Check For Punching Shear:: Pile Cap Design (PC3a)

Diunggah oleh

Sheikh Mizanur RahmanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Check For Punching Shear:: Pile Cap Design (PC3a)

Diunggah oleh

Sheikh Mizanur RahmanHak Cipta:

Format Tersedia

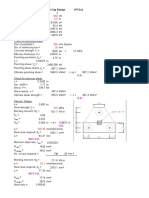

Pile Cap Design

No. of pile in the group, N =

3

Pile dia. =

457 mm =

0.457 m

c/c distance of piles =

1.371 m

Pile capacity =

540 kN

Cap thickness, t =

0.8 m

Area of cap, A =

3.2 m2

Weight of cap, W =

61.4 kN

Applied working load =

1558.6 kN

Applied factored load, P =

2005.0 kN

Pile reaction, R =

668.3 kN

Check for punching shear:

Size of pedestal =

Dia. of reinforcing bar =

Concrete strength, f'c =

( PC3a )

=

=

=

=

=

=

=

=

=

17.99

0.05

121.39

31.49

34.44

13.81

350.36

450.72

150.24

375 mm Square =

25 mm

3494.5

Effective thickness, d =

0.5875

Punching perimeter, b0 =

3.85

y=

0.48125 m

y_1=(s-dp)/2

0.457 m

y_2 =

0.563024 m

Punching shear, Vp =

1934.07

Punching shear stress, vp =

1006.0

psi

m

kN

kN/m

1630.7 kN/m2

Ultimate punching shear =

0.140625 sqm

24.10 MPa

23.124 inches

=

=

151.536 inches

18.942 inches

434.78 kips

Check for one-way shear:

x=

0.775 m

=

Sec. width =

1.00 m

=

Shear, V =

358.3 kN

=

Shear stress , v =

717.6 kN/m2

Ultimate shear strength =

815.4 kN/m2

> vp =

1006.0 kN/m2

O.K.

30.504 inches

39.36 inches

80.55 kips

> v=

717.6 kN/m2

O.K.

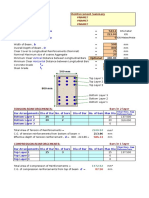

Flexure Design:

b=

Steel strength, fy =

0.757 m =

dreq =

29.796 inches

276 MPa = 40020 psi

Bending moment, M1 =

b1 =

0.85

rmax =

0.038

458.1 kN.m

0.057 m < d =

0.5875 m

O.K.

59 mm(Assumed)

a=

Steel area required, As =

3305.3 mm2

a=

58.83 mm

O.K.

Minimum steel ratio, rmin =

0.004998

As,min =

2223 mm2

As,Design =

No. of bars required =

Bending moment, M2 =

3305 mm2

6.7

inches

inches

kips

inches

sft

kips

kips

kips

kips

25 mm f

403.7 kN.m

a=

51 mm(Assumed)

Steel area required, As =

2891.7 mm2

a=

51.95 mm

O.K.

As,min =

2202 mm2

As,Design =

2892 mm2

Steel ratio =

0.00650

No. of bars required =

5.9

25 mm f

A, AA, Ac

Area of pile cap

Anda mungkin juga menyukai

- Discrete Element Method to Model 3D Continuous MaterialsDari EverandDiscrete Element Method to Model 3D Continuous MaterialsBelum ada peringkat

- Design of BracingDokumen4 halamanDesign of Bracingankkeshmundra1Belum ada peringkat

- RCC21 Subframe AnalysisDokumen9 halamanRCC21 Subframe AnalysisZayyan RomjonBelum ada peringkat

- Effective Length - Calc PDFDokumen1 halamanEffective Length - Calc PDFsundar_s_2k100% (1)

- W12x30 Beam To BeamDokumen6 halamanW12x30 Beam To BeamWin ThanBelum ada peringkat

- Wind Load Calculations On VesselsDokumen3 halamanWind Load Calculations On VesselssudhakarebvnBelum ada peringkat

- Giao An Thep 1Dokumen33 halamanGiao An Thep 1Trinh Duy KhanhBelum ada peringkat

- Breeder House FoundationDokumen16 halamanBreeder House FoundationRobbyTeresaBelum ada peringkat

- A23.3-04 CorbelsDokumen3 halamanA23.3-04 CorbelsDivyesh MistryBelum ada peringkat

- Mxy Abs MX MX Mxy Abs My My Mxy Abs MX MX: Sample CalculationDokumen3 halamanMxy Abs MX MX Mxy Abs My My Mxy Abs MX MX: Sample CalculationUttam Kumar GhoshBelum ada peringkat

- PurlinDokumen8 halamanPurlinRafaArdiSyahrezaBelum ada peringkat

- Steel Beam DesignDokumen36 halamanSteel Beam DesignTan Choon LengBelum ada peringkat

- Here: Mat Foundation Design Spreadsheet PDFDokumen2 halamanHere: Mat Foundation Design Spreadsheet PDFbiniamBelum ada peringkat

- M3D - SampleProblemSet ACI PDFDokumen6 halamanM3D - SampleProblemSet ACI PDFasaisenthilBelum ada peringkat

- Beam DesignDokumen7 halamanBeam DesignKasi ViswanathanBelum ada peringkat

- Is800-2007 Appendix PDFDokumen85 halamanIs800-2007 Appendix PDFDebasish MondalBelum ada peringkat

- Pinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryDokumen4 halamanPinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryTuanQuachBelum ada peringkat

- Eccentric FootingDokumen13 halamanEccentric FootingMegatech Engineering Consultants100% (1)

- Actual Base Plate Design-V1.2-42-210Dokumen6 halamanActual Base Plate Design-V1.2-42-210Livian TeddyBelum ada peringkat

- Lifting Lug CalculationDokumen2 halamanLifting Lug Calculationmih1Belum ada peringkat

- Storage SheetDokumen8 halamanStorage SheetFauzankalibataBelum ada peringkat

- For Battened Columns For Strength Cal 10% Increase in The KL/RDokumen4 halamanFor Battened Columns For Strength Cal 10% Increase in The KL/RvineetukBelum ada peringkat

- Reinf. AreaDokumen67 halamanReinf. AreaWaheed AhmadBelum ada peringkat

- 1.wind Load BNBC Aisc Open Code 60mDokumen9 halaman1.wind Load BNBC Aisc Open Code 60mAnonymous ep7LE5ZdP5Belum ada peringkat

- Column DesignDokumen2 halamanColumn DesignSathish SelvaBelum ada peringkat

- Analysis & Design of Combined Footing: Condition:1Dokumen3 halamanAnalysis & Design of Combined Footing: Condition:1Nikhil PoriyaBelum ada peringkat

- Concrete Column Design Based On ACI 318-05: Input Data & Design SummaryDokumen3 halamanConcrete Column Design Based On ACI 318-05: Input Data & Design SummaryManuel SueroBelum ada peringkat

- Estimating Deadloads On Timber CanopiesDokumen1 halamanEstimating Deadloads On Timber CanopiesConrad HarrisonBelum ada peringkat

- Design of Wind Pressure of SiloDokumen1 halamanDesign of Wind Pressure of SilosrinivasBelum ada peringkat

- Column Base PlateDokumen3 halamanColumn Base PlatePurnima ArkalgudBelum ada peringkat

- Planning, Analysis and Design of Open Air Cricket Stadium: Presented byDokumen12 halamanPlanning, Analysis and Design of Open Air Cricket Stadium: Presented byCatherine J. RoseBelum ada peringkat

- SteelDesign Composite Fu NewDokumen16 halamanSteelDesign Composite Fu Newpresentasi mankonBelum ada peringkat

- Pinned Base Plate - 03SF01Dokumen15 halamanPinned Base Plate - 03SF01vivekBelum ada peringkat

- 15 Ton Tank Concrete PlatformDokumen1 halaman15 Ton Tank Concrete PlatformerickquintoBelum ada peringkat

- CorbelDokumen5 halamanCorbelBharathi ThadigotlaBelum ada peringkat

- Thermal Stress ExamplesDokumen10 halamanThermal Stress ExamplesVishal V BhagwatBelum ada peringkat

- Vertical Vessel Foundation Design Input Parameters: Geometrical DescriptionDokumen8 halamanVertical Vessel Foundation Design Input Parameters: Geometrical DescriptionAnonymous xcFcOgMiBelum ada peringkat

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDokumen3 halamanAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoBelum ada peringkat

- Purlin DesignDokumen8 halamanPurlin DesignSalvatore ShwBelum ada peringkat

- Sleeper Rev1Dokumen23 halamanSleeper Rev1Yatendra TyagiBelum ada peringkat

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFDokumen5 halamanGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargBelum ada peringkat

- End Plate Moment ConnectionDokumen3 halamanEnd Plate Moment ConnectionIndustry Standard Structural DesignBelum ada peringkat

- Calculation Sheet Connection DesignDokumen1 halamanCalculation Sheet Connection DesignJay SenjaliaBelum ada peringkat

- تصميم الكمرات بطريقة ultimate PDFDokumen42 halamanتصميم الكمرات بطريقة ultimate PDFqaisalkurdyBelum ada peringkat

- Tata Projects Limited: 3. Wind Load CalculationDokumen1 halamanTata Projects Limited: 3. Wind Load CalculationSrinivas RegulavalasaBelum ada peringkat

- Lip C Purlin (KNL)Dokumen8 halamanLip C Purlin (KNL)KTMOBelum ada peringkat

- Reference Description of Problem Values Units: Infomile SolutionsDokumen3 halamanReference Description of Problem Values Units: Infomile SolutionsdhawanaxitBelum ada peringkat

- Earthquake Analysis ProcedureDokumen4 halamanEarthquake Analysis ProcedureV.m. RajanBelum ada peringkat

- Combined FootingDokumen34 halamanCombined FootingchakrapanithotaBelum ada peringkat

- Check For Punching Shear:: Pile Cap Design (PC3a)Dokumen4 halamanCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanBelum ada peringkat

- PileCap DESIGNDokumen5 halamanPileCap DESIGNSamik SenBelum ada peringkat

- Aci BeamDokumen6 halamanAci BeamkumsbamaBelum ada peringkat

- Pc-1 (Single Pile) : Therefore: VC 5mpa Vu VC, OkDokumen3 halamanPc-1 (Single Pile) : Therefore: VC 5mpa Vu VC, OkNeil SonBelum ada peringkat

- Design of Deep Beam by Strut and Tie Method and Fluxural Theory - Civil Engineering Ryerson Assignment 3-bDokumen14 halamanDesign of Deep Beam by Strut and Tie Method and Fluxural Theory - Civil Engineering Ryerson Assignment 3-bAfzal Waseem100% (1)

- Planning Analysis and Design of Shopping MallDokumen46 halamanPlanning Analysis and Design of Shopping MallSanjeev Kumar60% (15)

- Input Data: Subject: Base Plate ConnectionDokumen5 halamanInput Data: Subject: Base Plate ConnectionSambhav PoddarBelum ada peringkat

- Base Plate CalculationDokumen8 halamanBase Plate Calculationanbuaed100% (1)

- 3 PilesDokumen37 halaman3 PilesAnonymous nwByj9LBelum ada peringkat

- Design of Counterfort Retaining WallDokumen14 halamanDesign of Counterfort Retaining WallMonjit Gogoi100% (5)

- C3 Pr0bl3msDokumen41 halamanC3 Pr0bl3msLimuel Milo Lebios100% (3)

- Check For Punching Shear:: Pile Cap Design (PC3a)Dokumen4 halamanCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanBelum ada peringkat

- 2 PC CirDokumen4 halaman2 PC CirSheikh Mizanur RahmanBelum ada peringkat

- Septic Tank Design Program RAS2021 Updated 10.8.2009Dokumen12 halamanSeptic Tank Design Program RAS2021 Updated 10.8.2009Sheikh Mizanur RahmanBelum ada peringkat

- Pile Cap of Footing F1Dokumen4 halamanPile Cap of Footing F1Sheikh Mizanur RahmanBelum ada peringkat

- Arch 220 - Steel Frame ConstructionDokumen9 halamanArch 220 - Steel Frame ConstructionSheikh Mizanur RahmanBelum ada peringkat

- Civl432 Bridge Design SummaryDokumen5 halamanCivl432 Bridge Design SummarySheikh Mizanur RahmanBelum ada peringkat

- How To Adjust A NotchDokumen4 halamanHow To Adjust A NotchSheikh Mizanur RahmanBelum ada peringkat

- Main Axis of Contour PlateDokumen2 halamanMain Axis of Contour PlateSheikh Mizanur RahmanBelum ada peringkat

- Custom Elements Basics PDFDokumen5 halamanCustom Elements Basics PDFSheikh Mizanur RahmanBelum ada peringkat

- Structural Mechanics of Buried PipesDokumen11 halamanStructural Mechanics of Buried PipesSheikh Mizanur RahmanBelum ada peringkat