Calibration of Smart Transmitters

Diunggah oleh

Lugabaluga0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

110 tayangan4 halamanCalibration of Smart Transmitters

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniCalibration of Smart Transmitters

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

110 tayangan4 halamanCalibration of Smart Transmitters

Diunggah oleh

LugabalugaCalibration of Smart Transmitters

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

Calibration of Smart Transmitters (Pressure, Temperature, Level,

Flow, and Analytical)

The procedure for calibrating a smart digital transmitter is known as

Digital trimming. A digital trim is a calibration exercise that allows the user to

correct the transmitters digital signal to match plant standard or

compensate for installation effects. Digital trim in a smart transmitter can be

done in two ways:

a) A Sensor Trim: It consist of matching the process variable (be it

pressure, level, flow or temperature) reading of the transmitter to

a precision input. This process normally involves trimming the

digital circuit of the input Analog-to-Digital converter in the smart

transmitter.

b) A 4 20mA or Current Loop Trim: This is done by trimming

the output Digital-to-Analog converter in the transmitter.

Actions That

Transmitters

Do

Not

Constitute

Proper

Calibration

in

Smart

Before we discuss in detail what constitute a proper calibration, let us

mention certain common practice that are not proper calibrations:

a) Changing the range (LRV and URV) of a smart transmitter

constitute a configuration change and not a calibration. This

range change merely affects the mathematical computation

done by the microprocessor. It has no effect on the digital

process variable as read by a hand-held digital communicator.

b) Using only the zero and span adjustments to calibrate a smart

transmitter

often

corrupts the internal digital readings. You may not notice this if

you dont use a hand-held digital communicator to read the

range or digital process data.

c) Using a hand-held digital communicator to adjust the current

loop so that an accurate input to the transmitter agrees with

some readout device on the loop does not constitute a proper

calibration.

Procedure for Calibrating a Smart Transmitter

To do a proper calibration on a smart transmitter will involve both a

sensor trim and/or a 4 20mA trim depending on the application where the

transmitter is being used. A smart transmitter typically has high and low trim

functions which unlike the zero and span adjustments of an analog

transmitter, are non-interactive. That is adjusting the high trim function has

no effect on the low trim function and vice versa.

Before proceeding to the section below note that a smart transmitter

has three outputs which must be clearly understood:

a) Digital Process Variable (PV) usually read by a hand-held

communicator

b) Digital Value of the output current in mA (PVAO) which the

communicator also reads.

c) The analog 4 20mA signal output which can be read with a

suitable milliammeter but cannot be read by the digital handheld communicator.

For the smart transmitter to be properly calibrated, the error between

the applied input to the transmitter and the digital output (PV) must be

within the error specification of the manufacturer otherwise a sensor trim will

be required to correct this. Similarly, the error between the digital milliamp

value (PV AO) and the analog mA value must be within the error specification

of the manufacturer otherwise a 4 20mA trim is required.

Performing a Sensor Trim:

Before performing a sensor trim, run a test, commonly referred to as

the AS-FOUND TEST to confirm the consistency of the sensor and the input

Analog-to-Digital converter. Connect the test setup as shown below:

Performing a Sensor Trim on a Smart Transmitter

Use a precision calibrator to measure the applied input to the

transmitter. Read the resulting output (PV) with a hand-held communicator.

Calculate the resulting error between the applied input and the output (PV)

since both are in the same engineering units. Note that the desired accuracy

for this test will be the manufacturers accuracy specification. If this test

does not pass, then follow the manufacturers recommended procedure for

trimming the sensor.

Below are general guidelines for performing a sensor trim:

a) Apply the lower-range value stimulus to the transmitter, wait for it to

stabilize

b) Execute the low sensor trim function

c) Apply the upper-range value stimulus to the transmitter, wait for it to

stabilize

d) Execute the high sensor trim function stimulus as used here should

be understood to mean the process variable input to the transmitter.

Performing a 4 20mA Trim:

Before performing a 4 20mA trim, run a test, commonly referred to as

the AS-FOUND TEST to confirm the consistency of the output Digital-toAnalog converter and the analog output of the transmitter. This procedure

may also be called a 4-20 mA trim, a current loop trim, or a Digital-to-Analog

converter trim. Connect the test setup as shown below:

Performing a 4 - 20mA Trim on a Smart Transmitter

Use a hand-held digital communicator to put the smart transmitter into

a fixed current output mode. The input value for this test is the mA value

that you instruct the transmitter to produce. The output value is obtained

using a precision milliammeter to measure the resulting current. Calculate

the error between the digital mA value produced by the transmitter and the

analog mA value measured by the current meter. The desired accuracy for

this test should also reflect the manufacturers accuracy specification. If the

test does not pass, then follow the manufacturers recommended procedure

for trimming the output section. The trim procedure should require two trim

points close to or just outside of 4mA and 20 mA. Do not confuse this with

any form of re-ranging or any procedure that involves using zero

and span buttons on the transmitter.

Below are the general guidelines for performing a 4 20mA trim:

a) Execute the low output trim test function on the transmitter.

b) Measure the output signal with a precision milliammeter, noting the

value after it stabilizes

c) Enter this measured current value when prompted by the transmitter

d) Execute the high output trim test function

e) Measure the output signal with a precision milliammeter, noting the

value after it stabilizes

f) Enter this measured current value when prompted by the transmitter

After both the input and output (ADC and DAC) of a smart transmitter

have been trimmed (i.e. calibrated against standard references known to be

accurate), the lower- and upper-range values (LRV and URV) may be set. In

fact, once the trim procedures are complete, the transmitter may be ranged

and ranged again as many times as desired. The only reason for re-trimming

a smart transmitter is to ensure accuracy over long periods of time where

the sensor and/or the converter circuitry may have drifted out of acceptable

limits. The situation is very different in an analog transmitter, where reranging necessitates re-calibration.

Transmitter Damping:

Many HART transmitters support a parameter called damping. If this is

not set to zero, it can have an adverse effect on tests and adjustments.

Damping induces a delay between a change in the transmitter input and the

detection of that change in the digital value for the transmitter input reading

and the corresponding output value. It is advisable to adjust the transmitters

damping value to zero prior to performing tests or adjustments. After

calibration, be sure to return the damping constant to its required value.

Anda mungkin juga menyukai

- Flow & Level Calibration Notes: Differential Pressure Transmitter CalibrationDokumen9 halamanFlow & Level Calibration Notes: Differential Pressure Transmitter Calibrationterio16100% (1)

- Introduction To Smart TransmittersDokumen3 halamanIntroduction To Smart Transmitterssleepfox9Belum ada peringkat

- Calibration of Differential Pressure TransmitterDokumen8 halamanCalibration of Differential Pressure TransmitterLugabaluga100% (1)

- Standard Check List: Pressure TransmiterDokumen3 halamanStandard Check List: Pressure TransmiterROUNAK MANDALBelum ada peringkat

- Sip-Sop04-R0-2017 Sop DPT Level CalibrationDokumen2 halamanSip-Sop04-R0-2017 Sop DPT Level CalibrationDwi Mulyanti DwimulyantishopBelum ada peringkat

- DPT Calibration FFDokumen4 halamanDPT Calibration FFKram Alim VillonBelum ada peringkat

- Control Valve Calibration Procedure (Fisher HC6010)Dokumen14 halamanControl Valve Calibration Procedure (Fisher HC6010)Karen Cain93% (15)

- SIP-SOP02-R0-2017 SOP Differential Pressure Transmitter CalibrationDokumen3 halamanSIP-SOP02-R0-2017 SOP Differential Pressure Transmitter CalibrationDwi Mulyanti Dwimulyantishop100% (1)

- CAT CP 1 (T) Calibration of RTDDokumen4 halamanCAT CP 1 (T) Calibration of RTDAmar Singh100% (1)

- Field Instrumentation (Oil and Gas)Dokumen4 halamanField Instrumentation (Oil and Gas)Mohamed RaeesBelum ada peringkat

- EG 15-14-1.2 Instrument Calibration: ScopeDokumen21 halamanEG 15-14-1.2 Instrument Calibration: ScopeaminBelum ada peringkat

- Loop Check: Operator's GuideDokumen21 halamanLoop Check: Operator's Guidemc_prayerBelum ada peringkat

- InstrumentationDokumen7 halamanInstrumentationEmmanuel Enriquez0% (1)

- Method Statement For Instrument Calibration PDFDokumen14 halamanMethod Statement For Instrument Calibration PDFMohamed AdelBelum ada peringkat

- TransmittersDokumen20 halamanTransmittersTimothy LeonardBelum ada peringkat

- Instrument QuestionDokumen41 halamanInstrument QuestionMallick100% (1)

- Instrumentation CoursesDokumen2 halamanInstrumentation CoursesAbdul LateefBelum ada peringkat

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDokumen3 halaman6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARBelum ada peringkat

- Control Valve Calibration Procedure Fisher HC6010 PDFDokumen14 halamanControl Valve Calibration Procedure Fisher HC6010 PDFAnonymous JwOs90v6TUBelum ada peringkat

- Level Measurement (RADAR Trasnmitter)Dokumen17 halamanLevel Measurement (RADAR Trasnmitter)febri_bontangBelum ada peringkat

- Digital PID ControllersDokumen21 halamanDigital PID Controllerssopan saBelum ada peringkat

- Instrumentation Part 2omkarDokumen117 halamanInstrumentation Part 2omkaromkarvadlooriBelum ada peringkat

- DCS SystemDokumen19 halamanDCS Systemubaid100% (1)

- Elster Instromet Q.sonicDokumen2 halamanElster Instromet Q.sonicsaid_rahmansyah4750Belum ada peringkat

- METHOD STATEMENT PRESSURE SWITCH UAE Univ.Dokumen2 halamanMETHOD STATEMENT PRESSURE SWITCH UAE Univ.Muhamed RasheedBelum ada peringkat

- Transmitter and Smart TransmitterDokumen57 halamanTransmitter and Smart TransmitterBHAGSEN PARVATBelum ada peringkat

- DPI610 615 ManualDokumen90 halamanDPI610 615 ManualAbd Al-Rahmman Al-qatananiBelum ada peringkat

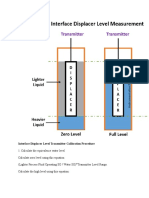

- Interface Displacer Level Transmitter Calibration ProcedureDokumen3 halamanInterface Displacer Level Transmitter Calibration ProcedureAs'adi MozartBelum ada peringkat

- Advanced Fieldbus Diagnostics Without FieldbusDokumen12 halamanAdvanced Fieldbus Diagnostics Without FieldbusMarcio RochaBelum ada peringkat

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDokumen38 halamanD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- Level Transmitter Calibration ReferenceDokumen6 halamanLevel Transmitter Calibration ReferenceSijo JoyBelum ada peringkat

- Calibration of Absolute Pressure TransmitterDokumen4 halamanCalibration of Absolute Pressure Transmitterget_engineer05Belum ada peringkat

- Loop Checking Procedure IdeasDokumen2 halamanLoop Checking Procedure IdeasJonatas13Belum ada peringkat

- Commissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD SingaporeDokumen52 halamanCommissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD Singaporesolo AdoBelum ada peringkat

- Loop Checking Basic ProcedureDokumen4 halamanLoop Checking Basic ProcedureHamada Elsharawy100% (1)

- Leak Detection in Pipeline-JijoDokumen17 halamanLeak Detection in Pipeline-Jijoamulbaby31Belum ada peringkat

- Appendix D: Engineering Standards Manual ISD 341-2Dokumen17 halamanAppendix D: Engineering Standards Manual ISD 341-2tadagidsBelum ada peringkat

- E&I Inspector Shahruddin AwangDokumen3 halamanE&I Inspector Shahruddin AwangMohd FiqrieBelum ada peringkat

- Basics of Instrumentation & ControlDokumen29 halamanBasics of Instrumentation & ControlprathmeshBelum ada peringkat

- Instrumentation Interview QuestionDokumen35 halamanInstrumentation Interview Questionabbutalibb100% (1)

- FBN04227 Fieldbus FDS SampleDokumen25 halamanFBN04227 Fieldbus FDS SampleJorge Pérez FrisanchoBelum ada peringkat

- Measurement and Calibration HandbookDokumen100 halamanMeasurement and Calibration HandbookAhmed Ramadan100% (2)

- GE Druck DPI610 615 Is ManualDokumen96 halamanGE Druck DPI610 615 Is Manualqasim_maqboolBelum ada peringkat

- A Report On Level Measuring Instruments: Submitted byDokumen54 halamanA Report On Level Measuring Instruments: Submitted byபிரசன்னகுமார் ஆனந்தன்Belum ada peringkat

- 1218 Instrument Testing & Calibration Procedure NTGFDPDokumen50 halaman1218 Instrument Testing & Calibration Procedure NTGFDPTaha Hasan100% (1)

- Calibration Procedure - Pressure TransmitterDokumen1 halamanCalibration Procedure - Pressure TransmittersathyanduraisamyBelum ada peringkat

- 1995 ISA Calibrating HART TransmittersDokumen11 halaman1995 ISA Calibrating HART TransmitterskevinakiniBelum ada peringkat

- Basic Inst.Dokumen15 halamanBasic Inst.mahesh4975Belum ada peringkat

- Yokogawa ADMAG AXF Magnetic FlowmeterDokumen133 halamanYokogawa ADMAG AXF Magnetic Flowmeter1234567890Belum ada peringkat

- DP Transmitter CalibrationDokumen2 halamanDP Transmitter CalibrationsupercontrollerBelum ada peringkat

- WP - EDDL CalibrationtrimDokumen13 halamanWP - EDDL CalibrationtrimDamien NeylonBelum ada peringkat

- Smart Transmitter HartDokumen31 halamanSmart Transmitter HartNur Aleeya FazlinBelum ada peringkat

- Intelligent Device Management Tutorial: CalibrationDokumen16 halamanIntelligent Device Management Tutorial: Calibrationtrozn2812100% (1)

- Chapter 1Dokumen135 halamanChapter 1Murali ShettyBelum ada peringkat

- Smart Is Process Jargon That Describes AnyDokumen16 halamanSmart Is Process Jargon That Describes AnyDevidutta PandaBelum ada peringkat

- EDD Calibration TrimDokumen23 halamanEDD Calibration TrimAnonymous cXjAZTBelum ada peringkat

- Help To Select Your Signal Level Meter: To Begin With There Are Three Varieties of MetersDokumen3 halamanHelp To Select Your Signal Level Meter: To Begin With There Are Three Varieties of Metersanmol149Belum ada peringkat

- Study of Various ADCs and Compare Their Performance and ParametersDokumen12 halamanStudy of Various ADCs and Compare Their Performance and ParametersijaertBelum ada peringkat

- Analog To Digital ConvertersDokumen11 halamanAnalog To Digital Convertersمحمد ماجدBelum ada peringkat

- Ad7714/Ad7715 Instrumentation Converter Faqs: Calibration: How Is Self-Calibration Implemented On The Ad7714/Ad7715?Dokumen4 halamanAd7714/Ad7715 Instrumentation Converter Faqs: Calibration: How Is Self-Calibration Implemented On The Ad7714/Ad7715?mhasansharifiBelum ada peringkat

- Managing Electrical Risks in The WorkplaceDokumen64 halamanManaging Electrical Risks in The WorkplaceNiyaz Mohammed Abdul KareemBelum ada peringkat

- Chapter 1 - CalculusDokumen50 halamanChapter 1 - CalculusLugabalugaBelum ada peringkat

- Calibration of Smart TransmittersDokumen4 halamanCalibration of Smart TransmittersLugabalugaBelum ada peringkat

- Calibration of Pressure GaugeDokumen2 halamanCalibration of Pressure GaugeLugabalugaBelum ada peringkat

- Calibration of Control Valve (Regulating)Dokumen5 halamanCalibration of Control Valve (Regulating)LugabalugaBelum ada peringkat

- Introduction To SafetyDokumen57 halamanIntroduction To SafetyLugabalugaBelum ada peringkat

- Instru ReportDokumen1 halamanInstru ReportLugabalugaBelum ada peringkat

- Corn ProductionDokumen12 halamanCorn ProductionAmeerah Cabangal83% (6)

- Introduction To Safety ManagementDokumen13 halamanIntroduction To Safety ManagementLugabalugaBelum ada peringkat

- Discrete Random VariableDokumen4 halamanDiscrete Random VariableLugabalugaBelum ada peringkat

- AguideDokumen107 halamanAguidejenkinwinBelum ada peringkat

- Instrumentation and ControlDokumen2 halamanInstrumentation and ControlLugabalugaBelum ada peringkat

- Summary of PEC1Dokumen37 halamanSummary of PEC1LugabalugaBelum ada peringkat

- Corn ProductionDokumen12 halamanCorn ProductionAmeerah Cabangal83% (6)

- Basic Principles of Instrument CalibrationDokumen6 halamanBasic Principles of Instrument CalibrationLugabaluga100% (1)

- Basic Electrical ConceptsDokumen17 halamanBasic Electrical ConceptsLugabalugaBelum ada peringkat

- DCS FundamentalsDokumen64 halamanDCS FundamentalsLugabalugaBelum ada peringkat

- Motor AND Motor Control CenterDokumen61 halamanMotor AND Motor Control CenterLugabalugaBelum ada peringkat

- Magnetically Coupled Circuits: Chapter ObjectivesDokumen25 halamanMagnetically Coupled Circuits: Chapter ObjectivesNitin MarwahBelum ada peringkat

- Lu DecompositionDokumen4 halamanLu DecompositionLugabalugaBelum ada peringkat

- OSH Standards 2017Dokumen422 halamanOSH Standards 2017Kap LackBelum ada peringkat

- Chapter 2. Random Variables: NiprlDokumen59 halamanChapter 2. Random Variables: NiprlLugabalugaBelum ada peringkat

- Chapter 2Dokumen59 halamanChapter 2LugabalugaBelum ada peringkat

- PechayDokumen1 halamanPechayLugabaluga60% (5)

- Diff Cal Rules EngDokumen4 halamanDiff Cal Rules EngAlexander Kim WaingBelum ada peringkat

- Final Examination Basic Electronics Name: Date of Exam: Subject/Section InstructorDokumen2 halamanFinal Examination Basic Electronics Name: Date of Exam: Subject/Section InstructorLugabalugaBelum ada peringkat

- Gen Math Quiz Simple and CompoundDokumen1 halamanGen Math Quiz Simple and CompoundLugabalugaBelum ada peringkat

- Trigo1Final Small FinalDokumen2 halamanTrigo1Final Small FinalLugabalugaBelum ada peringkat

- G JaxDokumen4 halamanG Jaxlevin696Belum ada peringkat

- Sewing Machins Operations ManualDokumen243 halamanSewing Machins Operations ManualjemalBelum ada peringkat

- Is 10719 (Iso 1302) - 1Dokumen1 halamanIs 10719 (Iso 1302) - 1Svapnesh ParikhBelum ada peringkat

- National Senior Certificate: Grade 12Dokumen13 halamanNational Senior Certificate: Grade 12Marco Carminé SpidalieriBelum ada peringkat

- The Fundamentals of Investing PPT 2.4.4.G1Dokumen36 halamanThe Fundamentals of Investing PPT 2.4.4.G1Lùh HùñçhòBelum ada peringkat

- Gujarat Technological UniversityDokumen2 halamanGujarat Technological UniversityBhavesh PatelBelum ada peringkat

- Computer System Sevicing NC Ii: SectorDokumen44 halamanComputer System Sevicing NC Ii: SectorJess QuizzaganBelum ada peringkat

- Ks 1609Dokumen5 halamanKs 1609krish dabhiBelum ada peringkat

- Triplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionDokumen2 halamanTriplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionMaz Ariez EkaBelum ada peringkat

- Relay Interface ModulesDokumen2 halamanRelay Interface Modulesmahdi aghamohamadiBelum ada peringkat

- Faida WTP - Control PhilosophyDokumen19 halamanFaida WTP - Control PhilosophyDelshad DuhokiBelum ada peringkat

- CasesDokumen4 halamanCasesNaveen Stephen LoyolaBelum ada peringkat

- h6811 Datadomain DsDokumen5 halamanh6811 Datadomain DsChristian EstebanBelum ada peringkat

- Company Law Handout 3Dokumen10 halamanCompany Law Handout 3nicoleclleeBelum ada peringkat

- OOPS Notes For 3rd Sem ALL ChaptersDokumen62 halamanOOPS Notes For 3rd Sem ALL Chaptersabhishek singh83% (6)

- จัดตารางสอบกลางภาคภาคต้น53Dokumen332 halamanจัดตารางสอบกลางภาคภาคต้น53Yuwarath SuktrakoonBelum ada peringkat

- ProAim InstructionsDokumen1 halamanProAim Instructionsfeli24arias06Belum ada peringkat

- VRIODokumen3 halamanVRIOJane Apple BulanadiBelum ada peringkat

- Review Questions Financial Accounting and Reporting PART 1Dokumen3 halamanReview Questions Financial Accounting and Reporting PART 1Claire BarbaBelum ada peringkat

- 7373 16038 1 PBDokumen11 halaman7373 16038 1 PBkedairekarl UNHASBelum ada peringkat

- Business Plan GROUP 10Dokumen35 halamanBusiness Plan GROUP 10Sofia GarciaBelum ada peringkat

- 1.2 The Main Components of Computer SystemsDokumen11 halaman1.2 The Main Components of Computer SystemsAdithya ShettyBelum ada peringkat

- Jainithesh - Docx CorrectedDokumen54 halamanJainithesh - Docx CorrectedBala MuruganBelum ada peringkat

- 1.functional Specification PTP With EDIDokumen36 halaman1.functional Specification PTP With EDIAnil Kumar100% (4)

- TRX Documentation20130403 PDFDokumen49 halamanTRX Documentation20130403 PDFakasameBelum ada peringkat

- Certification DSWD Educational AssistanceDokumen3 halamanCertification DSWD Educational AssistancePatoc Stand Alone Senior High School (Region VIII - Leyte)Belum ada peringkat

- Ss1169 - Telecom Frameworx l1TMFDokumen65 halamanSs1169 - Telecom Frameworx l1TMFPrince SinghBelum ada peringkat

- Modeling and Fuzzy Logic Control of A Quadrotor UAVDokumen5 halamanModeling and Fuzzy Logic Control of A Quadrotor UAVAnonymous kw8Yrp0R5rBelum ada peringkat

- Double Inlet Airfoil Fans - AtzafDokumen52 halamanDouble Inlet Airfoil Fans - AtzafDaniel AlonsoBelum ada peringkat

- POM 3.2 Marketing Management IIDokumen37 halamanPOM 3.2 Marketing Management IIDhiraj SharmaBelum ada peringkat