Emerson Power Transmission Corp. JRM11.PDF Types of Coupling Balance

Diunggah oleh

Lasse Hansen0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

129 tayangan12 halamanThis document discusses different types of coupling balancing:

1) As manufactured - couplings are supplied without balancing.

2) Component balancing - parts are balanced individually to achieve similar balance as assembly balancing at lower cost.

3) Assembly balancing - the entire coupling is rigidly mounted and balanced as a unit, providing best balance but at highest cost.

Deskripsi Asli:

Coupling Balance

Judul Asli

Lets Try to Really Understand Coupling Balance

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document discusses different types of coupling balancing:

1) As manufactured - couplings are supplied without balancing.

2) Component balancing - parts are balanced individually to achieve similar balance as assembly balancing at lower cost.

3) Assembly balancing - the entire coupling is rigidly mounted and balanced as a unit, providing best balance but at highest cost.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

129 tayangan12 halamanEmerson Power Transmission Corp. JRM11.PDF Types of Coupling Balance

Diunggah oleh

Lasse HansenThis document discusses different types of coupling balancing:

1) As manufactured - couplings are supplied without balancing.

2) Component balancing - parts are balanced individually to achieve similar balance as assembly balancing at lower cost.

3) Assembly balancing - the entire coupling is rigidly mounted and balanced as a unit, providing best balance but at highest cost.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 12

Courtsey Kop-Flex

Emerson Power

Transmission Corp.

JRM11.PDF

Tvnes of Couoline Balance

Most Coupling manufacturers can and will supply couplings that are

brought into balance. Some coupling manufacturers have what they

call standard balancing procedure and practice. Extra charges maybe

made for balancing procedures other than their standard practices. For

example, some coupling manufactares prefer to component balance

only. The different types of coupling balance used by manufactures

are:

As Manufactured . Today most couplings are supplied as

manufactured with no balancing.

Controlled Tolerances and Fits. This usually provides the most

Figure 7. Component Balancing a Rigid (with a mandrel)

significant improvement in the potential unbalance of couplings. This

also can substantially increase the price of a coupling. It also is the

most difficult to explain, so one usually ask that the coupling be

Comnonent Balance With Some Subassemblv Balance. With

balanced anyhow.

this type of balance one can sometimes exceed the potential

unbalance of an assembly balanced coupling. This is particularly true

Component Balance. Can usually produce potential unbalanced

values equal to an assembly balanced couplings. It offers the

of couplinns

_ - that must have running clearances. One example of this

would be Gear Couplings. If they are assembly balanced they are

advantage of being able to replace components (as related to balance,

balanced with the radial clearance between the sleeve and hubs tight,

some couplings are not interchangeable for other reasons) without

and then after balance the tips (usually of the hub) are machined to

replacing the assembly. This technique is shown in Figure 6 & 7

provide the proper operational clearance. Thereby the balance is truly

upset. Whereas if one bolts the sleeves to its spacer, machines

rolling bands on the OD of the sleeves (concentric to the gear) and

then balance this subassembly and the two hubs, one gets a better

balanced coupling.

Component Balance With Selective Assemblv. Sometimes

offers the best possible balance attainable without field balancing on

the equipment. Parts are component balanced and then runouts (TIRs)

are checked. The highs of the TlR readings between controlling

diameters for mating parts are marked. At final coupling assembly the

high spots are assembled 180 deg out of phase. This tends to negate

eccentricities and reduces the potential unbalance of the coupling.

The parts are still interchangeable as long as replacement parts are

Figure 6. Component Balancing a spacer & a hub

inspected and marked for their TIRs.

(no mandrels)

339

Figure 8. Assembly Balancing of a High Performance Disc Coupling.

Assemblv Balancing.- usually offers the best balance, but it

Field or Trim Balancing on the Eauinment - offers the best

usually expensive because it may require mandrels and/or fixtures

and of course usually the mostly way to balance a coupling because

that are made with extreme accuracy. The coupling is basically

of the trial and error and time involved. Usually one is balancing

ridgized with a mandrel or fixtures and balanced. For disc,

the entire train by making corrections on the coupling. This makes

diaphragm and some special types of gear couplings they can be

it impossible to change not only any part of the coupling of also of

locked rigid with various locking devices that are usually

the drive train without rebalancing

incorporated into the coupling design (Figure 8). The coupling is

rolled on rolling surfaces that are aligned or machined to the

COUPLING BALANCE SPECIFICATIONS

coupling bores or alignment pilots, This type of balance can usually

provide a better balance than can be achieved using a mandrel. This

A G M A

is because there is no added weight to the assembly when it is

The balance limit placed on a coupling should be its potential

balanced. On a very large or long coupling, a mandrel assembly can

unbalance limit and not its residual unbalance limit. The residual

weigh almost half of the weight of a coupling. This can introduce

unbalance limit usually has little to do with the true coupling

significant balancing errors. On assembly balanced couplings, parts

unbalance (potential). It can be seen in many cases that by cutting

cannot be replaced without the rebalancing of the coupling.

the residual unbalance limit in half, the coupling potential unbalance

Specification

may only change by five percent. The best method of determining

340

Anda mungkin juga menyukai

- Curva y Catalgo Bomba Borger UsaDokumen4 halamanCurva y Catalgo Bomba Borger UsacpchectorhBelum ada peringkat

- KMB IomDokumen51 halamanKMB Iomxxl_1972Belum ada peringkat

- 0001152572Dokumen14 halaman0001152572AhmadBelum ada peringkat

- Why EagleBurgmann 29.03.2011Dokumen15 halamanWhy EagleBurgmann 29.03.2011ybozbasBelum ada peringkat

- Velocity TrianglesDokumen17 halamanVelocity TriangleszainriazBelum ada peringkat

- Pump Cuplings:: Centrifugal PumpsDokumen5 halamanPump Cuplings:: Centrifugal PumpsSaswata PradhanBelum ada peringkat

- Operation Manual: SLM Nho Execution Acc. To Directive 94/9/ECDokumen49 halamanOperation Manual: SLM Nho Execution Acc. To Directive 94/9/ECkeyur1109Belum ada peringkat

- Amarinth delivers API 682 Plan53C technology to meet tight deadlines for North Sea oil rigDokumen1 halamanAmarinth delivers API 682 Plan53C technology to meet tight deadlines for North Sea oil rigShipra DuttBelum ada peringkat

- Improved Performance Model of Turbocharger Centrifugal CompressorDokumen7 halamanImproved Performance Model of Turbocharger Centrifugal CompressorjswxieBelum ada peringkat

- Gear Drive Issues Why Belt Is BetterDokumen5 halamanGear Drive Issues Why Belt Is BetterfranzumarragaBelum ada peringkat

- ALLWEILER-Pump GK 796451 CWH 250-500 GB PDFDokumen8 halamanALLWEILER-Pump GK 796451 CWH 250-500 GB PDFGeorge_Wabag_2014100% (1)

- Vacuumpump SihiDokumen9 halamanVacuumpump SihikzwinnenBelum ada peringkat

- Industrial RefrigerationDokumen5 halamanIndustrial RefrigerationApet GriffinBelum ada peringkat

- The Effect of Lubrication On Tribological Properties of Bearing Materials Using Pin On Disc: A ReviewDokumen10 halamanThe Effect of Lubrication On Tribological Properties of Bearing Materials Using Pin On Disc: A ReviewIJRASETPublicationsBelum ada peringkat

- What Is Perspective ManagementDokumen2 halamanWhat Is Perspective ManagementDiwasBelum ada peringkat

- Pub 45 Copper Alloy BearingsDokumen44 halamanPub 45 Copper Alloy BearingsIbrahim AbdouBelum ada peringkat

- Fluid Film Lubrication - Osborne Reynolds Centenary: FLUID FILM LUBRICATION - OSBORNE REYDari EverandFluid Film Lubrication - Osborne Reynolds Centenary: FLUID FILM LUBRICATION - OSBORNE REYBelum ada peringkat

- Crossmorse Timing Belts PDFDokumen52 halamanCrossmorse Timing Belts PDFDanilo RojasBelum ada peringkat

- Twin Screw PumpsDokumen56 halamanTwin Screw PumpsAyman MedaneyBelum ada peringkat

- Instruction Manual - OptiLobe - enDokumen32 halamanInstruction Manual - OptiLobe - enmagzigioBelum ada peringkat

- Self-similar boundary layer labDokumen12 halamanSelf-similar boundary layer labMubarak KazminBelum ada peringkat

- DGT W 16700 ETP 1140 IM 004 - A - Anexo - 4Dokumen25 halamanDGT W 16700 ETP 1140 IM 004 - A - Anexo - 4Ivan Maltsev100% (1)

- User Manual SIHI OkDokumen4 halamanUser Manual SIHI Okgame centerBelum ada peringkat

- Agitadores PlentyDokumen16 halamanAgitadores Plentyrolando tapiaBelum ada peringkat

- 5) Bearing Fundamentals PDFDokumen123 halaman5) Bearing Fundamentals PDFRizal Gunawan100% (1)

- Vortex SheddingDokumen3 halamanVortex SheddingMaheshBelum ada peringkat

- 04-Coupling 304 Motor-Gear PDFDokumen12 halaman04-Coupling 304 Motor-Gear PDFManuel Díaz VilloutaBelum ada peringkat

- SLM Svo ManualDokumen62 halamanSLM Svo Manualkeyur1109Belum ada peringkat

- TEM Balances Thrust in PumpsDokumen6 halamanTEM Balances Thrust in Pumpsxsi666Belum ada peringkat

- Lightnin Open Top Fixed Mount MixerDokumen16 halamanLightnin Open Top Fixed Mount MixerDave CBelum ada peringkat

- SLM Avp ManualDokumen48 halamanSLM Avp Manualkeyur1109Belum ada peringkat

- Jaw Coupling Installation GuideDokumen7 halamanJaw Coupling Installation GuideGnana Subramanian ArumugamBelum ada peringkat

- Critical Speed Analysis of Centrifugal Pump PDFDokumen8 halamanCritical Speed Analysis of Centrifugal Pump PDFPackage RotaryBelum ada peringkat

- Force coupling shaft hub calculation designDokumen23 halamanForce coupling shaft hub calculation designParag NaikBelum ada peringkat

- Fits&Tolerances SemI 0708Dokumen32 halamanFits&Tolerances SemI 0708Ashutosh PandeyBelum ada peringkat

- Energy transfer in turbomachinesDokumen60 halamanEnergy transfer in turbomachinesAtheer Sat0% (1)

- Life Calculation of Rolling Element BearingsDokumen23 halamanLife Calculation of Rolling Element BearingsMamdouh ElhanafyBelum ada peringkat

- Tolerances FitsDokumen25 halamanTolerances FitsAnonymous E2oSW7Belum ada peringkat

- Bearing Preload - What Is It and Why Is It Important - Engineering360Dokumen5 halamanBearing Preload - What Is It and Why Is It Important - Engineering360Mohan KBelum ada peringkat

- CompressorDokumen10 halamanCompressorArjun Shantaram ZopeBelum ada peringkat

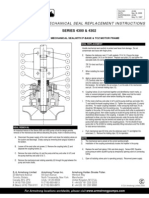

- Mechanical Seal Replacement InstructionsDokumen1 halamanMechanical Seal Replacement InstructionsGiorgio FerBelum ada peringkat

- Dynamic Modeling of Compressors Illustrated by An Oil Flooded Twin Helical Screw Compressor 2011 MechatronicsDokumen8 halamanDynamic Modeling of Compressors Illustrated by An Oil Flooded Twin Helical Screw Compressor 2011 MechatronicsTai Huu100% (1)

- A Comparative Study and Stiffness Analysis of Angular Contact Ball Bearings Under Different Preload MechanismsDokumen17 halamanA Comparative Study and Stiffness Analysis of Angular Contact Ball Bearings Under Different Preload MechanismskhelifiBelum ada peringkat

- Redscrew Twin Screw Iom RSW 10000 E 01 WebDokumen12 halamanRedscrew Twin Screw Iom RSW 10000 E 01 WebOscarBelum ada peringkat

- Cook Compression PackingDokumen2 halamanCook Compression PackingMuhammad Imran100% (1)

- Cherry Burrell Processor ManualDokumen48 halamanCherry Burrell Processor ManualMadan YadavBelum ada peringkat

- Royal Purple BarrierDokumen14 halamanRoyal Purple BarrierAnonymous H3I29yjBelum ada peringkat

- Pump Notes PDFDokumen25 halamanPump Notes PDFUsman KhalidBelum ada peringkat

- Fluid Mechanics PumpsDokumen22 halamanFluid Mechanics PumpsitzGeekInside100% (7)

- Von Karman FlowDokumen5 halamanVon Karman FlowAhmed LamineBelum ada peringkat

- ENGINEERING REFERENCE CHECKSDokumen2 halamanENGINEERING REFERENCE CHECKSMVSEETARAMANBelum ada peringkat

- Radial Thrust BRG Case StudiesDokumen14 halamanRadial Thrust BRG Case StudiesRajagopal100% (1)

- Warner Ball ScrewsDokumen45 halamanWarner Ball ScrewssaddlemanBelum ada peringkat

- Screw SelectionDokumen1 halamanScrew Selectionamarr1Belum ada peringkat

- Shaft Deflection Runout Vibration and Axial MotionDokumen21 halamanShaft Deflection Runout Vibration and Axial MotionMohd Ridzuan AhmadBelum ada peringkat

- Pump Repair and Restoration GuidelinesDokumen3 halamanPump Repair and Restoration GuidelinescuprotecBelum ada peringkat

- Vaneless DiffuserDokumen8 halamanVaneless Diffuseramir_karimiBelum ada peringkat

- Contact Stress Analysis of Gerotor SetDokumen10 halamanContact Stress Analysis of Gerotor Setsardhan.rajender84Belum ada peringkat

- Chapter 1 (Copy)Dokumen33 halamanChapter 1 (Copy)Andy ChoyBelum ada peringkat

- 2015.08 The Leak Index Feature in Windrock MDDokumen3 halaman2015.08 The Leak Index Feature in Windrock MDLasse HansenBelum ada peringkat

- 2015.06 Why You Cant Rely On Temperature MeasurementsDokumen4 halaman2015.06 Why You Cant Rely On Temperature MeasurementsLasse HansenBelum ada peringkat

- Smaller Than The Eye Can See, Vibration Analysis. Buyukozturk - WCNDT - 2016Dokumen10 halamanSmaller Than The Eye Can See, Vibration Analysis. Buyukozturk - WCNDT - 2016Lasse HansenBelum ada peringkat

- 2015.04 Eliminating Channel ResonanceDokumen3 halaman2015.04 Eliminating Channel ResonanceLasse HansenBelum ada peringkat

- GMRC Surge GuidelineDokumen75 halamanGMRC Surge Guidelinesbas84Belum ada peringkat

- Fundamentals of Steam Power PlantsDokumen50 halamanFundamentals of Steam Power PlantsImam Wahyudi100% (2)

- THE WANKEL EngineDokumen21 halamanTHE WANKEL Enginedramala100% (1)

- WL80100E Mounting & DismountingDokumen117 halamanWL80100E Mounting & DismountingSujanto WidjajaBelum ada peringkat

- Rotordynamics Standards - New Developments and TheDokumen1 halamanRotordynamics Standards - New Developments and TheLasse HansenBelum ada peringkat

- ME 343: Mechanical Design-3 Sheet 1: ShaftsDokumen1 halamanME 343: Mechanical Design-3 Sheet 1: ShaftsLasse HansenBelum ada peringkat

- Diesel Engine ConstructionDokumen53 halamanDiesel Engine ConstructionLasse HansenBelum ada peringkat

- One-Shot Balancing of Rigid Rotors, A Closed Form Solution - DeTC 2009Dokumen9 halamanOne-Shot Balancing of Rigid Rotors, A Closed Form Solution - DeTC 2009Lasse HansenBelum ada peringkat

- A Modified Balancing Method For Flexible Rotors Based On Multi-Sensor FusionDokumen5 halamanA Modified Balancing Method For Flexible Rotors Based On Multi-Sensor FusionPawan ChaturvediBelum ada peringkat

- Evaluating rotor imbalance in flexibly mounted machines using vibration measurementsDokumen13 halamanEvaluating rotor imbalance in flexibly mounted machines using vibration measurementsCésar TapiaBelum ada peringkat

- Steady Synchronous Response and Balancing of Rotor Systems With Residual Shaft BowDokumen8 halamanSteady Synchronous Response and Balancing of Rotor Systems With Residual Shaft BowLasse HansenBelum ada peringkat

- Robust Optimal Influence - Coefficient Control of Multiple-Plane Active Rotor Balancing SystemsDokumen6 halamanRobust Optimal Influence - Coefficient Control of Multiple-Plane Active Rotor Balancing SystemsLasse HansenBelum ada peringkat

- What Causes Wear in Gear-Type CouplingsDokumen5 halamanWhat Causes Wear in Gear-Type CouplingsLasse HansenBelum ada peringkat

- Review of Rotor BalancingDokumen8 halamanReview of Rotor BalancingLasse HansenBelum ada peringkat

- Community Noise 2Dokumen18 halamanCommunity Noise 2interlude347Belum ada peringkat

- How We Hear - Acoustics Listening MeasurementDokumen44 halamanHow We Hear - Acoustics Listening Measurementavalon_moonBelum ada peringkat

- Review of Rotor BalancingDokumen8 halamanReview of Rotor BalancingLasse HansenBelum ada peringkat

- Acoustic Emission Monitoring of North East Trunnion ShaftDokumen6 halamanAcoustic Emission Monitoring of North East Trunnion ShaftLasse HansenBelum ada peringkat

- OMS1Dokumen16 halamanOMS1Juan Daniel MoralesBelum ada peringkat

- Steel SpringFlexCoupling BackDokumen2 halamanSteel SpringFlexCoupling BackLasse HansenBelum ada peringkat

- Acoustic Treatment and Design For Recording Studios and Listening RoomsDokumen48 halamanAcoustic Treatment and Design For Recording Studios and Listening RoomsΚΙΚΗ ΜΗΛΛΙΟΥBelum ada peringkat

- Putting The Damper On Torsional VibrationDokumen5 halamanPutting The Damper On Torsional VibrationLasse HansenBelum ada peringkat

- Mission Critical Coupling1-05 PDFDokumen3 halamanMission Critical Coupling1-05 PDFLasse HansenBelum ada peringkat

- Grease Seperation Under Centrifugal ForcesDokumen6 halamanGrease Seperation Under Centrifugal ForcesLasse HansenBelum ada peringkat

- Heat Load Calculation IIDokumen2 halamanHeat Load Calculation IIsiruslara6491Belum ada peringkat

- Material Selection Guide - MILD STEELDokumen1 halamanMaterial Selection Guide - MILD STEELlouis donyBelum ada peringkat

- Dts-Lesson PlanDokumen3 halamanDts-Lesson Plansujithaa13Belum ada peringkat

- IFR 101 ManualDokumen28 halamanIFR 101 ManualsunhuynhBelum ada peringkat

- APEF - Electrochemistry - Multiple Choice Questions - Page 1 of 2Dokumen2 halamanAPEF - Electrochemistry - Multiple Choice Questions - Page 1 of 2alyaa sheirBelum ada peringkat

- 04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesDokumen1 halaman04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesRonaldBelum ada peringkat

- Powder Metallurgy LabDokumen8 halamanPowder Metallurgy Labשירי חדדBelum ada peringkat

- Pavement Materials: Highway and Transportation Engineering (Faculty of Engineering)Dokumen38 halamanPavement Materials: Highway and Transportation Engineering (Faculty of Engineering)atharBelum ada peringkat

- METAL ORGANIC FRAMEWORKS (MOFs)Dokumen8 halamanMETAL ORGANIC FRAMEWORKS (MOFs)FabianCcahuanaAymaBelum ada peringkat

- CVS Controls Series 470 Piston Actuators Sept 2014 PDFDokumen12 halamanCVS Controls Series 470 Piston Actuators Sept 2014 PDFVIVIANA ESQUIVELBelum ada peringkat

- Moulding Effects & DefectsDokumen91 halamanMoulding Effects & Defectsrijoy p pBelum ada peringkat

- Series: Standard Product CapabilitiesDokumen4 halamanSeries: Standard Product Capabilitiespmfg847633Belum ada peringkat

- Tulsion: Strong Acid Cation Exchange Resin Sodium CycleDokumen2 halamanTulsion: Strong Acid Cation Exchange Resin Sodium CycleKewl DudzBelum ada peringkat

- Poly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle ContentDokumen7 halamanPoly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle Contentastewayb_964354182Belum ada peringkat

- Precios y Cantidades de Recursos Requeridos Por TipoDokumen3 halamanPrecios y Cantidades de Recursos Requeridos Por TipoWilder Huaman MuñozBelum ada peringkat

- GSE ElectricDokumen46 halamanGSE ElectricoespanaBelum ada peringkat

- 7 SFW CFB BrochurerDokumen11 halaman7 SFW CFB BrochurerJuan SalcidoBelum ada peringkat

- ITA - Design Guidelines WaterproofingDokumen74 halamanITA - Design Guidelines WaterproofingDiana Cristina100% (1)

- FULL CERAMIC BEARINGS TECHNICAL GUIDEDokumen13 halamanFULL CERAMIC BEARINGS TECHNICAL GUIDEKatasterBelum ada peringkat

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)Dokumen3 halamanHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)crplzBelum ada peringkat

- AcknowledgementDokumen4 halamanAcknowledgementEndalkachew AddisBelum ada peringkat

- Estacion Manual Direccionable 52013 PDFDokumen2 halamanEstacion Manual Direccionable 52013 PDFLuis Ivan Moreno ParraBelum ada peringkat

- Science Presence of God J2Dokumen8 halamanScience Presence of God J2Kafui AugustineBelum ada peringkat

- Cat 03a en Compact Conductor System VKS10Dokumen25 halamanCat 03a en Compact Conductor System VKS10quang.an185Belum ada peringkat

- API RP505 Classfication SelectedDokumen2 halamanAPI RP505 Classfication SelectedSing Yew LamBelum ada peringkat

- Trace EvidenceDokumen43 halamanTrace EvidencevishnusrikanthrBelum ada peringkat

- Stress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsDokumen11 halamanStress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsEzzah HanifBelum ada peringkat

- 39 Tractor EmulsionDokumen4 halaman39 Tractor EmulsionJaga NathBelum ada peringkat

- An Accelerator Free Peroxide Vulcanization TechniqueDokumen17 halamanAn Accelerator Free Peroxide Vulcanization TechniqueClinton ThomsonBelum ada peringkat

- Cane Ite PDFDokumen4 halamanCane Ite PDFJim HaigBelum ada peringkat