API 14A Update

Diunggah oleh

Anonymous 70lCzDJv100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

382 tayangan13 halamanAPI 14A Update

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAPI 14A Update

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

382 tayangan13 halamanAPI 14A Update

Diunggah oleh

Anonymous 70lCzDJvAPI 14A Update

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 13

API 14A 12th Edition Overview

Addressing Critical Service and HPHT

SSSV Applications

Darren Bane Baker Hughes

March 17, 2015

API 14A 12th Edition Addressing Critical

Service and HPHT SSSV Applications

API 14A Twelfth Edition Overview

New Validation Levels and Associated Testing

Requirements

Additional Testing Requirements (when specified)

HPHT Annex Requirements for Design Verification

and Validation

HPHT Additonal Requirements

2

API 14A 12th Edition Overview

Published Jan 2015, Effective Jan 2016

Extensive changes justified 12 month

implementation timeframe

Key Revision highlights

Entire document reviewed and modified

Added 6 new Validation Grades in lieu of Classes of

Service

Scope now includes Injection Valves (SSISV) with

validation testing

API 14A 12th Edition Overview

Key Revision highlights

Added Normative and Informative Test Annexes to

align with new Validation Levels

Insert SCSSVs harmonized with API RP14B.

Design analysis methods added, including FEA and

CFD

Design Verification and Validation added for:

HPHT Environments and Applications (new Annex)

Alternate technology SSSVs

Secondary Tools for SSSVs (new Annex)

API 14A 12th Ed - New Validation Levels

and Associated Testing Requirements

New Validation Levels replace previous Classes

of Service designations

Allows better alignment with SSSV requirements

based on end user determination of testing required

Accommodates legacy equipment for previous

Class 1 and Class 2 validation ratings

New V1 and V1-H defined for critical or HPHT

applications

New V2 and V3 builds upon previous Class 1 & 2

with additional testing requirements

Removed Class 3 & 4, now in matl reqs section

API 14A 12th Ed - New Validation Levels

and Associated Testing Requirements

API 14A 12th Ed - New Validation Levels

and Associated Testing Requirements

V3 Validation Test

B.2 Table B.1 - Test Agency V3 steps

B.3

Gas flow test

B.5

Liquid leakage test

B.6

Unequalized opening test

B.7

Operating-pressure test

B.8

Propane test

B.9

Nitrogen leakage test

B.7

Operating-pressure test

B.10 V3 water flow test

Repeat B.9, B.7, and B.10 four times

B.5

Liquid leakage test

B.11 Controlled-temperature test

B.4

OD/ID Drift per B.4.2/B.4.3

New Requirements:

D.2

Temperature Cycle Test

D.3

Differential Opening Testing

D.4

Self-Equalizing Test

(if applicable)

Body Joint Evaluation

V2 Validation Test

B.2 Table B.2 - Test Agency V2 steps

Table B.1 (Steps 1-15)

B.7

Operating-pressure test

B.12 V2 Slurry Flow Test

B.9

Nitrogen Leakage Test

Repeat B.12 and B.9 six times

B.5

Liquid leakage test

B.4

OD/ID Drift per B.4.2/B.4.3

New Requirements:

D.2

Temperature cycle test

D.3

Differential opening testing

D.4

Self-Equalizing Test (if applicable)

Body Joint Evaluation

V2 validation completed

API 14A 12th Ed - New Validation Levels

and Associated Testing Requirements

V1 Validation Test

From a V2 validated valve, add:

G.3 Operating Life Test (500 cycles min.)

G.4 Differential Opening Testing

G.5 Equalization Mechanism Endurance

Testing

G.6 Special feature validation

G.7 ESSSV Electronics qualification (if

applicable)

Annex M Rated Performance Envelope

V1-H Validation Test

From a V1 validated valve, add:

Annex J Combined Load Operational Test

Annex L Dynamic Seal System Test

API 14A 12th Ed Additional Testing

Additional testing has been defined for

user/purchasers to specify when required

API 14A 12th Ed HPHT Annex Requirements for

Design Verification and Validation

New Annex H defines HPHT SSSV requirements

Defines the additional verification and validation requirements that shall

be followed in designing and manufacturing SSSV and secondary tools

for use in HPHT environment

H.2 Functional specification (User/purchaser requirements)

Additional requirements are to be specified including max flowing

temperature, shut in static temperature, and duration of time that SSSV

will operate at temperature

H.3 Technical specification (Supplier/manufacturer

requirements)

Temperature effects use temperature de-rated yield strength and

modulus of elasticity with testing on samples at mid-wall or mid radius

conducted in accordance with ASTM E21 and E111

Environmental effects compatibility of metals with well fluids shall be

evaluated, limits on castings (API 20A), limits on welding/structural

components

API 14A 12th Ed HPHT Annex Requirements for

Design Verification and Validation

H.3 Technical specification (Supplier/manufacturer

requirements)

Non-metals completions and stimulation fluid exposure to be

specified, compound evaluation for RGD and ageing along with

compound validation testing and evaluation

Design Verification User/purchaser specifies max anticipated shut-in

tubing pressure (SITP) at the SSSV and specify RWP > SITP.

The component shall conform to the requirements of 6.4 and the

following additional requirements:

For all metallic components integral to the tubing string and closure mechanism,

perform an elastic-plastic FEA using ASME BPVC Section VIII, Division 2

Localized stress discontinuities and localized yielding shall be evaluated by a qualified

person to determine if the design is acceptable or if additional analysis is required

When FEA has identified plastic strain in excess of 0.2 %, a ratcheting analysis shall be

performed per ASME BPVC Section VIII, Division 3, Paragraph KD-234 or ASME BPVC

Section VIII, Division 2, Paragraph 5.5.7

Perform a fatigue screening per ASME BPVC Section VIII, Division 2, Paragraph 5.5.2. If

the design exhibits fatigue sensitivity, conduct a fatigue analysis per API 579/ASME

FFS-1 using a safety factor of 2 on anticipated operating life

API 14A 12th Ed HPHT Annex Requirements for

Design Verification and Validation

H.3 Technical specification (Supplier/manufacturer

requirements)

Design Validation V1-H is normative, post-test NDE is required on all

critically stressed components from combined load test

Scaling of HPHT SSSVs comprehensive material review for scaled

designs (metal & non-metal) shall be reviewed and accepted

H.4 Additional supplier/manufacturer requirements

Metals verification yield strengths and modulus of elasticity for

components integral to the tubing string and the closure mechanism

shall be documented at max rated operating temperature

Functional Test Requirements the functional test pressure used in

Annex C shall be a minimum of 1.25 times RWP

Quality Plan shall be prepared per ISO 10005 and 6.4 for each order

placed and approved in writing by user/purchaser, any changes shall go

through the same approval process

Final Design Review final design review to verify that the SSSV and

secondary tools are suitable for the applicable HPHT environment

Questions?

Anda mungkin juga menyukai

- Well Testing Project Management: Onshore and Offshore OperationsDari EverandWell Testing Project Management: Onshore and Offshore OperationsBelum ada peringkat

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingDari EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingPenilaian: 5 dari 5 bintang5/5 (9)

- D-002 System Requirements Well Intervention EquipmentDokumen70 halamanD-002 System Requirements Well Intervention Equipmentbrucce13Belum ada peringkat

- Intervention/decommissioningDokumen15 halamanIntervention/decommissioningAnonymous ZO1piE3VBelum ada peringkat

- AOT Tubular HandlingDokumen112 halamanAOT Tubular HandlingrolandBelum ada peringkat

- Strength of Casing and Tubing - PetroWiki PDFDokumen15 halamanStrength of Casing and Tubing - PetroWiki PDFLuis David Concha CastilloBelum ada peringkat

- Annular Intervention EXPRO New Technology Project Final Report 2021 v1Dokumen18 halamanAnnular Intervention EXPRO New Technology Project Final Report 2021 v1Brahim LetaiefBelum ada peringkat

- HPHT Check ListsDokumen15 halamanHPHT Check ListsWaleed Barakat MariaBelum ada peringkat

- Drillin Manual Drill QuipDokumen295 halamanDrillin Manual Drill QuipSpeculeBelum ada peringkat

- Well Completion Maintenance Abandonment Guideline Sept Working v.1.18 2015 PDFDokumen57 halamanWell Completion Maintenance Abandonment Guideline Sept Working v.1.18 2015 PDFAwani KesterBelum ada peringkat

- Drilling Facilities: NORSOK Standard D-001Dokumen70 halamanDrilling Facilities: NORSOK Standard D-001Well Control100% (1)

- Preventive Maintenance Records AB Field WellsDokumen1 halamanPreventive Maintenance Records AB Field Wellseng7mohamed7hashimBelum ada peringkat

- Diverter System PDFDokumen46 halamanDiverter System PDFjairaso2950Belum ada peringkat

- HPHTDokumen106 halamanHPHTMohamed Hashem100% (1)

- rp90 1 E2 Ballot2 DraftDokumen85 halamanrp90 1 E2 Ballot2 Draftzero CHIRSTBelum ada peringkat

- Sentry Wellhead Catalog PDFDokumen129 halamanSentry Wellhead Catalog PDFMuhammad TahirBelum ada peringkat

- Evaluating Industry Standards for MMS RequirementsDokumen83 halamanEvaluating Industry Standards for MMS RequirementsSusan Diana Badillo Trejo0% (1)

- Pressure Control GroupDokumen4 halamanPressure Control GroupAbdelhamid HaramiBelum ada peringkat

- IWCF Well Intervention Pressure Control Level 3 and 4 Cross Reference FormDokumen82 halamanIWCF Well Intervention Pressure Control Level 3 and 4 Cross Reference FormairlinemembershipBelum ada peringkat

- D 007 Well Testing System PDFDokumen32 halamanD 007 Well Testing System PDFLaw100% (1)

- Units of Competence: Assistant Driller Level - 7Dokumen17 halamanUnits of Competence: Assistant Driller Level - 7Ben BieberBelum ada peringkat

- Performance Testing and Certification of Boots & Coots CT Well Control Accumulator SystemDokumen37 halamanPerformance Testing and Certification of Boots & Coots CT Well Control Accumulator SystemHKHKBOOKSBelum ada peringkat

- Otc 15179 MSDokumen10 halamanOtc 15179 MSHafiz AsyrafBelum ada peringkat

- Casing While DrillingDokumen22 halamanCasing While Drillingwulan zaedatusBelum ada peringkat

- Subsea Technology Development in Deep WaterDokumen36 halamanSubsea Technology Development in Deep WaterSpthefania DiazBelum ada peringkat

- Manual Coiled Tubing p1Dokumen500 halamanManual Coiled Tubing p1Luis Fernando Grajales MorenoBelum ada peringkat

- Wellhead Connector H4 TypeDokumen9 halamanWellhead Connector H4 Typeste7ieBelum ada peringkat

- CDS Crown Mounted Compensator SpecDokumen1 halamanCDS Crown Mounted Compensator SpecMarcos SobreiroBelum ada peringkat

- FMC Subsea Drilling Systems: 13 5/8” Wellhead SystemDokumen23 halamanFMC Subsea Drilling Systems: 13 5/8” Wellhead Systemsabilco13Belum ada peringkat

- Mudline Suspension2Dokumen2 halamanMudline Suspension2Emad JamshidiBelum ada peringkat

- NORSOK Standard D-010 Plugging and Abandonment GuidelinesDokumen35 halamanNORSOK Standard D-010 Plugging and Abandonment GuidelinesTiffany DacinoBelum ada peringkat

- Recommend Frequency of Well Integrity MonitoringDokumen1 halamanRecommend Frequency of Well Integrity MonitoringalizareiforoushBelum ada peringkat

- BOP Modifications GuideDokumen21 halamanBOP Modifications Guidecrd1990Belum ada peringkat

- Specialized Tools CatalogDokumen60 halamanSpecialized Tools CatalogGiorgiana Rosu100% (1)

- WOWS Introduction SnubbingDokumen40 halamanWOWS Introduction SnubbingFernando AbasBelum ada peringkat

- Cameron - CAMCHEC Riser Inspection - TC1484Dokumen4 halamanCameron - CAMCHEC Riser Inspection - TC1484jahehe2000Belum ada peringkat

- 2 JFE BEAR Design FeatureDokumen15 halaman2 JFE BEAR Design FeatureDaniel ChiriacBelum ada peringkat

- SPM Safety Iron Inspection and Maintenance ProcedureDokumen19 halamanSPM Safety Iron Inspection and Maintenance ProcedureIvan RojasBelum ada peringkat

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Dokumen40 halamanDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUBelum ada peringkat

- Volumetric Well Control - When It Will Be UsedDokumen17 halamanVolumetric Well Control - When It Will Be UsedR.GBelum ada peringkat

- Light Well Intervention System - LWISDokumen2 halamanLight Well Intervention System - LWISWilliam EvansBelum ada peringkat

- MIT-Multifinger Caliper Interpretation and ApplicationsDokumen43 halamanMIT-Multifinger Caliper Interpretation and ApplicationsAniekan SabastineBelum ada peringkat

- Rig Stacking Strategies for Long Term LayupDokumen14 halamanRig Stacking Strategies for Long Term LayupJeril PhilipBelum ada peringkat

- Stap A 1 Ss 1731 Rev B Casing and Tubing Power Tong WDokumen20 halamanStap A 1 Ss 1731 Rev B Casing and Tubing Power Tong WjalalBelum ada peringkat

- Well Barrier Schematics - Practical UseDokumen21 halamanWell Barrier Schematics - Practical UseDeepak RanaBelum ada peringkat

- Ops HB 02 Iss02 Rev01 Sbop Sections 1 9Dokumen58 halamanOps HB 02 Iss02 Rev01 Sbop Sections 1 9vikrant911Belum ada peringkat

- D-010 Well Integrity in Drilling and Well OperationsDokumen224 halamanD-010 Well Integrity in Drilling and Well OperationsJeong Hui Lee100% (4)

- Understanding Sour Service Performance of Coiled Tubing After H2S ExposureDokumen12 halamanUnderstanding Sour Service Performance of Coiled Tubing After H2S ExposureMubeenBelum ada peringkat

- Wellhead Fittings & Valve Components - PGI-WFDokumen28 halamanWellhead Fittings & Valve Components - PGI-WFIan KevinBelum ada peringkat

- DS-1 4th Ed - Volume 3 - Addendum 2Dokumen7 halamanDS-1 4th Ed - Volume 3 - Addendum 2MARVELBelum ada peringkat

- Well Integrity AssessmentDokumen2 halamanWell Integrity AssessmentAnubhuti Purohit BhatnagarBelum ada peringkat

- WCT 01 Handbook Second Edition Rev 1 PDFDokumen74 halamanWCT 01 Handbook Second Edition Rev 1 PDFOscar Bustos0% (1)

- Well Integrity for Workovers and RecompletionsDari EverandWell Integrity for Workovers and RecompletionsPenilaian: 5 dari 5 bintang5/5 (3)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbDari EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbPenilaian: 4.5 dari 5 bintang4.5/5 (11)

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeDari EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticePenilaian: 4 dari 5 bintang4/5 (2)

- Tender Document 2Dokumen368 halamanTender Document 2Anonymous 70lCzDJvBelum ada peringkat

- 1.0 Purpose: 2.1 LocationDokumen3 halaman1.0 Purpose: 2.1 LocationAnonymous 70lCzDJvBelum ada peringkat

- No. Name Company Designation Signature: List of AttendeesDokumen1 halamanNo. Name Company Designation Signature: List of AttendeesAnonymous 70lCzDJvBelum ada peringkat

- Questions From John 1 - 7Dokumen2 halamanQuestions From John 1 - 7Anonymous 70lCzDJvBelum ada peringkat

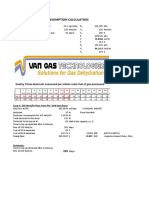

- Dessicant Consumption CalculationDokumen3 halamanDessicant Consumption CalculationAnonymous 70lCzDJvBelum ada peringkat

- Questions From John (Chapters 1 - 7) - PaulineDokumen2 halamanQuestions From John (Chapters 1 - 7) - PaulineAnonymous 70lCzDJvBelum ada peringkat

- Desiccant Consumption Calculation: Case-1: 105 Nm3/hr Flow From The 'VAN Gas Dryer'Dokumen1 halamanDesiccant Consumption Calculation: Case-1: 105 Nm3/hr Flow From The 'VAN Gas Dryer'Anonymous 70lCzDJvBelum ada peringkat

- Absorbent Desiccant 2019Dokumen4 halamanAbsorbent Desiccant 2019Anonymous 70lCzDJvBelum ada peringkat

- Absorbent Desiccant 2019Dokumen4 halamanAbsorbent Desiccant 2019Anonymous 70lCzDJvBelum ada peringkat

- Natural Gas Dryers: Pipeline SeriesDokumen2 halamanNatural Gas Dryers: Pipeline SeriesAnonymous 70lCzDJvBelum ada peringkat

- John's Bible questions answeredDokumen2 halamanJohn's Bible questions answeredAnonymous 70lCzDJvBelum ada peringkat

- The Institution of Engineers (India)Dokumen9 halamanThe Institution of Engineers (India)sai vivekBelum ada peringkat

- Answers For Questions From John 1 To 7Dokumen1 halamanAnswers For Questions From John 1 To 7Anonymous 70lCzDJvBelum ada peringkat

- Answers For Questions From John 1 To 7Dokumen1 halamanAnswers For Questions From John 1 To 7Anonymous 70lCzDJvBelum ada peringkat

- Amch1: Mathematics Iii: 1. Partial Differentiation and Partial Differential EquationDokumen2 halamanAmch1: Mathematics Iii: 1. Partial Differentiation and Partial Differential EquationAnonymous 70lCzDJv100% (1)

- Questions From John Chapter 8 To 14 PDFDokumen1 halamanQuestions From John Chapter 8 To 14 PDFAnonymous 70lCzDJvBelum ada peringkat

- Questions From John Chapter 8 To 14 PDFDokumen1 halamanQuestions From John Chapter 8 To 14 PDFAnonymous 70lCzDJvBelum ada peringkat

- Questions From John Chapter 8 To 14 PDFDokumen1 halamanQuestions From John Chapter 8 To 14 PDFAnonymous 70lCzDJvBelum ada peringkat

- Questions From John Chapter 8 To 14 PDFDokumen1 halamanQuestions From John Chapter 8 To 14 PDFAnonymous 70lCzDJvBelum ada peringkat

- Answers For Questions From John 1 To 7Dokumen1 halamanAnswers For Questions From John 1 To 7Anonymous 70lCzDJvBelum ada peringkat

- Questions From John 1 - 7Dokumen2 halamanQuestions From John 1 - 7Anonymous 70lCzDJvBelum ada peringkat

- Answers For Questions From John 1 To 7Dokumen1 halamanAnswers For Questions From John 1 To 7Anonymous 70lCzDJvBelum ada peringkat

- Engineering ToolBox Pressure Drop CalculatorDokumen6 halamanEngineering ToolBox Pressure Drop CalculatorAnonymous 70lCzDJvBelum ada peringkat

- Questions From John (Chapters 1 - 7) - PaulineDokumen2 halamanQuestions From John (Chapters 1 - 7) - PaulineAnonymous 70lCzDJvBelum ada peringkat

- The Questions Are From The Portion of Today's Devotion. Send The Answers With Bible ReferencesDokumen1 halamanThe Questions Are From The Portion of Today's Devotion. Send The Answers With Bible ReferencesAnonymous 70lCzDJvBelum ada peringkat

- Best Practices and Tips For Compressed Air Piping SystemsDokumen19 halamanBest Practices and Tips For Compressed Air Piping SystemsAnonymous 70lCzDJvBelum ada peringkat

- John's Bible questions answeredDokumen2 halamanJohn's Bible questions answeredAnonymous 70lCzDJvBelum ada peringkat

- 100 Overview of Tank DesignDokumen20 halaman100 Overview of Tank Designkoparan35Belum ada peringkat

- Compressed Air Pressure LossDokumen1 halamanCompressed Air Pressure Losswael hassanBelum ada peringkat

- Calculating Storage Volume For Compressed Air Systems.Dokumen68 halamanCalculating Storage Volume For Compressed Air Systems.Anonymous 70lCzDJvBelum ada peringkat

- Project 4 Ethylene OxideDokumen12 halamanProject 4 Ethylene OxideNhan Nguyen Van100% (4)

- MIDEL 7131 Technical Information Pack USDokumen15 halamanMIDEL 7131 Technical Information Pack USkatherine100% (1)

- Technical Data Sheet for Zinc PrimerDokumen4 halamanTechnical Data Sheet for Zinc PrimerBiju_PottayilBelum ada peringkat

- Waste Paper Pulp Product Industry Project ReportDokumen8 halamanWaste Paper Pulp Product Industry Project ReportSukhvinder SinghBelum ada peringkat

- UK Gate Valves Brochure High Res 02 - 2017Dokumen20 halamanUK Gate Valves Brochure High Res 02 - 2017Sivasubramanian PalaniappanBelum ada peringkat

- LT Compressor Condensate Loading To The Road Tankers Through Buffer TankDokumen2 halamanLT Compressor Condensate Loading To The Road Tankers Through Buffer TankMugesh KannaBelum ada peringkat

- FTIR Spectrometer AnalysisDokumen16 halamanFTIR Spectrometer AnalysisßraiñlĕsšȜĭnšteĭñBelum ada peringkat

- 9 KPremier 115 Vhighwall Ownersmanual 3Dokumen19 halaman9 KPremier 115 Vhighwall Ownersmanual 3mauricioBelum ada peringkat

- 2018 06 Baboo Caking of Urea in Summer SeasonDokumen14 halaman2018 06 Baboo Caking of Urea in Summer SeasonjainrakeshjBelum ada peringkat

- Claudia - Gavrilescu - XRAY Technology PDFDokumen51 halamanClaudia - Gavrilescu - XRAY Technology PDFdangthBelum ada peringkat

- Engineering Deliverables ListDokumen49 halamanEngineering Deliverables ListpavanBelum ada peringkat

- Datasheet Rockfon Medicare-StandardDokumen7 halamanDatasheet Rockfon Medicare-Standardsirikhwan wonganuntBelum ada peringkat

- 08032012-Ppt Strain TransformationDokumen44 halaman08032012-Ppt Strain Transformationمحمد عادل خٹکBelum ada peringkat

- QIS College Engineering & Tech Session Plan Metal CuttingDokumen13 halamanQIS College Engineering & Tech Session Plan Metal CuttingKalai ArasanBelum ada peringkat

- Fire CraftDokumen28 halamanFire CraftLooi Kok HuaBelum ada peringkat

- XDB102 3Dokumen3 halamanXDB102 3Young WuBelum ada peringkat

- MIG Welding Guide - Processes, Principles & Applications of GMAWDokumen23 halamanMIG Welding Guide - Processes, Principles & Applications of GMAWAsad Bin Ala Qatari50% (2)

- Legacy Product Catalog 2016 PDFDokumen40 halamanLegacy Product Catalog 2016 PDFCamilo Andrés Abello RégeasseBelum ada peringkat

- Stickmate 235 AC & 235 AC/DC Owner's ManualDokumen40 halamanStickmate 235 AC & 235 AC/DC Owner's ManualHobart Welding Products100% (1)

- Factsheet SGT-700 enDokumen2 halamanFactsheet SGT-700 enAzril DahariBelum ada peringkat

- Drying Shrinkage of ConcreteDokumen6 halamanDrying Shrinkage of Concretecrownguard100% (1)

- Impact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitDokumen14 halamanImpact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitRaman BansalBelum ada peringkat

- Byk Bykjet 9170Dokumen2 halamanByk Bykjet 9170ankitleedsBelum ada peringkat

- Paes 310Dokumen9 halamanPaes 310Jemina Jean Dorado SensanoBelum ada peringkat

- 9701 w19 QP 21 PDFDokumen12 halaman9701 w19 QP 21 PDFFaiza KhalidBelum ada peringkat

- Fig 21150 Vag Pico PRV Druk ReduceerDokumen2 halamanFig 21150 Vag Pico PRV Druk ReduceerAlberto DiazBelum ada peringkat

- Electrochemistry Cell Potentials and Half-ReactionsDokumen40 halamanElectrochemistry Cell Potentials and Half-ReactionsJithesh Parambath0% (1)

- Waterjet Cutting Systems: A Versatile Cutting ProcessDokumen2 halamanWaterjet Cutting Systems: A Versatile Cutting ProcessRamin SobatiBelum ada peringkat

- Total Water Management in Thermal Power StationsDokumen8 halamanTotal Water Management in Thermal Power StationsSarah FrazierBelum ada peringkat

- Cominox SterilClave 18-24 - User and Maintenance ManualDokumen68 halamanCominox SterilClave 18-24 - User and Maintenance ManualJose Tavares100% (2)