PV Data Sheet

Diunggah oleh

Mathivanan AnbazhaganHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PV Data Sheet

Diunggah oleh

Mathivanan AnbazhaganHak Cipta:

Format Tersedia

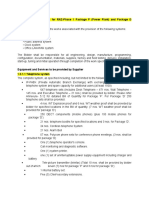

SHEET 1 OF 1

INSTRUMENT SPECIFICATION SHEET

3

0 4-11-2014

JOB NO. 13259

REV.

Control Valve,

Globe

MIA

DATE

ARQ

BY

FR

CHKD

APPVD

REV.

DATE

BY

CHKD

SPEC. NO. 13259-DD-04

APPVD

Tag No.

1PVXXXX1

1PVXXXX2

1PVXXXX3

1PVXXXX4

Service

1-EA-2002 A/B

1-EA-2003

1-EA-2004

1-EA-2005

3

4

P&ID No.

Line

120103

Size

Spec.

Sch. No.

120104

1-1/2"

A1D

120105

1-1/2"

80

A1D

120106

1-1/2"

80

A1D

1-1/2"

80

A1D

80

SERVICE CONDITIONS

7

Fluid

Flow Rate

Units

Wash Oil

m3/h

Wash Oil

m3/h

Wash Oil

m3/h

Wash Oil

Nor.

06

m3/h

06

m3/h

06

m3/h

06

m3/h

10

Max.

08

m3/h

08

m3/h

08

m3/h

08

m3/h

11

Diff. Press.

12

Min.

Nor.

13

14

Max.

Pressure

15

Nor.

20 barg

20 barg

20 barg

Max.

25 barg

25 barg

25 barg

16

Temperature

Nor.

17

Oper.Sp.Gr.

Mol. Wt.

18

Oper.Visc.

% Flash

19

Cp/Cv

Compressibility

20

m3/h

Min.

Max.

40 oC

75 oC

40 oC

0.827

Shut-Off Pressure (bar)

75 oC

20 barg

25 barg

40 oC

0.827

75 oC

40 oC

0.827

75 oC oC

0.827

3.84

3.84

3.84

3.84

VTA

VTA

VTA

VTA

BODY

21

Type of Body

22

Size

23

Material

24

End Conn. & Rating

25

Bonnet Type

26

Lubricator

27

Packing Material

28

Guiding

29

Valve Characteristic

30

Trim Material

Globe

Body

Port

Globe

A216GR.WCB

1

31

300#RF

Top

Top

300#RF

-

300#RF

Teflon Fiber

Single

1

Standard

EQ%

A216GR.WCB

Standard

Teflon Fiber

Single

A216GR.WCB

300#RF

EQ%

Globe

Standard

Teflon Fiber

No. of Port

A216GR.WCB

Standard

Isolation Valve

Globe

Top

P6315CL

Single

EQ%

Top

Single

EQ%

Seat

Plug

316SS

316SS

316SS

316SS

316SS

316SS

316SS

316SS

Cage

Stem

316SS

316SS

316SS

316SS

316SS

316SS

316SS

316SS

32

Required Seat Tightness

ANSI Class IV

ANSI Class IV

ANSI Class IV

ANSI Class IV

33

Allowable Sound Level dBA

85

85

85

85

34

Insulation

ACTUATOR & ACCESSORIES

35

Actuator Type

Diaphragm

Diaphragm

Diaphragm

Diaphragm

36

Fail Position

FC

FC

FC

FC

37

Positioner

I/P

I/P

I/P

38

Filt. Reg.

39

Input Signal

40

Solenoid Valve

Gauge

Bypass

Yes

Yes

Yes

Yes

Yes

I/P

Yes

Yes

4 - 20mA 24V DC

4 - 20mA 24V DC

Type

Action

42

Volt. DC or AC & Hz

43

Manual Operation

Q'ty

Limit Switch

45

Rating

Form

46

Enclosure

Flame Proof

Flame Proof

Flame Proof

Flame Proof

47

Elect. Conn.

1/2 NPT(F)

1/2 NPT(F)

1/2 NPT(F)

1/2 NPT(F)

48

Air Conn. Size

1/4 NPT(F)

1/4 NPT(F)

1/4 NPT(F)

1/4 NPT(F)

49

Handwheel

50

Volume Tank

51

Others(Note 1)

52

Manufacturer

VTA

VTA

VTA

VTA

53

Model No.

VTA

VTA

VTA

VTA

Notes :

4 - 20mA 24V DC

41

44

Yes

4 - 20mA 24V DC

1. See General Note of Engineering Specification for Piping Materials (SES-H-103E)

2. Vendor shall be responsible for final sizing and calculation of Control Valve .

SHEET 1 OF 1

GENERAL NOTE

JOB NO.

SC0593

REQ NO.

KAR501

REV

DATE

Control Valve,

Globe

30.APR.'04

SPEC.NO.

KA-501

1. Codes and Standard

(1) Sizing formula : ANSI / ISA S75.01

(2) Process connection : Flange ANSI B16.5

Thread ANSI B1.20.1

(3) Electrical signal connection : 1/2" or 3/4"NPT

(4) Pneumatic signal connection : 1/4"NPT

(5) Leakage class : ANSI / FCI 70.2

(6) Face to face dimensions of flanged globe control valve body : ANSI/ISA S75.03

2. Sizing Basis

(1) The sizing (furnished Cv) shall be based on the flow rate of :

- Normal flow rate only given : Cv is based on the 1.4 times normal flow rate.

- Maximum flow rate only given : Cv is based on the 1.1 times maximum flow rate.

- Normal and maximum flow rate given :

Cv is based on whichever is greater, 1.4 times normal flowrate or 1.1 times maximum flow rate

- if maximum flow specified on specification sheet when valve is full open, it shall be followed.

(2) The valve body size should be selected to allow for trim replacement, one size larger or smaller.

(3) The valve body size shall not be less than half the line size.

(4) The valves shall operate within 10% to 90% of their strokes.

(5) The sizes of the valves of on-off characteristics shall be same as line size.

(6) All globe valves shall be 1" minimum body size.

(7) The use of odd sizes such as 1 1/4", 2 1/2", 3 1/2", 5", 7" etc. shall be avoided.

3. Material

(1) Control valve body and trim materials shall be as specified in the specification sheets.

(2) Bolts/nuts exposed to atmosphere shall be of Type 304 stainless steel.

(3) The air tubing shall be of 1/4"O.Dx0.035T, 316SS tubing and double ferrules fittings.

(3/8"x0.035T & 1/2"O.Dx0.049T tubing also can be used as per actuator sizing.)

(4) The mechanical assembly such as spring, latch, pivots etc. shall be of stainless steel.

4. Painting

(1) The paint finish of the actuator cover shall be as Muncell No. 2.5G 4.5/8(RAL6032) for air fail opened valves

and Muncell No. 5R 4/13(RAL3032) for air fail closed valves.

5. Electric Enclosure

(1) Electrical area classification : Cl.1, Div. 2, Gr. B,C & D, T2 (except defined other code on specification sheet)

(2) Electrical enclosure : Flame-proof(except Limit Switch)

(3) To be certified by the appropriate such as CENELEC, BASEFFA, FM, TUV, TIIS, CSA, KEMA, etc.

(4) The proper explosion classification shall be identified with permanent tag plate of stainless steel.

6. Accessories

(1) Solenoid valve : DC 24V, Flame-proof, Low voltage drop, Low power consumption (ASCO Low Power Series)

(2) Limit switch : Proximity Type(Pepperl+Fuchs - NAMUR signal, Inductive Type), Intrinsically Safety

(3) I/P positioner : Flame-proof

(4) Stud bolt/nuts for mounting of flangeless(wafer) valves.

(5) Limit switches or solenoid valves with flying leads shall be provided with junction box for termination of the leads.

7. Air supply pressure is minimum 4 barg.

8. Detailed Specifications are specified on SES-K-152E.

-303AA4 ( Rev.0 )

SAMSUNG ENGINEERING CO., LTD

Anda mungkin juga menyukai

- Condensadora TTB TraneDokumen24 halamanCondensadora TTB TraneRoberto Reyes Lara100% (1)

- Especificacion ModeloDokumen12 halamanEspecificacion ModeloAnonymous qhVGVpBelum ada peringkat

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDokumen20 halamanLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimBelum ada peringkat

- ASCO SolenoidDokumen10 halamanASCO Solenoidsharib26Belum ada peringkat

- B.3.7 - Control Valves, Shut Down, Self Acting Regulators SpecDokumen11 halamanB.3.7 - Control Valves, Shut Down, Self Acting Regulators SpecThuc TruongBelum ada peringkat

- AMRI MAMMOUTwerrewrrH Type Series Booklet DataDokumen24 halamanAMRI MAMMOUTwerrewrrH Type Series Booklet Datarudiskw456Belum ada peringkat

- Integral Orifice Flow Elements, 1 and 1 Inch Pipe Sizes: Measurement Made EasyDokumen8 halamanIntegral Orifice Flow Elements, 1 and 1 Inch Pipe Sizes: Measurement Made EasyalanBelum ada peringkat

- Perrin High Pressure Valves For Hydrogen ServiceDokumen12 halamanPerrin High Pressure Valves For Hydrogen ServiceKunming Wang100% (1)

- MM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1Dokumen10 halamanMM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1gracemanotocBelum ada peringkat

- Gates CatalogDokumen72 halamanGates CatalogAldo B Aldo BBelum ada peringkat

- 1150ADokumen28 halaman1150AHamdi SaidBelum ada peringkat

- KinetrolDokumen8 halamanKinetrolimbasdBelum ada peringkat

- W13018-YT01-GDF-457110 Rev 5-APVDokumen8 halamanW13018-YT01-GDF-457110 Rev 5-APVJosé santanaBelum ada peringkat

- CraneDokumen32 halamanCranesabes26100% (1)

- SS2 Agv200 0300 01Dokumen12 halamanSS2 Agv200 0300 01RaymondIlyasBelum ada peringkat

- Cartridge Valves For Submarine, Aircraft Carrier Rocket LauncherDokumen27 halamanCartridge Valves For Submarine, Aircraft Carrier Rocket LauncherPeter JonesBelum ada peringkat

- s05nmdl2sm PDFDokumen22 halamans05nmdl2sm PDFmn_aminBelum ada peringkat

- Asco Valve 8327Dokumen2 halamanAsco Valve 8327Yorkist100% (1)

- Actuator DRD DREDokumen35 halamanActuator DRD DRESandi AslanBelum ada peringkat

- Fluid Tech-Info enDokumen17 halamanFluid Tech-Info enadhityaBelum ada peringkat

- BTC Gate ValvesDokumen26 halamanBTC Gate ValvesCamilo Sanchez VanegasBelum ada peringkat

- Valvulas Sole No Ides IsDokumen12 halamanValvulas Sole No Ides Isaaa3131Belum ada peringkat

- Pressure and Vacuum Switches - 216Dokumen32 halamanPressure and Vacuum Switches - 216Nirav GandhiBelum ada peringkat

- Re 10223Dokumen26 halamanRe 10223medi38Belum ada peringkat

- Is - 14845Dokumen17 halamanIs - 14845mechftpBelum ada peringkat

- Solenoid Select ChartDokumen47 halamanSolenoid Select Chartسامح الجاسمBelum ada peringkat

- 12AT/50AT Series: Spin-On FiltersDokumen8 halaman12AT/50AT Series: Spin-On FiltersPartsGopher.comBelum ada peringkat

- 3600 - Hi-Lo Pilot SwitchDokumen10 halaman3600 - Hi-Lo Pilot Switchsumesh19778933Belum ada peringkat

- Washpipe Packing AssembliesDokumen10 halamanWashpipe Packing AssembliesJohn Holding100% (1)

- ButterflyDokumen6 halamanButterflysachin2010Belum ada peringkat

- INVALCO CatalogDokumen24 halamanINVALCO Catalogemuno008Belum ada peringkat

- Anderson Greenwood Needle ValvesDokumen14 halamanAnderson Greenwood Needle ValvesDanielle JohnsonBelum ada peringkat

- Water Control Valve DV-5Dokumen8 halamanWater Control Valve DV-5Christian FherBelum ada peringkat

- Appendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Dokumen14 halamanAppendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Fadil WimalaBelum ada peringkat

- 8214 200aDokumen8 halaman8214 200aisaac-espinosa-430Belum ada peringkat

- PSI PumpsDokumen12 halamanPSI PumpsagiacomuzoBelum ada peringkat

- Pipe Handling System: 1 ForewordDokumen3 halamanPipe Handling System: 1 ForewordysilangitBelum ada peringkat

- EGE13B10Dokumen46 halamanEGE13B10Jhonny Rafael Blanco CauraBelum ada peringkat

- Specification For Lube Oil and Dry Gas Seal SystemDokumen17 halamanSpecification For Lube Oil and Dry Gas Seal Systemjahosolaris5512Belum ada peringkat

- 43-7500401 (Versa) PDFDokumen20 halaman43-7500401 (Versa) PDFAnthony WilliamsBelum ada peringkat

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dokumen3 halamanDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiBelum ada peringkat

- Valvula ASCO Falcon SB2500Dokumen2 halamanValvula ASCO Falcon SB2500Elmer HuashuayoBelum ada peringkat

- Air Preparation ProductsDokumen6 halamanAir Preparation ProductssenamotoBelum ada peringkat

- QHP CatalogDokumen7 halamanQHP CatalogsanjeevvangeBelum ada peringkat

- Válvula DurcoDokumen12 halamanVálvula DurcoJames Henrry López EspejoBelum ada peringkat

- General Service Solenoid Valves for Fluid ControlDokumen4 halamanGeneral Service Solenoid Valves for Fluid Controlpacho916Belum ada peringkat

- Data Sheet Tag 180-Pu-011eDokumen8 halamanData Sheet Tag 180-Pu-011eSarah PerezBelum ada peringkat

- Codeline, 150 PSI, Drawing - 80S15Dokumen3 halamanCodeline, 150 PSI, Drawing - 80S15RamanNegiBelum ada peringkat

- Technical System Pumps Specifications of Equipment For Each WWTPDokumen13 halamanTechnical System Pumps Specifications of Equipment For Each WWTPBimal DeyBelum ada peringkat

- ARO Flo 1500 SeriesDokumen11 halamanARO Flo 1500 SeriesEliasBelum ada peringkat

- Check-Trol: Isolation Flow Control FlangeDokumen2 halamanCheck-Trol: Isolation Flow Control FlangeAnonymous 7xHNgoKE6eBelum ada peringkat

- ACUMULADORESDokumen18 halamanACUMULADORESJuan GuillermoBelum ada peringkat

- TX & TXD Series: Sliding Vane PumpsDokumen2 halamanTX & TXD Series: Sliding Vane PumpsedwinramonBelum ada peringkat

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Dari EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Penilaian: 3.5 dari 5 bintang3.5/5 (3)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDari EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryBelum ada peringkat

- Performance ModelDokumen5 halamanPerformance ModelMathivanan AnbazhaganBelum ada peringkat

- Instrument Specification SheetDokumen1 halamanInstrument Specification SheetMathivanan AnbazhaganBelum ada peringkat

- APIL P&ID Comments for TG ProjectDokumen1 halamanAPIL P&ID Comments for TG ProjectMathivanan AnbazhaganBelum ada peringkat

- GCCDokumen1 halamanGCCMathivanan AnbazhaganBelum ada peringkat

- FI Data SheetsDokumen1 halamanFI Data SheetsMathivanan AnbazhaganBelum ada peringkat

- Alfanar: Emmar The Economic CityDokumen1 halamanAlfanar: Emmar The Economic CityMathivanan AnbazhaganBelum ada peringkat

- RAZDokumen178 halamanRAZMathivanan Anbazhagan100% (1)

- Security LocksDokumen12 halamanSecurity LocksMathivanan AnbazhaganBelum ada peringkat

- KKS Classification SystemDokumen227 halamanKKS Classification SystemMathivanan Anbazhagan100% (2)

- RFQ-Supply of Field InstrumentsDokumen2 halamanRFQ-Supply of Field InstrumentsMathivanan AnbazhaganBelum ada peringkat

- 16 - Annexures A and BDokumen74 halaman16 - Annexures A and BMathivanan AnbazhaganBelum ada peringkat

- Show floor cutout in 3D modelDokumen1 halamanShow floor cutout in 3D modelMathivanan AnbazhaganBelum ada peringkat

- TenderDokumen3 halamanTenderMathivanan AnbazhaganBelum ada peringkat

- LEED v4 Ballot Version (BDC) - 13 11 13Dokumen159 halamanLEED v4 Ballot Version (BDC) - 13 11 13rasheedillikkalBelum ada peringkat

- XV Data SheetDokumen1 halamanXV Data SheetMathivanan Anbazhagan100% (1)

- PT Data SheetDokumen2 halamanPT Data SheetMathivanan AnbazhaganBelum ada peringkat

- Scope of WorkDokumen4 halamanScope of WorkMathivanan AnbazhaganBelum ada peringkat

- Schedule B - Attachment IiiDokumen5 halamanSchedule B - Attachment IiiMathivanan AnbazhaganBelum ada peringkat

- Software ManualDokumen7 halamanSoftware ManualMathivanan AnbazhaganBelum ada peringkat

- SH 51MW Bop 033 I 001 Rev.2Dokumen15 halamanSH 51MW Bop 033 I 001 Rev.2Mathivanan AnbazhaganBelum ada peringkat

- FO Data SheetDokumen1 halamanFO Data SheetMathivanan AnbazhaganBelum ada peringkat

- ClarificationsDokumen1 halamanClarificationsMathivanan AnbazhaganBelum ada peringkat

- Instrument Installation Material List (BM Bulk Material List), Rev 1Dokumen1 halamanInstrument Installation Material List (BM Bulk Material List), Rev 1Mathivanan AnbazhaganBelum ada peringkat

- Mepl-Design and Engg StatusDokumen170 halamanMepl-Design and Engg StatusMathivanan AnbazhaganBelum ada peringkat

- Projects Activities - ElectricalDokumen4 halamanProjects Activities - ElectricalMathivanan Anbazhagan100% (1)

- Activities For Doing ProjectDokumen1 halamanActivities For Doing ProjectMathivanan AnbazhaganBelum ada peringkat

- Jayamoorthy Mugunthan MR 26oct RuhDokumen3 halamanJayamoorthy Mugunthan MR 26oct RuhMathivanan AnbazhaganBelum ada peringkat

- Tce Consulting Engineers Limited Quality Assurance Compliance Report For Enquiry SpecificationsDokumen2 halamanTce Consulting Engineers Limited Quality Assurance Compliance Report For Enquiry SpecificationsMathivanan AnbazhaganBelum ada peringkat

- Jayamoorthy Mugunthan MR 14nov MaaDokumen3 halamanJayamoorthy Mugunthan MR 14nov MaaMathivanan AnbazhaganBelum ada peringkat

- Urinary System 1. List The Functions of The KidneysDokumen6 halamanUrinary System 1. List The Functions of The KidneysheerBelum ada peringkat

- Tata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data SheetDokumen6 halamanTata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data Sheetsujit5584Belum ada peringkat

- Rexnord Thomas Flexible Disc Couplings - Series 71 - 8Dokumen2 halamanRexnord Thomas Flexible Disc Couplings - Series 71 - 8Orlando ReisBelum ada peringkat

- Measles/ Rubella & VPD Surveillance:: Allotment of EPID Number and Outbreak IDDokumen7 halamanMeasles/ Rubella & VPD Surveillance:: Allotment of EPID Number and Outbreak IDDevendra Singh TomarBelum ada peringkat

- Ted TalkDokumen4 halamanTed Talkapi-550727300Belum ada peringkat

- SPR MAN 4 14 ET Operating ManualDokumen24 halamanSPR MAN 4 14 ET Operating ManualJason WeeksBelum ada peringkat

- Installation TubeeeDokumen7 halamanInstallation TubeeeDini NovitrianingsihBelum ada peringkat

- Work, Energy Power RevDokumen31 halamanWork, Energy Power RevRency Micaella CristobalBelum ada peringkat

- Employment Law Lubs 3915Dokumen4 halamanEmployment Law Lubs 3915ogunsatoBelum ada peringkat

- En50443 - SC9XC - 11656 - Enq2e (Mod 7 10 10)Dokumen32 halamanEn50443 - SC9XC - 11656 - Enq2e (Mod 7 10 10)Levente CzumbilBelum ada peringkat

- Colours of the RainbowDokumen16 halamanColours of the RainbowMd A RAZZAKBelum ada peringkat

- Load Summary for Premise Under 100kVADokumen2 halamanLoad Summary for Premise Under 100kVAMuhammad Zulhelmi ZawawiBelum ada peringkat

- Cholinergic DrugsDokumen29 halamanCholinergic DrugsKiranBelum ada peringkat

- 1154ec108nanoelectronics PDFDokumen3 halaman1154ec108nanoelectronics PDFLordwin CecilBelum ada peringkat

- Human Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamDokumen23 halamanHuman Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamkamranBelum ada peringkat

- Project Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.Dokumen6 halamanProject Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.EIRI Board of Consultants and Publishers0% (1)

- Acute Atelectasis Prevention & TreatmentDokumen9 halamanAcute Atelectasis Prevention & TreatmentmetabolismeproteinBelum ada peringkat

- FAQ: Product RegistrationDokumen5 halamanFAQ: Product RegistrationCalvin WangBelum ada peringkat

- Summative Test in Respiratory SystemDokumen2 halamanSummative Test in Respiratory SystemEden Manlosa100% (4)

- Stormwater CalculationDokumen66 halamanStormwater CalculationDinesh DurairajBelum ada peringkat

- Full Text 01Dokumen72 halamanFull Text 01aghosh704Belum ada peringkat

- Technical Information Bulletins Ajax # 010717Dokumen28 halamanTechnical Information Bulletins Ajax # 010717harley florezBelum ada peringkat

- Osteo Book Final 2014Dokumen51 halamanOsteo Book Final 2014hyanandBelum ada peringkat

- Technical Bulletins Miglow Underwater12Dokumen1 halamanTechnical Bulletins Miglow Underwater12Arnaud PoliBelum ada peringkat

- Hybridization Review WorksheetDokumen6 halamanHybridization Review WorksheetRejed VillanuevaBelum ada peringkat

- Materi Bahasa Inggris Kelas 9 - LabelsDokumen12 halamanMateri Bahasa Inggris Kelas 9 - LabelsEnglish Is fun67% (3)

- Chapter - 10 NanoshellsDokumen13 halamanChapter - 10 NanoshellskarthikBelum ada peringkat

- Kathrein Antenna Dual BandDokumen4 halamanKathrein Antenna Dual BandAmine AchrafBelum ada peringkat

- FICHA TECNICA Smart-EvoDokumen4 halamanFICHA TECNICA Smart-EvoClaudio A.Belum ada peringkat

- Early Signs of AutismDokumen27 halamanEarly Signs of AutismErica Alejandra Schumacher100% (1)