum ada peringkat

- The New Order of BarbariansDokumen39 halamanThe New Order of Barbariansbadguy100% (1)

- Wealth and Poverty in The Book of Proverbs PDFDokumen133 halamanWealth and Poverty in The Book of Proverbs PDFMaahes Cultural Library100% (1)

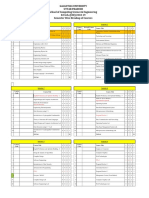

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDokumen2 halamanGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiBelum ada peringkat