Risk assessment form for forklift operations

Diunggah oleh

Fachri HidayatJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Risk assessment form for forklift operations

Diunggah oleh

Fachri HidayatHak Cipta:

Format Tersedia

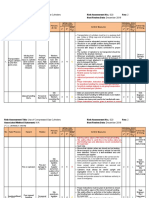

FORM:

Health, Safety, and Environment (HSE)

TITLE:

PLANT/EQUIPMENT &/OR TASK RISK ASSESSMENT

NUMBER:

F01.1_2

P 00012

Risk Assessment Reference #

Work Area

Switchboards & Contracting

Location of Plant/Equipment

Regency Park

Plant/Equipment #

Komatsu Forklift GF25-12

Date of Assessment

8 February 2012

Assessed by

Debbie Nation/Dario

Dametto/Nathan Bissell

Last reviewed (if applicable)

Task and/or use of Plant/Equipment

Moving and lifting loads, loading and unloading

Reason for Assessment

Comment

Review Existing Task

New Task

Change in task, or

legislation

Report of injury

Requested

Is the task or use of the plant/ equipment a hazardous manual handling task If any of the boxes have

been ticked/checked a separate Manual handling risk assessment requires be completed and

attached/referenced to this risk assessment.

Repetitive

or

sustained

force

Task

High or

sudden

force

Sustained

or

awkward

postures

Repetitive

movement

Exposure

to

vibrations

Operating Forklift (Reversing)

Lifting items

Moving items

Loading & Unloading

Ascending & Descending forklift cabin

Changing forklift gas cylinder

Hazard

Consequence

Uncontrolled when printed

Version: 2

Issued: August 2011

Review: 2016

No

No

Rx Number

Reason for no

Controls

MH 008

Risk Post

RatingControl

Re

f#

Yes

Yes

Rating

Risk

Manual Handling Risk Assessment Required

Attached ( if no give reason)

Page 1 of

Ensure forklift is fitted with speed control

devices ( Max 10km/hr)

Ensure personnel wear high visibility clothing

when in areas where forklift operates

Ensure tines set at maximum width for load

Keep tines at the correct height low to the

ground with backtilt when travelling with load

Ensure personnel wear high visibility clothing

when in areas where forklift operates

Ensure warning light is on top of the forklift to

improve conspicuity.

Develop Floor Traffic Management Plan

Ensure forklifts are fitted with seatbelts

Ensure forklift is fitted with speed control

devices.

Ensure operator is trained and competent in

the use of the forklift and is aware of its

lifting capacity.

Provide weather/rain protection where

required, as practicable.

Ensure good housekeeping by cleaning up oils

spills

Ensure tyres are well maintained

Ensure inspection and maintenance is

conducted in refuelling area

Ensure no hot work or naked flames in or

around refuelling area (within 6 metres)

Prevent any sparks or naked flames from

entering the refuelling area.

Ensure pre-start checks are completed daily

Ensure maintenance schedules are maintained

Maintain three points of contact getting on and

off the forklift

Negotiate one step at a time and do not jump

down from the forklift cabin

Ensure steps are clean and free from oil or

slippery substances before ascending or

descending

Load falls off

elevated tines onto

pedestrian whilst

travelling

Crush injury

M8

Forklift hits

pedestrian

Crush injury

M8

Forklift tips over

Crush injury

M8

Forklift loses

control on wet

surface

Crush injury

M8

During refuelling

gas leak occurs

Explosion

H12

Hydraulic hose

burst spraying oil

Environmental/eye

injury

M6

Fall getting on/ off

forklift

Sprain, strain,

laceration

M6

Musculo-skeletal

injury

M6 Alternate looking over left and right shoulders

L4

H12 Ensure tips of tines are painted yellow to

improve conspicuity

Instruct workers to keep tines at the correct

height low to ground with backtilt when

travelling without load.

Ensure personnel wear high visibility clothing

when in areas where forklift operates

M4

8

9

Twisting back to

look when

reversing

Tines puncture

object or person

Puncture injury,

Property damage

Uncontrolled when printed

Version: 2

Issued: August 2011

Review: 2016

L4

L4

L4

L4

M4

L3

L3

Page 2 of

10

Changing forklift

gas cylinder

Develop Floor Traffic Management Plan

Ensure fork gas cylinder has been

disconnected and straps removed before

attempting to lift from forklift

Wear gloves and get firm grip with both hands

M6

when handling cylinder.

Keep body aligned when lifting (nose over

toes)

Know your own limitations and seek

assistance if required.

Musculo-skeletal

injury

Action Plan Developed

Yes

No

Ref Number

Attached ( if no give reason)

Yes

No

Reason for no

Uncontrolled when printed

Version: 2

Issued: August 2011

Review: 2016

L4

AP 00016

Page 3 of

Examples Risk Assessment: Measures of Consequence (or Impact)

Level

HSE

1. Insignificant

2. Minor

3. Moderate

4. Major

5. Catastrophic

Environment

No significant injuries.

No significant impact on personnel.

Small number of injuries; first aid or out-patients treatment

required.

Some inconvenience to personnel.

A number of injuries requiring hospitalisation and long-term

treatment.

Moderate disruption to work routines and schedules.

Major disruption to work routines and practices. Additional

resources may be required.

Significant number of serious injuries requiring hospitalisation

and long-term treatment. Small number of fatalities.

Long-term disruption to work practices and routines. Impact on

well-being of personnel. Extensive, life-threatening impact;

potentially large numbers of serious injuries and fatalities.

Minor breach of environmental policy / practices.

Negligible impact on the environment.

Minor localised impact; one-off situation easily

remedied.

Moderate impact on the environment; no long term or

irreversible damage. May incur cautionary notice or

infringement notice

Severe impact requiring remedial action and review of

processes to prevent reoccurrence. Penalties and / or

direction or compliance order incurred.

Long-term, large-scale damage to habitat or

environmental.

Serious / repeated breach of legislation / licence

conditions.

Cancellation of licence and / or prosecution.

Risk Assessment: Measures of Likelihood

Level

Almost certain

Description (As per AS/NZS 4360)

Examples

The event is expected to occur in most conditions

Expected frequency range: Greater than one or more per annum

Expected frequency range: Between one in 5 years and one per

annum

Expected frequency range: Between one in 10 years and one in 5

years

Expected frequency range: Between one in a 100 years and one in

10 years

Likely

The event will probably occur in most conditions

Possible

The event should happen at some time

Unlikely

The event could happen at some time

Rare

The event may only occur in exceptional

circumstances

Expected frequency range: Less than one in a hundred years

Consequence/Severity

Likelihood

Rating

Catastrophic

Major

Moderate

Minor

Insignificant

Almost certain

Extreme (25)

Extreme (20)

High (15)

High (10)

Medium (5)

Likely

Extreme (20)

Extreme (16)

High (12)

Medium (8)

Medium (4)

Possible

High (15)

High (12)

High (9)

Medium (6)

Low (3)

Unlikely

High (10)

Medium (8)

Medium (6)

Low (4)

Low (2)

Rare

Medium (5)

Medium (4)

Low (3)

Low (2)

Low (1)

Risk Rating

Timeframe

Whom

Extreme

immediate action required executive management and

HSE

High

Within 2 to 3 days senior management attention needed

HSE Manager, Division Manager, Construction Manager ,

HSR & Safety-Coordinator

Construction Manager, Project Manager, Safety

coordinator, HSR & Supervisor

Moderate

Within a week management responsibility must be specified

Project Manager, Safety Coordinator , HSR & Supervisor

Low

Within 14 days manage by routine process.

Supervisor

Uncontrolled when printed

Version: 2

Issued: August 2011

Review: 2016

Page 4 of

Uncontrolled when printed

Version: 2

Issued: August 2011

Review: 2016

Page 5 of

Anda mungkin juga menyukai

- Fork Lift Daily Check: (Only For FL Operated by Batery)Dokumen1 halamanFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloBelum ada peringkat

- HSE guidance on safety devices for rapid roller doorsDokumen11 halamanHSE guidance on safety devices for rapid roller doorsmsc920138Belum ada peringkat

- Flagman & Lookout Requirement for Vehicle ReversingDokumen1 halamanFlagman & Lookout Requirement for Vehicle ReversingarslanahmedkhawajaBelum ada peringkat

- Vehicle Hoist Safe Work ProcedureDokumen2 halamanVehicle Hoist Safe Work ProcedureWiwinIndahSariEffendiBelum ada peringkat

- Flagman TrainingDokumen58 halamanFlagman TrainingIndermohan MehtaBelum ada peringkat

- JHA Jack Hydraulic PalletDokumen1 halamanJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- Risk Assessment/Management FormDokumen4 halamanRisk Assessment/Management FormNazriBelum ada peringkat

- Risk Assessment for Compressed Gas Cylinder UseDokumen7 halamanRisk Assessment for Compressed Gas Cylinder UsejeffreyBelum ada peringkat

- Jacks and Vehicle Stands PDFDokumen1 halamanJacks and Vehicle Stands PDFcityofdarwingisBelum ada peringkat

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDokumen1 halamanScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilBelum ada peringkat

- Forklift TruckDokumen1 halamanForklift TruckShazaley AbdullahBelum ada peringkat

- Hand Trolley PDFDokumen1 halamanHand Trolley PDFcityofdarwingisBelum ada peringkat

- Lifting Operations Risk Assessment Crane Risk AssessmentDokumen13 halamanLifting Operations Risk Assessment Crane Risk Assessment9853318441Belum ada peringkat

- 05 - Banks ManDokumen58 halaman05 - Banks ManHALOFFBelum ada peringkat

- SOP of ForkDokumen15 halamanSOP of ForkGyanendra Narayan NayakBelum ada peringkat

- Safety Topic 863 - Working Under Suspended LoadsDokumen2 halamanSafety Topic 863 - Working Under Suspended LoadsAshishBelum ada peringkat

- Working On Brake System (WS)Dokumen12 halamanWorking On Brake System (WS)John KalvinBelum ada peringkat

- Safe Unloading of Cut and BentDokumen16 halamanSafe Unloading of Cut and BentAbhinav SinhaBelum ada peringkat

- Topic For TBMDokumen19 halamanTopic For TBMdauxomBelum ada peringkat

- Loading & Lifting ProcedureDokumen5 halamanLoading & Lifting Procedurekhurram shahzadBelum ada peringkat

- Manual Rubbish Handling SafetyDokumen1 halamanManual Rubbish Handling SafetyScribder0% (1)

- Swa ProcedureDokumen5 halamanSwa ProcedureVasilis IliopoulosBelum ada peringkat

- Welding Oxy A4Dokumen2 halamanWelding Oxy A4LoveBelum ada peringkat

- Boom Lift SWPDokumen2 halamanBoom Lift SWPSayed AbbasBelum ada peringkat

- MSDS - Asada Threading Oiil Red - ENDokumen7 halamanMSDS - Asada Threading Oiil Red - ENnghiaBelum ada peringkat

- Ladder Safety: Safe Use of Ladder ChecklistDokumen2 halamanLadder Safety: Safe Use of Ladder ChecklistRedouane Naceri100% (1)

- Akk Jha Installation of Diesel TankDokumen3 halamanAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Fall ProtectionDokumen24 halamanFall Protectionmdfahad0047Belum ada peringkat

- 1) SWP - Forklifts - 2Dokumen4 halaman1) SWP - Forklifts - 2John Rey PerlasBelum ada peringkat

- Job Safety Analysis - Clinker StorageDokumen4 halamanJob Safety Analysis - Clinker StorageMohammed MinhajBelum ada peringkat

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDokumen14 halamanMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottBelum ada peringkat

- Lockout Tagout TRNG GuideDokumen7 halamanLockout Tagout TRNG GuideSyed Mujtaba Ali Bukhari100% (1)

- Lifting Beams and SpreadersDokumen2 halamanLifting Beams and SpreadersNadeem MalikBelum ada peringkat

- Confined Space Entry Program 11 2021Dokumen16 halamanConfined Space Entry Program 11 2021zaka ullahBelum ada peringkat

- JSA - Crane Setuppdf PDFDokumen12 halamanJSA - Crane Setuppdf PDFChoko ChokriBelum ada peringkat

- Lifting Equipment PDFDokumen2 halamanLifting Equipment PDFcityofdarwingisBelum ada peringkat

- Metal Chop Saw SopDokumen2 halamanMetal Chop Saw SopkylealamangoBelum ada peringkat

- Scaffolder Erector Medical ExaminationDokumen6 halamanScaffolder Erector Medical ExaminationZulqarnain RamliBelum ada peringkat

- Heavy Vehicle/ Forklift Spotter.: Health, Safety and EnvironmentDokumen24 halamanHeavy Vehicle/ Forklift Spotter.: Health, Safety and EnvironmentsitiBelum ada peringkat

- Unloading of EWPs From ContainersDokumen10 halamanUnloading of EWPs From ContainersPirashanth SathananthanBelum ada peringkat

- Daily JSADokumen4 halamanDaily JSAumn_mlkBelum ada peringkat

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDokumen21 halamanShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajBelum ada peringkat

- Aerial-Scissor-Lift-Safety-Program SAMPLEDokumen19 halamanAerial-Scissor-Lift-Safety-Program SAMPLEluis Veloz100% (1)

- Crane Hoist Sling Safety ProgramDokumen14 halamanCrane Hoist Sling Safety Programomar sadiqBelum ada peringkat

- SOP SOP0007 Hitachi Electric Jack HammerDokumen3 halamanSOP SOP0007 Hitachi Electric Jack HammerWidya BungaBelum ada peringkat

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDokumen2 halamanJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinBelum ada peringkat

- Monthly Ladder Inspection ChecklistDokumen1 halamanMonthly Ladder Inspection ChecklistshahidBelum ada peringkat

- Mechanical Trades SOPDokumen5 halamanMechanical Trades SOPadventmanurungBelum ada peringkat

- Elevating Work PlatformDokumen1 halamanElevating Work PlatformKostan AbdillahBelum ada peringkat

- Building De-Dusting JSADokumen3 halamanBuilding De-Dusting JSAJayesh J PillaiBelum ada peringkat

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDokumen5 halamanJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- JSA PRE-TEST UploadDokumen2 halamanJSA PRE-TEST UploadDenny Kurniawan PrawiraBelum ada peringkat

- JHA Maintenance Tech HVACDokumen2 halamanJHA Maintenance Tech HVACMdavaBelum ada peringkat

- Manual Handling Policy GuideDokumen13 halamanManual Handling Policy GuideVibas BBelum ada peringkat

- Risk Assessment New Site Lifting Operations 07-06-2015Dokumen3 halamanRisk Assessment New Site Lifting Operations 07-06-2015ANAND MLBelum ada peringkat

- Index: Cv. Dira Utama SejahteraDokumen12 halamanIndex: Cv. Dira Utama SejahteraFreshop SurabayaBelum ada peringkat

- Risk Assessment For Minibuses Final Version For WebsiteDokumen10 halamanRisk Assessment For Minibuses Final Version For WebsiteFachri HidayatBelum ada peringkat

- Annals 2011 3 10Dokumen5 halamanAnnals 2011 3 10Fachri HidayatBelum ada peringkat

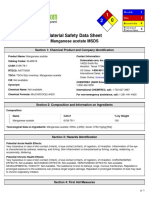

- Health hazards of manganese acetateDokumen5 halamanHealth hazards of manganese acetateFachri HidayatBelum ada peringkat

- Managing Risks DriversDokumen214 halamanManaging Risks DriversFachri Hidayat100% (1)

- HAZOP Process GuideDokumen62 halamanHAZOP Process GuideMolti Mol MolBelum ada peringkat

- 9938chang FlyashDokumen5 halaman9938chang FlyashFachri HidayatBelum ada peringkat

- 9938chang FlyashDokumen5 halaman9938chang FlyashFachri HidayatBelum ada peringkat

- 9938chang FlyashDokumen5 halaman9938chang FlyashFachri HidayatBelum ada peringkat

- Pentatonic Guitar MagicDokumen7 halamanPentatonic Guitar MagicTiffany Malone100% (6)

- 20ANEXO7Dokumen11 halaman20ANEXO7Fachri HidayatBelum ada peringkat

- Bahruddin - Psap@ugm - Ac.id M: Bahruddin, Jurusan Pembangunan Sosial Dan Kesejahteraan Fisipol, UgmDokumen44 halamanBahruddin - Psap@ugm - Ac.id M: Bahruddin, Jurusan Pembangunan Sosial Dan Kesejahteraan Fisipol, UgmFachri HidayatBelum ada peringkat

- Kusmiyati - RK Report Steam ExplosionDokumen15 halamanKusmiyati - RK Report Steam ExplosionFachri HidayatBelum ada peringkat

- HIRARC FormDokumen43 halamanHIRARC FormFachri Hidayat50% (2)

- EpaDokumen134 halamanEpaFachri HidayatBelum ada peringkat

- 5.7 Hazop V1.0Dokumen14 halaman5.7 Hazop V1.0Ricardo CorreaBelum ada peringkat

- HAZOP Process GuideDokumen62 halamanHAZOP Process GuideMolti Mol MolBelum ada peringkat

- Excel Solutions To The Chemical Engineering Problem SetDokumen54 halamanExcel Solutions To The Chemical Engineering Problem SetAna Isabel Roldán ToroBelum ada peringkat

- HAZOPDokumen21 halamanHAZOPJuan Carlos San RomanBelum ada peringkat

- HAZOPDokumen21 halamanHAZOPJuan Carlos San RomanBelum ada peringkat

- Aspen PlusDokumen140 halamanAspen PlusTayeb SherifBelum ada peringkat

- 6-Ethanol Fuel GradeDokumen7 halaman6-Ethanol Fuel GradeDavid LambertBelum ada peringkat

- Nureg 1738Dokumen369 halamanNureg 1738William IvansBelum ada peringkat

- Standards Functional Safety and Risk Assessment EN ISO 12100, EN ISO 13849 and IEC 62061Dokumen1 halamanStandards Functional Safety and Risk Assessment EN ISO 12100, EN ISO 13849 and IEC 62061krishna kumar100% (1)

- Man Sci Case Study FINALDokumen19 halamanMan Sci Case Study FINALMai Mai VarelaBelum ada peringkat

- EPWired Magazine February IssueDokumen41 halamanEPWired Magazine February IssueBorbála Heléna (Macika)Belum ada peringkat

- Gartner - Build Momentum in The Transition To Digital GovernmentDokumen45 halamanGartner - Build Momentum in The Transition To Digital GovernmentDemo EtternavnBelum ada peringkat

- Financial Institutions Management A Risk Management Approach 8Th Full ChapterDokumen41 halamanFinancial Institutions Management A Risk Management Approach 8Th Full Chapterjessica.walsh233100% (29)

- Module 2 Lesson 1Dokumen6 halamanModule 2 Lesson 1Christella Margarejo Delos ReyesBelum ada peringkat

- Decision Tree Analysis for PVI Delivery CostsDokumen18 halamanDecision Tree Analysis for PVI Delivery CostsDaniel VillenaBelum ada peringkat

- Phoenix - Revisiting Past Refinery Accidents From A HRADokumen13 halamanPhoenix - Revisiting Past Refinery Accidents From A HRAsteveBelum ada peringkat

- Guidelines for Health, Safety, Security and Environmental ManagementDokumen19 halamanGuidelines for Health, Safety, Security and Environmental ManagementAbfreddy SánchezBelum ada peringkat

- Offshore Installations (Safety Case) Regulations 2005 (PDF 181KB)Dokumen12 halamanOffshore Installations (Safety Case) Regulations 2005 (PDF 181KB)Jaewan LeeBelum ada peringkat

- Praj Annual Report 2020 21Dokumen192 halamanPraj Annual Report 2020 21Aayushi ChandwaniBelum ada peringkat

- COVID-19 Impact on Malaysian Banking IndustryDokumen15 halamanCOVID-19 Impact on Malaysian Banking IndustryPei Qi ErBelum ada peringkat

- How Much Is Enough For Rehabilitation - High Running Workloads Lower Limb InjuryDokumen6 halamanHow Much Is Enough For Rehabilitation - High Running Workloads Lower Limb InjuryMatt SiniscalchiBelum ada peringkat

- Innovation Strategy of Mcdonald Business From Historical PerspectivesDokumen13 halamanInnovation Strategy of Mcdonald Business From Historical PerspectivesArchana SarmaBelum ada peringkat

- A Tale of Three College Buildings Navigating BureaucracyDokumen9 halamanA Tale of Three College Buildings Navigating BureaucracyJM Hilario de OlazoBelum ada peringkat

- Volume Secret MasterDokumen45 halamanVolume Secret MasterErezwa95% (20)

- COVID-19 Guidance School Case Contact and Outbreak Management 2021-08-11 FINAL AODA enDokumen27 halamanCOVID-19 Guidance School Case Contact and Outbreak Management 2021-08-11 FINAL AODA enCityNewsTorontoBelum ada peringkat

- Cargo Tanks Doping, Adding AdditivesDokumen5 halamanCargo Tanks Doping, Adding AdditivesJeet SinghBelum ada peringkat

- Benifit Pension ObligationDokumen20 halamanBenifit Pension ObligationTouseefBelum ada peringkat

- Vistaar - Annual Report 2022 - F PDFDokumen93 halamanVistaar - Annual Report 2022 - F PDFAnandBelum ada peringkat

- Risk Assessment - ACS & CCTVDokumen3 halamanRisk Assessment - ACS & CCTVUmair Liaqat86% (7)

- Guidelines On Health Emergency Management Manual For PDFDokumen173 halamanGuidelines On Health Emergency Management Manual For PDFChris-Goldie Lorezo100% (1)

- Textbook SpringDokumen242 halamanTextbook SpringAditya D RBelum ada peringkat

- The Basics of Underwriting InsuranceDokumen4 halamanThe Basics of Underwriting Insurancenetishrai88Belum ada peringkat

- Safety Support Guide Book: Ple Type4 Safety Light Curtain GL-R SeriesDokumen32 halamanSafety Support Guide Book: Ple Type4 Safety Light Curtain GL-R Seriesrettore84Belum ada peringkat

- Risk management techniques for Birzeit UniversityDokumen3 halamanRisk management techniques for Birzeit UniversityAya alawiBelum ada peringkat

- ISO 31000 - Moving From 2009 To 2018 Revision - Version 5-ENDokumen56 halamanISO 31000 - Moving From 2009 To 2018 Revision - Version 5-ENAlex DaliBelum ada peringkat

- Document Incorporated by Reference BASF Financial Statements 2014 2016 09 12 PDFDokumen76 halamanDocument Incorporated by Reference BASF Financial Statements 2014 2016 09 12 PDFChanduSaiHemanthBelum ada peringkat

- CV Thomas GruenthalerDokumen2 halamanCV Thomas GruenthalerProstarBelum ada peringkat