11-5 Proracun Ekspanzione Posude 320kw

Diunggah oleh

Asima NezirevicHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

11-5 Proracun Ekspanzione Posude 320kw

Diunggah oleh

Asima NezirevicHak Cipta:

Format Tersedia

AMG doo

Version 1.1.15

Project:

Date:

Page:

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

1

Remark:POSLOVNI OBJEKT

Data of the heating system

Heat generator

No. Type

1 Steel boiler/blast burner

Total

Output

[in kW]

320

320

Water content

[ Litre ]

1.155

1.155

Expansion pipe

L <= 10m

10 < L <= 30m

DN 20

DN 20

DN 20

DN 20

Lay out design according to

EN 12828, VDI 4708

Flow temperature

tv

75,0 C

Return temperature

tr

65,0 C

Expansion

n

3,6 %

Antifreeze

0,0 %

Min. system temperature

10,0 C

Setpoint safety temperature limiter (-controller)

95,0 C

Static pressure

pst

1,5 bar (o)

Minimum operation-/precharge pressure

po

1,7bar (o)

Safety valve opening pressure

psv

3,0 bar (o)

Maximum system pressure

pe

2,5 bar (o)

Setpoint value minimum pressure limiter

0,0 bar (o)

Setpoint safety pressure limiter

2,8 bar (o)

Requirements regarding functioning: Pressure maintainance / automatic water make-up \ central automatic degassing \ Protection of

the system by a dirt separator equipped with a magnet rod.

Water make-up supply pressure

pn

4,0 bar (o)

Maximum vessel diameter

4.400 mm

Maximum vessel height

3.500 mm

Type of heating surface

1. Flat radiator

2. Ventilation

Content of the long distance pipelines

Content of other equipment (e.g. storage tanks)

System/circuit content

Content heat generator Vk

Buffer tank

Total system content Va

Share in kW

50

257

Expansion volume

Water reserve

DIN 4807: min. 0,5% or 3 litres

Real water reserve

Ve

Content in litre

234

104

940

100

1.378

1.155

0

2.533

91Litre

0,5 %

13 Litre

2,1%

52 Litre

or

or

Approximate values for the system operating pressure = filling pressure at corresponding temperature

max. system temp. in C

Pressure in bar ()

10

2,0

20

2,1

30

2,1

40

2,2

50

2,3

60

2,4

70

2,5

The indicated values in this table can only be accurate if the real system data are in accordance with the calculation criteria.

E-Mail: info@reflex.de

Internet: www.reflex.de

AMG doo

Version 1.1.15

Project:

Date:

Page:

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

2

Remark:POSLOVNI OBJEKT

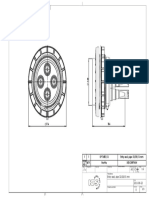

1. Protection system/circuit

Position

1.1

Article no.

8218300

quantity

1

Item text

Reflex N,

diaphragm expansion vessel for

closed heating and cooling systems,

built acc. to EN 13831.

Approval acc. to EU Pressure Equipment

Directive 97/23/EC

Price

910,00

Total price

910,00

45,70

45,70

373,00

373,00

3.178,00

3.178,00

-foot construction from N 35

-durable external powder coated finish

-non-replaceable diaphragm

Type

:

N 500

Nominal volume

:

500 Litre

Useful volume max:

:

450 Litre

perm. flow temp. supp. Ins.:

120 C

perm. op. temp. diaphragm :

70 C

perm. op. overpressure

:

6 bar

Gas inlet press. Ex works :

1,5 bar

Gas inlet press. set

:

1,7 bar

Diameter

:

740 mm

Height

: 1.321 mm

Net weight

: 52,0 kg

System connection

:

R 1

Colour

:

grey

1.2

7613100

Reflex Lockshield valve,

shut off/drain, for membrane expansion

vessels in sealed heating and cooling

systems. With a protected shut-open

facility against inadvertent closing,

also with drain outlet (draining vessel

contents) acc. to EN 12828.

Type:

SU R 1 x 1

Connection:

R 1 x R 1

perm. op. pressure:

PN 10

perm. op. temperature:

120 C

1.3

6811105

Reflex Fillset,

Prefabricated assembly with wall bracket

for the direct connection of make-up

units for heating and cooling systems

with the drinking water mains.

Consists of:

- two isolating ball valves

- type BA backflow preventer (RPZ valve)

according to DIN 1988/T4 (EA) respectively EN 1717 (BA), with integrated

dirt strainer

- water meter

- wall bracket supplied for horizontal

mounting

Type

:

max. operating pressure

: 10 bar

max. operating temperature: 60 C

Flow value kvs

: 0,8 m3/h

Net weight

:

1,7 kg

Length

:

293 mm

Connection

Inlet:

G 1/2

Outlet:

G 1/2

1.4

8830720

E-Mail: info@reflex.de

Reflex Servitec,

vacuum spray degassing unit with

integrated automatic refill for closed

heating or chilled water circuits which

are equipped with pressurization units

Internet: www.reflex.de

AMG doo

Version 1.1.15

Project:

Date:

Page:

Position

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

3

Remark:POSLOVNI OBJEKT

Article no.

quantity

Item text

as well as installations with static

precharged expansion vessels.

Price

Total price

Active and central degassing of the

installation according to the principle

of vacuum degassing.

Unit for wall mount existing of a

hydraulic part and a Reflex Control Basic

operating unit. The entire unit is

protected against dirt intrusion by

means of a housing made of expanded

polypropylene with a removable hood for

maintenance access.

It is featuring an "auto-setup" function

including a selfoptimizing operation.

The deaerator eliminates entirely the

free gases in the installation and

withdraws up to 90% of the dissolved

gases of the installation water.

The vacuum degassing of a partial flow

of the installation water is processed

according to an optimised time schedule

with selectable degassing programmes.

After a period of continuous degassing

(adjustable and depending on the installation volume) at the start up, the

control switches automatically to an

economic mode (interval degassing).

The hydraulic part is standard provided

with a discharge and with isolating

lockshield ball valves on all connection

pipes. Both the inlet line equipped with

a strainer and the supply for the integrated automatic water make-up are

connected to a three-way electrically

actuated fail safe ball valve.

Possibility to connect the make-up

supply to the water mains or to a break

tank (eventually also for glycol

mixture make-up). The vacuum spray

chamber is part of the stainless steel

pump body.

The multistage pump discharge is

connected to a modulating electrically

actuated ball valve with position optimisation through the microprocessor

control.

The Reflex Control Basic is integrated

in a sturdy pre wired plastic cabinet

which has IP 54 protection class and

in which all electric and electronic

components are integrated. The control

panel is consisting of a display

and a membrane keyboard which is insensitive to dirt.

The Control Basic is a fully automatic

freely programmable microprocessor

control unit.On the two-line LCD screen,

operation mode,failures and system

pressure are indicated in plain text.

(16 language display).

E-Mail: info@reflex.de

Internet: www.reflex.de

AMG doo

Version 1.1.15

Project:

Date:

Page:

Position

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

4

Remark:POSLOVNI OBJEKT

Article no.

quantity

Item text

Also two function-LED indicate the

unit to be in automatic mode and malfunction. The control features a

parameter- and error memory. This way

it is possible to display in chronological order the last 20 error

messages with indication of date and

time.

Price

Total price

The control as standard is provided with:

-RS 485 Interface

for transfer of complete operation information to a BMS e.g. by use of a bus

module or for data exchange between

multiple Reflex control units

-a volt free output for common fault

message.

-an input terminal for evaluation of a

contact water meter pulse

The control is reading the system

pressure via a pressure transducerThe degassing of a partial flow of the

installation water is processed according to an optimised time schedule with

selectable degassing programmes. After

a period of continuous degassing

(adjustable and depending on the installation volume) at the start up, the

control switches automatically to an

economic mode (interval degassing).

When the water make-up is activated,

error message will be triggered if the

water make-up cycle goes over a time

limit and/or if the number of make-up

cycles is exceeded over a given period.

This will result in an error message in

both cases and interruption.

In case the water supply line is fitted

with a contact water meter, also the

total added water volume is indicated on

the display and an error message is

activated in the event of overshooting

the maximum make-up volume (added up).

This is also the case when the established

input make-up quantity is exceeded against

an input volume in one filling cycle,

or if the make-up system because of

malfunction lets water through without

being activated by the control.

Documentation and monitoring of the

connected HVAC-system with respect to

the above-mentioned parameters.

Type

:

adm. excess oper. press.

:

8 bar

adm. operating temp.

:

70 C

adm. ambient temp.

:

>0..35 C

sound level

: < 55 dB(A)

power supply

:230 V/ 50 Hz

electr. power cons.

:

0,75 kW

electr. nominal curr.

:

3,0 A

depth x width x height (mm): 285/257/653

empty weight

:

13,0 kg

E-Mail: info@reflex.de

30

Internet: www.reflex.de

AMG doo

Version 1.1.15

Project:

Date:

Page:

Position

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

5

Remark:POSLOVNI OBJEKT

Article no.

quantity

Item text

Price

connections pressure-side :

G 1/2

flow-off side

:

G 1/2

make-up

:

G 1/2

elimin. degree of dissolved gases:

up to 90 %

part. vol.flow netw. up to :

0,05 m/h

make-up volume flow up to :

0,05 m/h

Total price

Data of the connected supply system

water content

: 2.533 Litre

heat generator SV

:

3,0 bar

advance press. exp. vessel :

1,7 bar

or min. operating press.

final press. press.maint. :

2,5 bar

min. flow press. make-up

:

0,1 bar

1.5

7945600

Reflex Commissioning,

of a standard Variomat, Reflexomat or

Servitec system with 1 pump or

compressor by the responsible Reflex

field technician.

341,00

341,00

901,00

901,00

The commissioning can be operated in

3 weeks within germany, international in

6 weeks after appropriate assignment.

Requirements:

electrical and hydraulical connection of

the control unit and the accessory components. System circuits are filled.

The expansion vessels of the pressurization

unit must not be filled with water.

A sufficient supply with filling water

is to be ensured.

The pressure maintenance expansion tanks

must not be filled with water prior to

commissioning. An adequate supply of filling

water must be provided.

Commissioning costs are NET COSTS!!

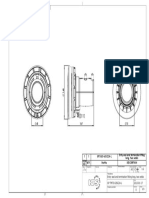

1.6

8252130

Reflex Exdirt,

dirt and sludge separator for heating

and cooling systems respectively for

sealed system circuits.

Suitable for use with water and

water/glycol mixture to a maximum of 50%

concentration.

Fitting for the removal of dirt particles up to a size of 5,0 m out of

the liquid flow by way of a specifically designated insert.

The collection area can be easily

emptied at regular intervals using a

drain ball valve while the system remains in operation. The flanged collection chamber can be removed for inspection.

Type

:

D 114.3

Housing material :

steel coated

Installation model:

horizontal

Connection type

:

welding ends

System connection :

114.3 mm

Drain connection :

Rp 1

max. operating pressure:

10 bar

max. operating temperature:

110 C

E-Mail: info@reflex.de

Internet: www.reflex.de

AMG doo

Version 1.1.15

Project:

Date:

Page:

Position

1.7

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

6

Remark:POSLOVNI OBJEKT

Article no.

9254841

quantity

Item text

max. flow

kvs

Length

Height

Diametre

Weight

:

:

:

:

:

:

Price

Total price

169,00

169,00

...........

...........

397,00

397,00

47 m/h

244,3 m/h

370 mm

583 mm

206 mm

9 kg

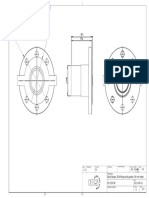

Reflex Exiso,

Thermal EPP foam insulation for Reflex

Exvoid microbubble separators or

Exdirt dirt separators.

Consists of two formed sections which are

easily individually adaptable using cut

off marks. Inclusive snap closure or

tightening strap.

Type

:

80 - 114.3

Height

:

567 mm

Diameter

:

290 mm

Lagging thickness :

31 mm

max. operating temperature:

110 C

1.8

Separator is also available in an

in line vertical installation design to

suit your application.

Please check the dimensions in advance.

-

1.9

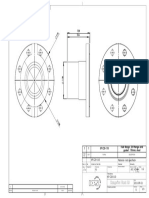

9258300

Reflex Exferro,

High-energy permanent magnet which can

be retrofitted in Reflex Exdirt dirt

separator.

Magnet consists of an isostatically

pressed Neodymium magnet rod screwed

into a threaded sleeve.

Magnetic particles within the solution

are attracted to the magnetic sleeve

which is located in the separator housing. Particles are removed by unscrewing

the magnetic rod from the sleeve causing

them to collect at the base and subsequently flushed away.

Type

Length

Diameter

Thread connection

E-Mail: info@reflex.de

: D 50-114.3

:

300 mm

:

25 mm

:

G1

Internet: www.reflex.de

AMG doo

Version 1.1.15

Project:

Date:

Page:

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

7

Remark:POSLOVNI OBJEKT

2. Protection for the heat generator 1

Position

2.1

Article no.

9250000

quantity

1

Item text

Reflex Exvoid-T,

high venting capacity automatic air vent

for heating and cooling systems

respectively sealed system circuits.

Price

51,50

Total price

51,50

...........

...........

...........

...........

...........

...........

Designed to facilitate venting or

admitting air into the system with high

reliability.

Safe operation even if the system medium

is charged with impurities.

Type

:

Housing material :

System connection :

max. operating pressure:

max. operating temperature:

Height:

:

Diameter

:

Weight

:

2.2

1/2

brass

IG 1/2

10 bar

10 bar

110 C

122 mm

63 mm

Safety valve for heat generators,

acc. to TRD 721, code letter H.

Nominal inlet width

:

G 1 1/4

Nominal outlet width

:

G 1 1/2

Drainage rate required

:

320 kW

Opening pressure

:

3,0 bar

T H I R D PARTY P R O D U C T

2.3

Water level limiter,

for water level monitoring of heat

generators, type tested acc. to

German VD-TV data sheet water level

100/2

Also it is possible to integrate:

-a minimum pressure limiter or

flow limiter

against inadmissible heating in case

of water deficiency.

T H I R D

2.4

P R O D U C T

Maximum pressure limiter

type tested acc. to VD TV data

sheet pressure 100/1, for systems acc.

to EN 12828

Set pressure

T H I R D

E-Mail: info@reflex.de

PARTY

PARTY

: 2,8 bar

P R O D U C T

Internet: www.reflex.de

AMG doo

Version 1.1.15

Project:

Date:

Page:

Position

2.5

IDEJNI PROJEKT GRIJANJA

Project number: 1-10_2016

19.11.2016

Administrator:ELVIR NEZIREVIC, dipl.ing.mas.

8

Remark:POSLOVNI OBJEKT

Article no.

quantity

1

Item text

Safety temperature limiter,

acc. to EN 60730-2-9 (as additional

safety device in the event of leaving

out the expansion trap)

Temperature setting

T H I R D PARTY

Price

...........

Total price

...........

: 95 C

P R O D U C T

Articles without article-no. Are not part of the Reflex delivery program

E-Mail: info@reflex.de

Internet: www.reflex.de

Anda mungkin juga menyukai

- EPI Flowmeter Data SheetDokumen5 halamanEPI Flowmeter Data SheetEduardo PachecoBelum ada peringkat

- Kalorimetar Data Sheet UH50 - UH106 101kDokumen15 halamanKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneBelum ada peringkat

- Condenserless Liquid ChillersDokumen12 halamanCondenserless Liquid ChillersBader ShrbajiBelum ada peringkat

- Mmy 170Dokumen4 halamanMmy 170thotalnBelum ada peringkat

- Chiller Selection Building C, E+F Heat Pump Rev 1Dokumen7 halamanChiller Selection Building C, E+F Heat Pump Rev 1Anton WelgemoedBelum ada peringkat

- Submittal Asd872aDokumen9 halamanSubmittal Asd872ajibanez003Belum ada peringkat

- Petrodist 400 CCDokumen6 halamanPetrodist 400 CCJoao FernándezBelum ada peringkat

- Automatic Electronic Drain Valve Atlas Copco EWD 330Dokumen1 halamanAutomatic Electronic Drain Valve Atlas Copco EWD 330american_guy1050% (4)

- Elgi Screw CompressorDokumen12 halamanElgi Screw CompressorRAVINDER DHINGRABelum ada peringkat

- Brochure Ex-P Pressurized Enclosure System Zone1 f850sDokumen6 halamanBrochure Ex-P Pressurized Enclosure System Zone1 f850ssaman749Belum ada peringkat

- Anonymous 1-1en PDFDokumen6 halamanAnonymous 1-1en PDFAlexander BrewerBelum ada peringkat

- Bronkhorst EL-FLOW Dastec SRLDokumen4 halamanBronkhorst EL-FLOW Dastec SRLHesser Taboada MichelBelum ada peringkat

- JMS 312 GS-B.L: Technical SpecificationDokumen4 halamanJMS 312 GS-B.L: Technical SpecificationMartin KratkyBelum ada peringkat

- Air Conditioning Telecommunications ShelterDokumen16 halamanAir Conditioning Telecommunications ShelterLuis Hewson100% (1)

- Product Specification: Model RefDokumen6 halamanProduct Specification: Model RefHermawan HerryBelum ada peringkat

- J316V21 enDokumen4 halamanJ316V21 enMartin KratkyBelum ada peringkat

- ML434 V12 D758Dokumen40 halamanML434 V12 D758darkchess76Belum ada peringkat

- Pilodist: Petrodist 400 CCDokumen7 halamanPilodist: Petrodist 400 CCWaheed ZebBelum ada peringkat

- B) Galileo TP - Leak Test LineDokumen2 halamanB) Galileo TP - Leak Test LinenairnavkrishBelum ada peringkat

- 30GXDokumen12 halaman30GXAdolfo Riquelme Novoa0% (1)

- J312V202 enDokumen4 halamanJ312V202 enMartin KratkyBelum ada peringkat

- Mahlepi270 GBDokumen5 halamanMahlepi270 GBHassanBelum ada peringkat

- Omd 11 eDokumen22 halamanOmd 11 eBenja87100% (3)

- Diesel Compressor Controller: Description FeaturesDokumen2 halamanDiesel Compressor Controller: Description FeaturesMiu MiuBelum ada peringkat

- 1808720010ff SpecificationDokumen7 halaman1808720010ff SpecificationJezrell JaravataBelum ada peringkat

- AutoclaveDokumen2 halamanAutoclaveSaif AliBelum ada peringkat

- PT INDOLAKTO 27-10-2023 RevDokumen5 halamanPT INDOLAKTO 27-10-2023 RevSaepul HerdianBelum ada peringkat

- Hs 1101 LFDokumen6 halamanHs 1101 LFJavier MamarandiBelum ada peringkat

- Industrial Washing MachineDokumen10 halamanIndustrial Washing MachineDiêm Công ViệtBelum ada peringkat

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDokumen8 halaman30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersvickersBelum ada peringkat

- Jenbacher 320Dokumen4 halamanJenbacher 320arjmandquest75% (8)

- 3-En2200-B - 4VP01Dokumen15 halaman3-En2200-B - 4VP01najafali1Belum ada peringkat

- Aer Conditionat Multisplit LG Unitati Externe Pliant Date Tehnice PDFDokumen9 halamanAer Conditionat Multisplit LG Unitati Externe Pliant Date Tehnice PDFClau HerleaBelum ada peringkat

- 8388 Mmy170Dokumen56 halaman8388 Mmy170thotalnBelum ada peringkat

- CR 5 9 A A A e HqqeDokumen5 halamanCR 5 9 A A A e HqqeAlexander Ramos GutierrezBelum ada peringkat

- TSS70 130 PDFDokumen12 halamanTSS70 130 PDFararrefBelum ada peringkat

- FOCSWATER.C Water Cooled Chiller - R134aDokumen8 halamanFOCSWATER.C Water Cooled Chiller - R134antt_121987Belum ada peringkat

- Cat 30RB 2013Dokumen10 halamanCat 30RB 2013Denise Koh Chin HuiBelum ada peringkat

- J208V06 enDokumen4 halamanJ208V06 enMartin KratkyBelum ada peringkat

- Ecocota 1100 Life Pearl by Shahid FDCDokumen5 halamanEcocota 1100 Life Pearl by Shahid FDCMohammed ZubairBelum ada peringkat

- Data - BCJD 23-50Dokumen4 halamanData - BCJD 23-50Erno RuzsaBelum ada peringkat

- Greenline 8000 Basic Price and InfoDokumen6 halamanGreenline 8000 Basic Price and InfoRobson SantosBelum ada peringkat

- ML17Dokumen2 halamanML17Stevan BoljevicBelum ada peringkat

- PRESSCONTROL Pressure Regulator GuideDokumen30 halamanPRESSCONTROL Pressure Regulator GuideThanos KantBelum ada peringkat

- Ipr RegDokumen34 halamanIpr RegNicolae PopBelum ada peringkat

- 1905 - Carrier 30 GZ 190 PDFDokumen6 halaman1905 - Carrier 30 GZ 190 PDFbilal almelegyBelum ada peringkat

- Lab4 RK Dehydrator User Manual: Doc. N. C5574.012-E.MUB Data 18/01/10 Rev. BDokumen10 halamanLab4 RK Dehydrator User Manual: Doc. N. C5574.012-E.MUB Data 18/01/10 Rev. BBilge AdamBelum ada peringkat

- Ultraflow 150: Ultrasonic Gas Flow and Temperature MonitorDokumen6 halamanUltraflow 150: Ultrasonic Gas Flow and Temperature MonitorSrikala VenkatesanBelum ada peringkat

- Inert Gas System (IGG)Dokumen3 halamanInert Gas System (IGG)Fadzil NorBelum ada peringkat

- Multipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deDokumen2 halamanMultipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deJoshua PhillipsBelum ada peringkat

- h2 Generators - WM Series - Uk AsyntDokumen2 halamanh2 Generators - WM Series - Uk Asyntapi-234089277Belum ada peringkat

- JMS 208 GS-N.L: Technical SpecificationDokumen4 halamanJMS 208 GS-N.L: Technical SpecificationMartin KratkyBelum ada peringkat

- Grundfosliterature 1370Dokumen8 halamanGrundfosliterature 1370no nameejjBelum ada peringkat

- Duplex Systems 6Dokumen2 halamanDuplex Systems 6Eng.Gihad EladlBelum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- Mark Twain QuotesDokumen1 halamanMark Twain QuotesBen ChongBelum ada peringkat

- Immersion Temperature Sensors QAE21 10861 HQ enDokumen7 halamanImmersion Temperature Sensors QAE21 10861 HQ enPrasad MahajanBelum ada peringkat

- RTM FazaDokumen1 halamanRTM FazaAsima NezirevicBelum ada peringkat

- Test CertificateDokumen1 halamanTest CertificateAsima NezirevicBelum ada peringkat

- Title/Name: First Angle Projection EDokumen1 halamanTitle/Name: First Angle Projection EAsima NezirevicBelum ada peringkat

- KP 8-63FC02 PDFDokumen1 halamanKP 8-63FC02 PDFAsima NezirevicBelum ada peringkat

- Title/Name: First Angle Projection EDokumen1 halamanTitle/Name: First Angle Projection EAsima NezirevicBelum ada peringkat

- SunPump Installation RequirementsDokumen1 halamanSunPump Installation RequirementsAsima NezirevicBelum ada peringkat

- Kungsörs Plast AB Property Document Protected by LawDokumen1 halamanKungsörs Plast AB Property Document Protected by LawAsima NezirevicBelum ada peringkat

- Certificate of Complience - Issue 4 First PageDokumen1 halamanCertificate of Complience - Issue 4 First PageAsima NezirevicBelum ada peringkat

- KP 4-63FC PDFDokumen1 halamanKP 4-63FC PDFAsima NezirevicBelum ada peringkat

- KP 8-90FC PDFDokumen1 halamanKP 8-90FC PDFAsima NezirevicBelum ada peringkat

- IP2 - Cert - of - Comp Ip2 2005-10-11Dokumen4 halamanIP2 - Cert - of - Comp Ip2 2005-10-11Asima NezirevicBelum ada peringkat

- KP 3-110FC PDFDokumen1 halamanKP 3-110FC PDFAsima NezirevicBelum ada peringkat

- KP 4-110FC PDFDokumen1 halamanKP 4-110FC PDFAsima NezirevicBelum ada peringkat

- KP M50-32 PDFDokumen1 halamanKP M50-32 PDFAsima NezirevicBelum ada peringkat

- KP TM75-54 PDFDokumen1 halamanKP TM75-54 PDFAsima NezirevicBelum ada peringkat

- DIJELOVIDokumen24 halamanDIJELOVIAsima NezirevicBelum ada peringkat

- KP TM32-15 PDFDokumen1 halamanKP TM32-15 PDFAsima NezirevicBelum ada peringkat

- KP TM125-90Dokumen1 halamanKP TM125-90Asima NezirevicBelum ada peringkat

- KP TM75-63SC03Dokumen1 halamanKP TM75-63SC03Asima NezirevicBelum ada peringkat

- Title/Name: First Angle Projection EDokumen1 halamanTitle/Name: First Angle Projection EAsima NezirevicBelum ada peringkat

- Kungsörs Plast AB DocumentDokumen1 halamanKungsörs Plast AB DocumentAsima NezirevicBelum ada peringkat

- Title/Name: First Angle Projection EDokumen1 halamanTitle/Name: First Angle Projection EAsima NezirevicBelum ada peringkat

- KP C20-90 Stub flange, DIN flange and gasket, 90 mm steelDokumen1 halamanKP C20-90 Stub flange, DIN flange and gasket, 90 mm steelAsima NezirevicBelum ada peringkat

- Material KP C20-110: U 2011-09-22 Revno Revision Note Date SignatureDokumen1 halamanMaterial KP C20-110: U 2011-09-22 Revno Revision Note Date SignatureAsima NezirevicBelum ada peringkat

- Title/Name: First Angle Projection EDokumen1 halamanTitle/Name: First Angle Projection EAsima NezirevicBelum ada peringkat

- KP 50LPG100 PDFDokumen1 halamanKP 50LPG100 PDFAsima NezirevicBelum ada peringkat

- Title/Name: First Angle Projection EDokumen1 halamanTitle/Name: First Angle Projection EAsima NezirevicBelum ada peringkat

- KP C20-63 PDFDokumen1 halamanKP C20-63 PDFAsima NezirevicBelum ada peringkat

- ISO 8655-3 2022 Ed.2 - Id.68798 Publication PDF (En)Dokumen14 halamanISO 8655-3 2022 Ed.2 - Id.68798 Publication PDF (En)Qualidade FrilaboBelum ada peringkat

- John Deere ECU Control Wiring ExplanationDokumen8 halamanJohn Deere ECU Control Wiring Explanationsaiman75% (4)

- Measures of AverageDokumen7 halamanMeasures of AveragemomathtchrBelum ada peringkat

- Field Artillery Journal - Jul 1918Dokumen187 halamanField Artillery Journal - Jul 1918CAP History LibraryBelum ada peringkat

- T238 Digital Trigger UnitDokumen5 halamanT238 Digital Trigger UnitGuilherme SousaBelum ada peringkat

- The Reactivity Series PDFDokumen33 halamanThe Reactivity Series PDFSandipan Chakraborty100% (1)

- Murakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDokumen14 halamanMurakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDavid C HouserBelum ada peringkat

- Functions Modeling Change: A Precalculus CourseDokumen239 halamanFunctions Modeling Change: A Precalculus CourseDeniell Joyce MarquezBelum ada peringkat

- Shearwall Design of RCCCC Structure 111111222222298909Dokumen77 halamanShearwall Design of RCCCC Structure 111111222222298909Shams KhattakBelum ada peringkat

- CSD Full TermDokumen29 halamanCSD Full TermNishat Farha SharmiBelum ada peringkat

- Preparation and Characterization of Tin Oxide Based Transparent Conducting Coating For Solar Cell ApplicationDokumen5 halamanPreparation and Characterization of Tin Oxide Based Transparent Conducting Coating For Solar Cell Applicationcrypto fanbabyBelum ada peringkat

- AMD64 Architecture Programmers ManualDokumen386 halamanAMD64 Architecture Programmers Manualxxx54Belum ada peringkat

- ECE61labmanua Dukel PDFDokumen80 halamanECE61labmanua Dukel PDFVictorAbrahamGuerreroBelum ada peringkat

- Topic 11 RevisionDokumen26 halamanTopic 11 RevisionYun Ho CHOBelum ada peringkat

- Computer History Timeline PPTX 1Dokumen11 halamanComputer History Timeline PPTX 1api-295907175Belum ada peringkat

- EtherWAN EX35080-00B Data SheetDokumen4 halamanEtherWAN EX35080-00B Data SheetJMAC SupplyBelum ada peringkat

- Pile CAP CALCULATIONSDokumen9 halamanPile CAP CALCULATIONSJUAN MANUEL VIZCAINOBelum ada peringkat

- WorkplqceDokumen116 halamanWorkplqceRaferBelum ada peringkat

- Color TheorypdfDokumen99 halamanColor TheorypdfNews OffbeatBelum ada peringkat

- A Simple Homing Direction Finder Using A DDF7001 and An Android DeviceDokumen11 halamanA Simple Homing Direction Finder Using A DDF7001 and An Android DeviceKarolŚwierczyńskiBelum ada peringkat

- Modulator Bias Controller For Single and Dual Drive IQ ModulatorsDokumen6 halamanModulator Bias Controller For Single and Dual Drive IQ ModulatorsTatiani PivemBelum ada peringkat

- 01-An Approach To Improved CNC Machining Using Vision-Based SystemDokumen11 halaman01-An Approach To Improved CNC Machining Using Vision-Based SystemCătălina StahurschiBelum ada peringkat

- Econometrics PaperDokumen24 halamanEconometrics PaperPam Ramos0% (1)

- MIT Haystack Lunch Talk 2-3-10Dokumen19 halamanMIT Haystack Lunch Talk 2-3-10Stu SutherlandBelum ada peringkat

- Human ActivityDokumen53 halamanHuman ActivityabiramanBelum ada peringkat

- MECANIQUE - Construction Practice Onshore SteelDokumen54 halamanMECANIQUE - Construction Practice Onshore SteelYaser ShabasyBelum ada peringkat

- Module 3 - Advance Database Concepts-Lesson 2Dokumen5 halamanModule 3 - Advance Database Concepts-Lesson 2jjBelum ada peringkat

- Mole Concept: Prepared By: K. Walker-DawkinsDokumen26 halamanMole Concept: Prepared By: K. Walker-DawkinsMr. CrustBelum ada peringkat

- Owner's Manual For Porsgrunn Rotary Vane Steering Gear S-1995Dokumen124 halamanOwner's Manual For Porsgrunn Rotary Vane Steering Gear S-1995O olezhaod100% (4)

- EnriqueHernandez Fatima M19S2AI4Dokumen7 halamanEnriqueHernandez Fatima M19S2AI4ScribdTranslationsBelum ada peringkat